Patents

Literature

34results about How to "Improve plugging quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

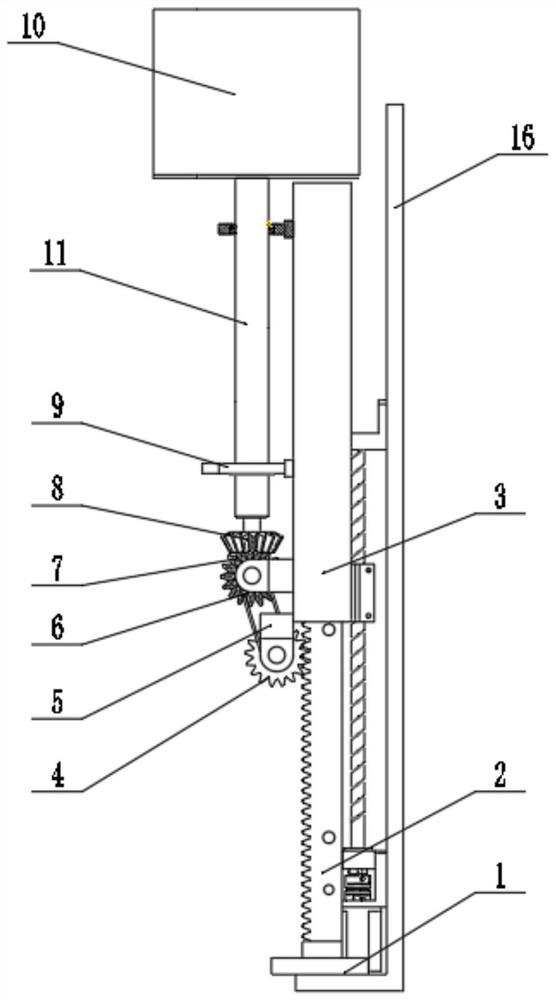

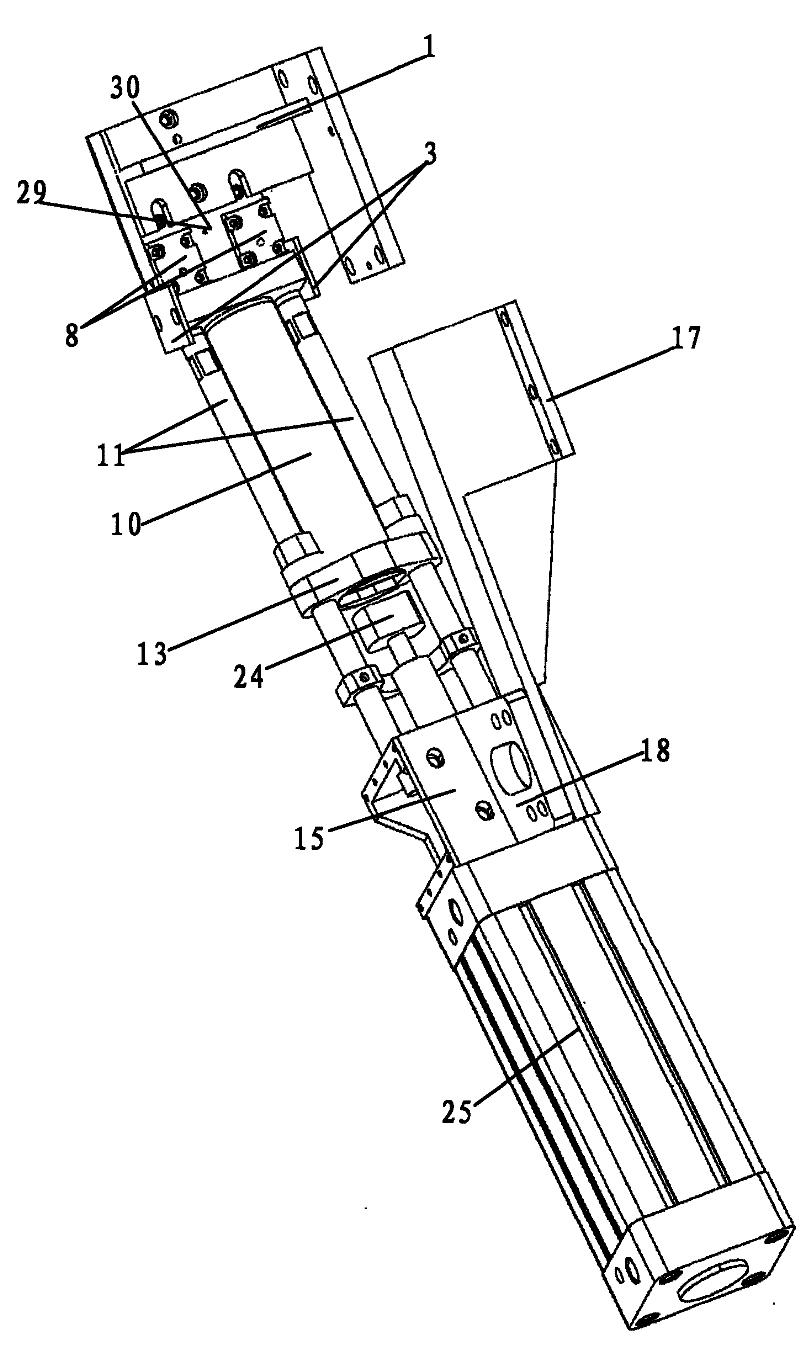

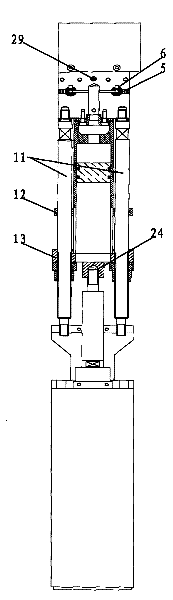

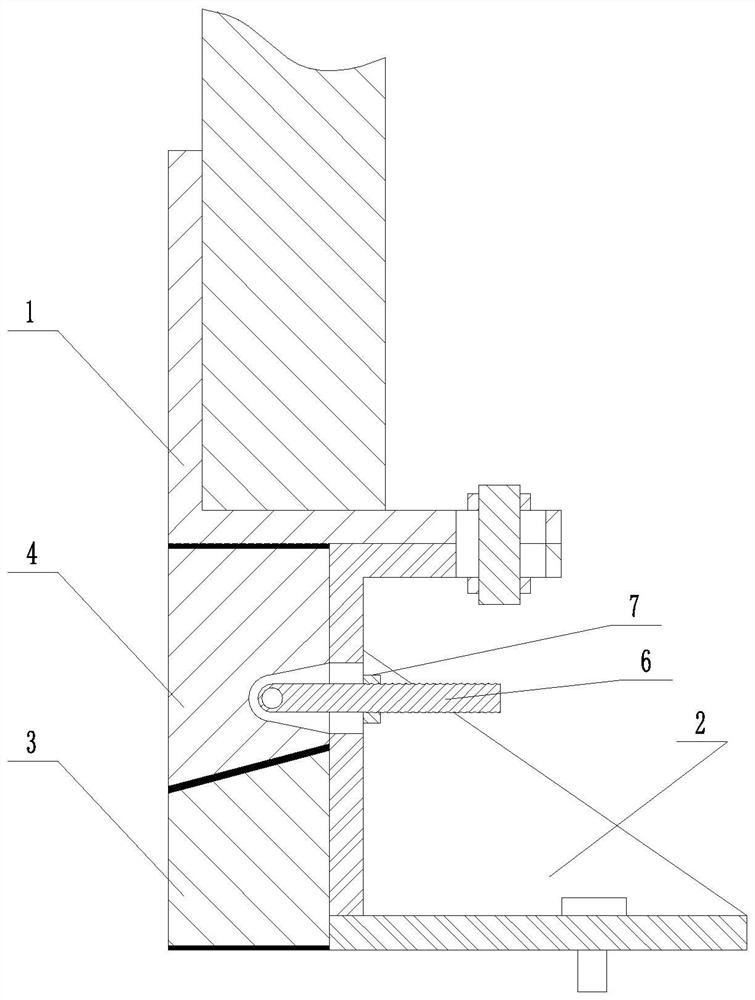

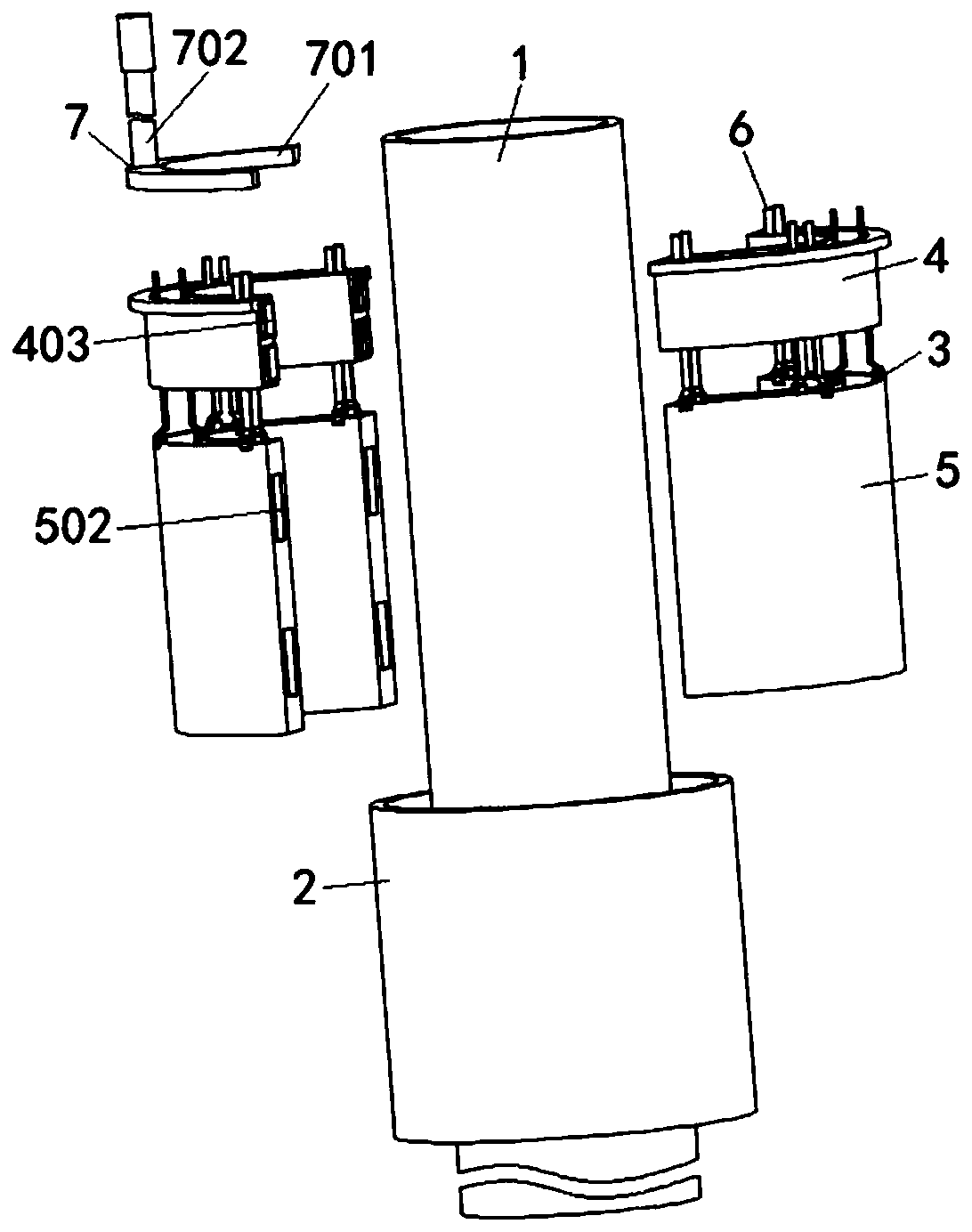

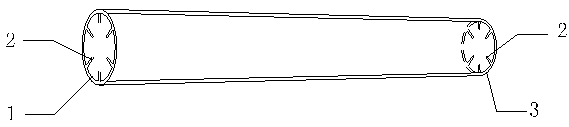

Spherical dual-seal plugging device

InactiveCN103277627AImprove plugging efficiencyImprove plugging qualityPipe elementsHydraulic cylinderEngineering

