Lead-free sealing glass with transitional expansion coefficient

A technology of expansion coefficient and glass, which is applied in the field of transition expansion coefficient lead-free sealing glass, can solve the problems of complex sealing process, difficult control of product quality, and increased difficulty, and achieve simple sealing process, low cost and easy product quality The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The parts by weight of raw materials used are: 52.18 parts of quartz sand, 3.85 parts of aluminum hydroxide, 14.05 parts of bismuth trioxide, 2.17 parts of ferric oxide, 3.85 parts of magnesium oxide, 14.53 parts of sodium carbonate, 4.66 parts of sodium nitrate, potassium carbonate 19.47 parts, 5.54 parts of potassium nitrate.

[0023] The specific steps of the manufacturing method are as follows:

[0024] Step 1: Accurately weigh and mix the above-mentioned raw materials evenly, and heat them in a silicon-molybdenum rod electric furnace at 1753K for 2 hours to prepare a uniform molten glass. The homogeneous molten glass was quickly cast in a preheated stainless steel mold and annealed at 720 K for 1 hour to obtain a transparent, uniform and bubble-free bulk base glass.

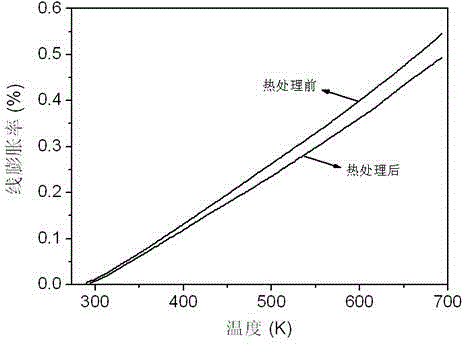

[0025] Step 2: Obtain the glass transition temperature T of each sample according to the DSC test results of the base glass g , Put the basic glass into a closed crucible filled with carbon powder, ...

Embodiment 2

[0027] The raw materials used are composed of 51.41 parts by weight of quartz sand, 3.79 parts of aluminum hydroxide, 13.84 parts of bismuth trioxide, 2.14 parts of ferric oxide, 9.46 parts of calcium carbonate, 14.31 parts of sodium carbonate, 4.59 parts of sodium nitrate, potassium carbonate 19.18 parts, 5.46 parts of potassium nitrate.

[0028] The specific steps of the manufacturing method are as follows:

[0029] Step 1: Use quartz sand, aluminum oxide, aluminum hydroxide, bismuth trioxide, ferric oxide, calcium carbonate, soda ash, sodium nitrate, potassium carbonate, etc. as raw materials, and accurately weigh and mix them according to the above chemical composition. The silicon-molybdenum rod electric furnace was kept at 1753K for 2 hours to obtain a uniform molten glass. The homogeneous molten glass is quickly cast in a preheated stainless steel mold, and annealed at 730K for 1 hour to obtain a transparent, uniform and bubble-free bulk basic glass.

[0030] Step 2: ...

Embodiment 3

[0032] The parts by weight of raw materials used are: 49.22 parts of quartz sand, 3.63 parts of aluminum hydroxide, 13.25 parts of bismuth trioxide, 2.05 parts of ferric oxide, 13.36 parts of strontium carbonate, 13.7 parts of sodium carbonate, 4.39 parts of sodium nitrate, potassium carbonate 18.37 parts, 5.23 parts of potassium nitrate.

[0033] The specific steps of the manufacturing method are as follows:

[0034] Step 1: Use quartz sand, aluminum oxide, aluminum hydroxide, bismuth trioxide, ferric oxide, strontium carbonate, soda ash, sodium nitrate, potassium carbonate, etc. as raw materials, accurately weigh and mix them according to the above chemical composition, and The silicon-molybdenum rod electric furnace was kept at 1743K for 2 hours to obtain a uniform molten glass. The homogeneous molten glass is quickly cast in a preheated stainless steel mold, and annealed at 710K for 1 hour to obtain a transparent, uniform and bubble-free bulk basic glass.

[0035] Step 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com