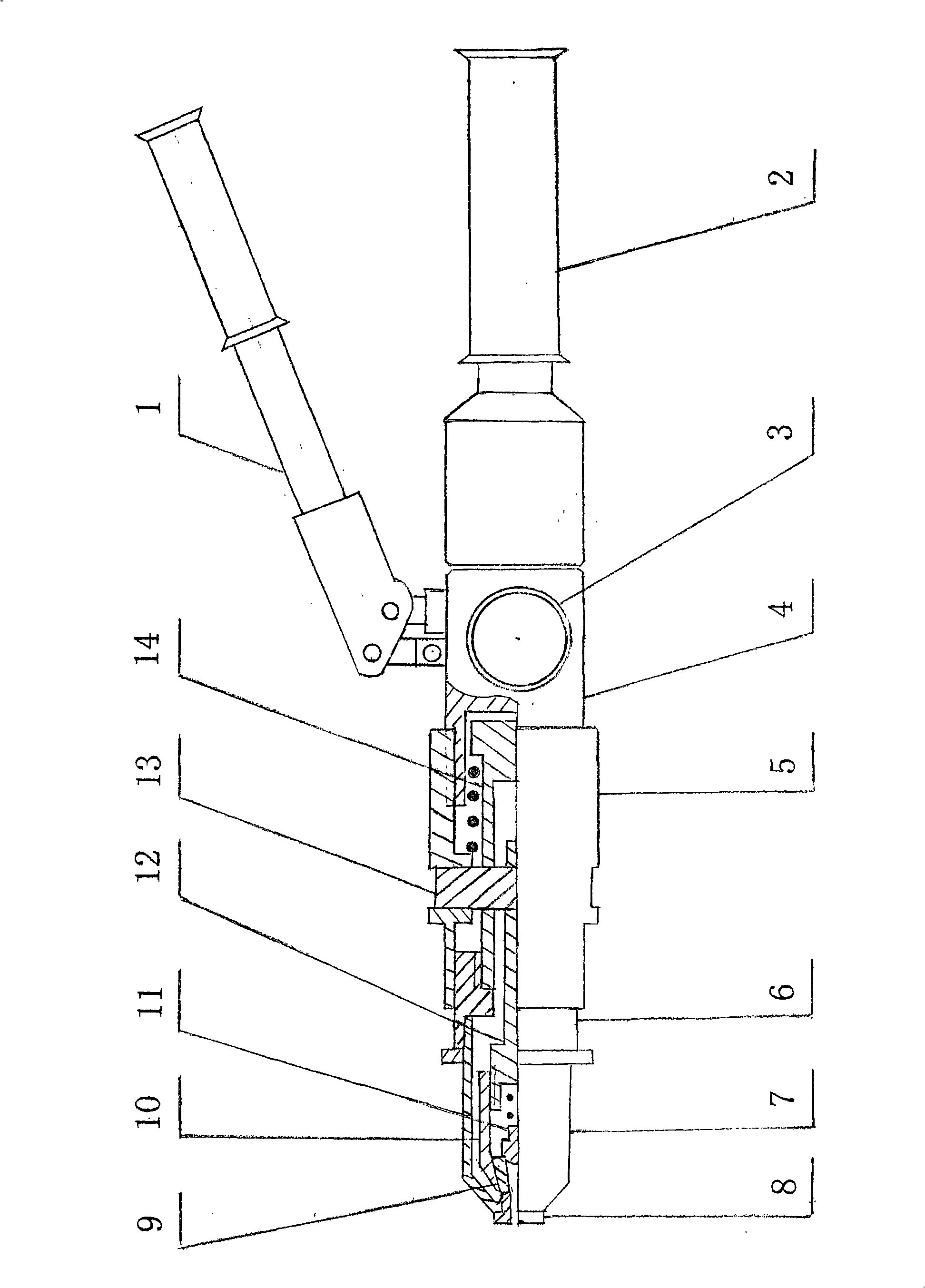

Manual hydraulic pressure strong pulling rivet gun

A riveting gun, strong technology, applied in the field of manual hydraulic powerful riveting gun, can solve the problems of low connection strength, limited use, complex structure, etc., achieve the effect of compact structure, novel design, and expanded use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