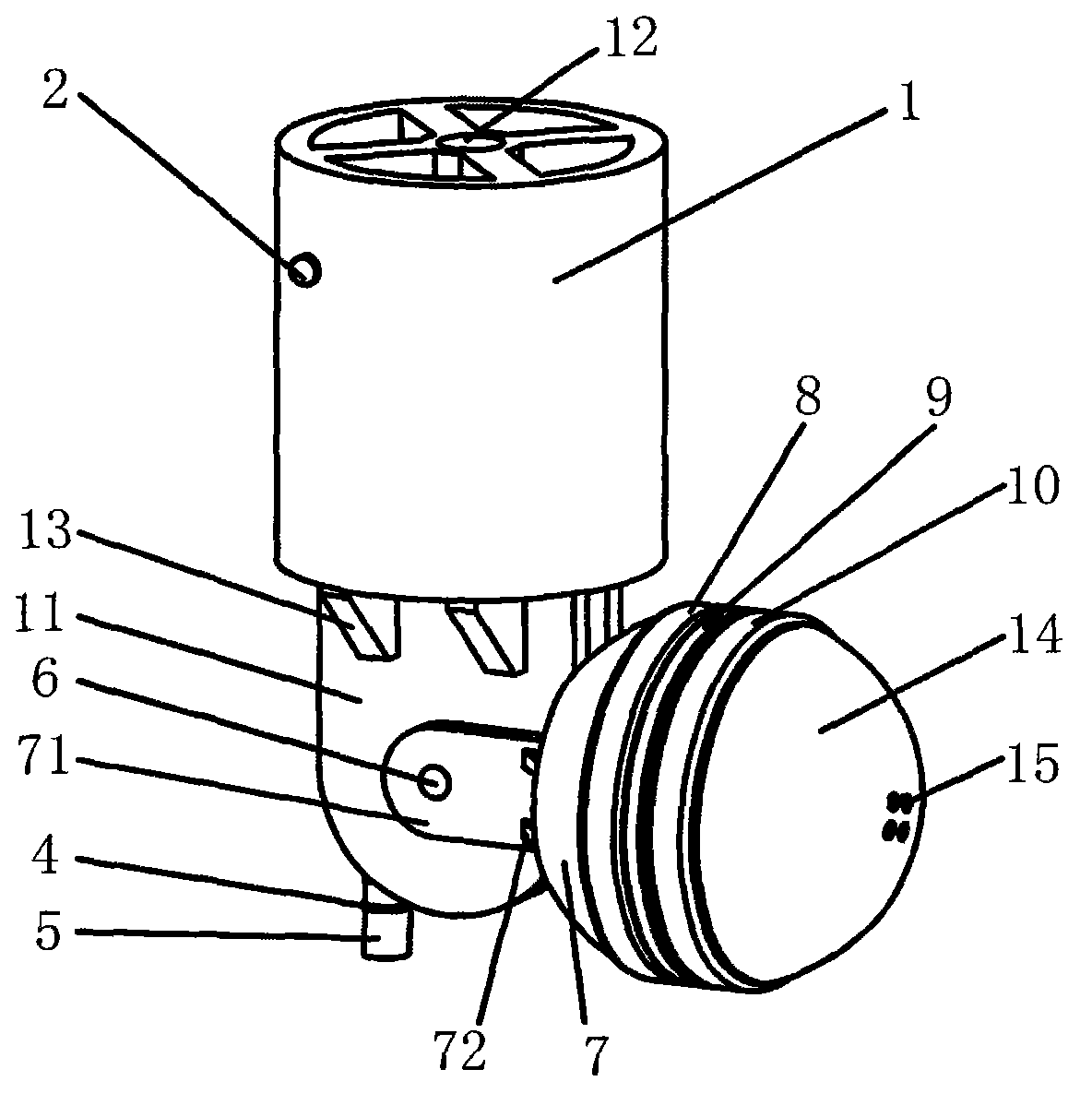

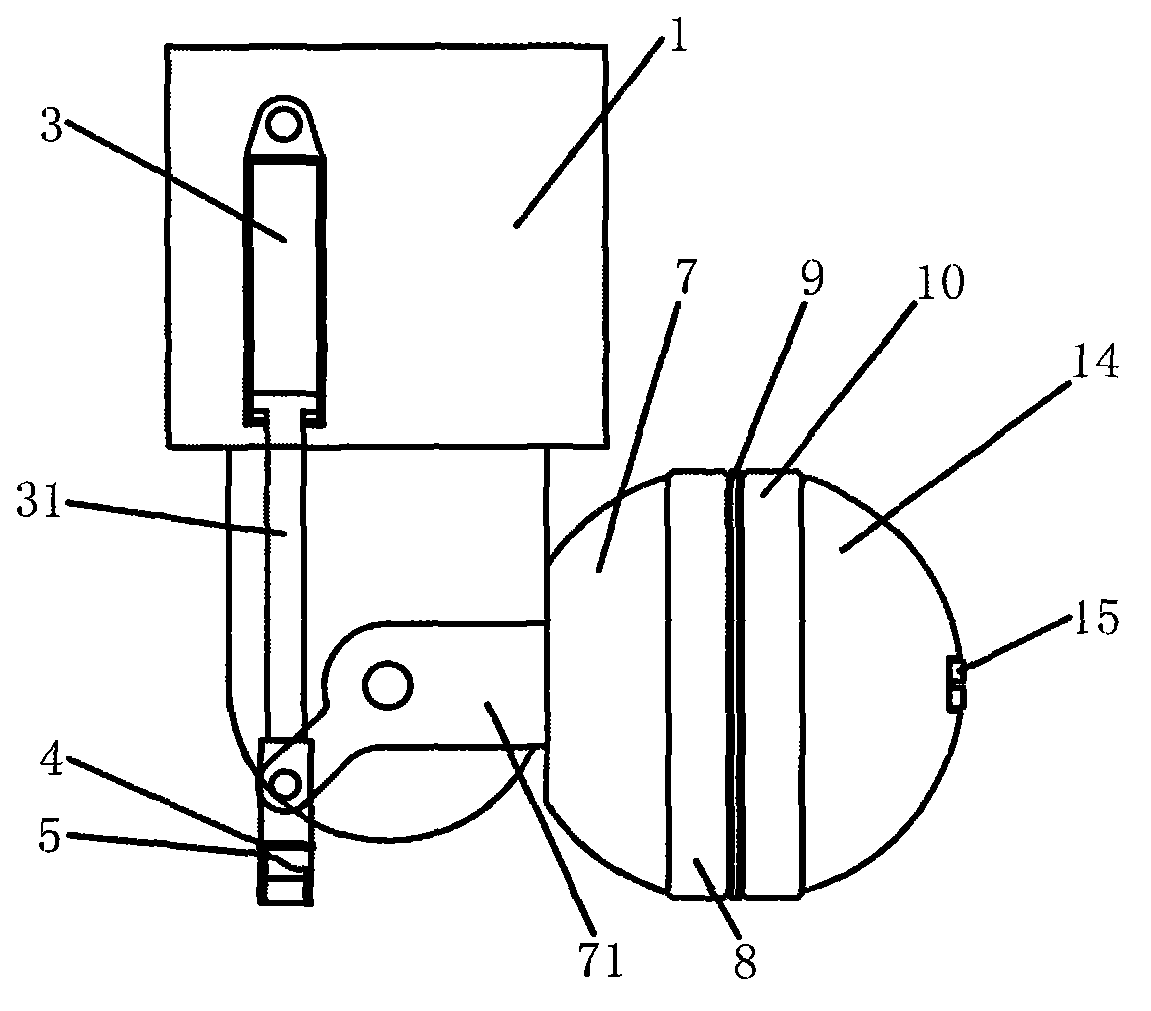

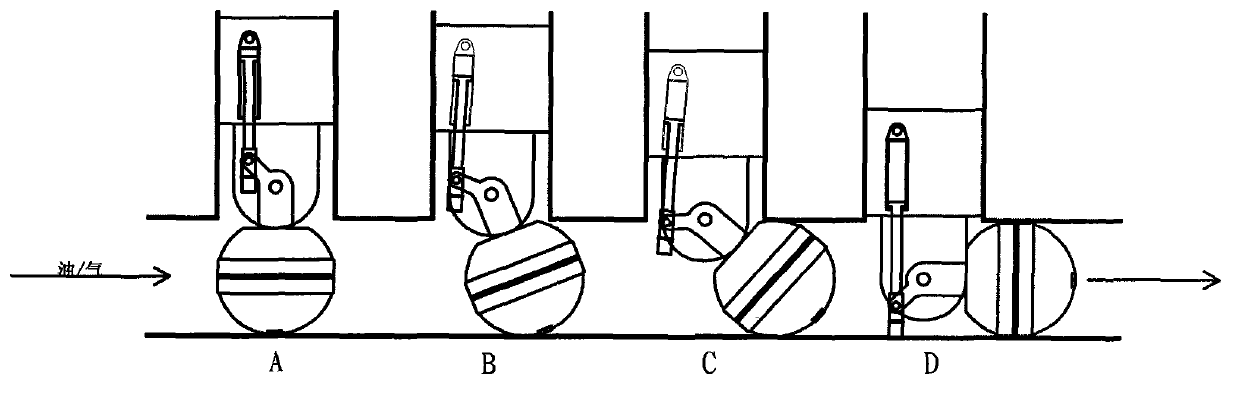

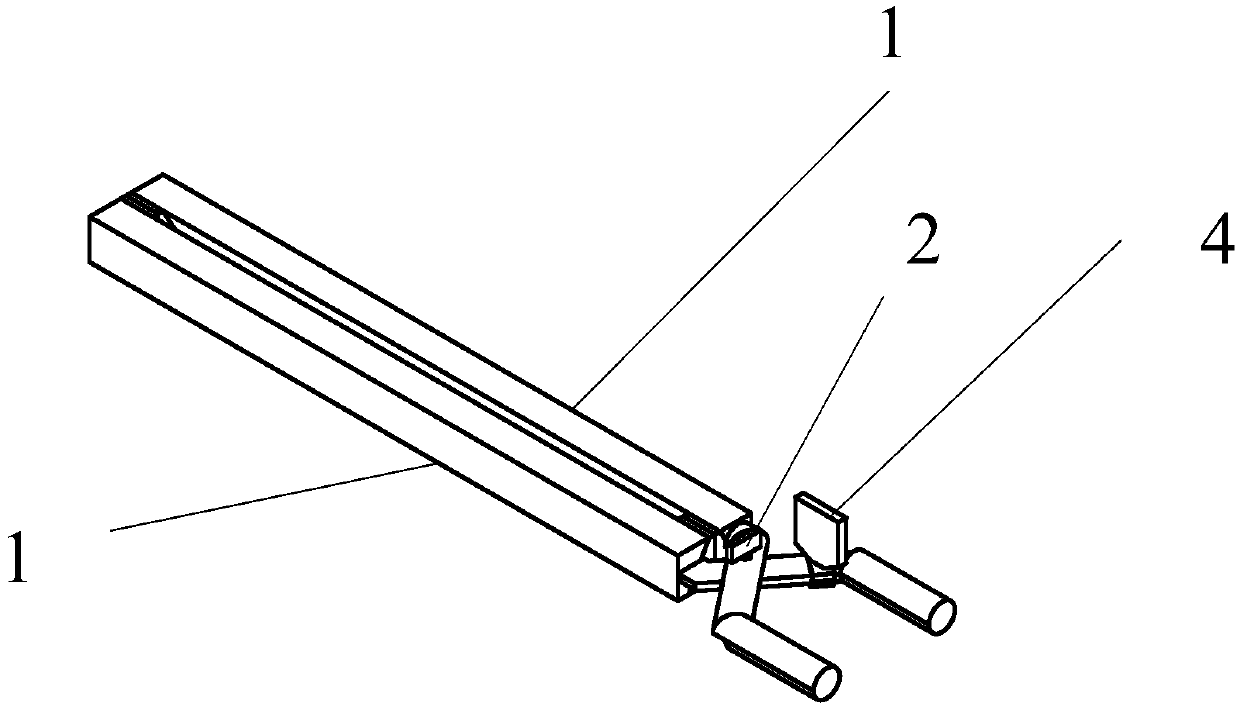

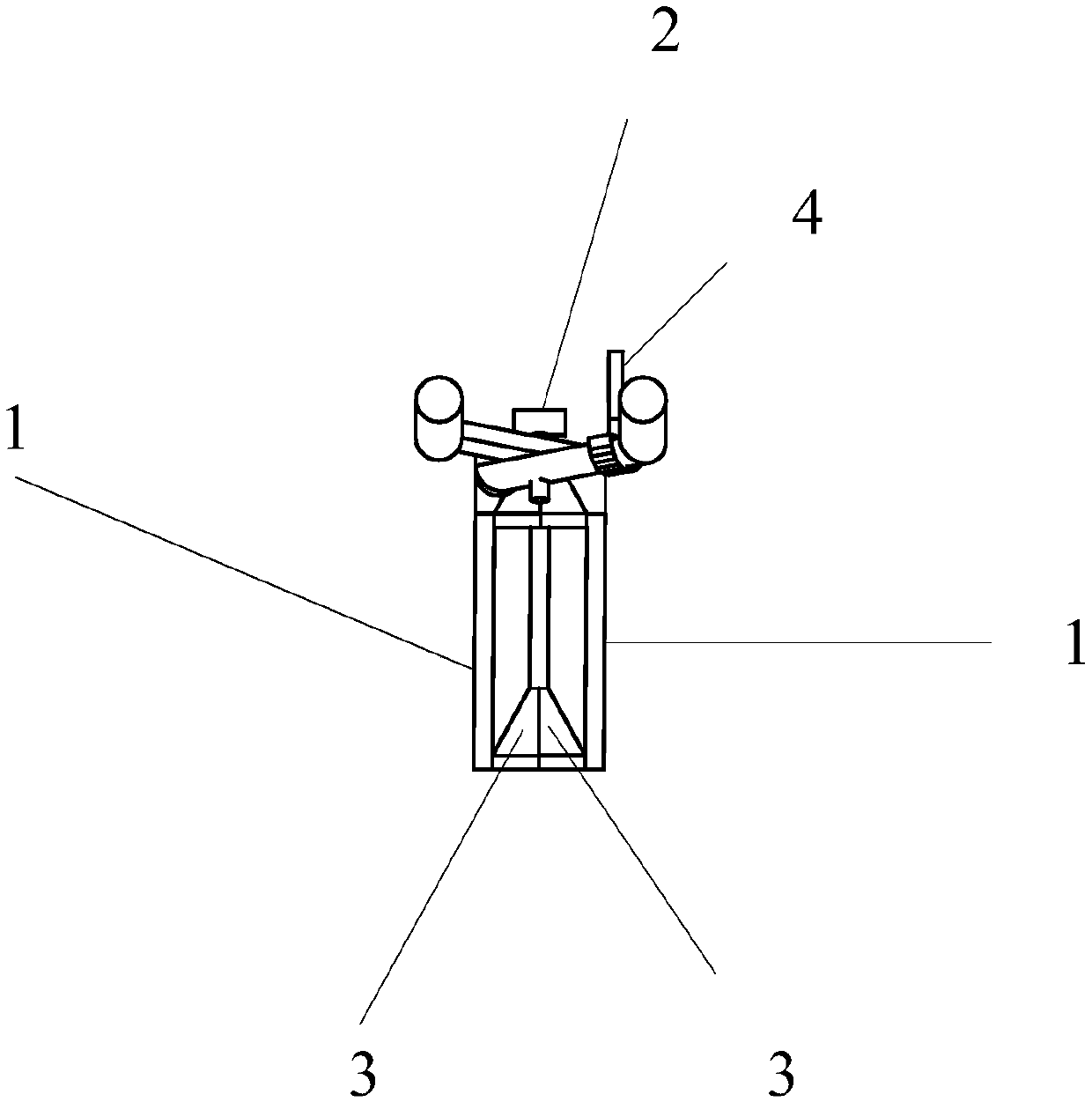

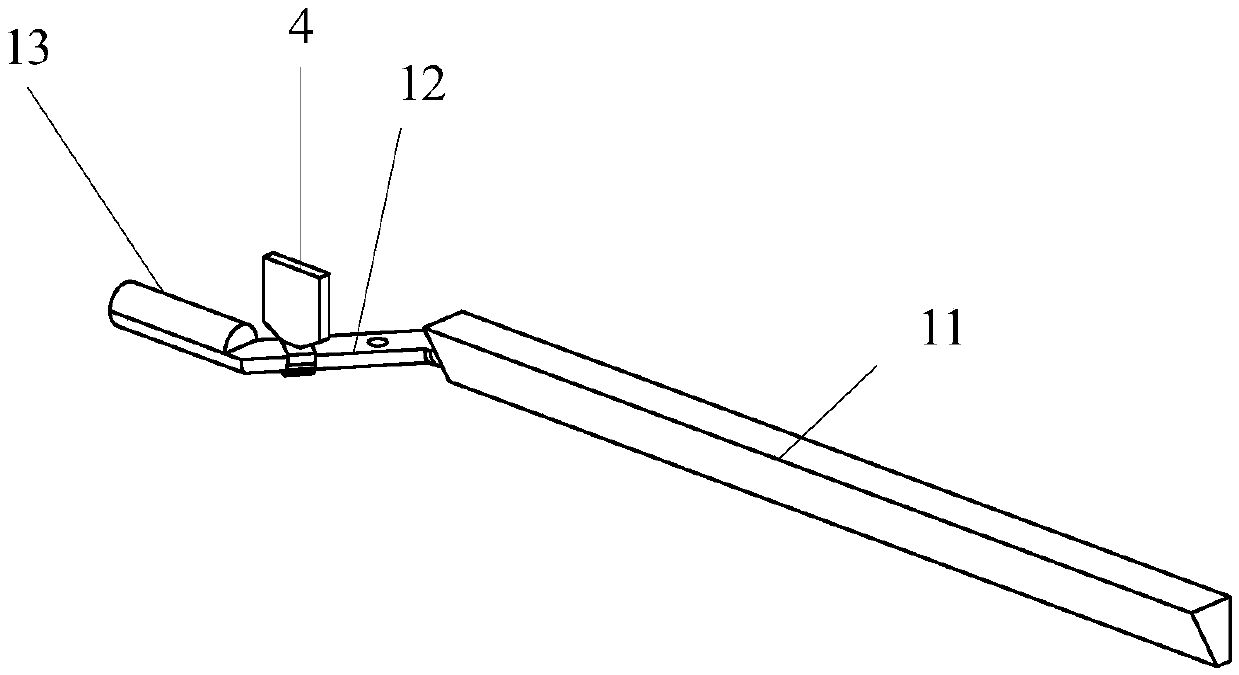

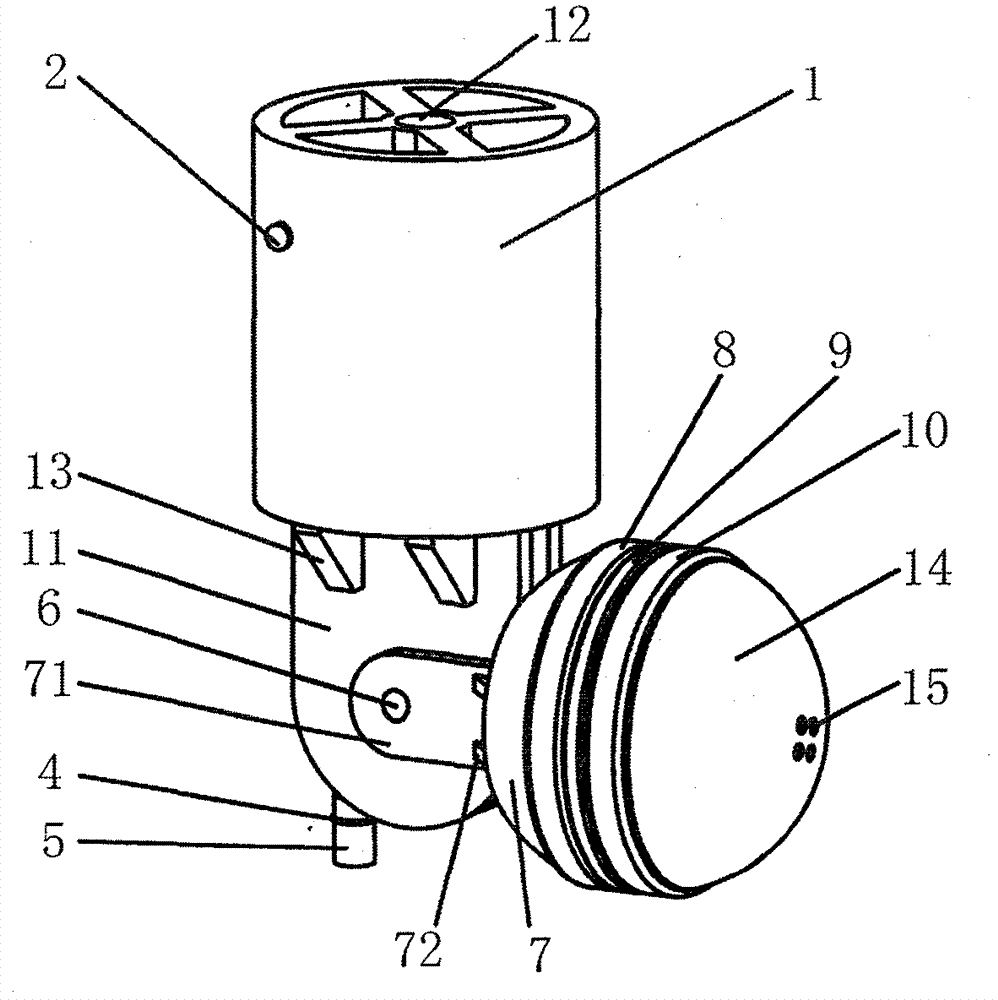

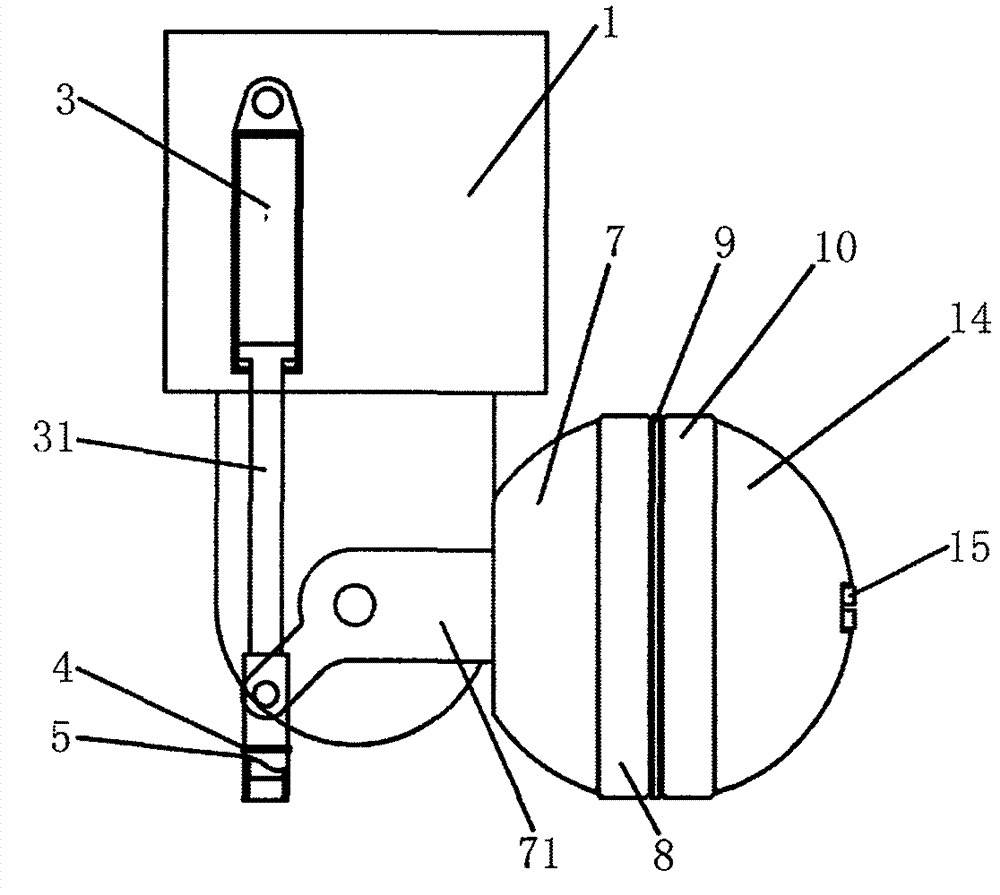

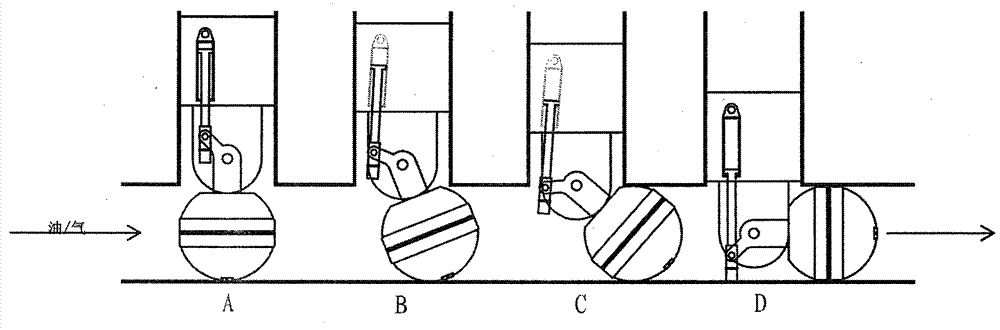

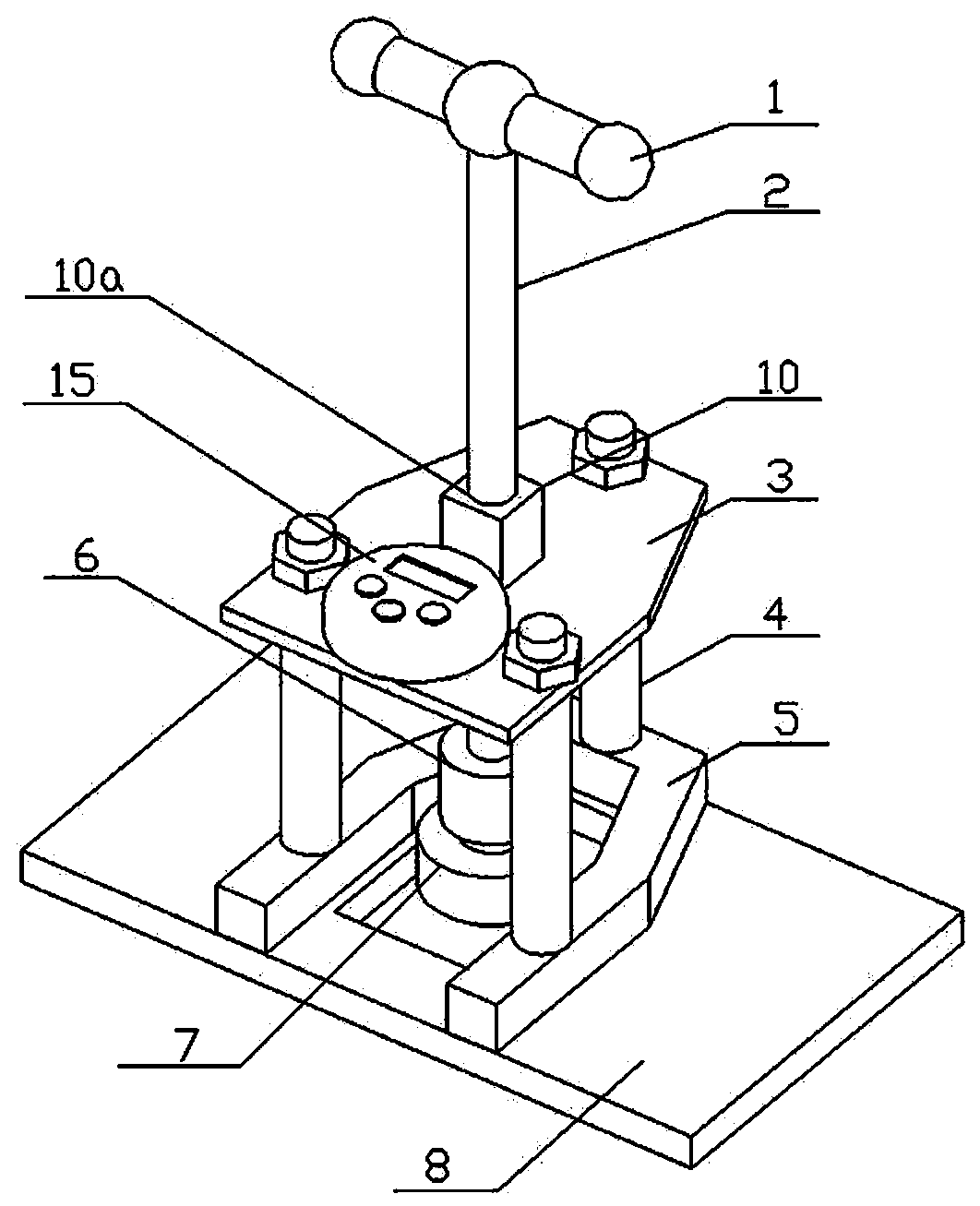

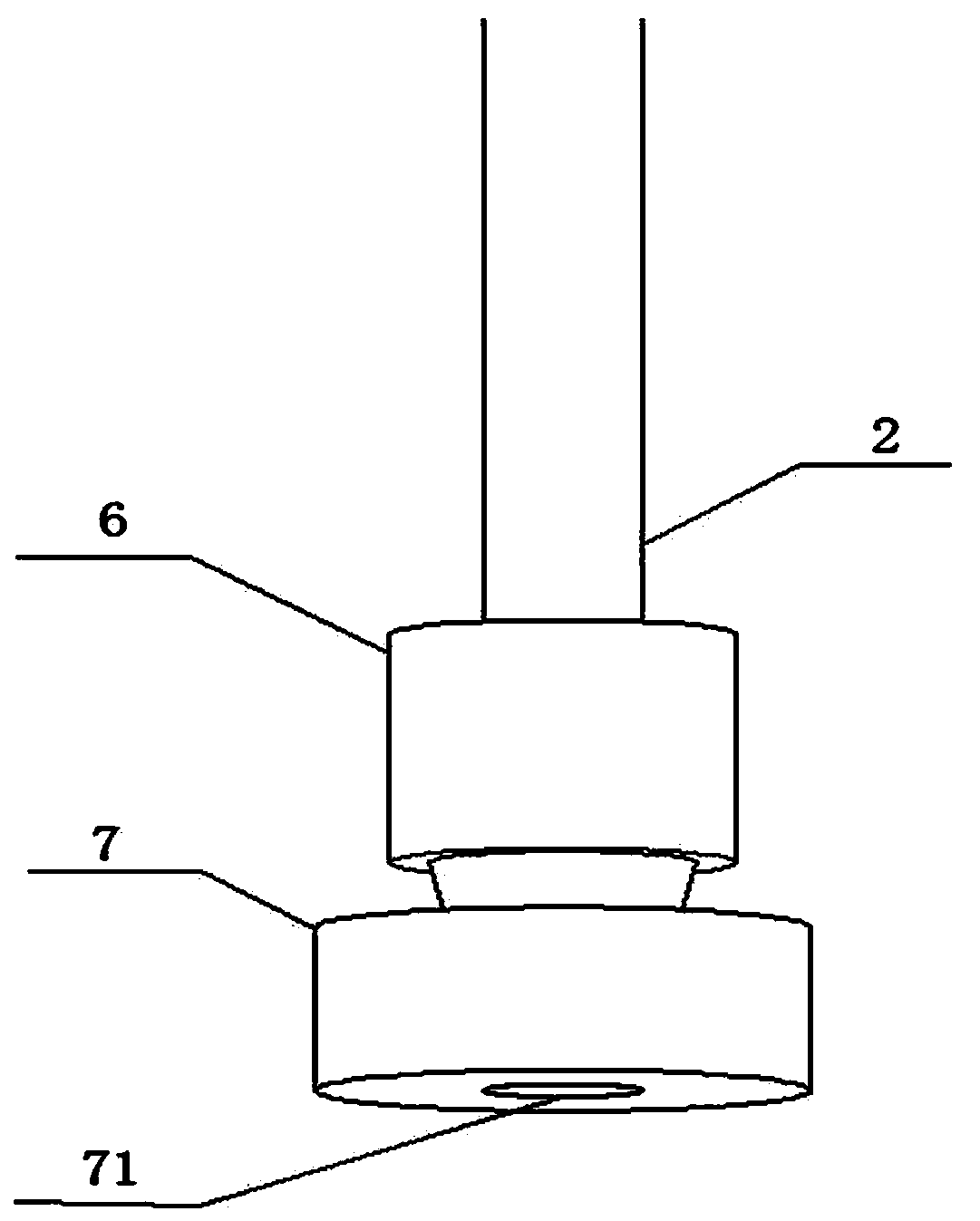

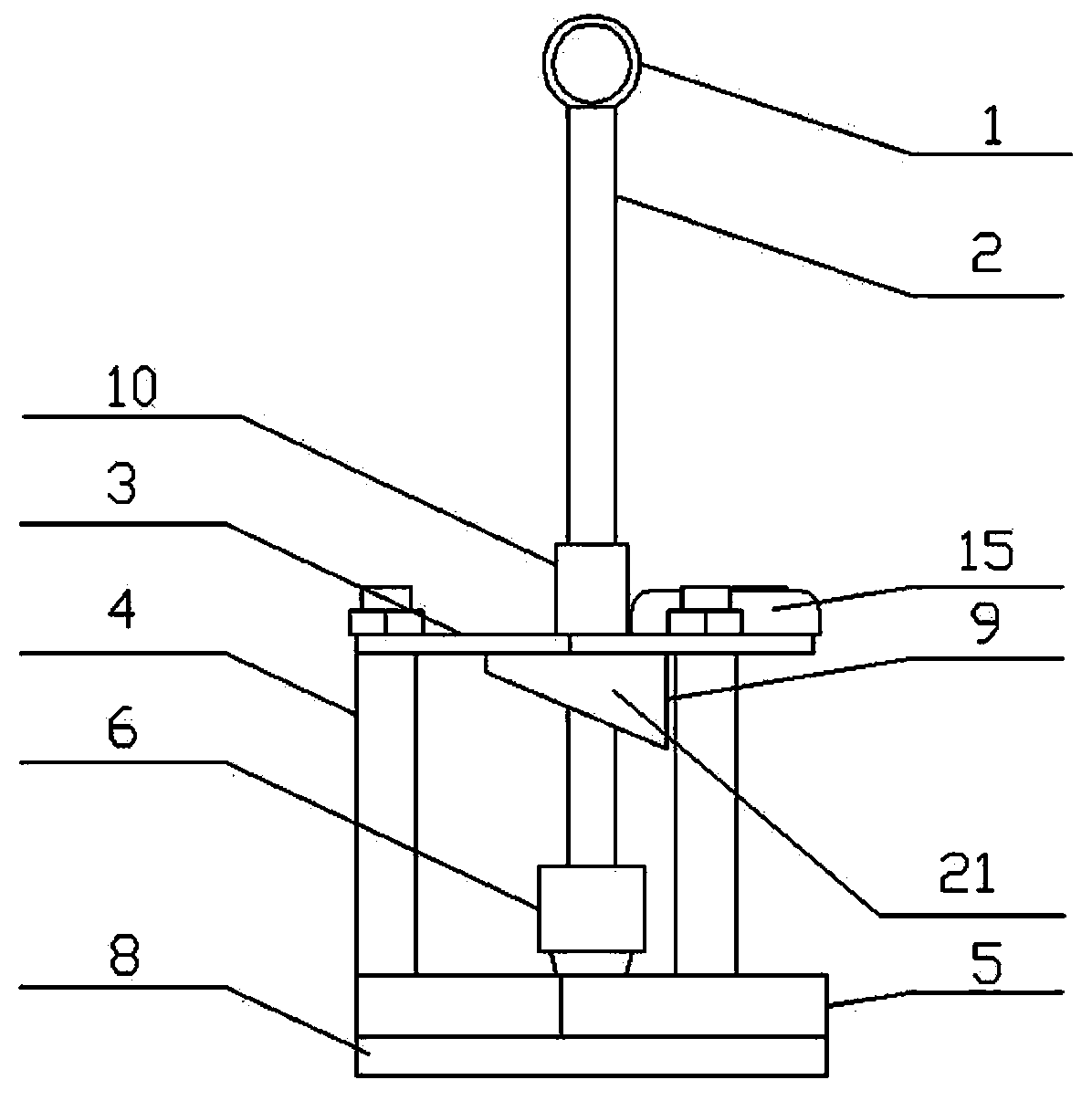

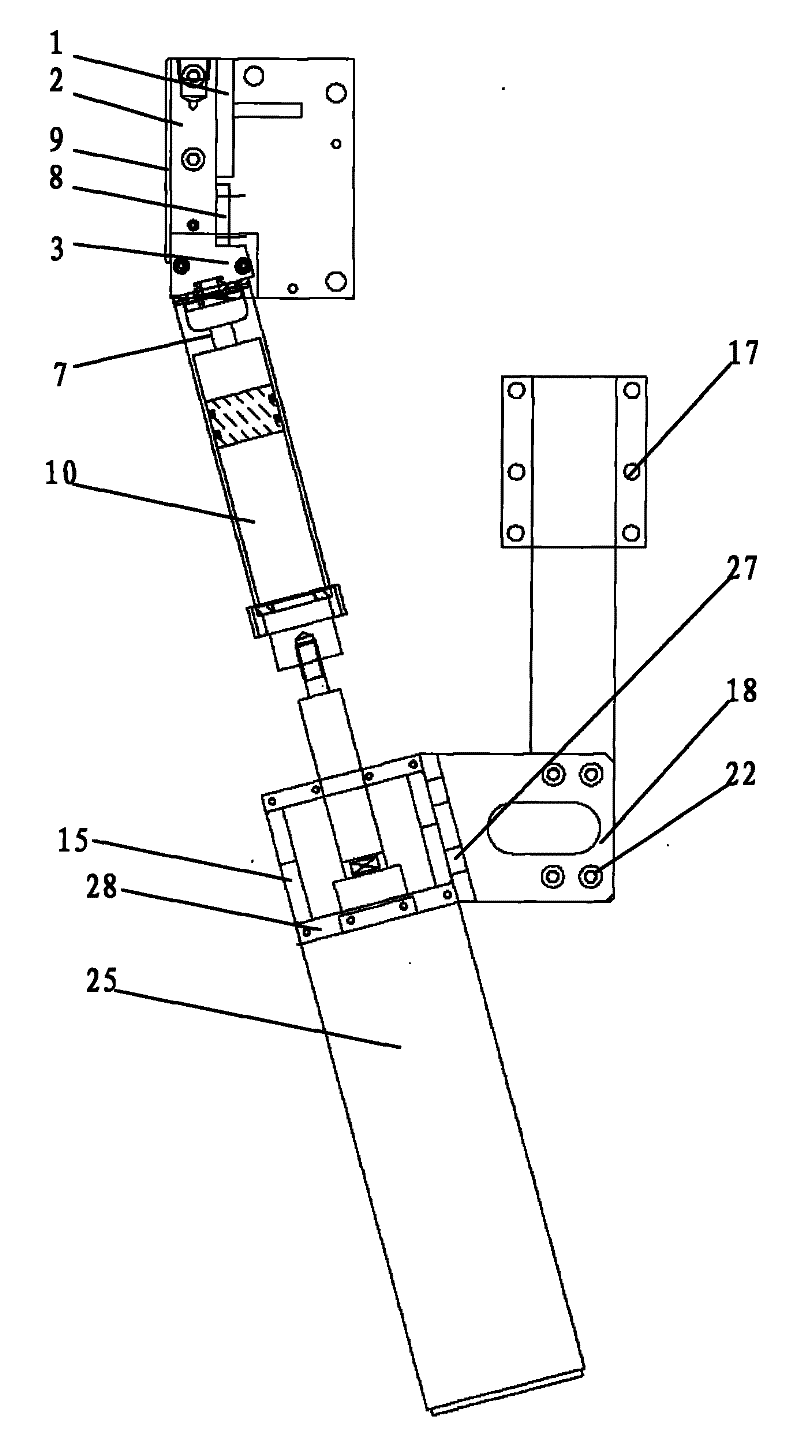

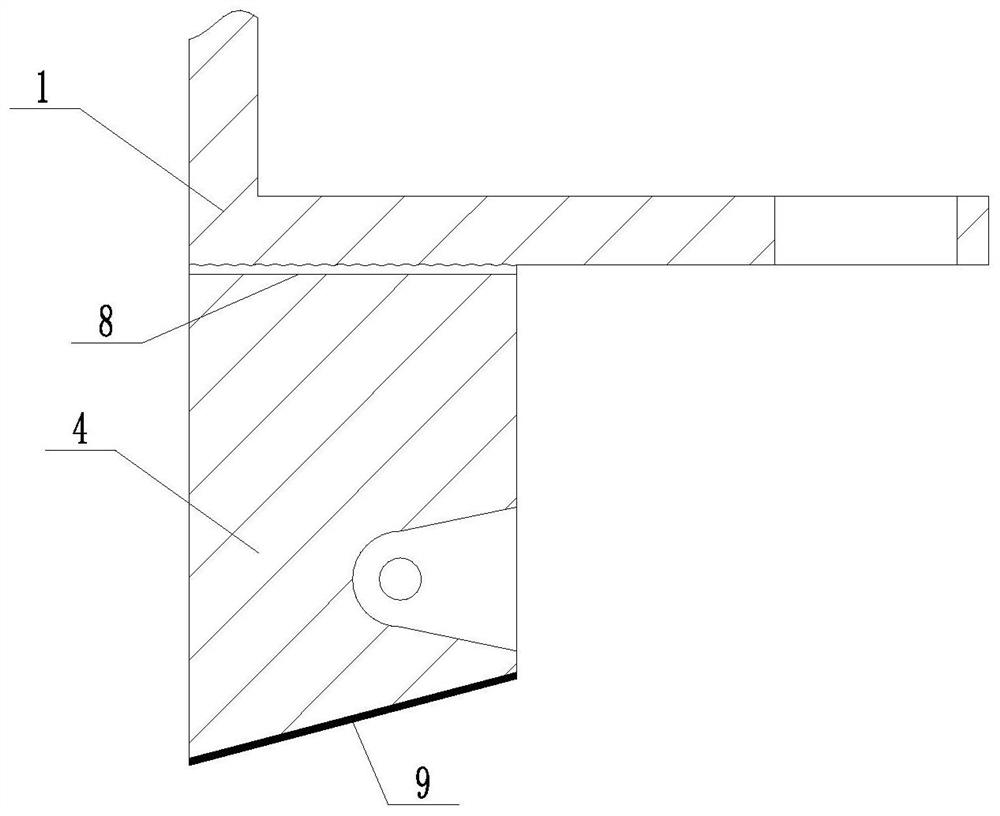

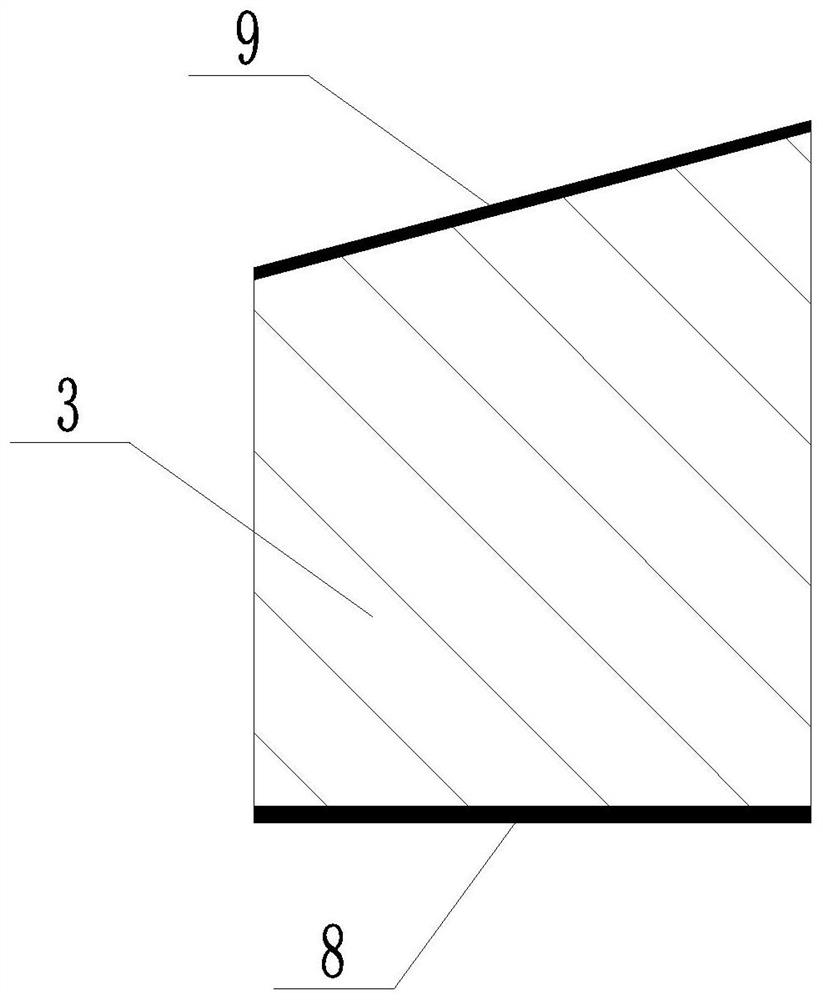

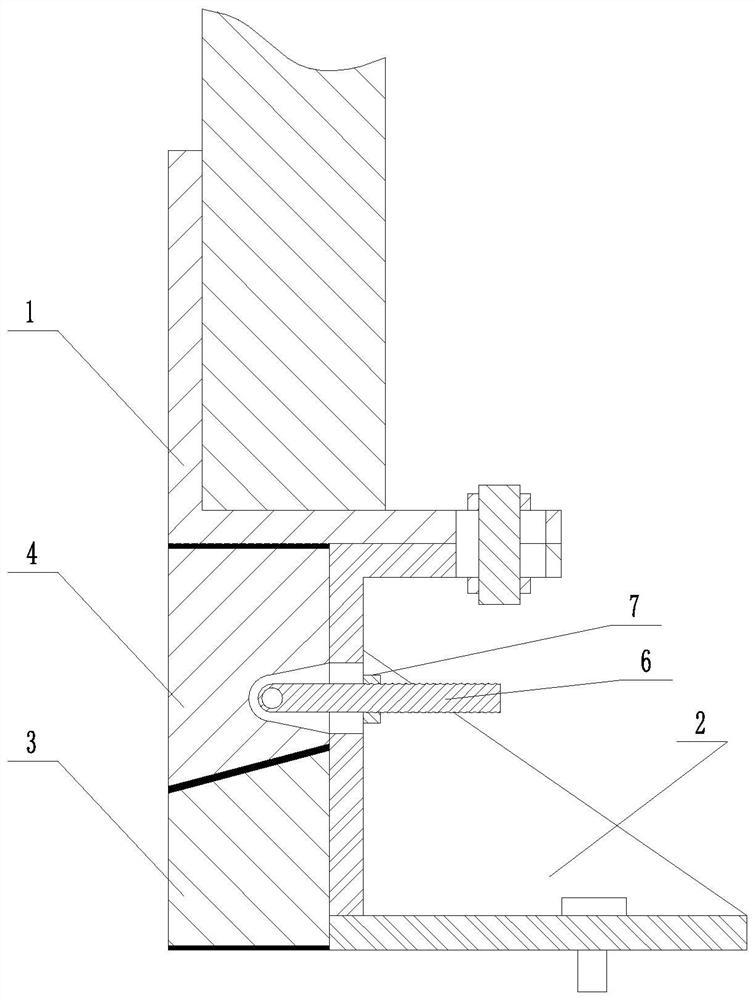

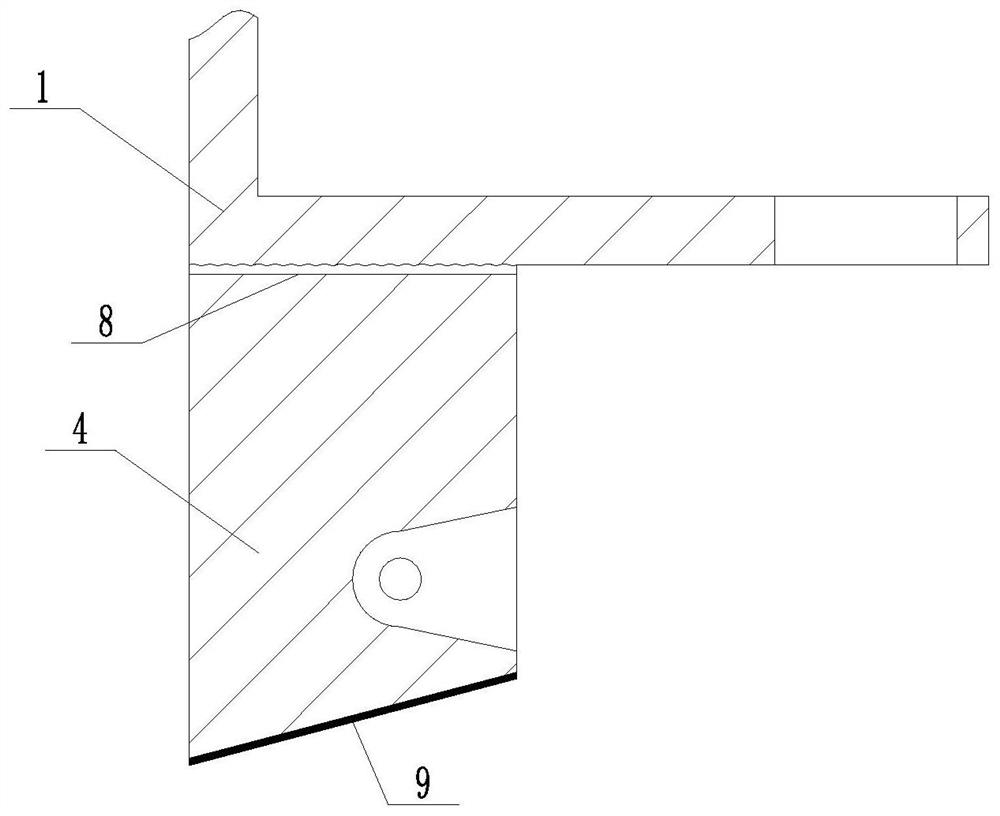

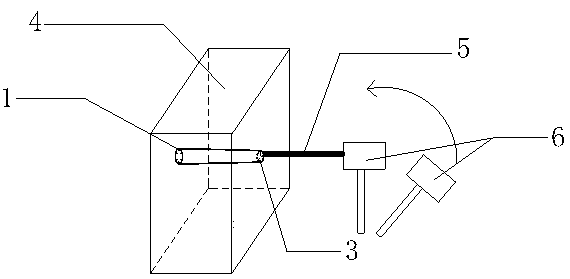

The invention provides a spherical dual-seal plugging device. The device comprises a main support cylinder 1, a small rotary shaft 2, a rotary hydraulic cylinder 3, a washer 4, an anchoring sleeve 5, a rotary mandrel 6, a plugging device casing 7, a rear sealing rubber sleeve 8, an isolation ring 9, a front sealing rubber sleeve 10, a plugging device ball cover 14, an inner hexagon screw 15 and a driving hydraulic cylinder 16. The driving hydraulic cylinder 16, the plugging device ball cover 14, the plugging device casing 7, the front sealing rubber sleeve 10, the rear sealing rubber sleeve 8 and the isolation ring 9 form a plugging mechanism. The rotary hydraulic cylinder 3, the small rotary shaft 2, a rotary shaft 71 and the rotary mandrel 6 form a rotary mechanism of the spherical dual-seal plugging device. The anchoring sleeve 5, the washer 4 and a rotary hydraulic cylinder piston rod 31 form an anchoring mechanism of the spherical dual-seal plugging device. According to the plugging device, sections to be plugged of pipelines can be plugged under a non-stop conveying technology of pipelines.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

