Riveting gun capable of throwing out the rivet core

A technology for riveting guns and rivets, which is applied in the field of riveting guns and can solve problems such as difficult removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

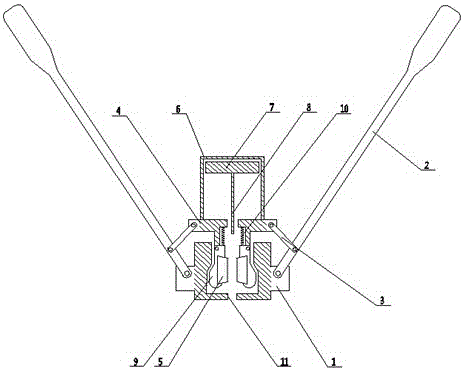

[0011] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0012] The riveting gun capable of throwing out the rivet core includes a handle 2, a support rod 3 and a gun head 1 with a pulling sleeve 4 connected to the jaw seat 9 at the rear, and is characterized in that: the middle of the rear end of the pulling sleeve 4 has a Through the hole, the rear end of the sleeve 4 is connected to the piston sleeve 6, and the piston sleeve 6 is provided with a piston rod; the front end of the piston rod passes through the through hole at the rear end of the sleeve 4 and enters between the two jaw seats. The piston sleeve 6 is a cylindrical sleeve with one end sealed and the other end open, and one end of the piston sleeve 6 opening is connected to the rear end of the sleeve 4; one end of the piston rod is a cylindrical piston rod cap 7, forming The sliding device can make the piston rod slide in one direction in the piston sleeve, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com