Process for carrying out low-temperature glass sealing after titanium alloy electrochemical oxidation

A low-temperature glass and titanium alloy technology, used in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of insufficient adhesion of oxide films, high sealing temperature, easy to fall off, etc., to achieve superior process consistency and The effect of reproducibility, high bond strength and simple sealing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

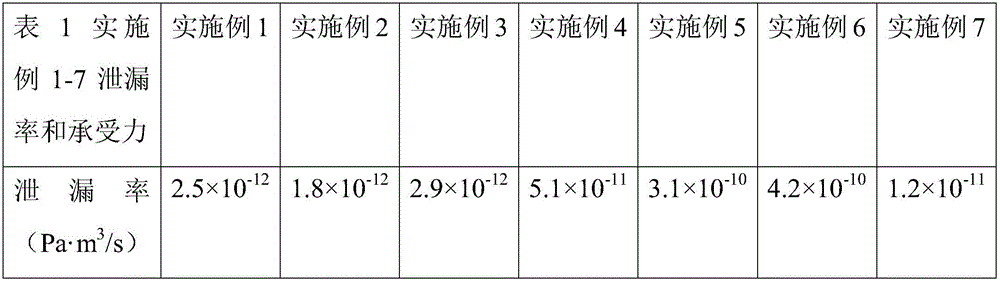

Examples

Embodiment 1

[0023] A low-temperature glass sealing process after electrochemical oxidation of titanium alloy, comprising the following steps:

[0024] (1) After TC4 titanium alloy workpiece is machined, spray glass shot or chemical polishing to remove burrs, etc., and then perform conventional degreasing treatment;

[0025] (2) The softening temperature is 430°C, the sealing temperature is 520°C, and the thermal expansion coefficient is 8.96×10 -6 / (25~300℃), resistivity greater than 10 14 The low-temperature sealing glass of Ω·cm is prepared into a glass gob according to a conventional method;

[0026] (3) At 20°C, use a sulfuric acid solution with a concentration of 180g / L as the electrolyte, the degreased titanium alloy as the anode, and the lead plate as the cathode, and electrolyze for 30 minutes at a DC voltage of 24V to form a titanium alloy surface A uniform blue oxide film;

[0027] (4) Process the inner conductor with semi-hard 4J50, degrease the inner conductor workpiece con...

Embodiment 2

[0033] A low-temperature glass sealing process after electrochemical oxidation of titanium alloy, comprising the following steps:

[0034] (1) After TC4 titanium alloy workpiece is machined, spray glass shot or chemical polishing to remove burrs, etc., and then perform conventional degreasing treatment;

[0035] (2) The softening temperature is 460°C, the sealing temperature is 540°C, and the thermal expansion coefficient is 8.96×10 -6 / (25~300℃), resistivity greater than 10 14 Ω·cm low-temperature sealing glass, which is prepared into a glass gob according to a conventional method;

[0036] (3) At 20°C, use a sulfuric acid solution with a concentration of 180g / L as the electrolyte, the degreased titanium alloy as the anode, and the lead plate as the cathode, and electrolyze for 30 minutes at a DC voltage of 24V to form a titanium alloy surface A uniform blue oxide film;

[0037] (4) Use semi-hard 4J50 to process the inner conductor, degrease the inner conductor workpiece c...

Embodiment 3

[0042] A low-temperature glass sealing process after electrochemical oxidation of titanium alloy, comprising the following steps:

[0043] (1) After TA2 titanium alloy workpiece is machined, spray glass shot or chemical polishing to remove burrs, etc., and then perform conventional degreasing treatment;

[0044] (2) The softening temperature is 450°C, the sealing temperature is 530°C, and the thermal expansion coefficient is 8.96×10 -6 / (25~300℃), resistivity greater than 10 14 Ω·cm low-temperature sealing glass, which is prepared into a glass gob according to a conventional method;

[0045] (3) At 20°C, use a sulfuric acid solution with a concentration of 170g / L as the electrolyte, the degreased titanium alloy as the anode, and the lead plate as the cathode, and electrolyze for 30 minutes at a DC voltage of 23V to form a titanium alloy surface A uniform blue oxide film;

[0046] (4) Use semi-hard 4J50 to process the inner conductor, degrease the inner conductor workpiece c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| sealing temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com