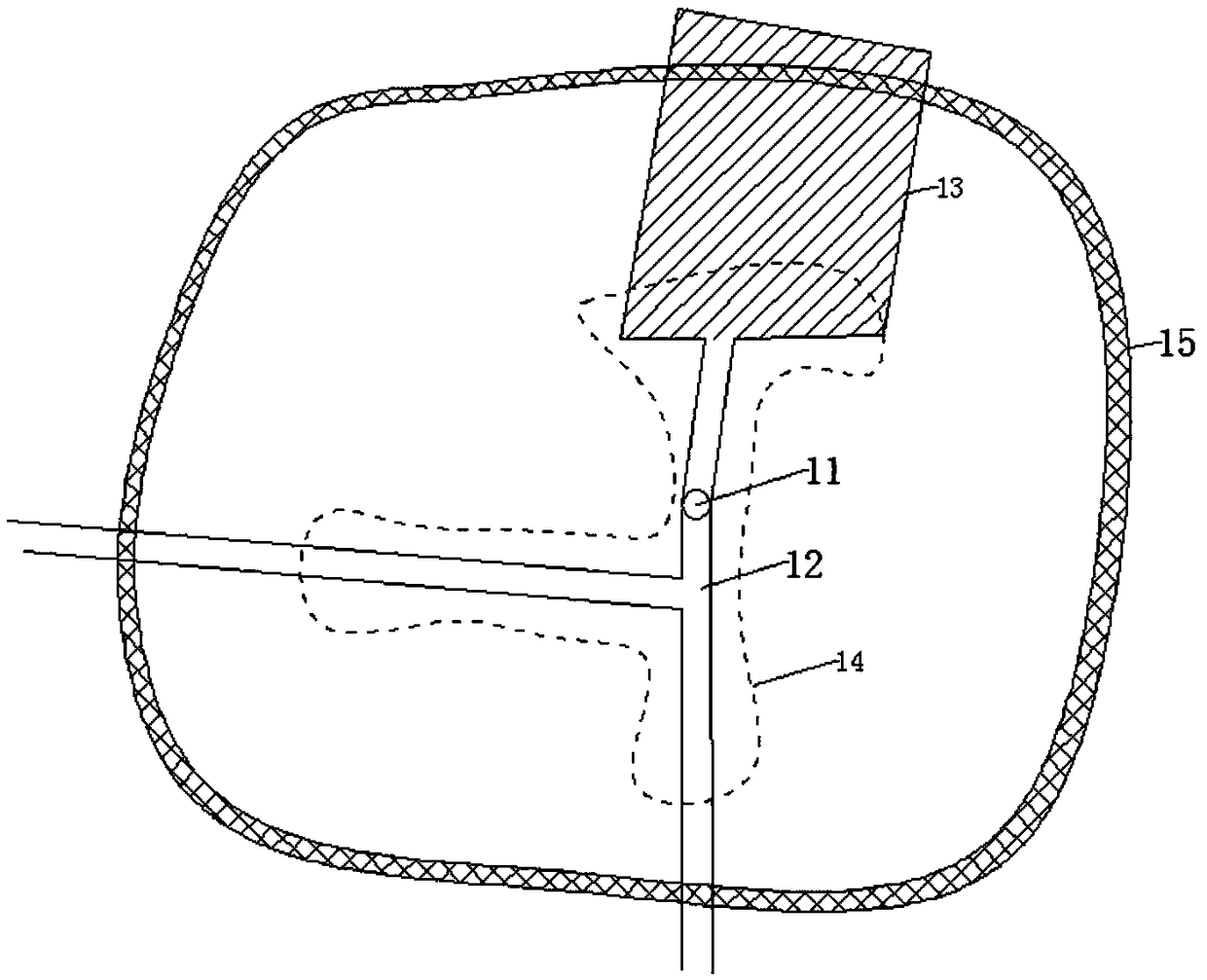

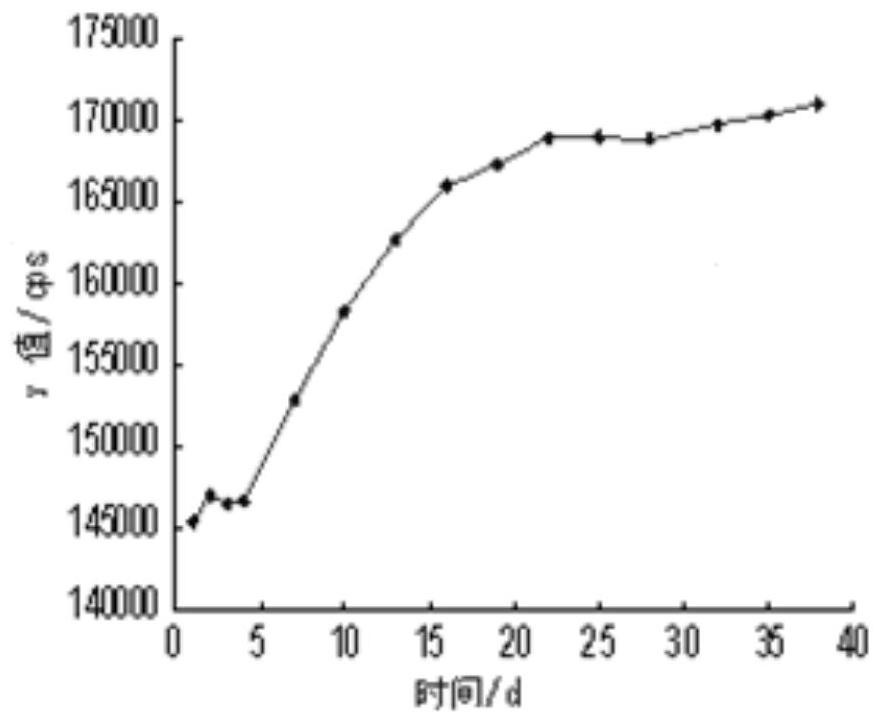

Indoor simulation experiment device and method for temporary blocking of near wellbore formation

PendingCN107976520ANovel structureOperational securitySealing/packingMaterial analysisEngineeringConstruction design

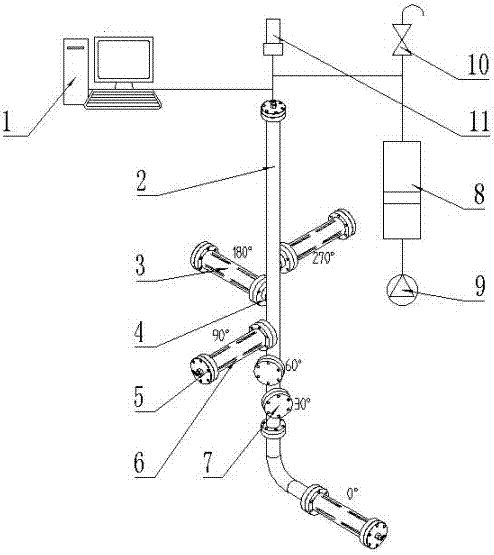

The invention relates to an indoor simulation experiment device for temporary blocking of a near wellbore formation. The indoor simulation experiment device comprises an experiment end and an information acquisition end, wherein the experiment end comprises an injection main body and an experiment main body; the experiment main body comprises a vertical shaft and at least one branch; at least onebranch connector is arranged on a side wall at the lower part of the vertical shaft; a simulation blast hole and a simulation crack are arranged on the side wall of a branch; the information acquisition end is connected with a sensor arranged in the experiment main body. An indoor simulation experiment method for the temporary blocking of the near wellbore formation is applied to the indoor simulation experiment device for the temporary blocking of the near wellbore formation. The indoor simulation experiment device and method for the temporary blocking of the near wellbore formation can be used for really simulating different blast holes and corresponding crack conditions so that a near wellbore temporary blocking process is simulated, an on-site construction design is effectively guidedand the construction effect is improved. The information acquisition end is used for acquiring data and the result credibility is high; on-site experience is not needed, and the actual plugging effectand plugging quality are improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

