Tube well used for unwatering and pressure-reducing drainage and drainage method of tube well

A technology for draining wells and relief wells, applied in construction and infrastructure engineering, etc., can solve problems such as difficulty in ensuring the sealing performance of water stopper devices, increasing construction complexity and difficulty, increasing construction costs, etc., to achieve improved The effect of soil dehydration and precipitation efficiency, high construction efficiency, and increasing catchment area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

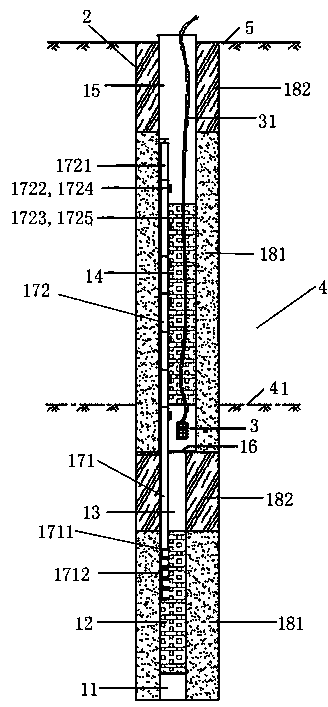

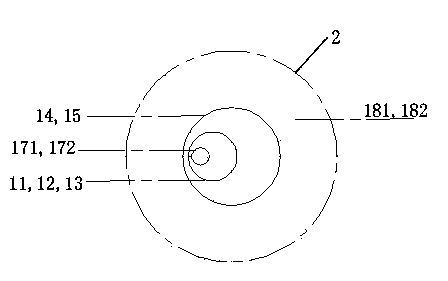

[0026] see Figure 1-Figure 4 , as shown in the illustration therein, a tube well for simultaneously dewatering and decompression dewatering includes a well tube, a hole 2 and a submersible pump 3, and the hole 2 is opened in the foundation pit 4.

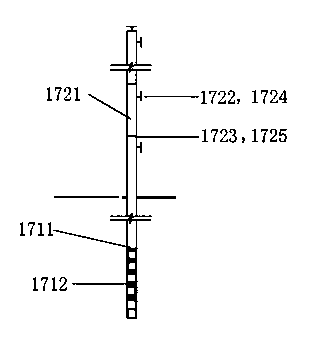

[0027]The above-mentioned well pipe includes a settling pipe 11, a decompression filter pipe 12, a decompression well wall pipe 13, a draining water filter pipe 14 and a draining well wall pipe which are sequentially arranged in the hole 2 from bottom to top. 15. A sealing plate 16 is installed at the junction of the decompression well wall pipe 13 and the draining and filtering pipe 14. An artesian pipe is installed on the sealing plate 16. The artesian pipe has an inlet pipe section 171 extending to the bottom of the sealing plate 16 and Extending to the water outlet pipe section 172 above the sealing plate 16, the water outlet pipe section 172 is sequentially arranged as eight socket pipes 1721 in the axial direction, and the ad...

Embodiment 2

[0042] The rest is the same as the first embodiment, the difference is that the above-mentioned eight upper water outlets are detachably connected to a corresponding partition plug, because only one partition plug is needed each time, thus reducing the number of partition plugs used , reducing the construction cost, and there will be no problems such as unnecessary plug loss.

Embodiment 3

[0044] The rest are the same as the first or second embodiment, the difference is that the inner diameter of the lower decompression well pipe is smaller than the inner diameter of the upper dewatering well pipe and is connected by a reducing pipe, and the above-mentioned sealing plate is installed on the above-mentioned reducing pipe. On the pipe, the above-mentioned reducer is a stepped reducer or a gradual reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com