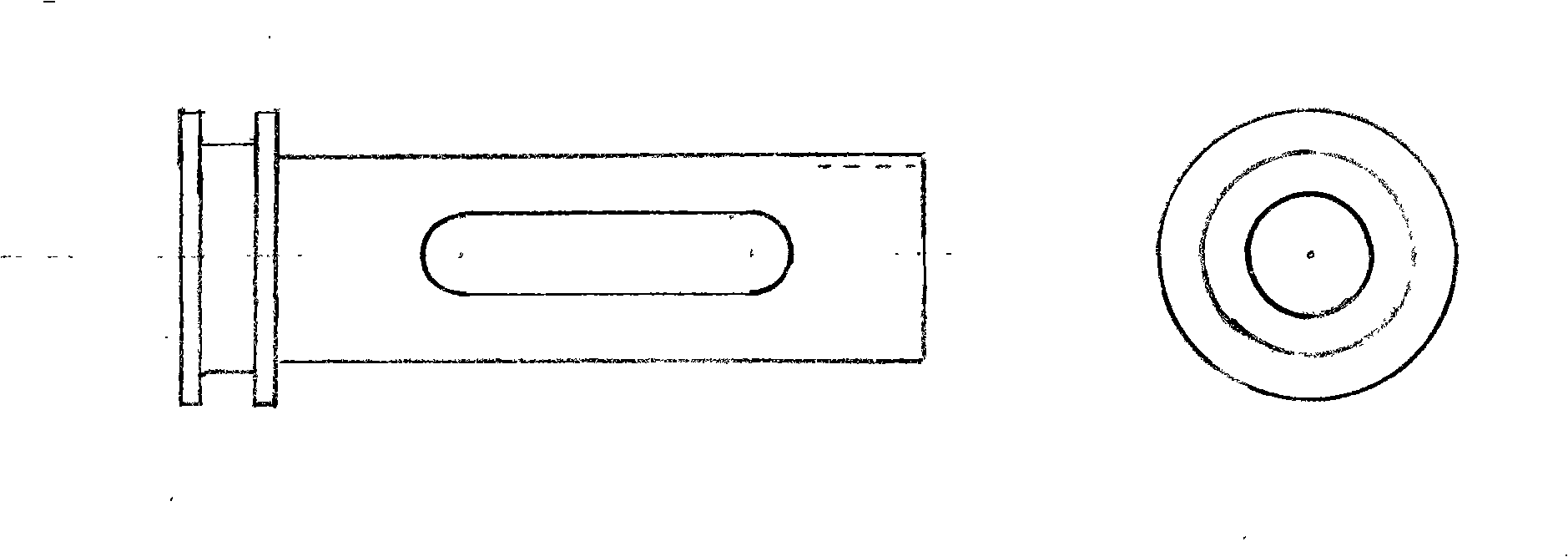

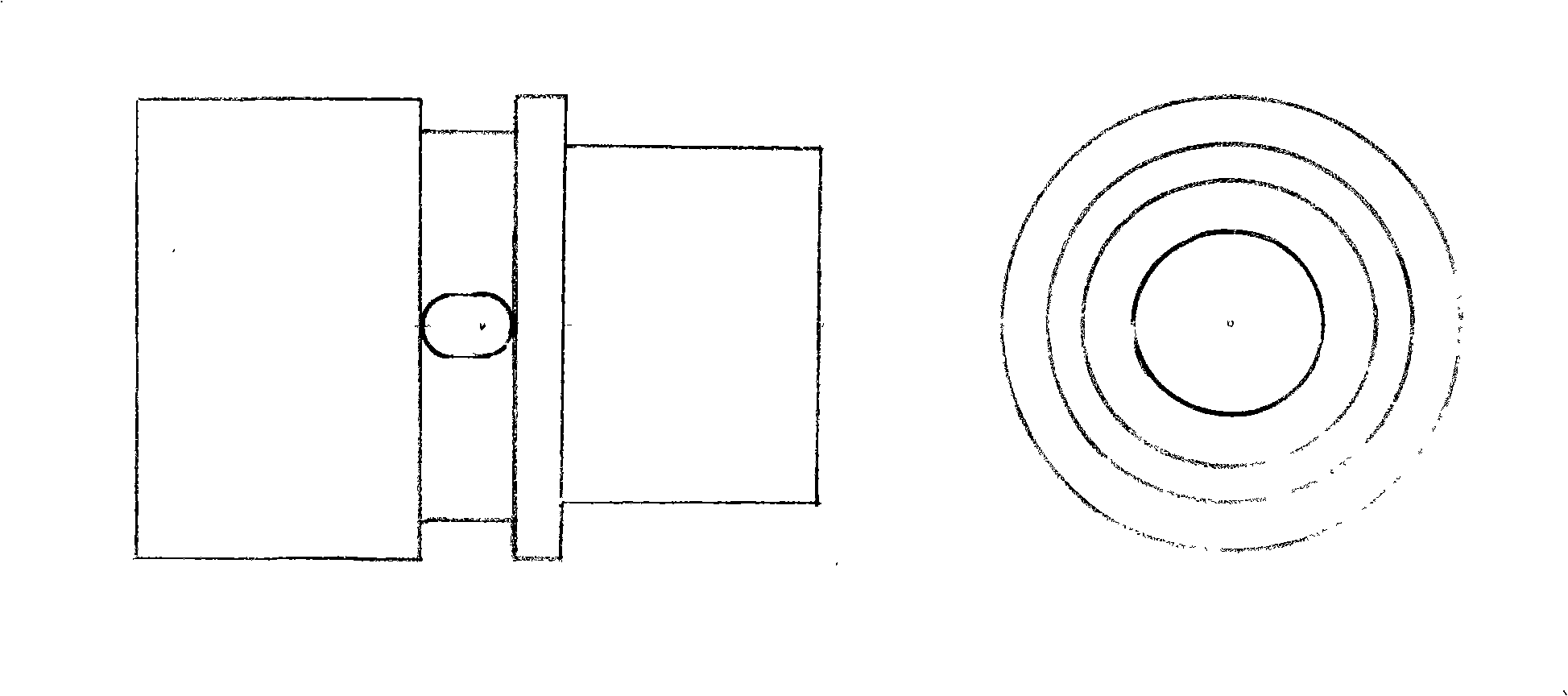

[0011] Tighten the oil return valve (3) before use. At this time, due to the restriction of the gun head (8), the clamping jaws (9) are in a relaxed state. First, make holes in the workpiece to be riveted according to the diameter of the blind rivet, put the tail of the blind rivet into the hole of the riveting gun head (8), push the front end into the drilled hole of the workpiece, and press the movable handle (1), the piston (14) drives the connecting sleeve (6), the gun head sleeve (7) and the gun head (8) to move forward. Without the restriction of the gun head (8), the three clamping claws (9) gradually clamp the tail of the blind rivet under the action of the top core (11). ), the tensioning screw (12) is fixed on the cylinder liner (5) by the horizontal bar (13) and stands still, so the actual effect is that the blind rivet is continuously pulled back, and the tail of the blind rivet is clamped three times. The more the claw (9) is clamped, the tighter it becomes, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com