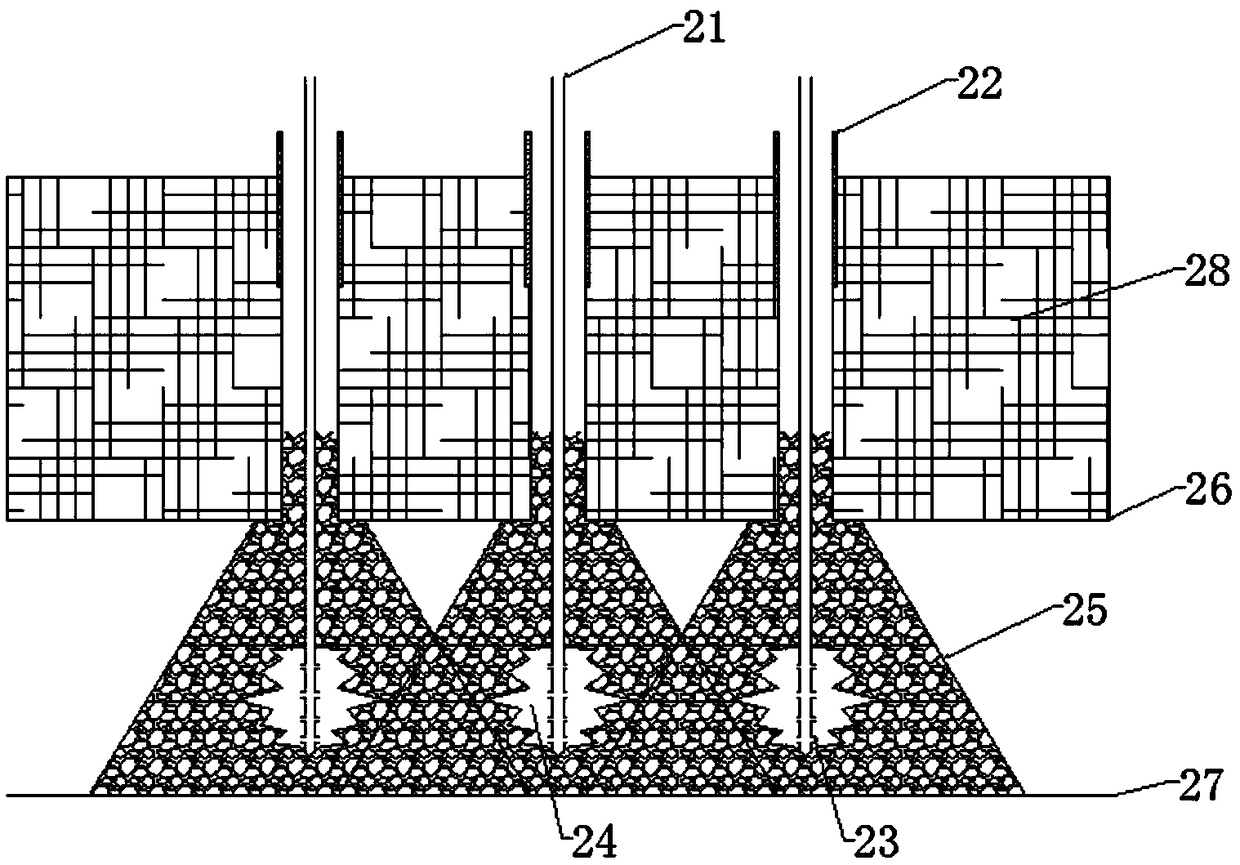

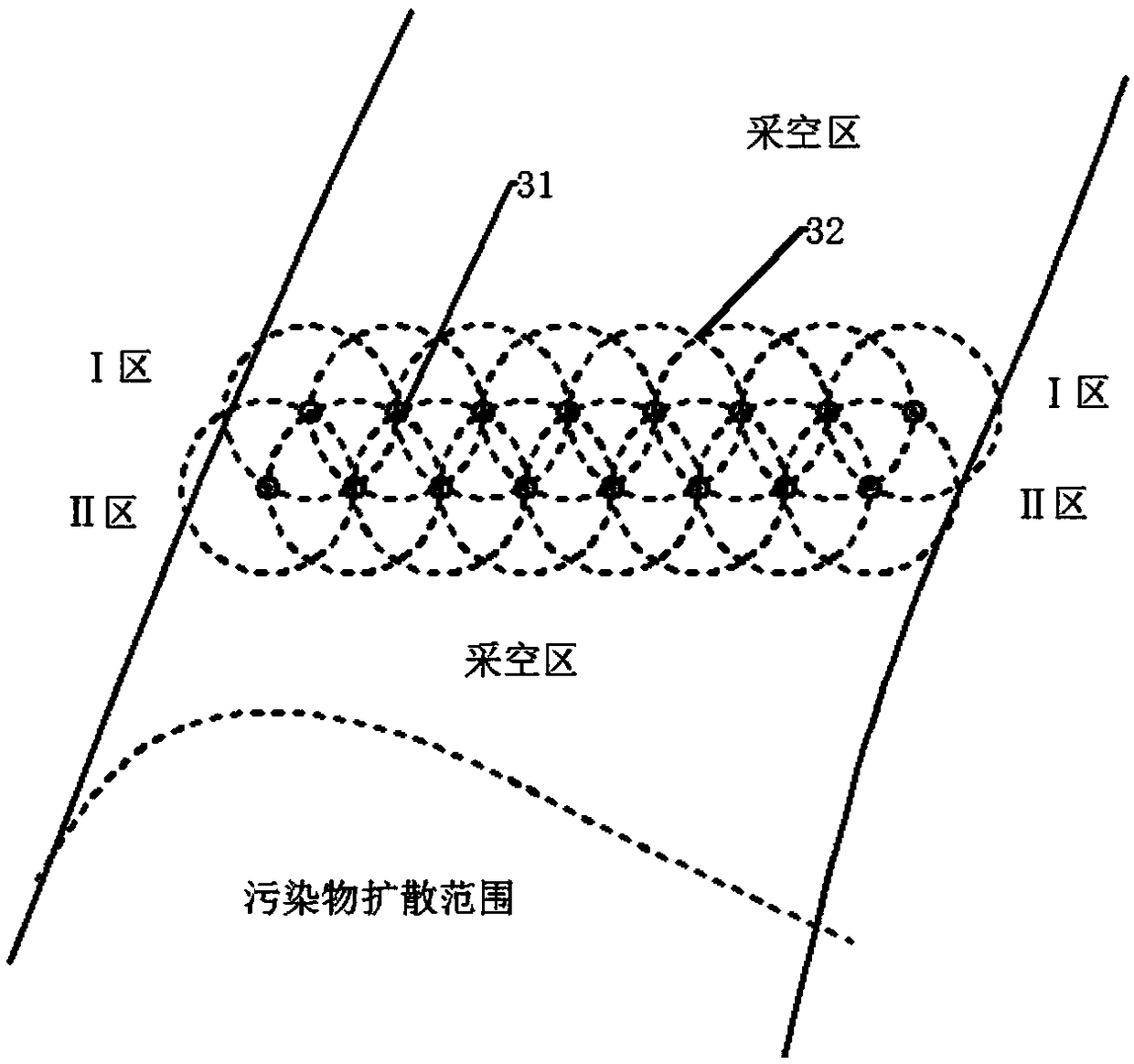

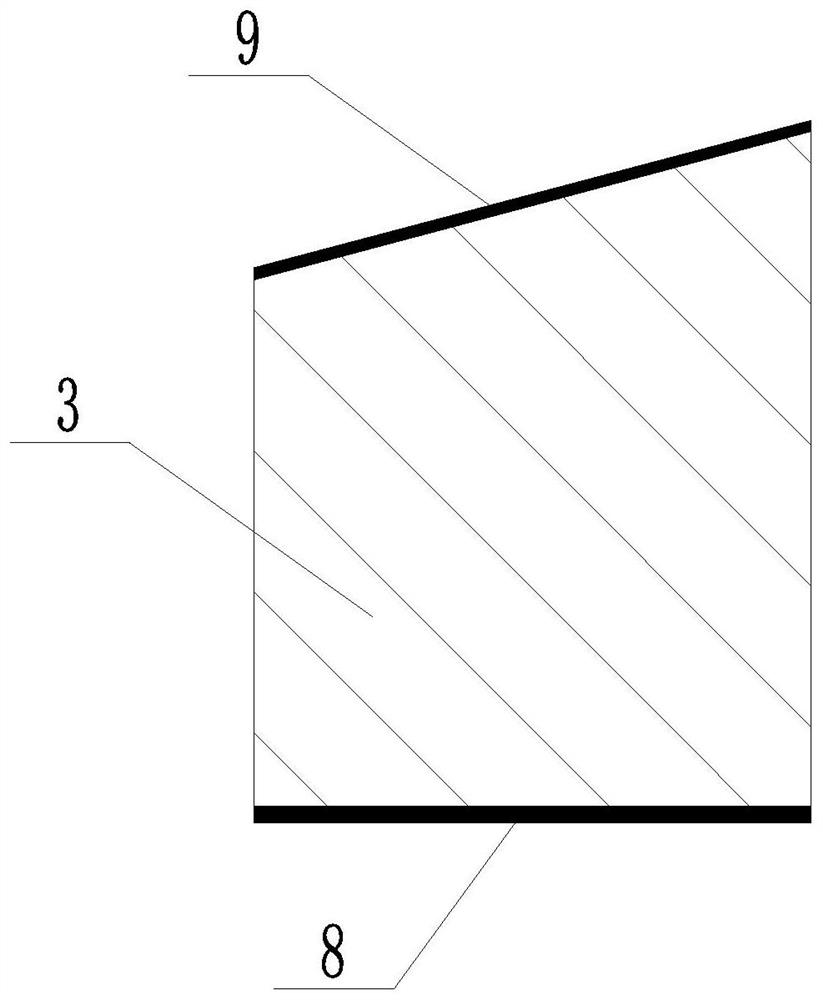

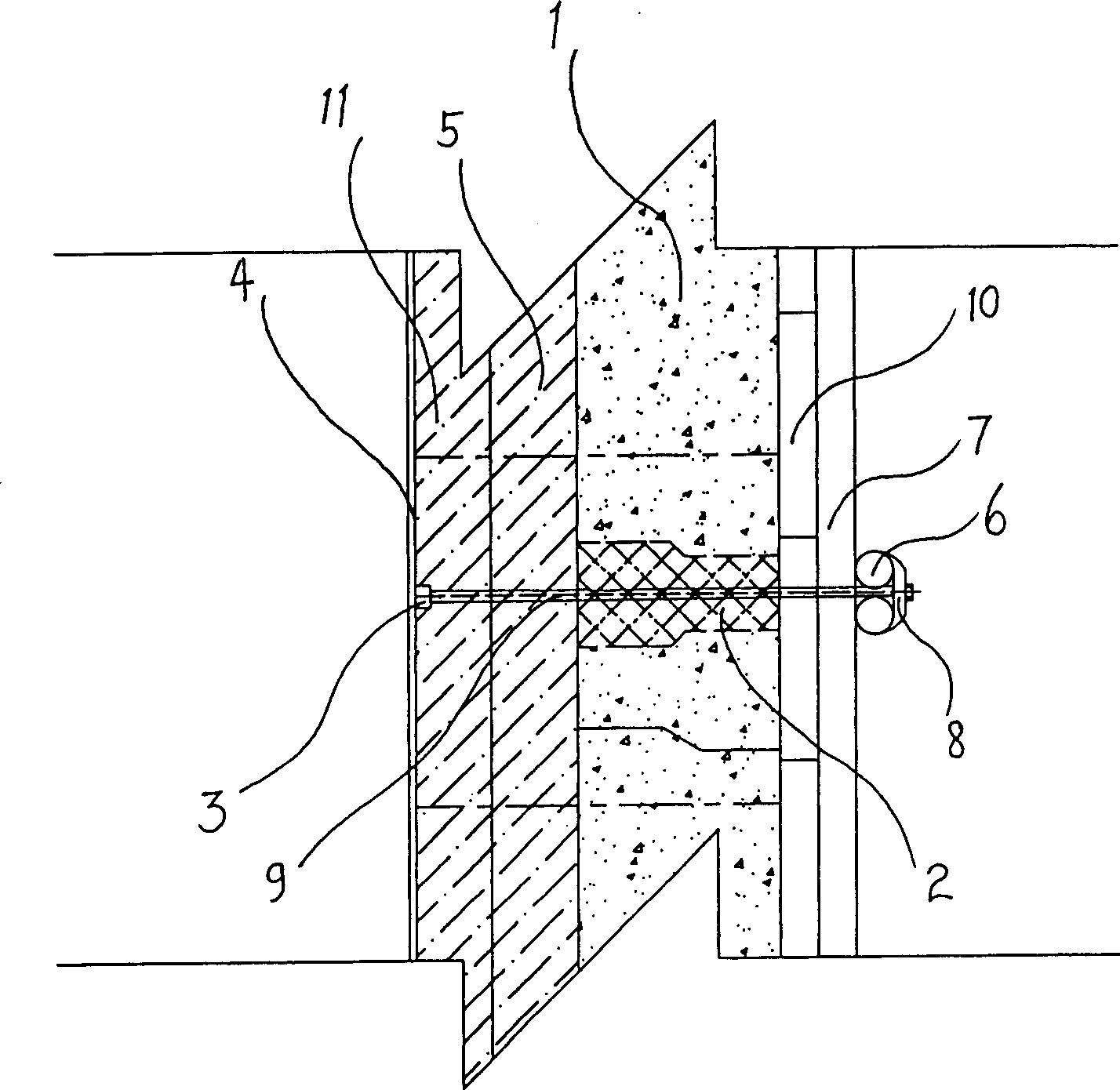

Isolation blocking technology for pollutants under mine

The invention relates an isolation blocking technology for pollutants under a mine and an isolation technology for the pollutants in an underground space of a mine area, in particular to the technicalfield of isolation treatment of manually-dumped pollutant sites of roadways and goafs. During treatment of the pollutants in a downhole roadway and a goaf, the pollutants need to be isolated firstly.Underground spaces of the roadway and the goaf are large, a large amount of cement grout is prone to flow away, grouting top filling is difficult to form, the blocking effect is difficult to achieve,and mixing of the grout and the pollutants further causes the defects of large pollution treatment difficulty and high cost. The invention provides a novel roadway and goaf grouting technology, and the novel roadway and goaf grouting technology comprises the construction processes that common grouting holes (also serving as roadway and goaf exploration holes) are constructed, goaf or roadway grouting holes are constructed, floral tubes are put downward and stone is put in, and grouting is conducted. Compared with a traditional grouting technology, the novel roadway and goaf grouting technology has the advantage of small use amount of the cement grout and aggregate and further has the advantages that the grouting influence radius is small, top filling can be achieved, and impermeability ishigh.

Owner:山东省地质矿产勘查开发局八〇一水文地质工程地质大队

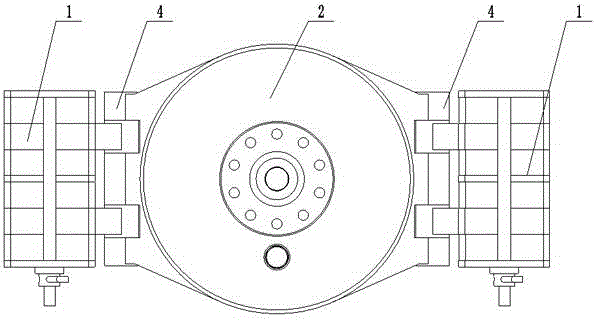

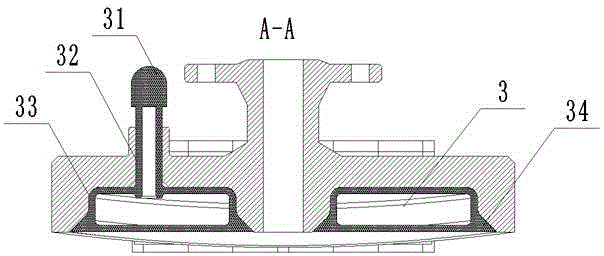

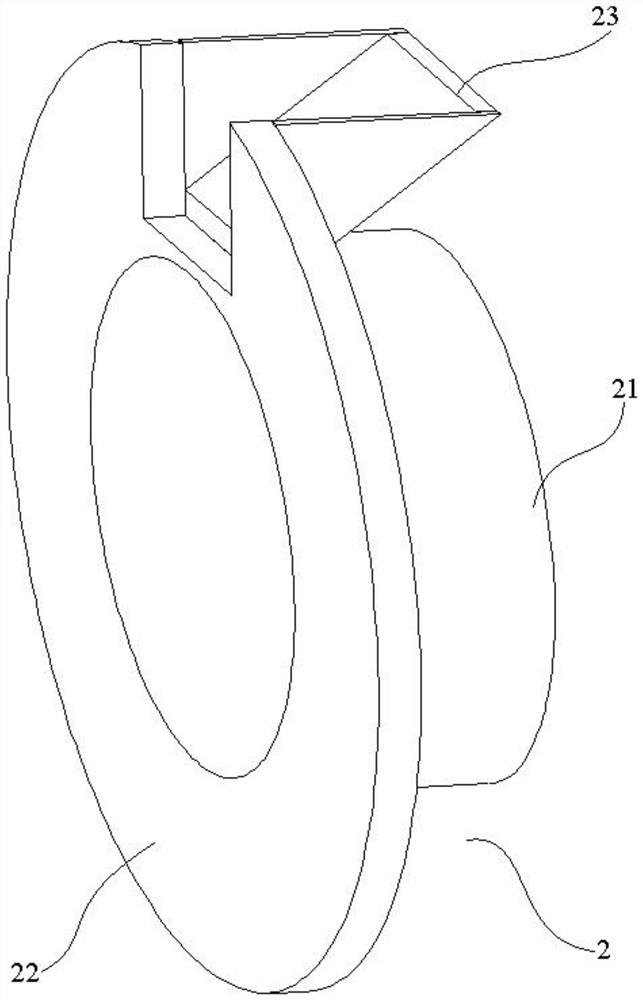

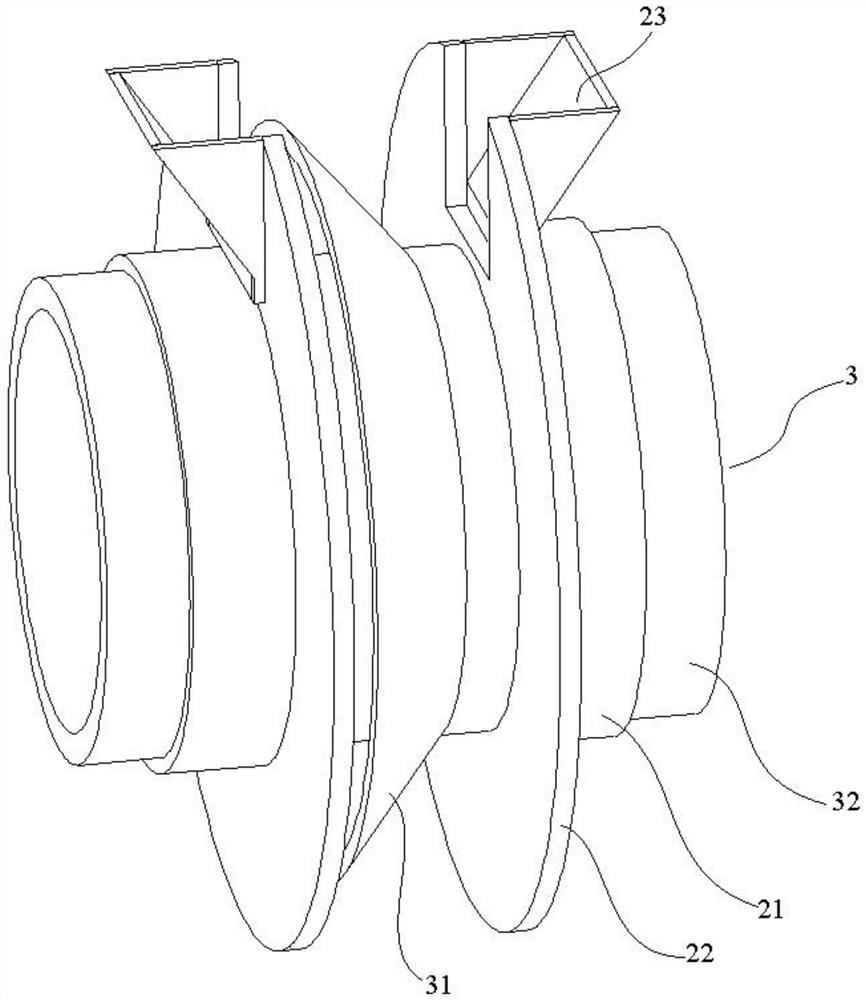

Strongly magnetic positioning airbag outer plugging device

ActiveCN104565663AQuick positioning installationIncrease flexibilityPipe elementsMagnetic tension forceEngineering

The invention provides a strongly magnetic positioning airbag outer plugging device which is high in mounting speed, low in mounting resistance, highly adaptive to a leakage surface and applicable to plugging of a large-sized pipeline. According to the adopted technical scheme, the strongly magnetic positioning airbag outer plugging device comprises strongly magnetic mechanisms, a shell and an airbag, wherein the strongly magnetic mechanisms are arranged at of two ends of the shell; the airbag is embedded into the shell, extends outwards through a hole formed in the shell and is connected with a compressor guide pipe; each strongly magnetic mechanism owns an independent magnetic switch and is connected with the shell through a hinge. The strongly magnetic positioning airbag outer plugging device can be widely applied to the technical fields of leakage plugging processing of a dangerous source, safe pipeline conveying and strongly magnetic positioning.

Owner:ZHONGBEI UNIV

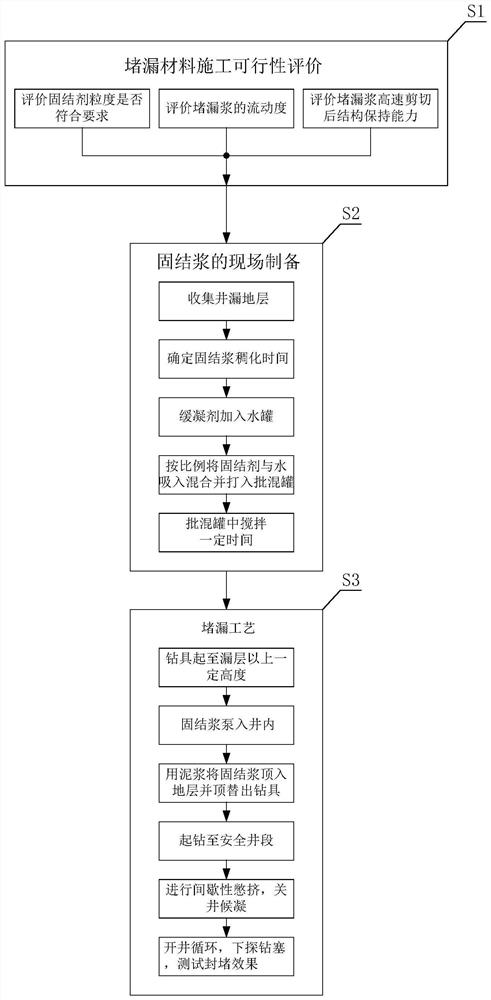

Reversible gel consolidation plugging method

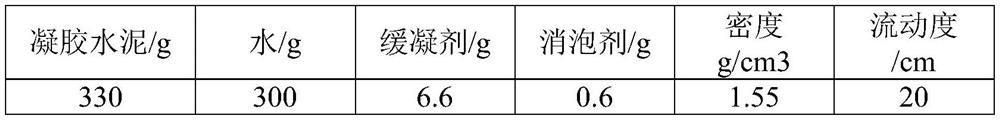

PendingCN113863894ASolve the problem of well leakage in the formation of waterWell mixedDrilling compositionSealing/packingWater useProcess engineering

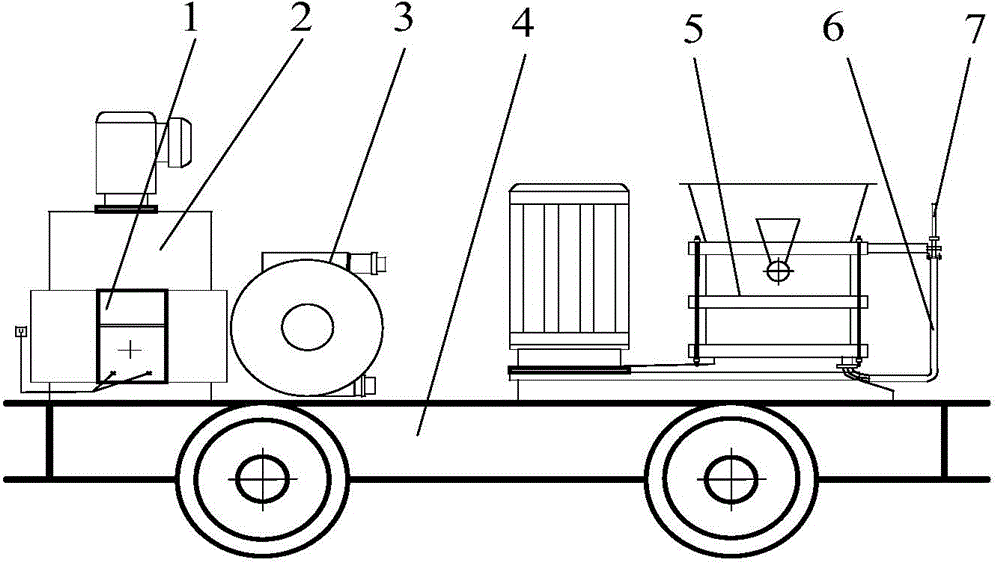

The invention discloses a reversible gel consolidation plugging method. The method comprises the following steps: evaluation of the construction feasibility of a plugging material: judging whether the granularity of a consolidation agent meets the requirement or not; in-situ preparation of consolidation slurry: collecting parameters such as well leakage stratum depth, pressure, temperature and water output amount, determining the thickening time of the consolidation slurry, adjusting the adding amount of a retarder according to in-situ water, adding the retarder into a water tank to be evenly stirred, sucking and mixing the consolidation agent and water according to a certain proportion through a batch mixing pump, pumping the mixture into a batch mixing tank, conducting stirring in the batch mixing tank for a certain time, and detecting the performance of the consolidation slurry; the plugging process: preparing the consolidation slurry according to a designed amount, lifting a drilling tool to a certain height above a leakage layer, pumping the prepared consolidation slurry into a well, jacking the consolidation slurry into a stratum by using slurry to jack the drilling tool out, lifting the drilling tool to a safe well section, carrying out intermittent extrusion according to conditions, further enabling a plugging agent to permeate into the leakage layer in a thickening process, closing the well and waiting for setting, opening the well for circulation, and downward putting a drill plug to test the plugging effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

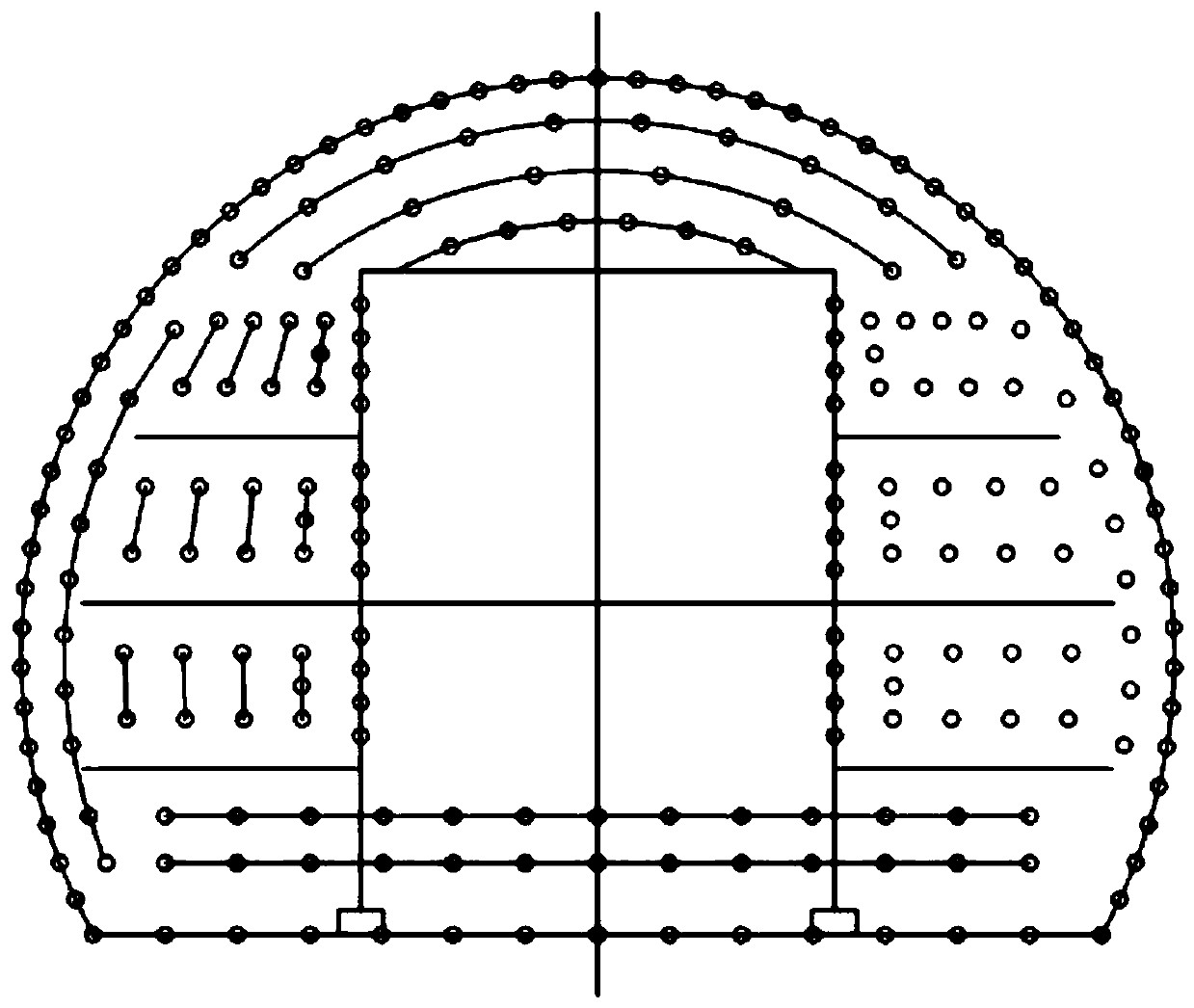

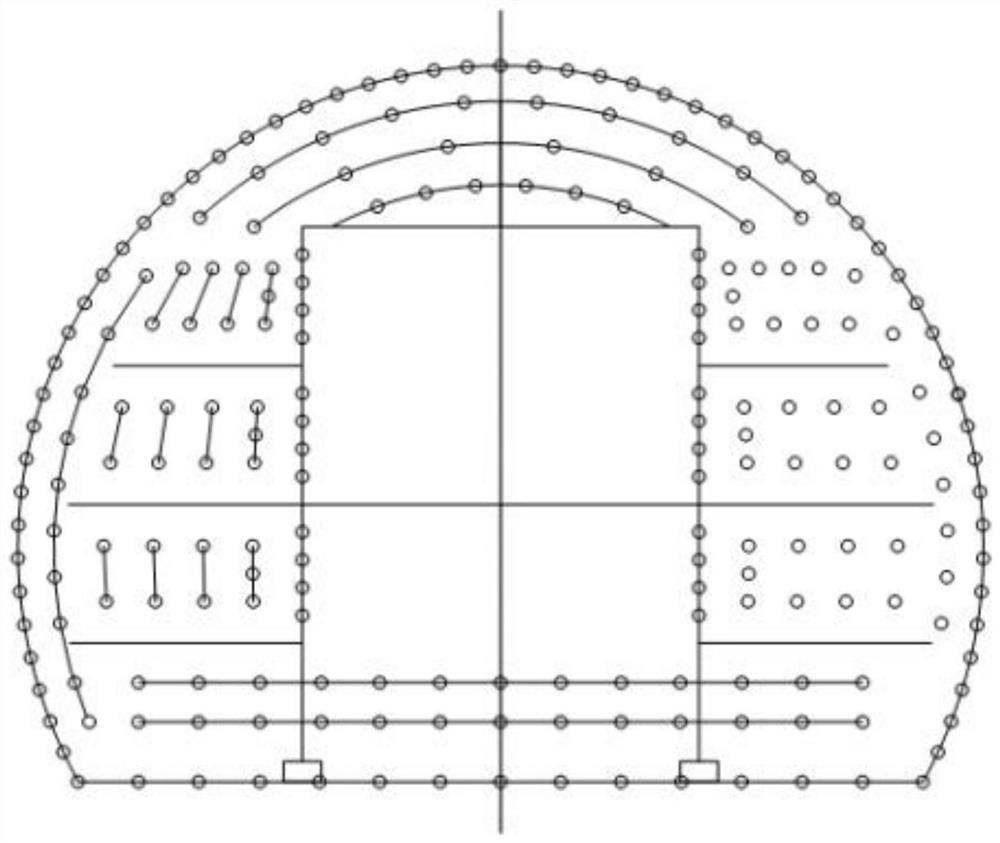

Tunnel soft rock full-section multi-stage ultra-deep hole double-end plug and stemming plugging high-efficiency blasting method

The invention discloses a tunnel soft rock full-section multi-stage ultra-deep hole double-end plug and stemming plugging high-efficiency blasting method, and relates to the technical field of tunnelblasting. The full-section multi-stage same-depth inverted square-frustum-shaped ultra-deep hole double-end plug and clay stemming high-efficiency blasting method is adopted, wherein a No. 2 rock emulsion explosive is used as an explosive, a non-electric millisecond detonator is used as a detonator, and a detonating network is formed by serial and parallel connection of detonating tubes; a pneumatic rock drill is used for drilling; a blast hole layout diagram is as follows: multiple cutting holes, inner ring holes, peripheral holes and bottom plate holes are arranged; a charging structure is formed in such a way that the cutting holes are continuously charged, the peripheral holes are charged at intervals, the inner ring holes and the bottom plate holes are continuously charged, and the cutting holes, the peripheral holes, the inner ring holes and the bottom plate holes are plugged each through a combined mode of a plug, stemming and a plug; and the blasting footage is 3.9-4.1m, and the surrounding rock is sealed by concrete primary spraying after slag discharge. The method overcomes the defects of poor blasting effect, low blasting efficiency and poor safety in the prior art, andcan improve the blasting effect, the blasting efficiency and the safety.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +2

