Long conveyance pipe defect positioning method and positioning system

A long-distance pipeline and positioning system technology, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of large mileage error, difficulty in significantly improving positioning accuracy, and high cost, and achieve low cost, High defect location accuracy and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

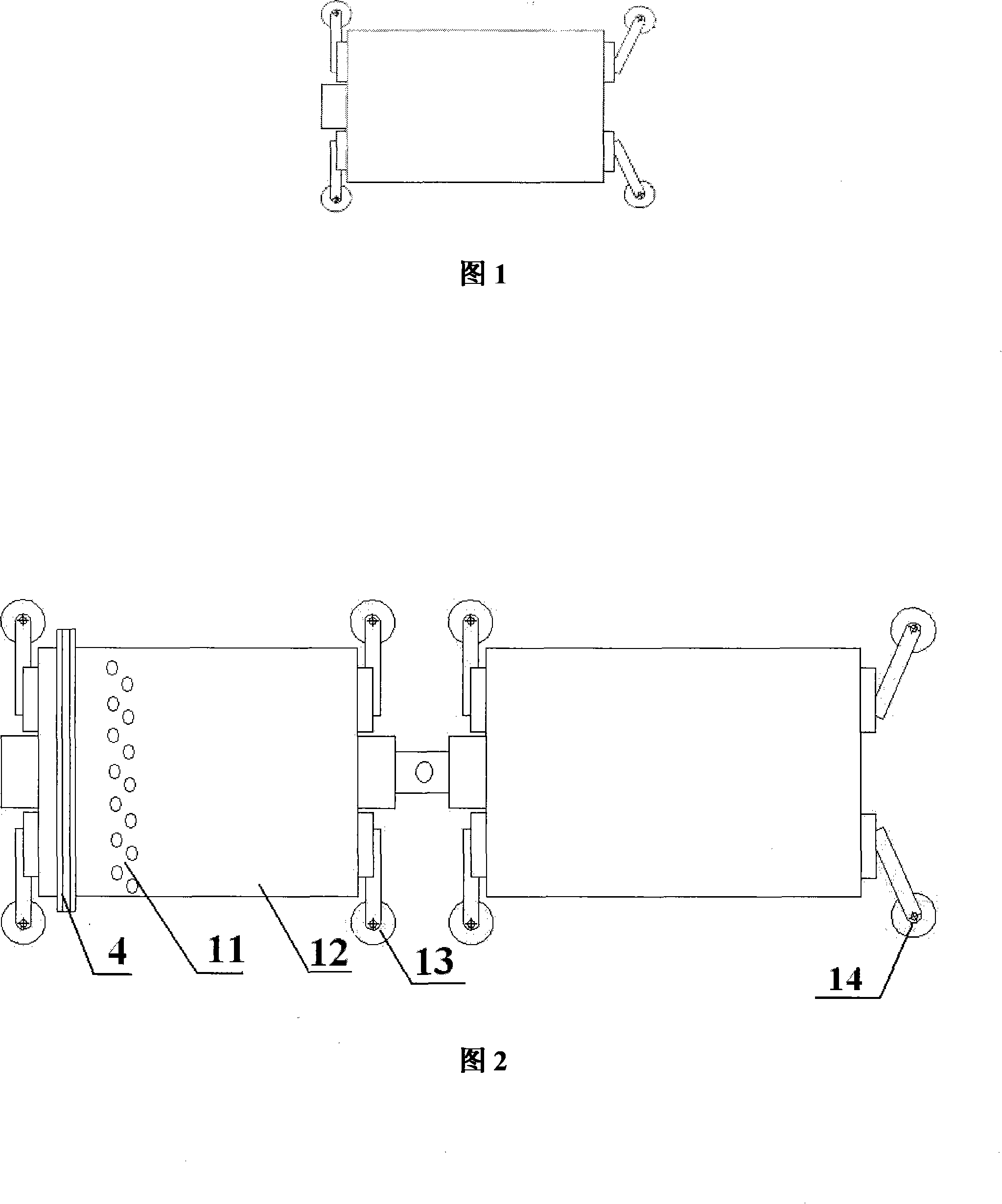

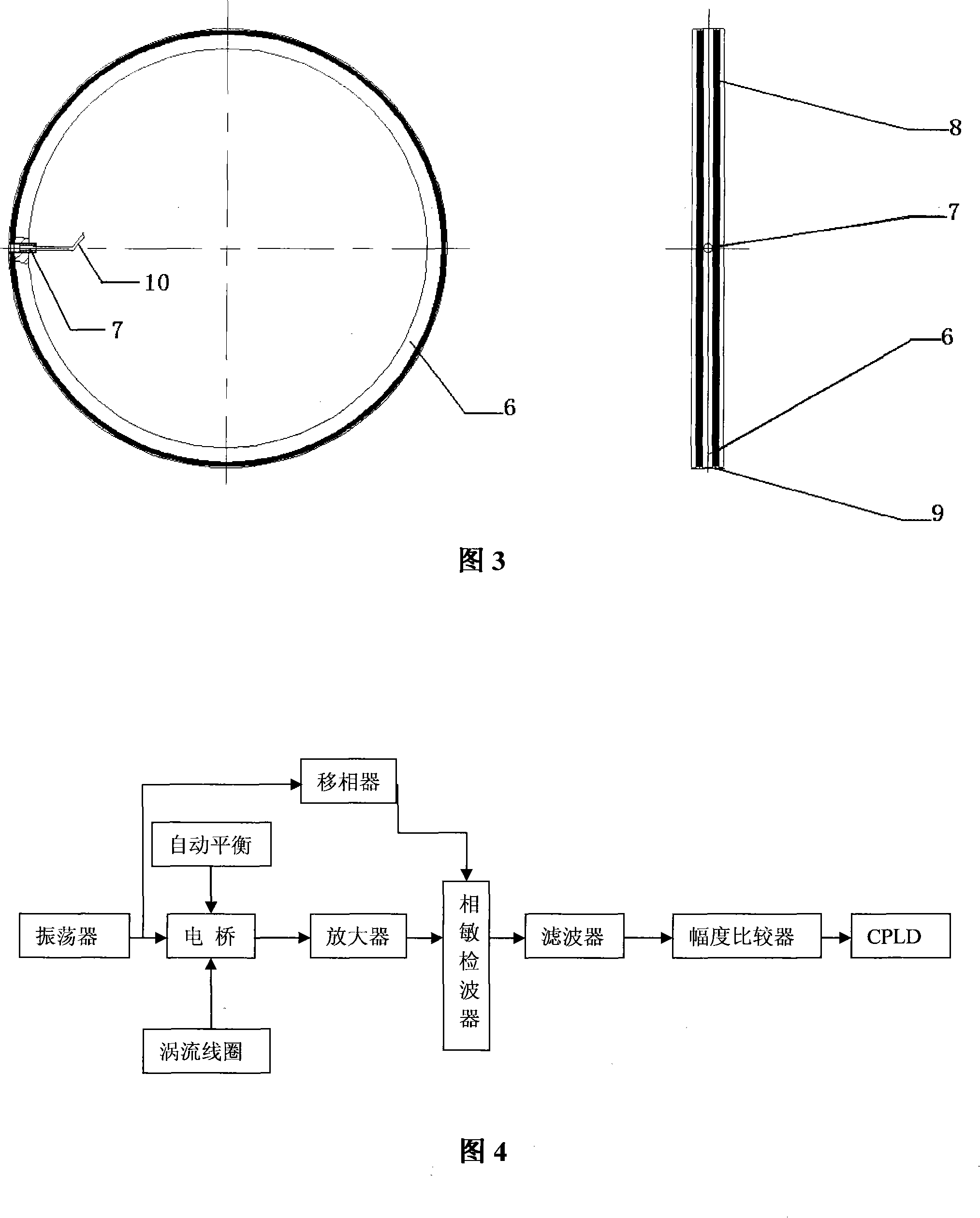

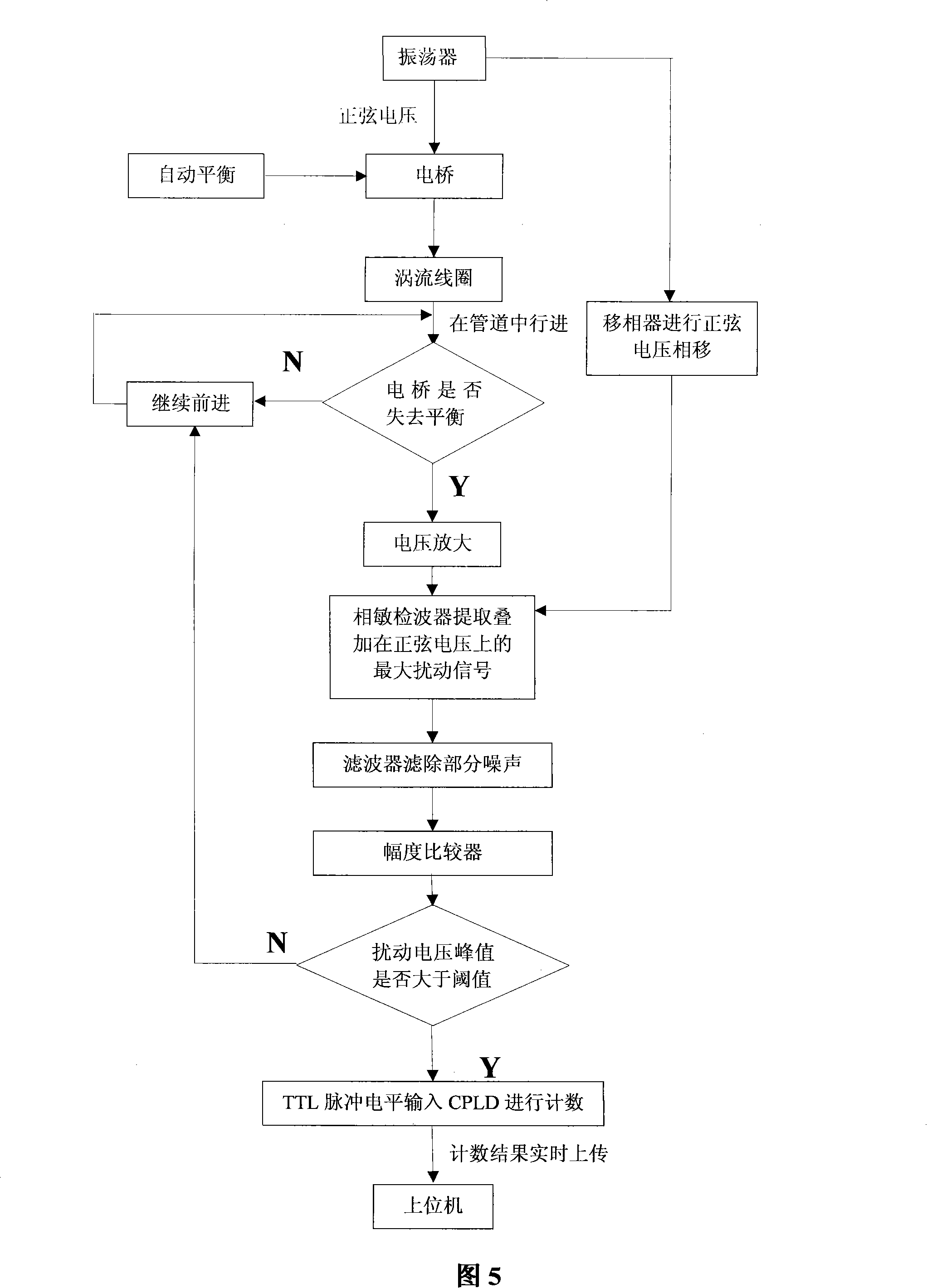

[0027] The method and system for locating defects in long-distance pipelines according to the present invention will be further described below in conjunction with the accompanying drawings.

[0028] In the method for locating defects of long-distance pipelines according to the present invention, a series of butt girth welds are formed in the long-distance pipelines during installation, while wheel-type odometers are used in the long-distance pipelines for mileage measurement and positioning, eddy current The detection device detects when the butt girth weld has passed, and the information is stored and analyzed simultaneously with the mileage data of the wheel odometer, so as to determine the position of the pipeline defect as Xmm away from the Nth weld .

[0029] The specific working process of the long-distance pipeline defect location method described in the present invention is as follows:

[0030] (1) In the long-distance pipeline, the wheel-type odometer is used to mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com