Electrode device of electromagnetic flow meter

A technology of electromagnetic flowmeter and electrode device, which is applied in the field of electrode device and electromagnetic flowmeter, can solve the problems that the inner wall of the measuring tube is not smooth, is not suitable for mass production, and affects the measurement accuracy, and achieves simple sealing process, low cost and high measurement The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

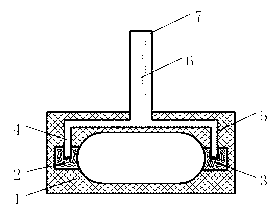

[0043] see figure 1 , wherein the measuring tube 1 is a part of the flow path of the electromagnetic flowmeter, and is made of plastic with low water permeability, such as polypropylene resin. The measuring tube 1 can be manufactured integrally with the electromagnetic flowmeter body, or can be manufactured independently. A magnetic field (not marked in the figure) is distributed in the vertical direction of the flow channel of the measuring tube 1, and a first electrode 2 and a second electrode 3 are arranged horizontally on both sides for measuring the induced potential. The electrodes are made of conductive plastic. In this embodiment, the polypropylene resin material containing carbon fiber is selected, that is, a certain amount of carbon fiber is added to the polypropylene resin. The main material of the measuring tube 1 and the electrode in this embodiment is made of polypropylene plastic, so the two parts can be well fused during the injection molding process, avoiding...

Embodiment 2

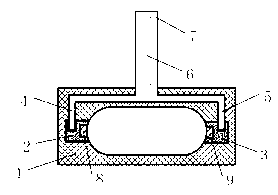

[0047] see figure 2 Compared with Embodiment 1, the difference of this embodiment is that a metal material is added on the electrode surface to reduce the resistance between the electrode surface and the fluid. Wherein, the first electrode metal 8 is combined with the first electrode 2 to form a composite electrode, and the second metal 9 is combined with the second electrode 3 to form a composite electrode. In this embodiment, when the electrode is injection-molded, the metal part is preset in the mold to complete the combination of the metal part and the electrode. In order to prevent leakage, there is no contact between the metal parts and the printed circuit board 7 . This embodiment indirectly provides a solution to the metal electrode to improve the leakage problem of the existing metal electrode.

[0048] In addition to the above embodiments, the lead wire of the present invention can also be made of conductive plastic. In the injection molding process, the lead wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com