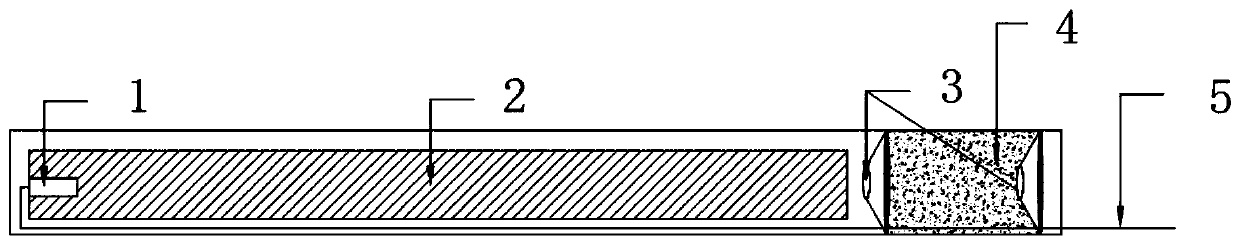

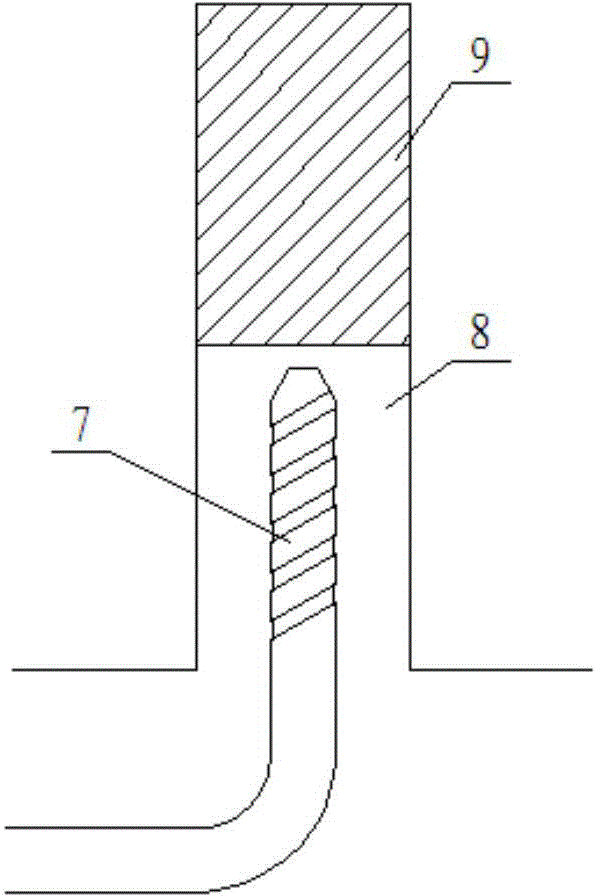

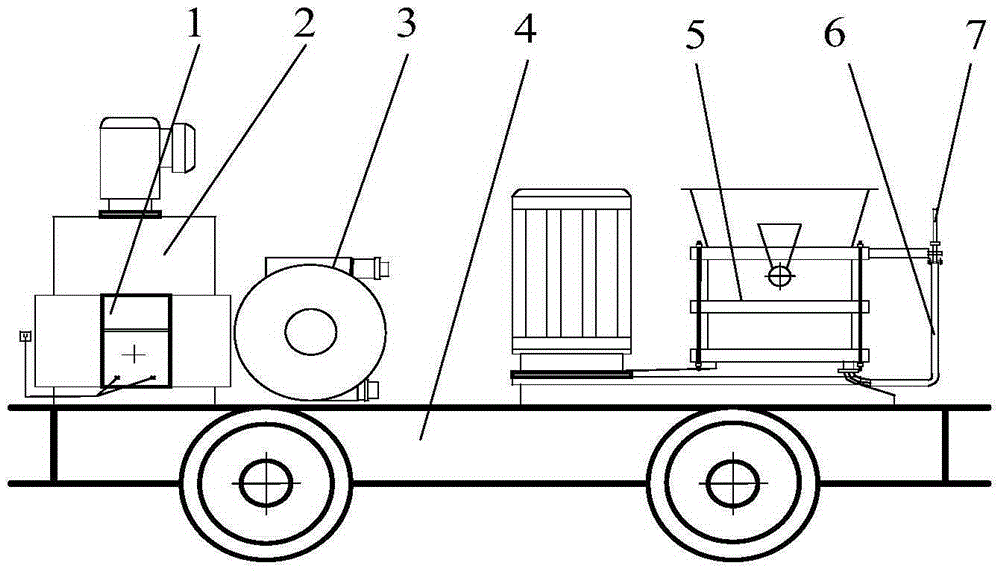

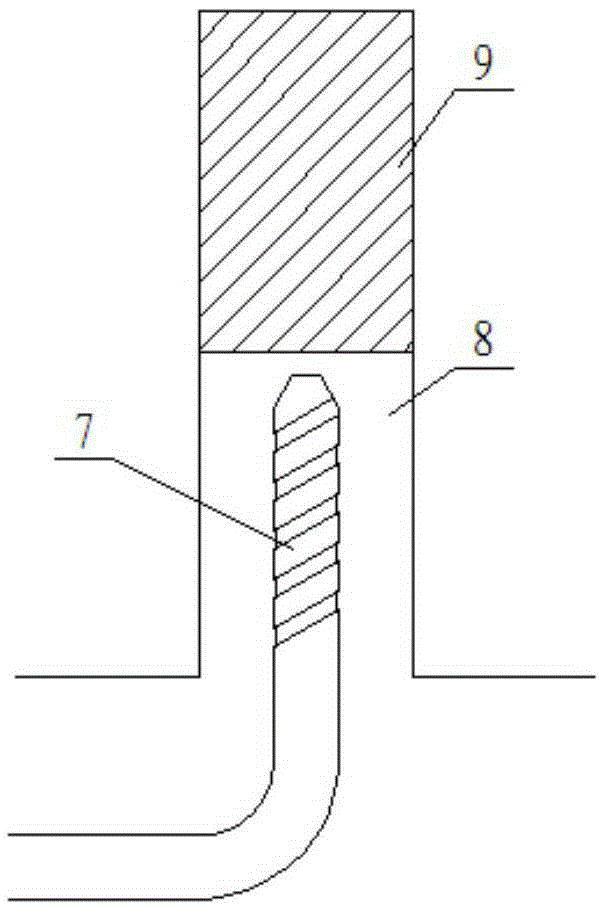

Blocking method for blastholes of underground blasting projects and stemming injection machine

The invention relates to a stemming injection machine, which comprises a water storage device, a water outlet tube, a carriage, a stemming agitator, a stemming outlet tube and a helical injection head; the stemming injection machine also comprises a water pump for pumping the water of the water storage device into the stemming agitator; the stemming injection machine also comprises an automatic water control device for controlling the quantity of water added into the stemming agitator; the stemming injection machine also comprises a hydraulic stemming supply pump. A blocking method for blastholes of underground blasting projects includes: (Step 1) stemming material is prepared; (Step 2) the stemming material is loaded into the stemming injection machine; (Step 3) the automatic water control device controls the weight ratio of the stemming material to water at 1:0.12 to 0.13, and the stemming material and the water are mixed, so that homogeneous stemming is obtained. The invention has the following advantages: the quality of stemming and the efficiency of blasthole blockage are increased, staffing is saved, labor condition is improved, meanwhile, the safety of construction is ensured, the quality of blasting is greatly increased, the cost of blasting is reduced, and thereby good economic benefit is obtained.

Owner:WUHAN UNIV OF SCI & TECH

Assembled building component joint seam shear-type bin separation plugging construction tool and method

PendingCN109537746AImprove convenienceQuality improvementBuilding material handlingBuilding insulationsIndustrial engineeringBuilding construction

The invention provides an assembled building component joint seam shear-type bin separation plugging construction tool and method. The tool is in a scissors shape, an operation part is a gripping handle, the gripping handle is slightly thick, a knife edge part is changed into a straight plate with a certain thickness, the inner side of the straight plate has an inclined angle, and a bin separationstrip with an inclined angle is conveniently formed, and can be used for joint seam plugging to form a plugging strip after the tool is split. By means of the tool and the method, after a prefabricated component is installed, unified bin separation and plugging can be conducted, and the disorder of working procedures is avoided; moreover, the position and depth of bin separation and plugging canbe effectively controlled, the operation is convenient, the construction efficiency is high, the quality of bin separation and plugging is improved, and good conditions are provided for subsequent grouting construction.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

Spherical dual-seal plugging device

InactiveCN103277627BImprove plugging efficiencyImprove plugging qualityPipe elementsHydraulic cylinderEngineering

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

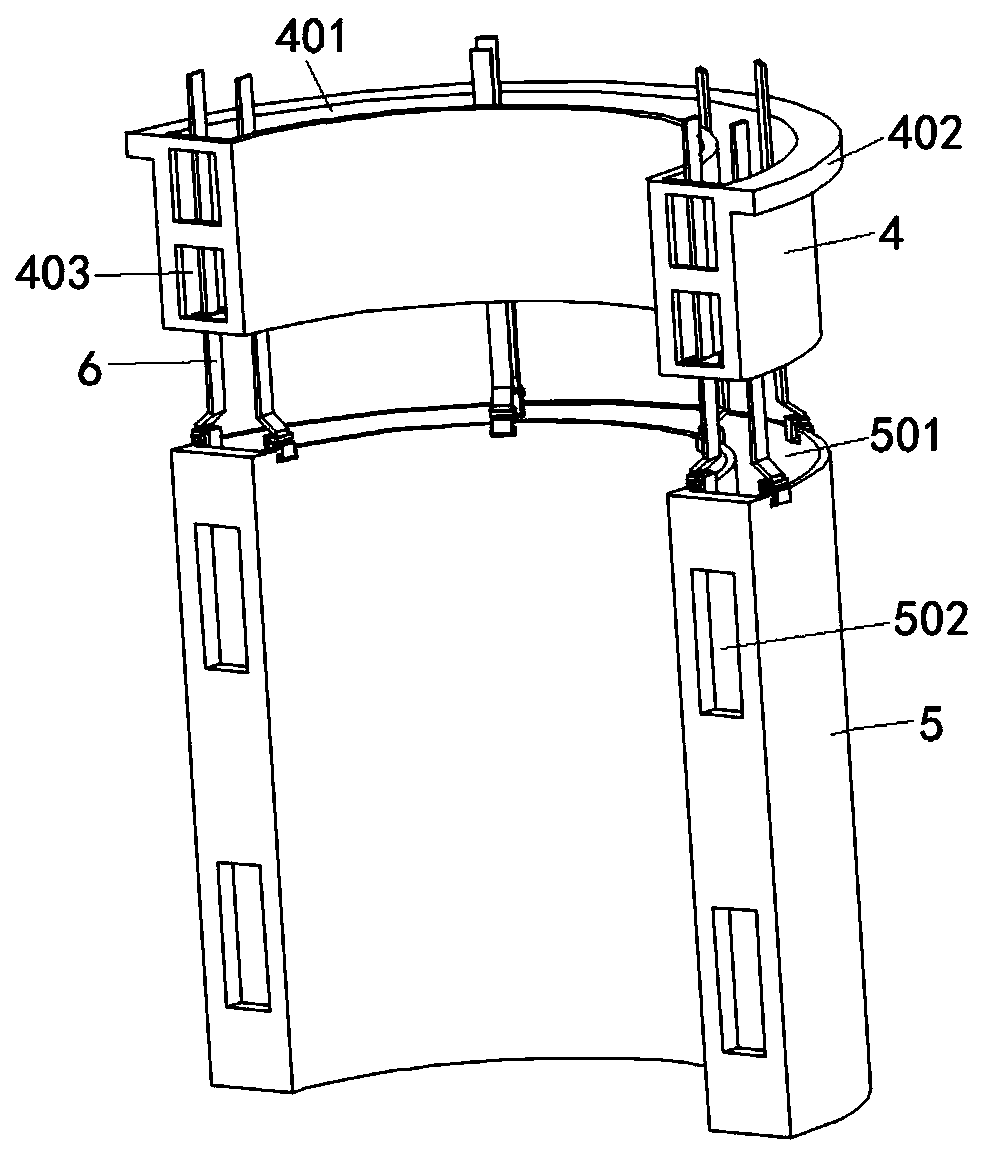

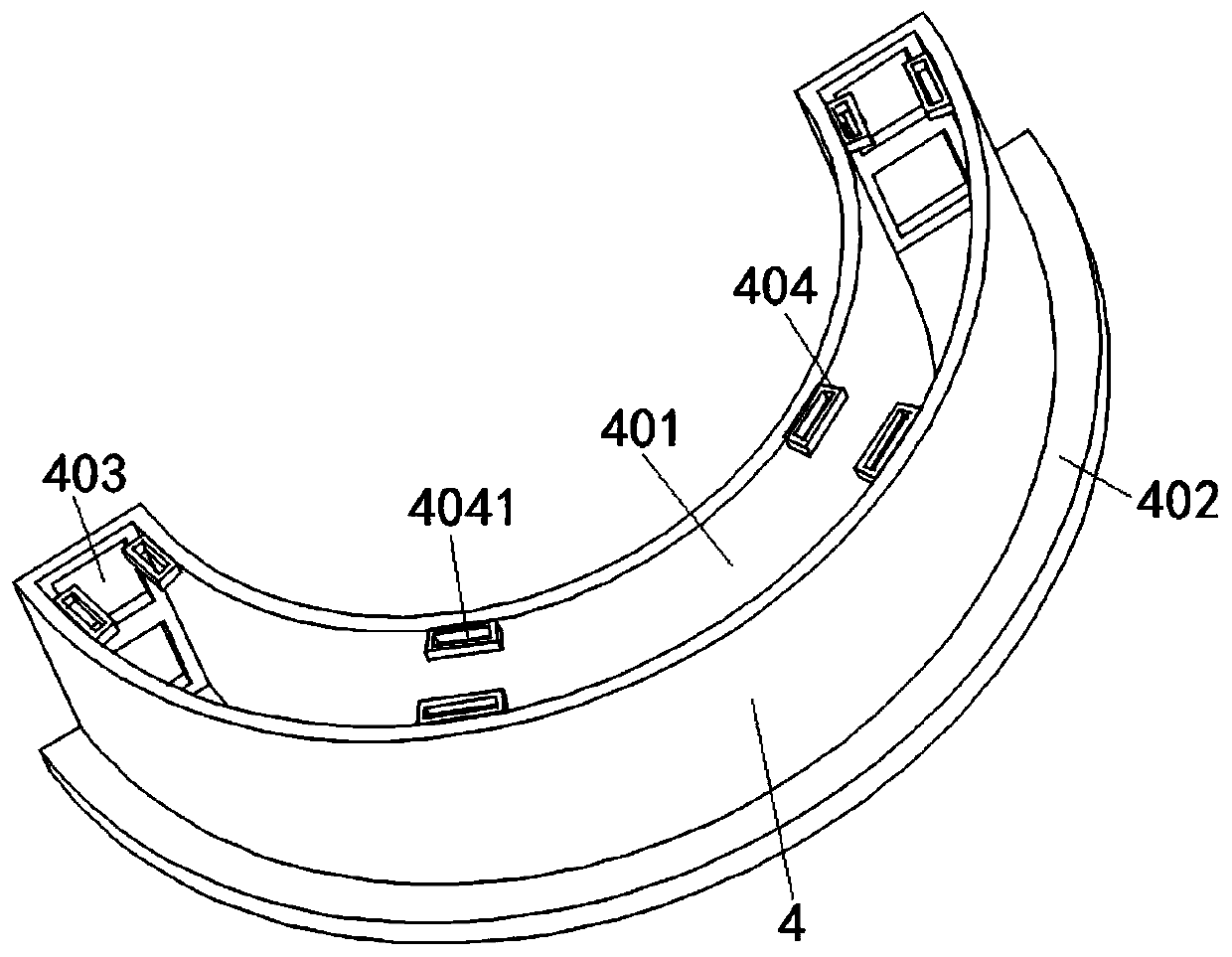

Tunnel seepage preventing and leaking stoppage device and method

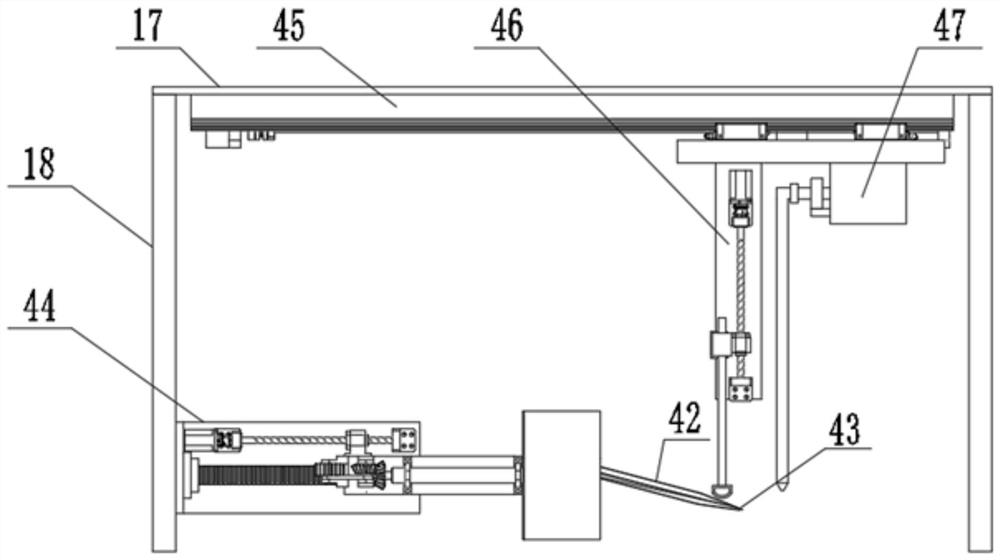

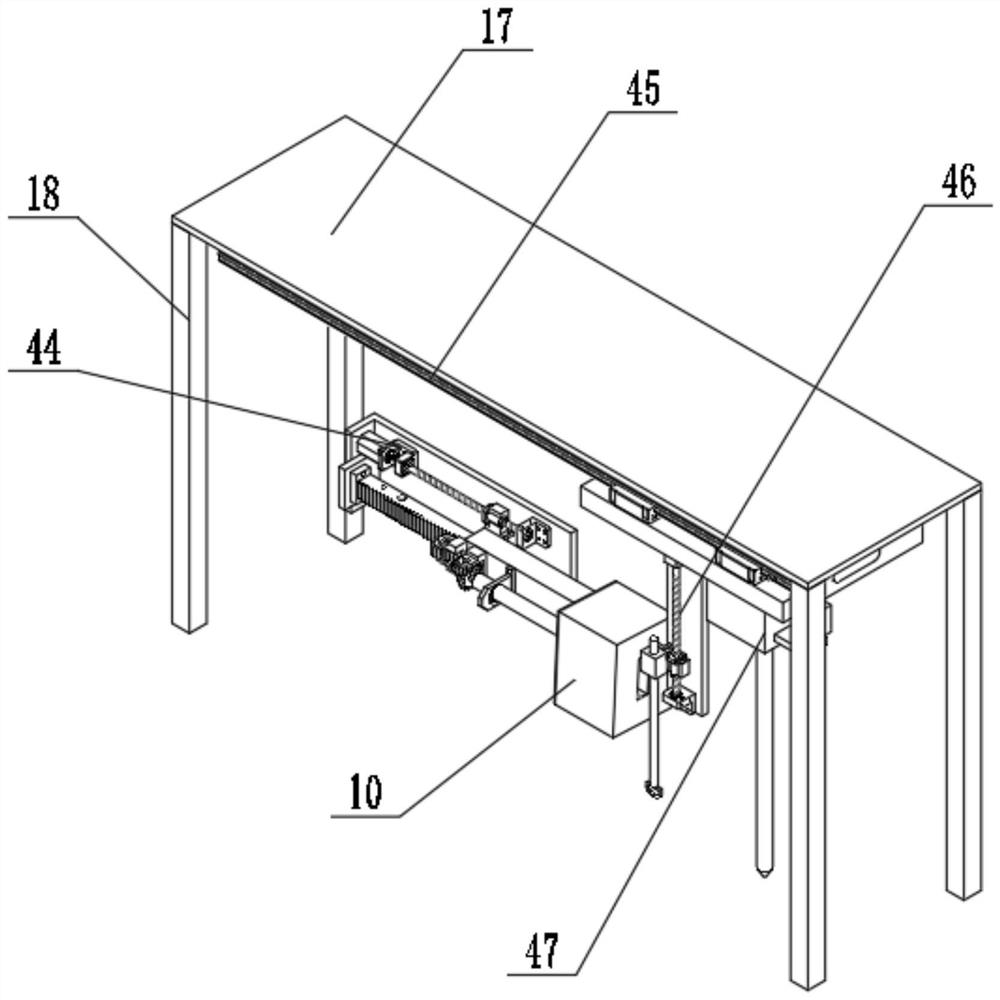

ActiveCN112610247AImprove the sealing effectImprove plugging qualityUnderground chambersTunnel liningGeotechnical engineeringElectric machine

The invention discloses a tunnel seepage preventing and leaking stoppage device and method. The tunnel seepage preventing and leaking stoppage device comprises a support frame, a cloth belt mounting mechanism, a track running mechanism, a cloth strip plugging mechanism and a grouting mechanism, wherein the support frame is composed of a track plate and support legs. The cloth belt mounting mechanism, the track running mechanism, the cloth strip plugging mechanism and the grouting mechanism are arranged on the track plate and the support legs; through mutual cooperation of all the mechanisms, plugging operation of a gap is completed; when a tunnel has the gap, a cloth belt can be fixed to the initial end of the gap, a power switch of a first motor is turned on, and the cloth belt mounting mechanism drives a cloth belt box assembly body to rotate while moving rightwards under the action of a power mechanism of the cloth belt mounting mechanism; and the cloth belt is twisted into a roll shape in the movement process of the cloth belt box assembly body, so that it can be guaranteed that the cloth belt better adapts to the size of the gap before being placed into the gap, the sealing effect of the cloth belt is further improved, and the plugging quality of the gap is improved.

Owner:中原豫安建设工程有限公司

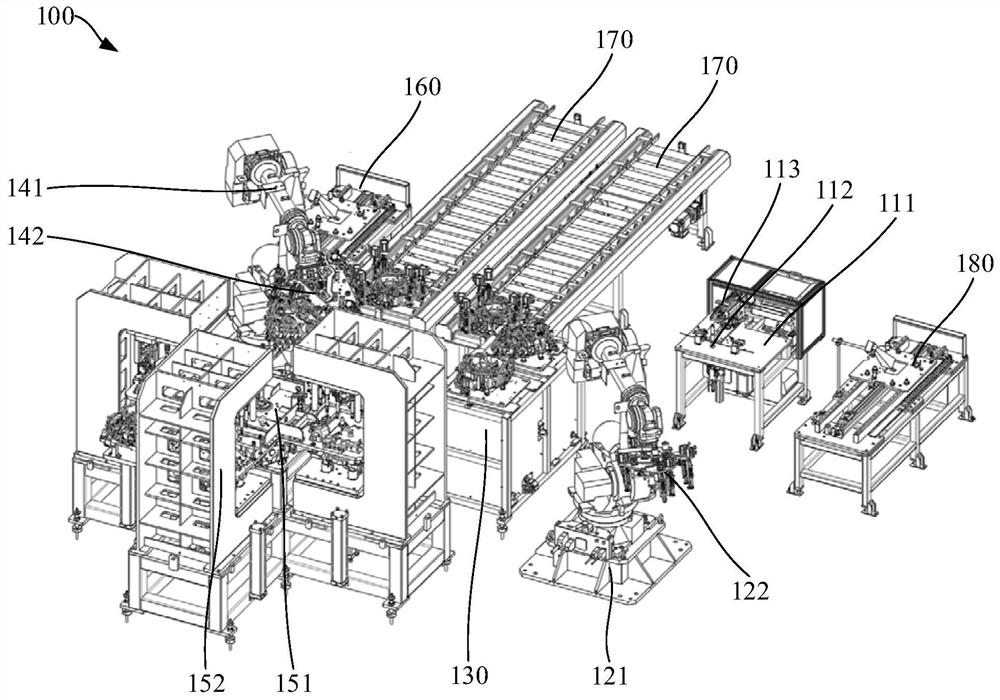

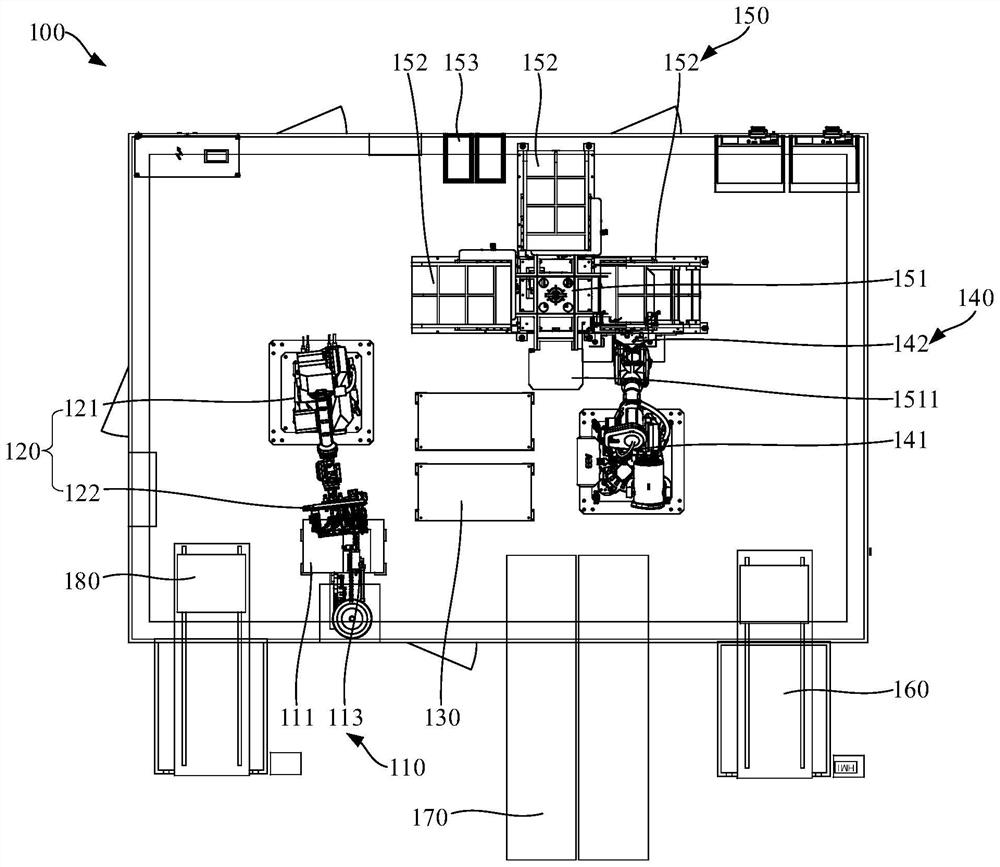

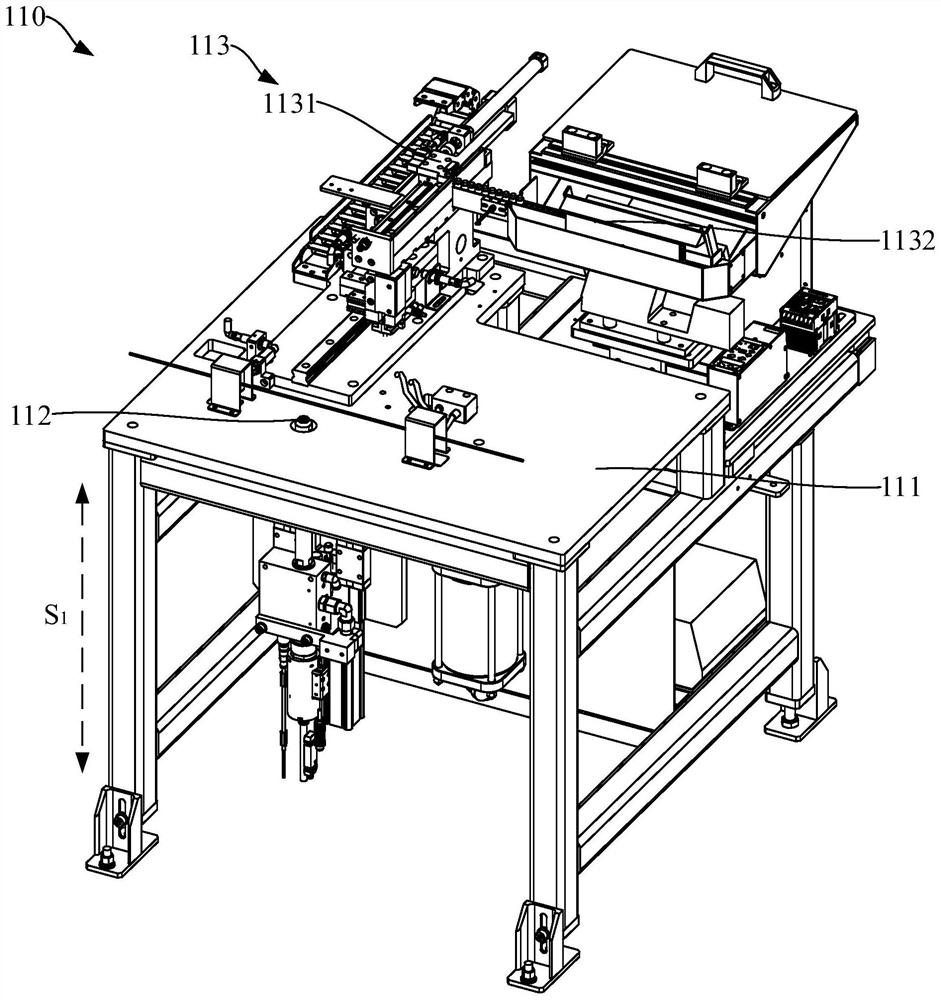

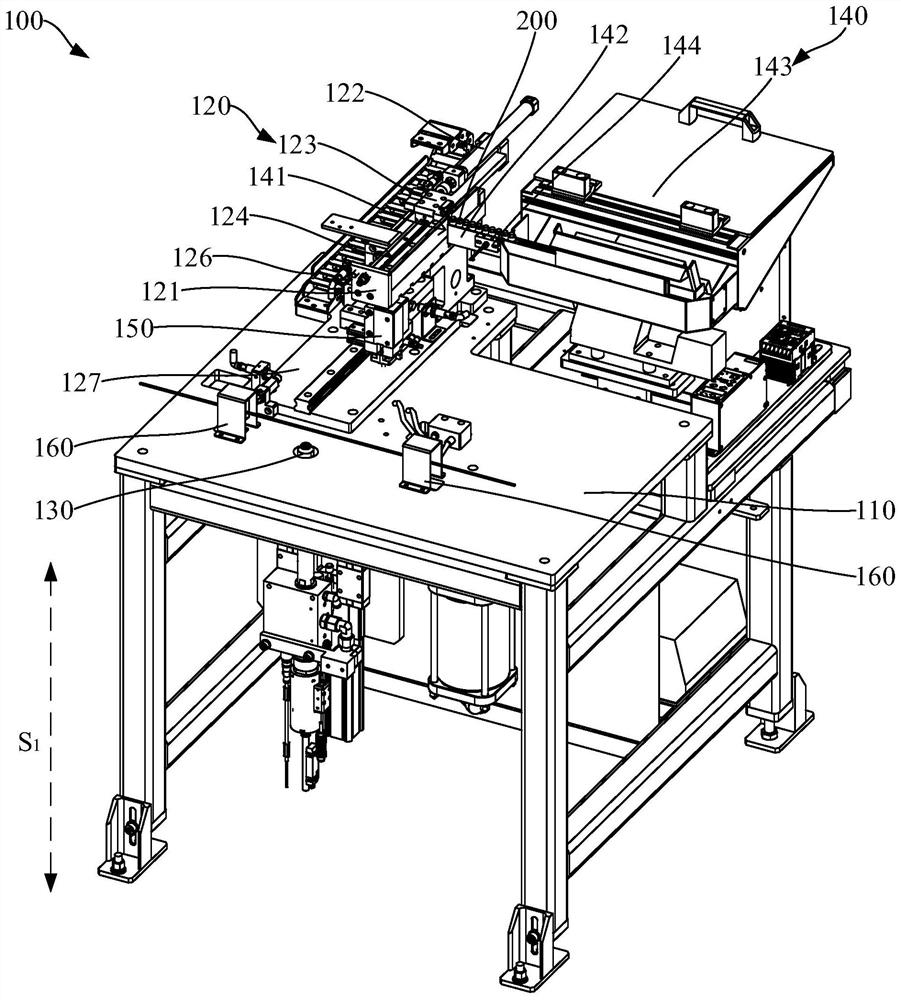

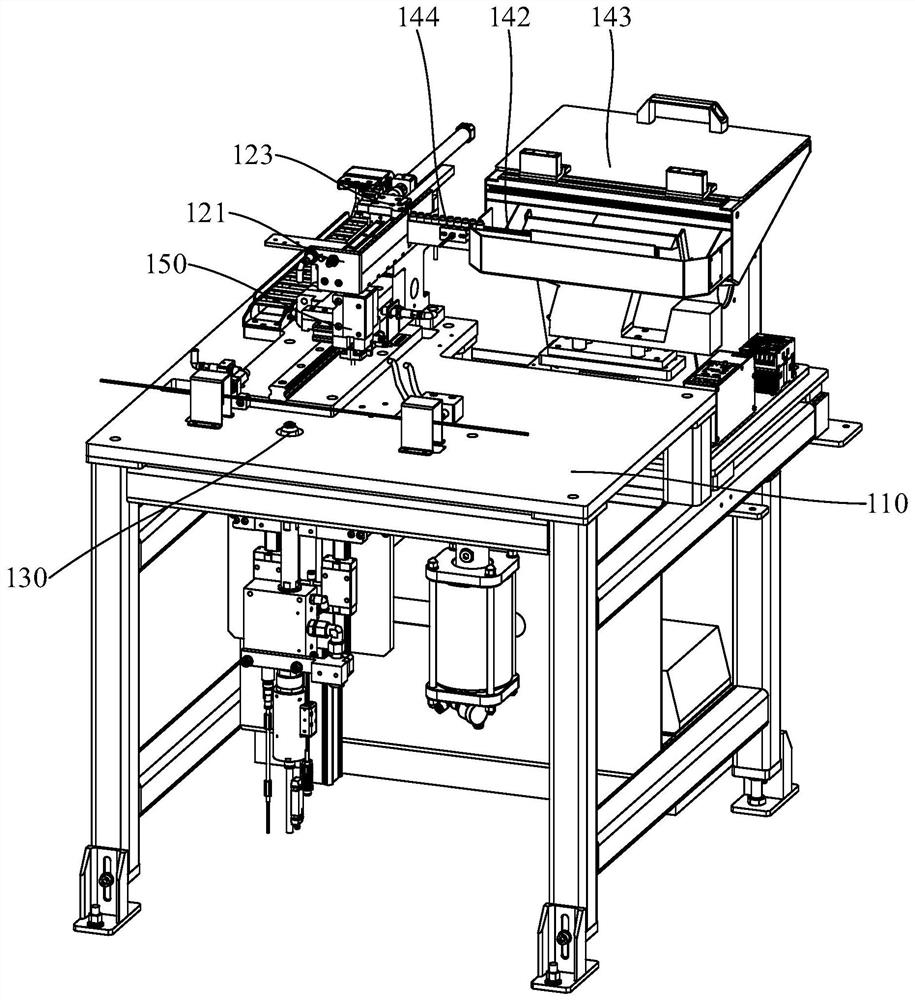

Air tightness detection system

PendingCN114659715AImprove work efficiencyImprove plugging qualityFluid-tightness measurement using fluid/vacuumTransfer mechanismAir tightness

Owner:UPTON AUTOMATION SYST (GUANGZHOU) CO LTD

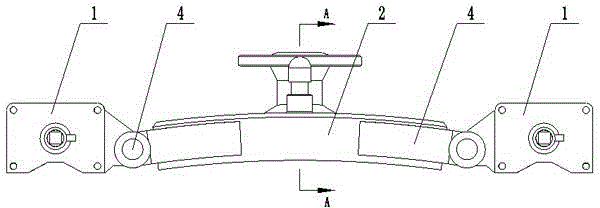

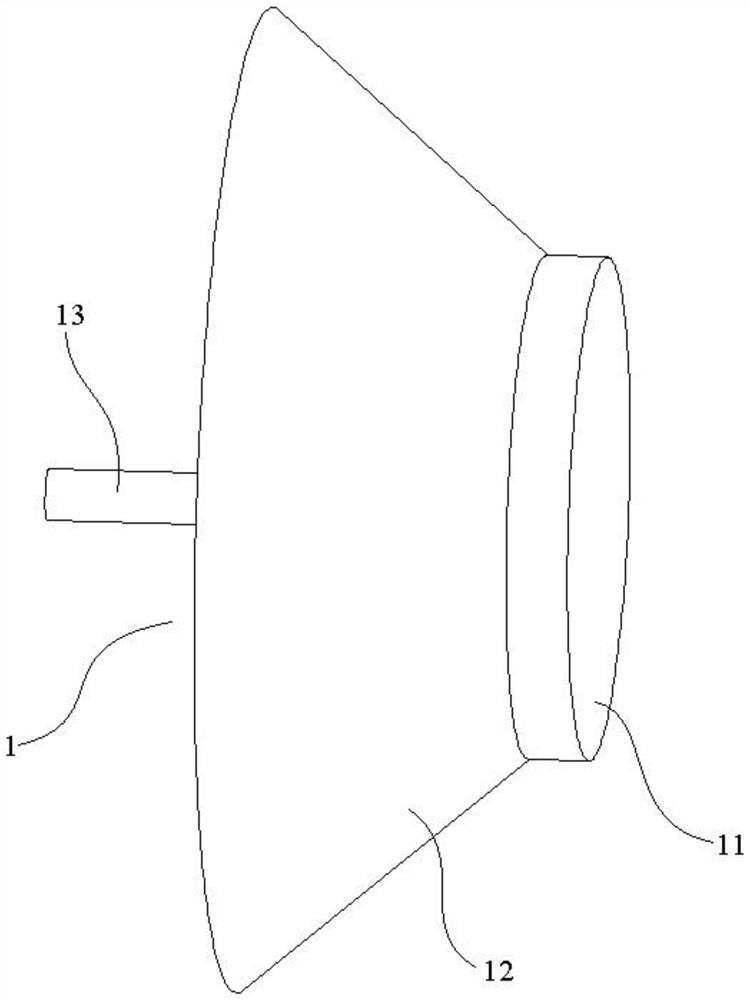

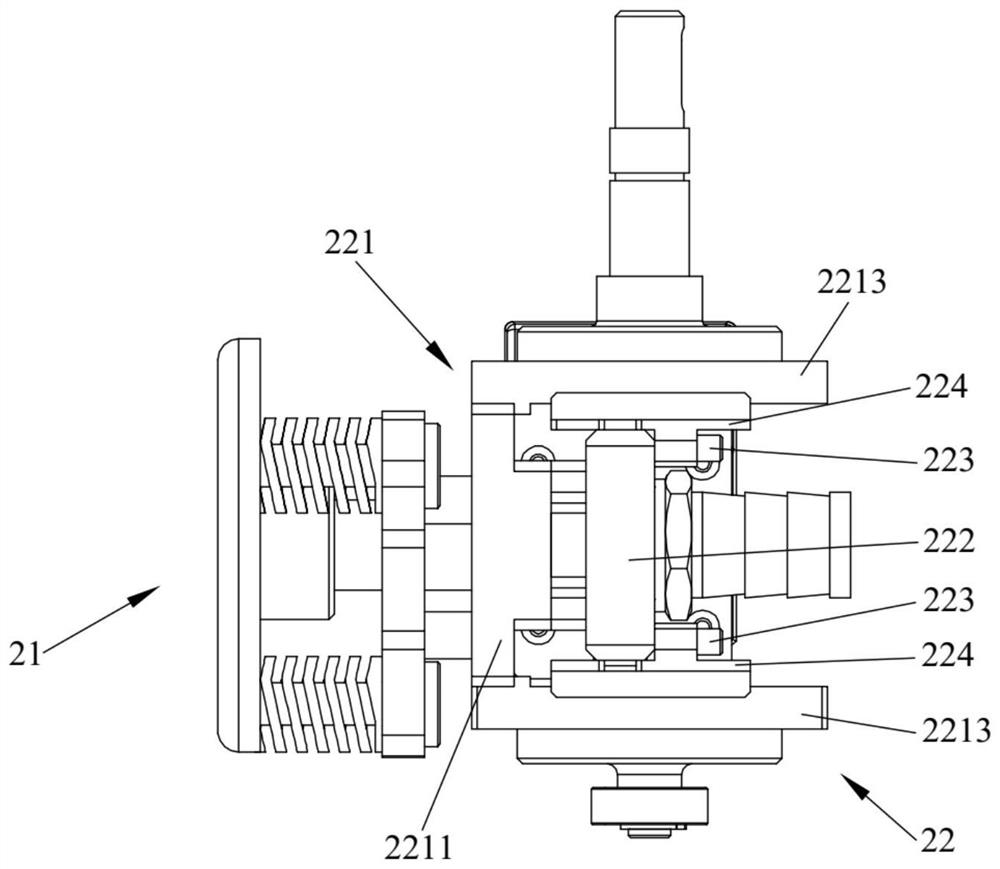

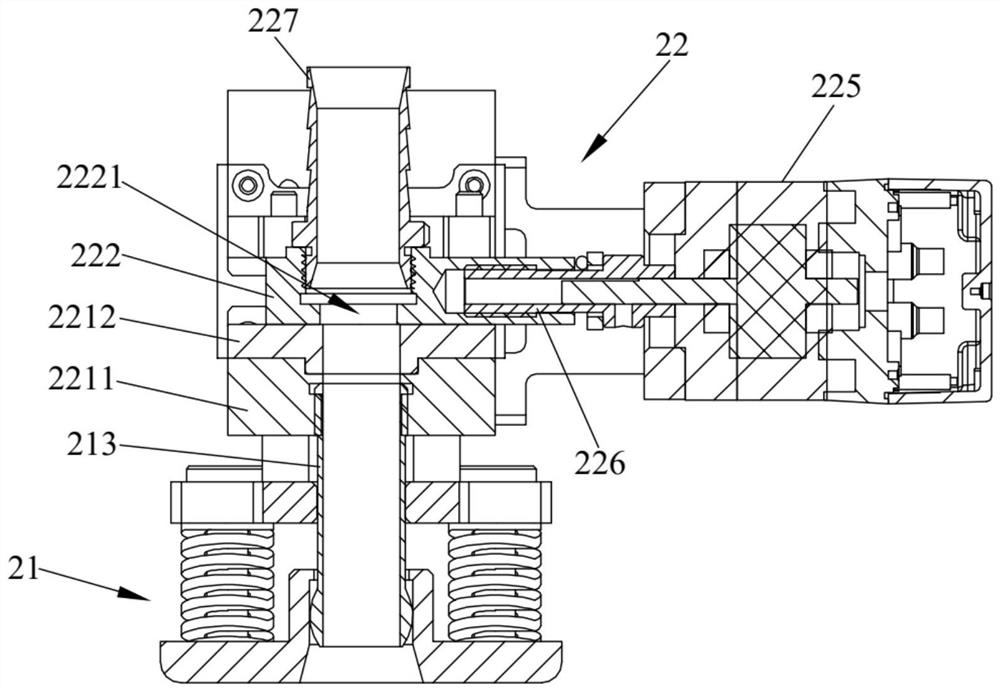

Hot-melt plug welding positioning press and working method thereof

PendingCN109109321AReduce crackingImprove plugging qualityTubular articlesPressure stabilizationPipe fitting

The invention relates to a hot-melt plug welding positioning press, and belongs to the field of pipeline processing equipment. The hot-melt plug welding positioning press comprises a handle, a pressure rod, a top plate, a support member, a positioning body, a mold, a positioning clamping member, and a bottom plate, wherein the handle, the pressure rod, the positioning body and the mold are sequentially connected from top to bottom, the top plate, the support member, the positioning clamping member and the bottom plate are sequentially connected from top to bottom, and the pressure rod vertically passes through the top plate. A pipeline material injection hole, a pipe fitting material injection hole, a hot-melt sleeve port material injection hole and an exhaust hole are accurately subjectedto hot-melt sealing by pressurization and pressure stabilization during advance positioning and hot-melt sealing, the tensile strength of a repairing part is high, the repairing part is not easy to damage, and a pipeline around the plugging part cannot be damaged during plugging, so that the service life of the plugged pipeline is prolonged.

Owner:河北汇东管道股份有限公司

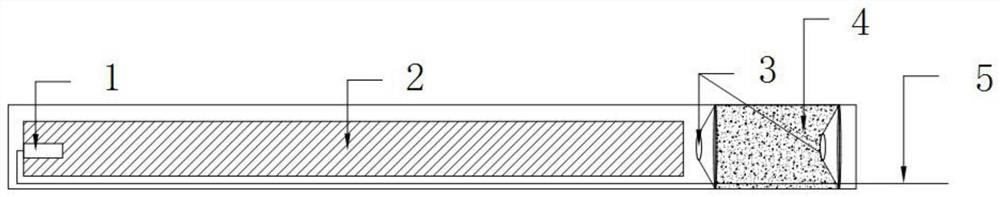

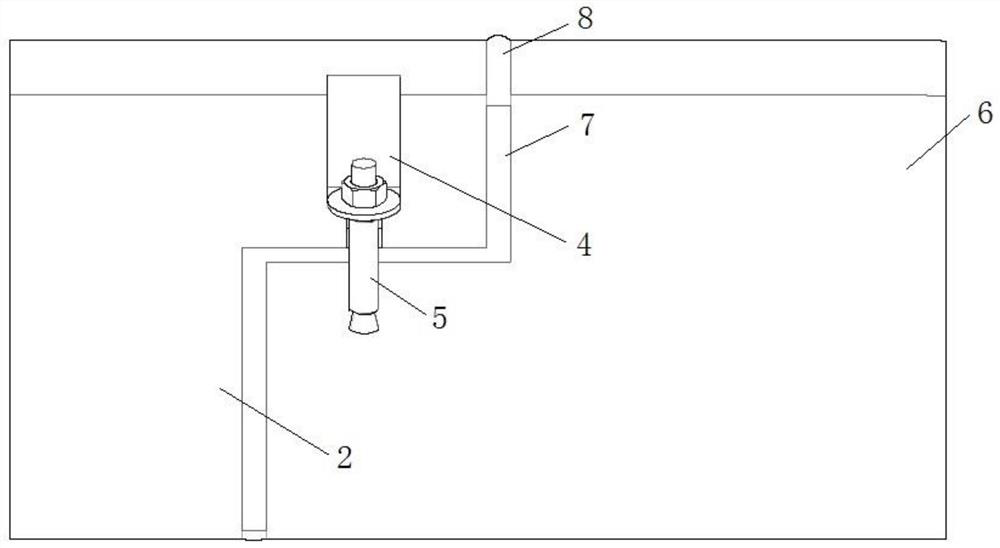

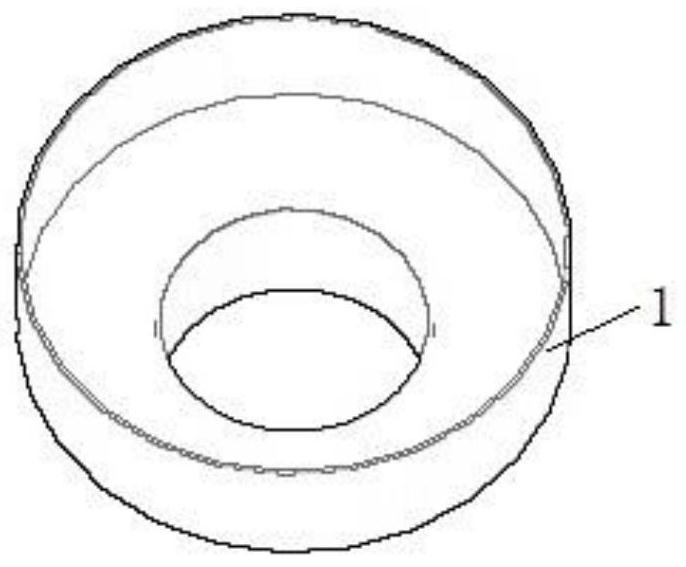

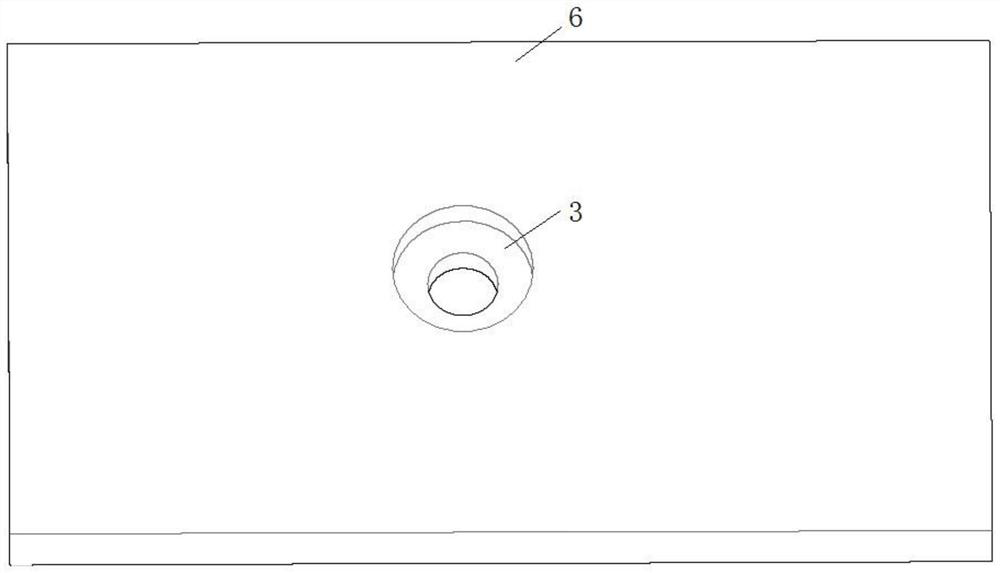

Embedded-free casing pipe mounting structure and casing pipe mounting method

PendingCN113293805AImprove plugging qualityImprove water tightnessPipesProtective foundationWater stopReamer

The invention relates to an embedded-free casing pipe mounting structure and a casing pipe mounting method. The mounting structure comprises a reamer bit and two hole sealing templates, wherein the reamer bit comprises a flat bit section, a reaming section and a connecting pipe; the reaming section is in a circular truncated cone shape and is connected to the flat bit section through the upper end surface of the reaming section; the connecting pipe is concentrically connected to the lower end surface of the reaming section; each hole sealing template comprises a cylindrical fastening ring, a hole sealing ring mounted on the fastening ring and a feeding port formed in the hole sealing ring; and the hole sealing templates can be mounted on a water stop casing pipe through the fastening rings. According to the embedded-free casing pipe mounting structure and the casing pipe mounting method, a horn-shaped water stop wing ring of the water stop casing pipe is implanted into a concrete structure, so that the path of water and air on the upstream face of the structure flowing into the downstream face is increased.

Owner:CHINA FIRST METALLURGICAL GROUP

Novel outer wall split bolt hole three-color polyurethane plugging process

InactiveCN112502299AImprove plugging qualityImprove management qualityPolyurea/polyurethane coatingsBuilding insulationsPolymer scienceEngineering

The invention discloses a novel outer wall split bolt hole three-color polyurethane plugging process. The novel outer wall split bolt hole three-color polyurethane plugging process comprises four steps of base layer treatment, waterproof expansive cement mortar filling, waterproof expansive cement mortar curing and waterproof coating brushing. During base layer treatment, after an outer wall formwork is detached, an outer wall split bolt hole is pulled out, a PVC pipe exposed out of a wall surface is cut flat, meanwhile, residual mortar on the periphery of the hole is cleaned up, the split bolt hole is expanded into a horn mouth shape through an electric drill, the PVC pipe in the hole is smashed, and the interior of the hole is cleaned up through a steel wire brush or a pneumatic pump. The process has the advantages that the outer wall split bolt hole three-color polyurethane is used in order to improve the plugging quality of the outer wall split bolt hole, improve the management quality level of an enterprise and ensure safe and civilized construction on site, the 1:2.5 waterproof expansive cement mortar is adopted for plugging compactly, the outer side of a wall body is coatedwith a circular polyurethane waterproof coating film for three times, a novel roller tool is used for brushing waterproof paint quickly and conveniently, and the construction quality is improved.

Owner:THE FOURTH OF CHINA EIGHTH ENG BUREAU

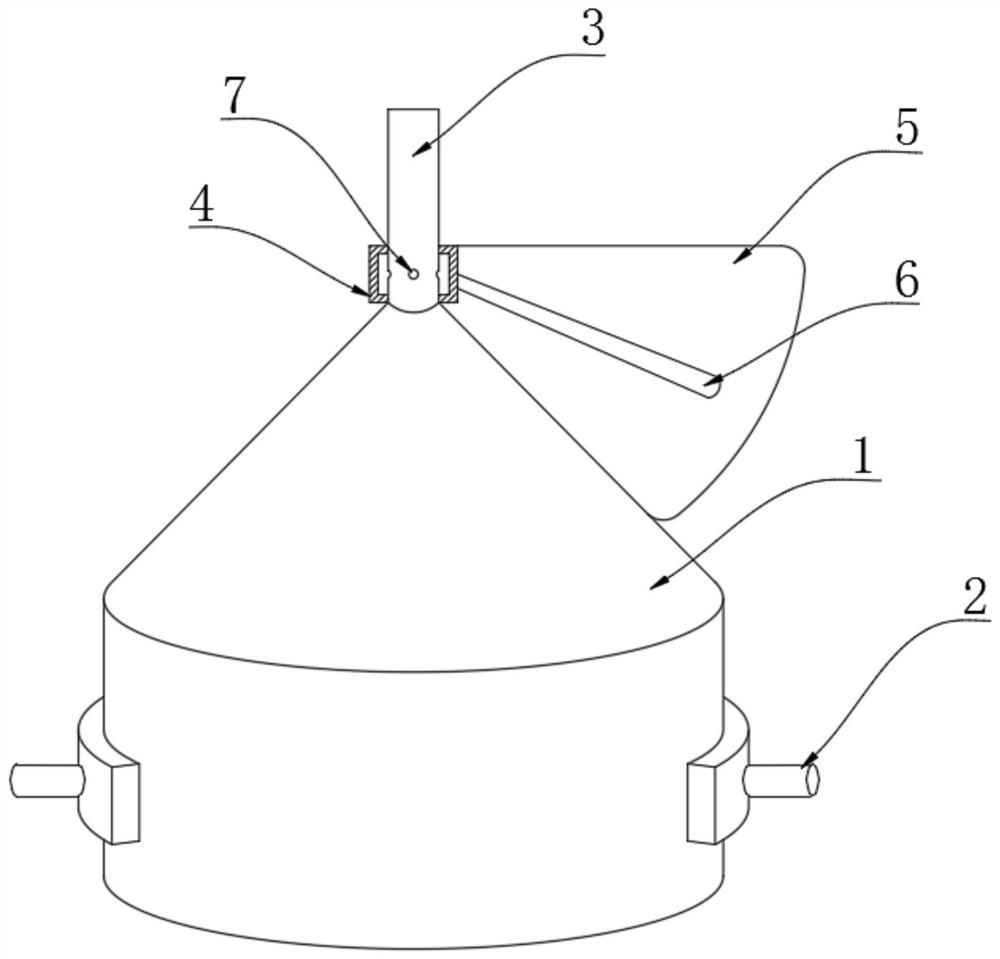

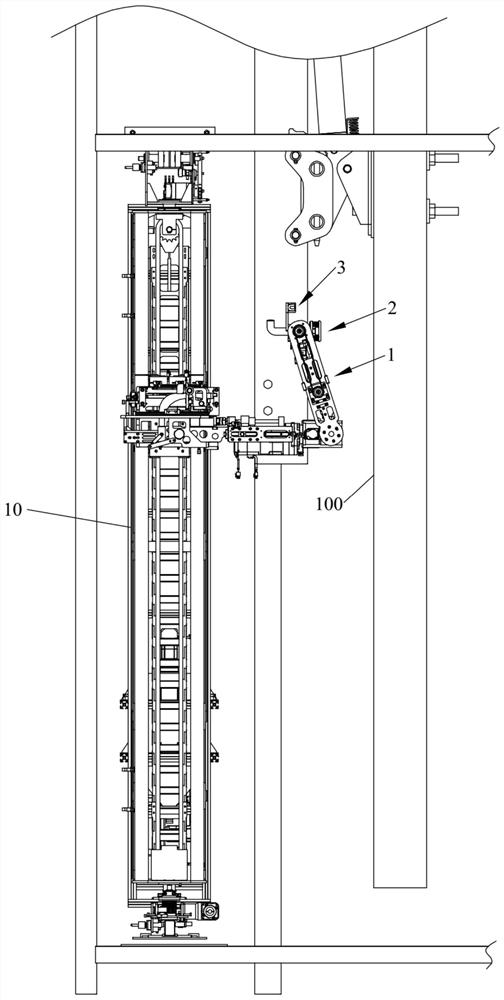

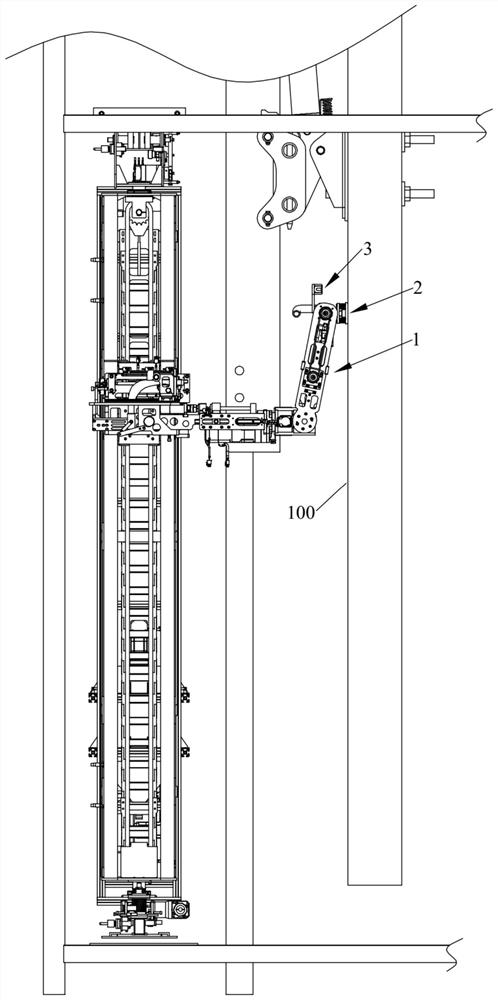

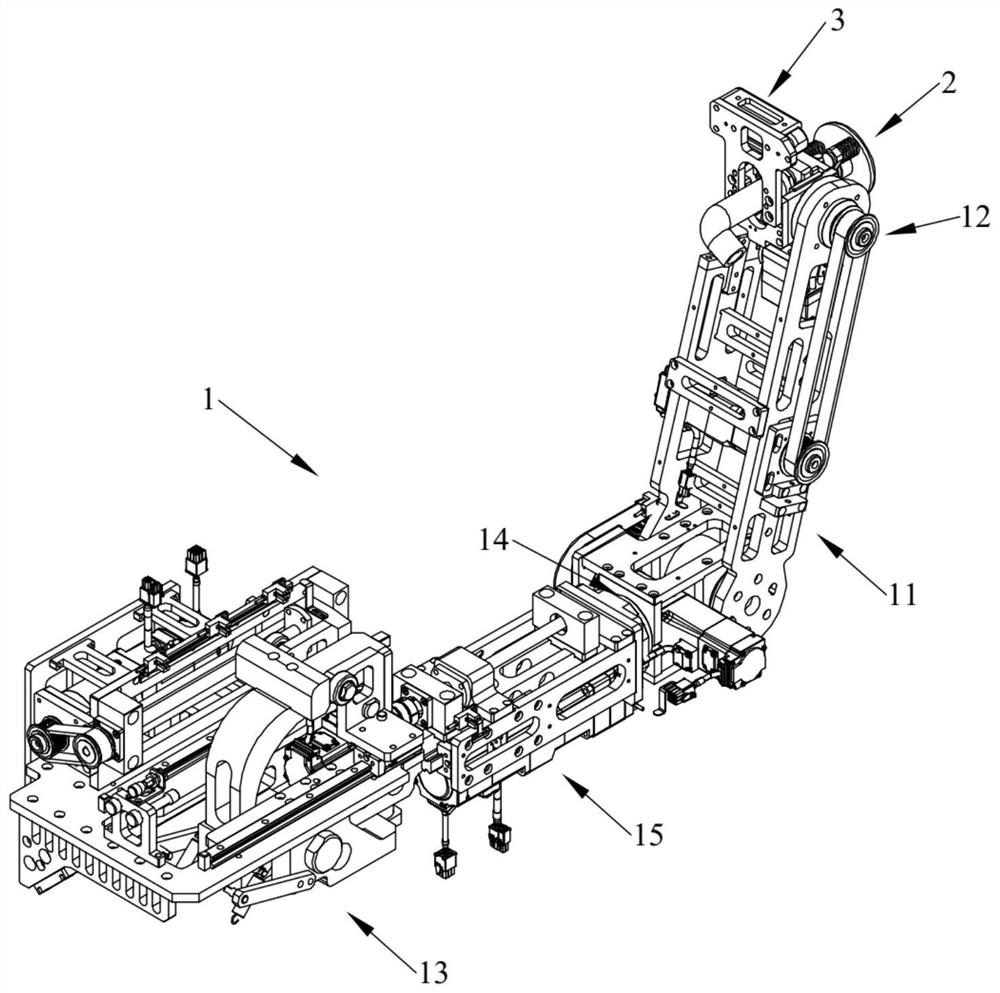

Mechanical arm, hole plugging device and hole plugging robot

ActiveCN113445772AImprove plugging efficiencyImprove plugging qualityBuilding repairsAuxillary members of forms/shuttering/falseworksVertical planeMechanical engineering

The invention relates to the technical field of building machinery, and discloses a mechanical arm, a hole plugging device and a hole plugging robot. The mechanical arm comprises a swing arm mechanism, a plugging head rotating mechanism and a turnover mechanism; the connecting end of the swing arm mechanism can rotate around a first axis parallel to the construction face so as to drive the swing end of the swing arm mechanism to swing in the direction close to or away from the construction face; the plugging head rotating mechanism is arranged at the swing end of the swing arm mechanism, the plugging head rotating mechanism is connected with the plugging head and can drive the plugging head to rotate around a second axis, the working face of the plugging head is adjusted to be parallel to the construction face, and the second axis is parallel to the first axis; and the turnover mechanism is connected with the connecting end of the swing arm mechanism, and the turnover mechanism can drive the swing arm mechanism to turn over in a vertical plane perpendicular to the construction face so that the swing arm mechanism can avoid obstacles. According to the mechanical arm, the plugging head can be driven to realize automatic plugging of a hole, and the plugging efficiency and the plugging quality are improved.

Owner:广东博鼎建筑科技有限公司

Glue injection device for insulating glass molecular sieve filling machine

InactiveCN101671128BClean upAvoid pushing glue pressure too high or too lowMolecular sieveInjection device

The invention relates to a glue injection device, in particular to a glue injection device for an insulating glass molecular sieve can filling machine, which belongs to glass processing machinery. The glue injection device comprises a hot die support, a hot die, a side baffle plate, a connector, a cover plate, a flat plate, a glue barrel, a pull rod, a clamping plate, a glue barrel seat, an air cylinder support, a connecting plate, an inclined connecting plate, an air cylinder ejector rod, an air cylinder, a resistance wire and a thermocouple sensor; the heating resistance wire and the thermocouple sensor are additionally arranged in the hot die and a PLC is applied to control temperature of glue blocking, the control accuracy achieve 0.1 DEG C, and the glue plugging quality is effectively improved; two glue sleeves are installed in the hot die, the glue flows out from the glue sleeves during the glue plugging process and does not directly flow out from the hot die, and the glue sleeves are connected with the hot die through keys, thus being convenient to assembly and the disassembly and being beneficial to removal of the residue glue; and a glue pushing device adopts an air cylinder for pushing glue, thereby being beneficial to control on the glue pushing pressure and avoiding excessively high or small glue pushing pressure.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY +1

Casing bottom plugging device and method

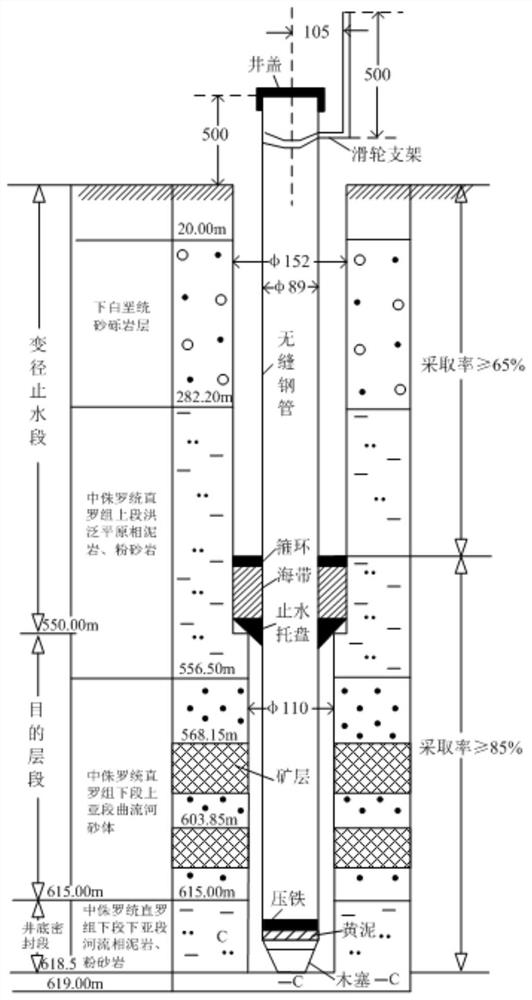

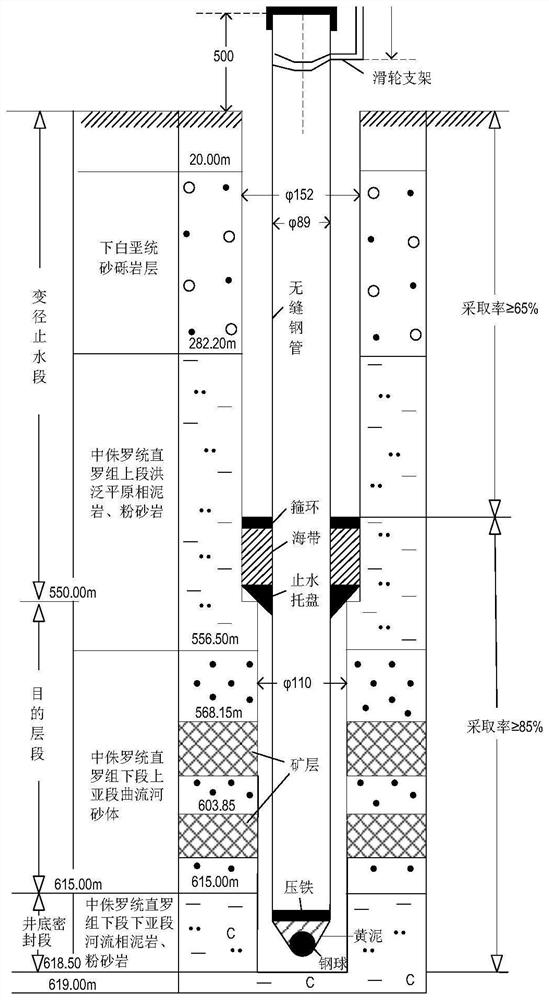

PendingCN112324380AImprove plugging qualitySimplify the plugging processSealing/packingSite selectionSlurry

The invention particularly relates to a casing bottom plugging device. The casing bottom plugging device comprises a plug and a steel ball. The plug is of a hollow structure. A turnbuckle matched witha casing is arranged on the plug. Before the casing is placed downwards, the plug is connected with the bottom of the casing in a screwed mode in a turnbuckle mode, and the steel ball is placed on the hollow structure. In the process that the casing is arranged downwards, slurry jacks up the steel ball through the hollow structure of the plug to enter the casing; and when a steel casing is connected during stopping, the steel ball naturally falls down and seals an opening. According to a casing bottom plugging method, casing bottom plugging can be completed at a time, the situation of repeated plugging or poor plugging effect is avoided, the plugging procedure of parameter holes is simplified, the problem that a special bottom plate of a part of section is difficult to plug is solved, meanwhile, the site selection range during parameter hole design in the future is widened, the plugging quality of the casing is improved, and the production cost is also reduced.

Owner:核工业二〇八大队

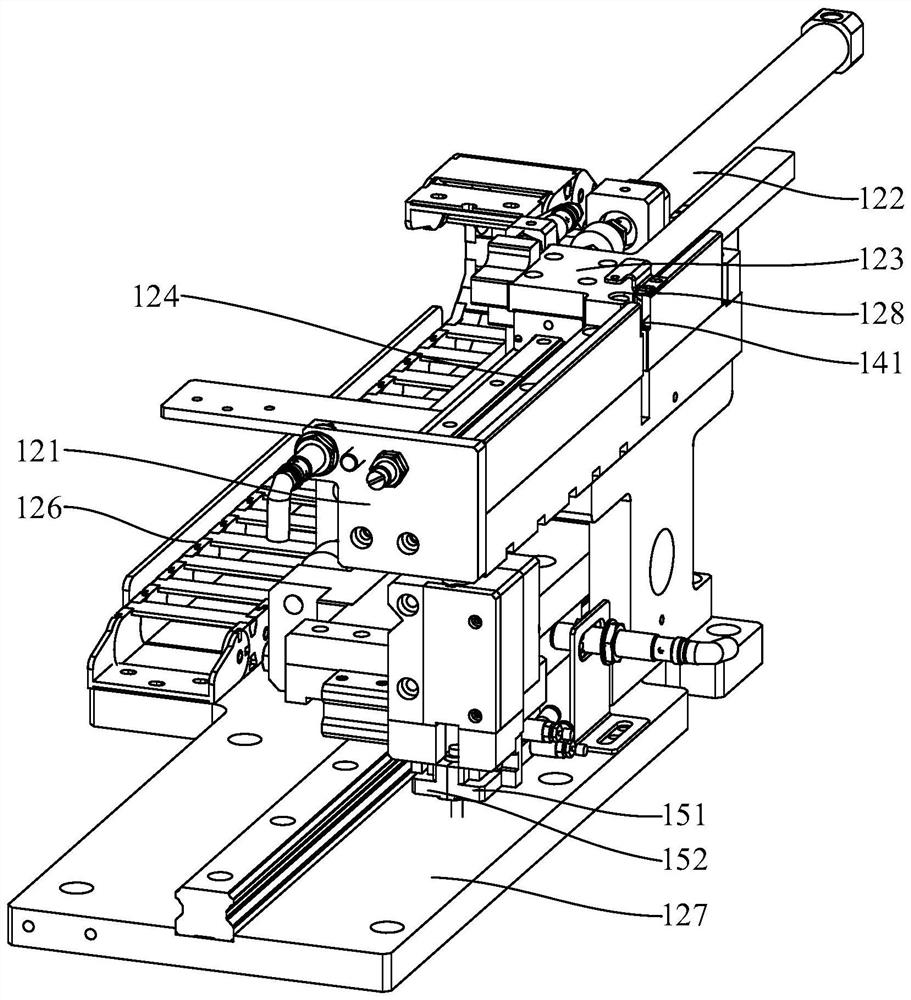

Automatic rivet pulling device

PendingCN114713758AImprove plugging qualityImprove leak detection efficiencyHand riveterIndustrial engineering

The invention relates to an automatic rivet pulling device. The automatic rivet pulling device comprises a working platform, a riveting device and a riveting device, the feeding mechanism comprises a feeding seat, a first driving part and a feeding clamp, the feeding seat is movably connected with the working platform, a feeding groove is formed in the feeding seat, a penetrating hole is formed in the bottom wall of the feeding groove, and rivets can penetrate through the penetrating hole; the hand riveter is arranged on the working platform, and a muzzle of the hand riveter is opposite to the through hole in the height direction of the automatic rivet pulling device; and the feeding mechanism is provided with a feeding port. According to the automatic rivet pulling device, in the working process, an original plugging technology is replaced with a rivet pulling mode, the plugging quality is improved, and then the reliability of a test result is improved. Meanwhile, the automatic rivet pulling mode is beneficial to improving the working efficiency, so that the sealing performance detection efficiency is improved.

Owner:UPTON AUTOMATION SYST (GUANGZHOU) CO LTD

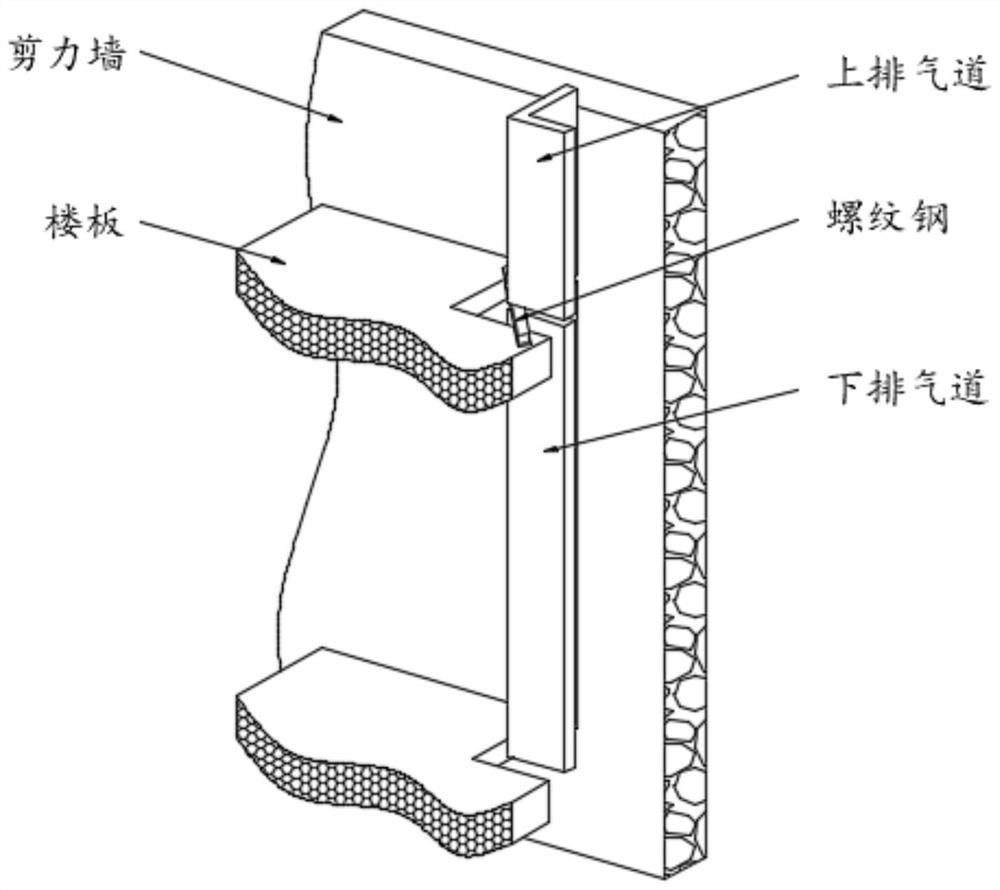

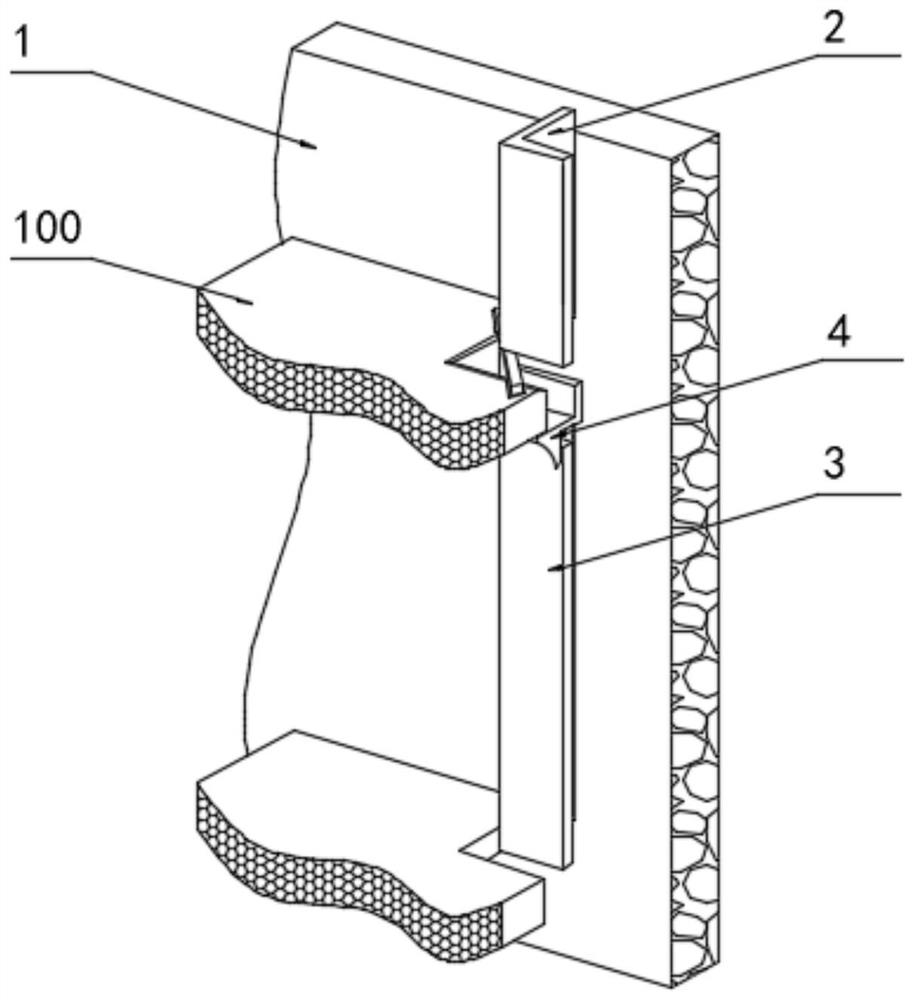

A kind of plugging device and construction method of anti-rotting root angle steel of shear wall

ActiveCN111980212BControl Connection StrengthAchieving tightnessWallsProtective foundationUltimate tensile strengthMechanical engineering

Owner:CHINA MCC17 GRP

Root rotting prevention angle steel plugging device for shear wall and construction method

ActiveCN111980212AControl Connection StrengthAchieving tightnessWallsProtective foundationUltimate tensile strengthShear wall

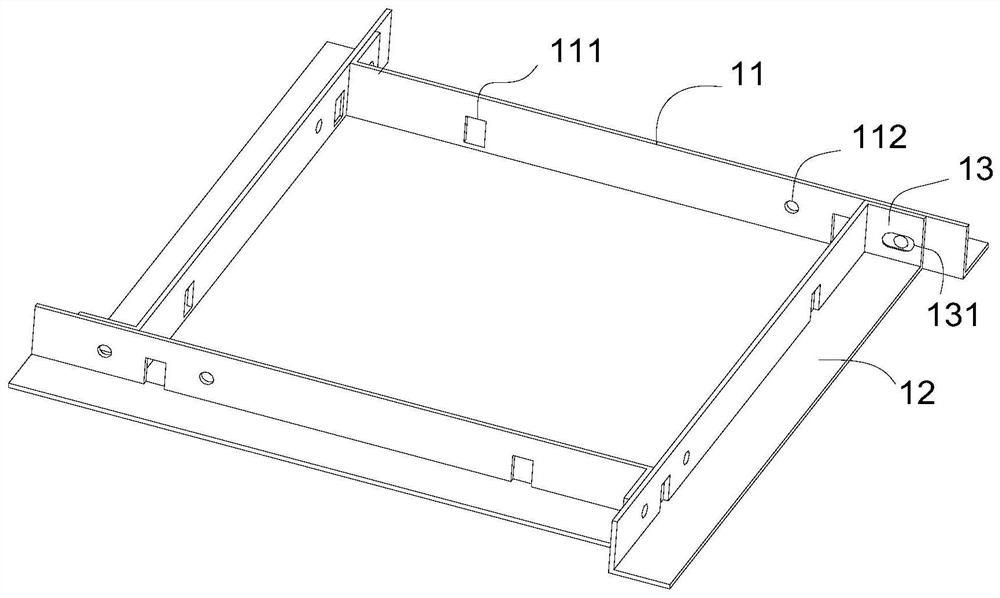

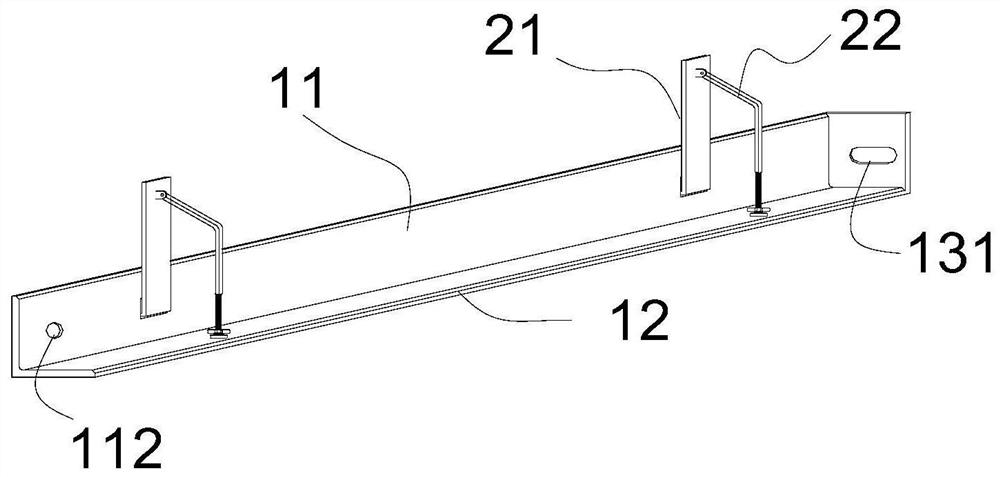

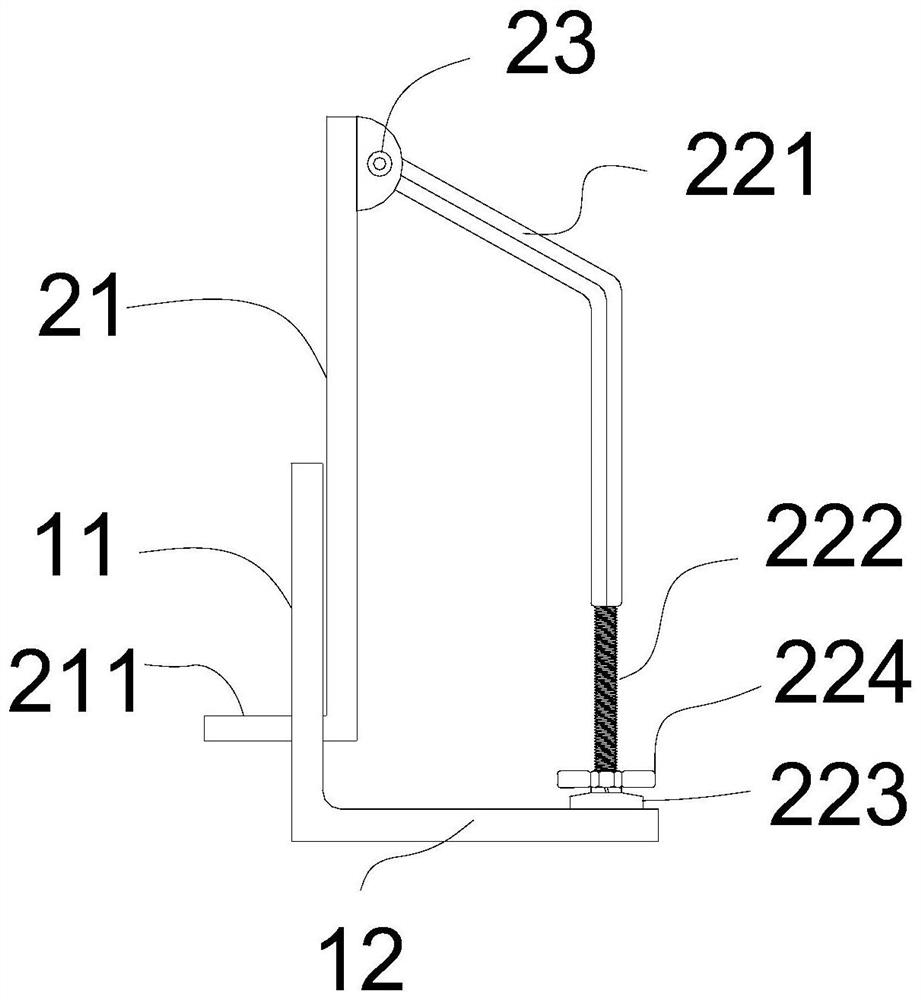

The invention discloses a root rotting prevention angle steel plugging device for a shear wall and a construction method, and belongs to the technical field of wall root plugging devices. According tothe root rotting prevention angle steel plugging device, positioning angle steel, a fixed support, fixed angle steel, an anti-seepage mounting block, an anti-seepage moving block, an adjusting rod and an adjusting piece are arranged, the fixed angle steel and the positioning angle steel are connected and fixed through connecting bolts, on one hand, the connecting strength between the positioningangle steel and the fixed angle steel is controlled, and the rollover phenomenon is prevented when the anti-seepage moving block is adjusted to extrude the positioning angle steel; and one the other hand, a formwork is supported in an auxiliary mode to prevent running and form-expanding at the root, and the anti-seepage mounting block and the anti-seepage moving block are adjusted to compress a connecting seam of the anti-seepage mounting block and the anti-seepage moving block, a connecting seam of the positioning angle steel and the anti-seepage moving block and a connecting seam of the anti-seepage mounting block and the ground under the action of the adjusting piece on the adjusting rod, so that the sealing effect of the root is achieved, the quality of the root is guaranteed, the process construction is safe and reliable, the efficiency is high, and the rotten root of the shear wall root can be effectively eliminated.

Owner:CHINA MCC17 GRP

A method for plugging blastholes in underground blasting engineering and blasting mud injection machine

The invention relates to a stemming injection machine, which comprises a water storage device, a water outlet tube, a carriage, a stemming agitator, a stemming outlet tube and a helical injection head; the stemming injection machine also comprises a water pump for pumping the water of the water storage device into the stemming agitator; the stemming injection machine also comprises an automatic water control device for controlling the quantity of water added into the stemming agitator; the stemming injection machine also comprises a hydraulic stemming supply pump. A blocking method for blastholes of underground blasting projects includes: (Step 1) stemming material is prepared; (Step 2) the stemming material is loaded into the stemming injection machine; (Step 3) the automatic water control device controls the weight ratio of the stemming material to water at 1:0.12 to 0.13, and the stemming material and the water are mixed, so that homogeneous stemming is obtained. The invention has the following advantages: the quality of stemming and the efficiency of blasthole blockage are increased, staffing is saved, labor condition is improved, meanwhile, the safety of construction is ensured, the quality of blasting is greatly increased, the cost of blasting is reduced, and thereby good economic benefit is obtained.

Owner:WUHAN UNIV OF SCI & TECH

High-efficiency blasting method for multi-stage ultra-deep holes with double-headed plugs and mud plugging for full-section soft rock tunnels

The invention discloses a high-efficiency blasting method for tunnel soft rock full-section multi-stage ultra-deep hole double-head gun plug mud plugging, which relates to the technical field of tunnel blasting. High-efficiency blasting method with head plug + clay gun mud plugging; among them, No. 2 rock emulsion explosive is used for the explosive, non-electric millisecond detonator is used for the detonator, and nonel tubes are connected in series and parallel for the detonation network; holes are drilled with a pneumatic rock drill; blast hole layout : Cutting eye, inner ring eye, peripheral eye and bottom plate eye are all multiple, charge structure: cutting eye is continuously charged, peripheral eye is charged at intervals, inner ring eye and bottom plate eye are continuously charged, cut eye, Peripheral holes, inner ring holes and floor holes are all sealed with gun plugs + gun mud + gun plugs; the blasting footage is 3.9-4.1m, and the surrounding rocks are sealed by initial spraying of concrete after the ballasting. The invention overcomes the defects of poor blasting effect, low blasting efficiency and poor safety in the prior art, and can improve blasting effect, blasting efficiency and safety.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +2

Non-designed reserved hole plugging device and plugging method

PendingCN112459267AReduce consumptionRealize simultaneous constructionForms/shuttering/falseworksBuilding insulationsArchitectural engineeringSealant

The invention discloses a non-designed reserved hole plugging device and plugging method, and belongs to the technical field of building construction. The plugging device comprises a reserved hole pre-buried formwork, a hole plugging plate, and a sealant; the hole plugging plate is manufactured according to the removed reserved hole pre-buried formwork, and the shape of the hole plugging plate isthe same as the shape of the reserved hole pre-buried formwork; the size of the hole plugging plate is obtained by subtracting the size of a mounting gap from the reserved hole pre-buried formwork; anchor bolt preformed holes are formed in the hole plugging plate; the hole plugging plate is fixed through anchor bolts during installation; and after the hole plugging plate is mounted, the mounting gap is filled with the sealant. According to the non-designed reserved hole plugging method, the plugging device is adopted for plugging a non-designed reserved hole. The non-designed reserved hole plugging device is designed for the non-designed reserved hole on site, so that the purposes of simplifying the construction process, reducing the construction cost, improving the construction efficiencyand ensuring the construction quality are achieved.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

Formwork-hanging-free pipeline and casing interior fireproof blocking modular filling device and construction method thereof

The invention discloses a formwork-hanging-free pipeline and casing interior fireproof blocking modular filling device and a construction method thereof, and relates to the technical field of fireproof engineering and pipelines. The formwork-hanging-free pipeline and casing interior fireproof blocking modular filling device comprises a pipeline and a floor casing, and a filling device body is fixedly mounted between the pipeline and the floor casing; the filling device body comprises two semi-feeding casings and two semi-lifting casings, and the semi-feeding casings are connected with the semi-lifting casings through ribbons; and an extrusion tool is arranged on one of the semi-feeding casings in a matched mode. A feeding casing and a lifting casing are placed between the pipeline and thefloor casing, the lifting casing ascends and descends based on the feeding casing through the ribbons so as to adapt to different floor slab thicknesses, finally, fireproof material blocking is conducted in the feeding casing and the lifting casing, and the pipeline and the floor casing are filled and fixed; and the structure is simple, operation is convenient, the risks of manual climbing and formwork hanging are avoided in the process, and the blocking efficiency and standardization of fireproof materials between the pipeline and the floor casing are improved.

Owner:HEFEI KDLIAN SAFETY TECHNOLOGY CO LTD

Recyclable through-wall PVC (polyvinyl chloride) sleeve for shear wall split bolts

InactiveCN108843017ANovel structureEasy to useAuxillary members of forms/shuttering/falseworksPolyvinyl chlorideEngineering

The invention relates to a recyclable through-wall PVC (polyvinyl chloride) sleeve for shear wall split bolts. The sleeve is characterized in that the PVC sleeve is a PVC pipe being 200 mm long, diameters of two ends of the PVC pipe are different, the wall thickness of the pipe is 4 mm, and a plurality of stiffening ribs made of the same material are uniformly arranged on the inner wall of the pipe. The recyclable through-wall PVC sleeve for the shear wall split bolts has the advantages that the PVC pipe is novel in structure and convenient to use, hole plugging quality of external wall through screws is improved, the leakage rate is reduced, the through-wall PVC sleeve can be easily taken out and is recyclable, and the engineering cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

A plugging plate and a plugging device for a grouting sleeve communicating chamber

The invention discloses a plugging plate of a grouting sleeve communicating silo, comprising a baffle plate and a vertical fastening component. The baffle plate includes a vertical plate and a horizontal plate arranged perpendicular to each other, and the vertical plate is provided with a fixing hole; the vertical fastening The assembly includes an L-shaped support plate and an adjustment rod, the lower part of the L-shaped support plate is arranged opposite to the inner side of the vertical plate, and the end of the lower part of the L-shaped support plate is inserted into the fixing hole, and the first end of the adjustment rod is connected to the upper part of the L-shaped support plate. The hinge joint and the second end are pressed and arranged on the inner side surface of the horizontal plate. The invention also provides a plugging device for a grouting sleeve communicating bin, which is formed by combining more than two plugging plates, and the ends of the adjacent plugging plates are compressed and fixed by clips. The plugging device of this scheme is arranged at the joints of the upper and lower prefabricated components to form a closed empty warehouse to ensure that the grouting sleeve does not leak during the grouting process; it reduces the hidden danger of grouting quality; the installation is fast and convenient, no grouting is required during construction, and the construction efficiency is high. , can be used for multiple turnovers; fine-tuning range is reserved in both the horizontal and vertical directions, which is highly practical.

Owner:筑友智造建设科技集团有限公司

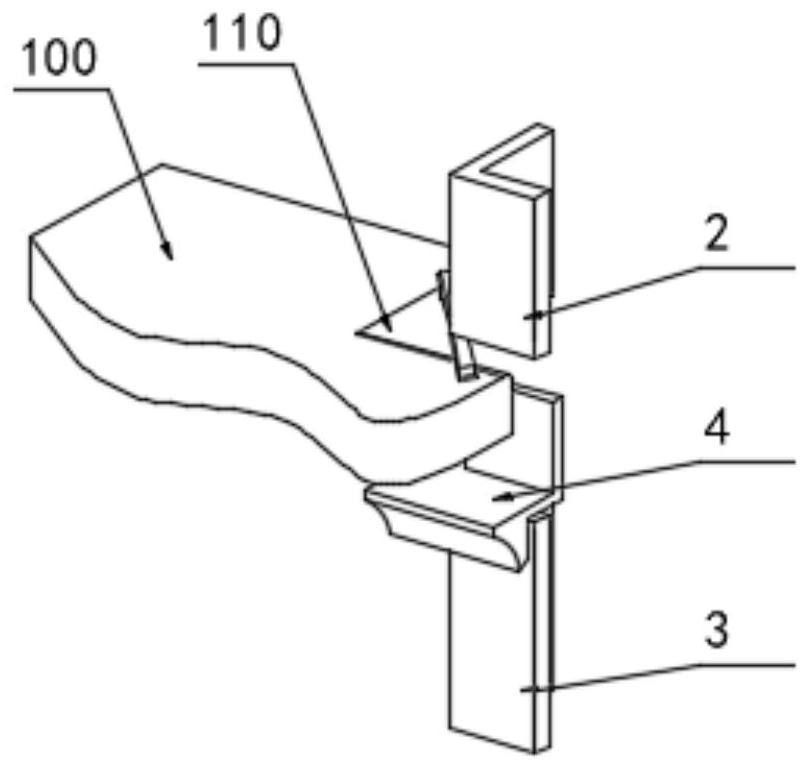

Plugging prefabricated part and plugging method for assembled flue hanging hole

PendingCN114482463APlugging is easy to installLow costForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksWater leakageFloor slab

The invention discloses an assembly flue hanging hole plugging prefabricated part and a plugging method, and particularly relates to the technical field of flue hanging hole plugging, the assembly flue hanging hole plugging prefabricated part comprises two walls which are vertically connected, the wall surfaces of the walls are fixedly connected with a plurality of floors, holes are formed in the positions, close to the two adjacent walls, of the surfaces of the floors, and the holes are communicated with the walls. An upper exhaust flue is arranged in the hole, a lower exhaust flue is arranged below the upper exhaust flue, and a prefabricated part block is arranged at the joint of the upper exhaust flue and the lower exhaust flue in a sleeving mode. The prefabricated part block, the upper exhaust flue and the lower exhaust flue are installed at the same time, sleeving of the upper exhaust flue and the lower exhaust flue is achieved, meanwhile, fine aggregate concrete borne at a hole is poured and tamped through the horizontal formwork, the problems of formwork erecting, smoke leakage, water leakage and the like are solved, mortar permeates into gaps between the prefabricated part block and the upper exhaust flue and between the prefabricated part block and the lower exhaust flue, and the construction efficiency is improved. Horizontal smoke leakage and water leakage are prevented, and construction steps are simplified.

Owner:湖南三达数据科技有限公司

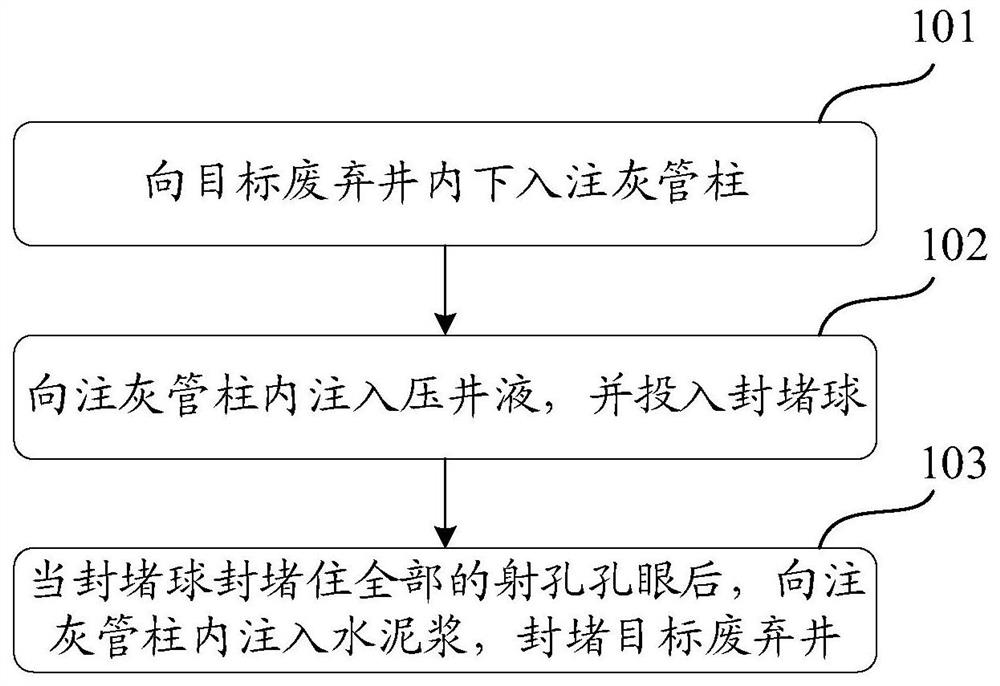

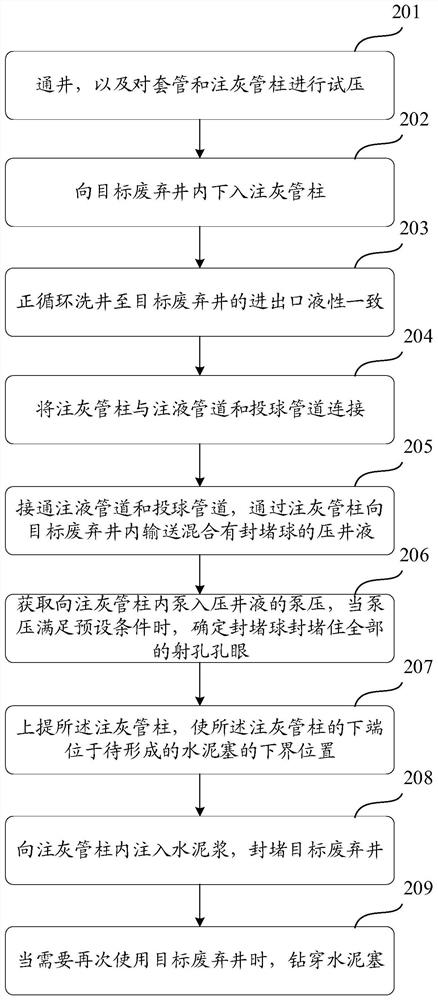

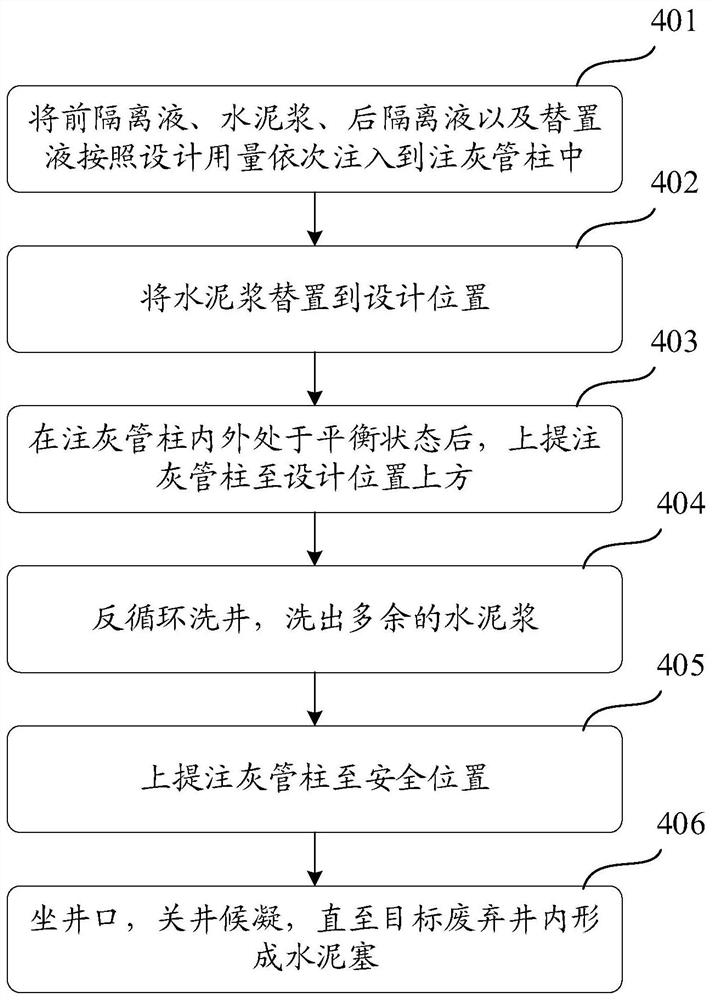

Waste well plugging method

PendingCN114718502AImprove plugging qualityIncrease success rateSealing/packingWell killEnvironmental engineering

The invention discloses an abandoned well plugging method. The method comprises the following steps that a cement injection pipe column is put into a target abandoned well; well killing fluid is injected into the cement injection pipe column, a plugging ball is put in, and the plugging ball is used for plugging a perforation hole of the target abandoned well; and after all the perforation holes are plugged by the plugging ball, cement paste is injected into the cement injection pipe column, and the target abandoned well is plugged. According to the abandoned well plugging method, the plugging quality and the plugging success rate of the abandoned well can be improved.

Owner:PETROCHINA CO LTD +1

Formwork metthod for paired drawing walls of furnace in integral cast structural furnace

ActiveCN1278003CReduce lossGuaranteed integrityHeat proofingForms/shuttering/falseworksBrickCement slurry

This invention is a method to support the model plate on the structural furnace wall by pull oppositely method. This method is: on the base of original method increase following: thicken nut (3), two end screw thread oppositely pull rod (9) and oppositely pull block (2). The productive steps are: 1) To define the position of the pull rod, fixed the thicken nut on the inside of the furnace-cover steel plate (4); 2) To brick the bottom of furnace wall. 3) To pour the heat preservation layer (11) and brick the fixed block (5); 4) To drill the steel model plate, and screwed in the thicken nut on the end of pull rod, the other end of this rod is fixed on the horizontal scaffold (6) by the connected member (8); 5) Pouring cement slurry; 6) To circulate the above steps till whole furnace be poured; 7) Pouring maintain materials to maintain it; 8) Take out model plate and pull rod; 9) to seal holes.

Owner:CHINA MCC20 GRP CORP

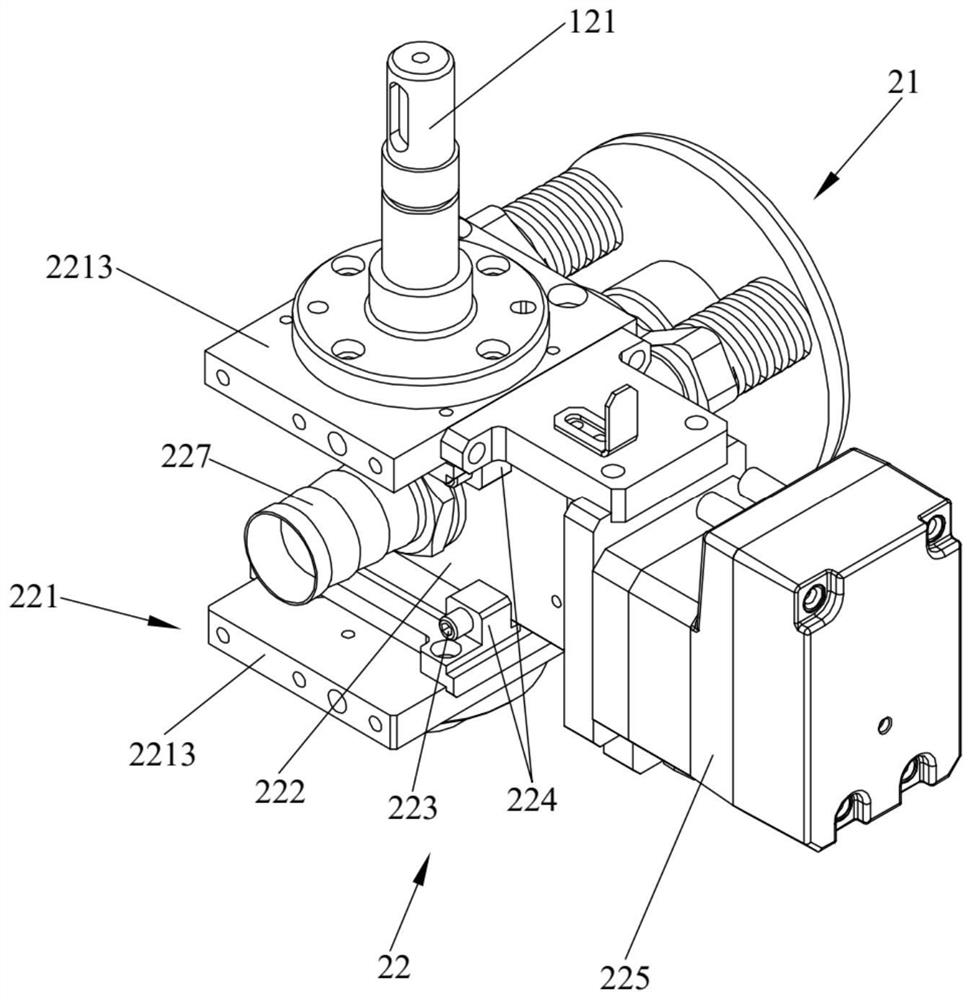

Gate valve control mechanism, plugging head, hole plugging device and hole plugging robot

ActiveCN113445773AControl start and stopPush smoothOperating means/releasing devices for valvesBuilding repairsSlurryGate valve

The invention relates to the technical field of building machinery, and discloses a gate valve control mechanism, a plugging head, a hole plugging device and a hole plugging robot. The gate valve control mechanism comprises a mounting seat, a gate valve push plate, a gate valve driving unit and a pre-tightening piece; a through hole communicating with a slurry outlet pipe is formed in the mounting seat; the gate valve push plate is movably arranged on the mounting seat, and a feeding hole is formed in the gate valve push plate; the gate valve driving unit is mounted on the mounting seat and can drive the gate valve push plate to move, so that the feeding hole is aligned to or staggered from the through hole; and the pre-tightening piece can adjust the pressure between the gate valve push plate and the mounting seat so that the gate valve push plate can move relative to the mounting seat, and the gate valve push plate and the mounting seat can be kept sealed. According to the gate valve control mechanism, starting and stopping of slurry conveying can be rapidly controlled, the sealing performance is good, the phenomena of slurry leakage and slurry flowing can be effectively avoided, and the gate valve control mechanism is simple in structure, convenient to use and practical.

Owner:广东博鼎建筑科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com