Non-designed reserved hole plugging device and plugging method

A technology for reserving openings and sealing devices, which is applied in the direction of formwork/formwork/working frame, building components, building insulation materials, etc., and can solve problems such as uneven construction quality, large construction cost investment, and complicated construction process. Achieve the effect of reducing labor consumption, improving construction quality, and less quality control points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

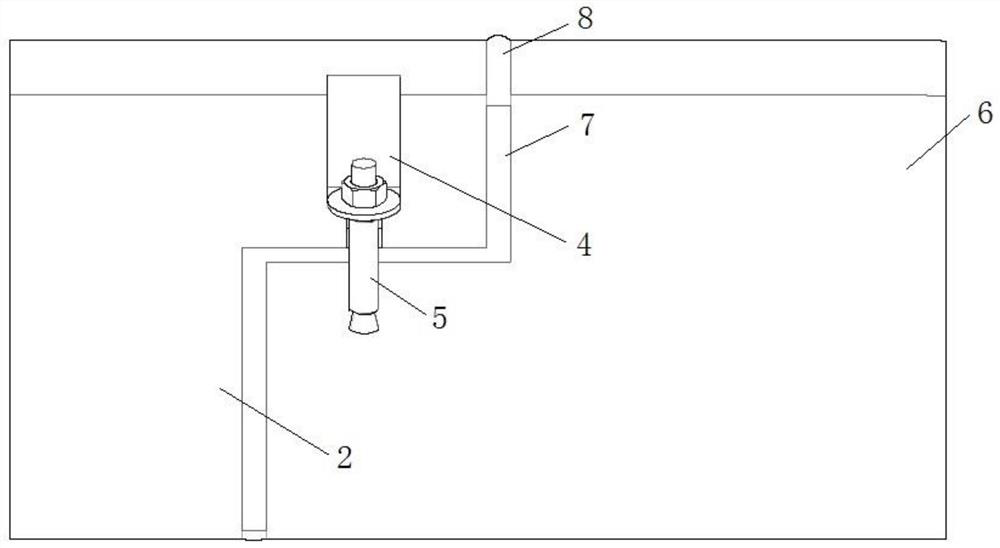

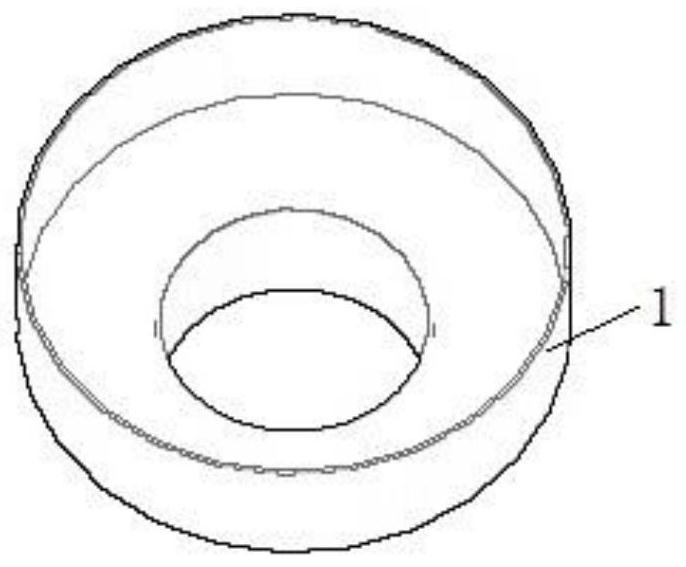

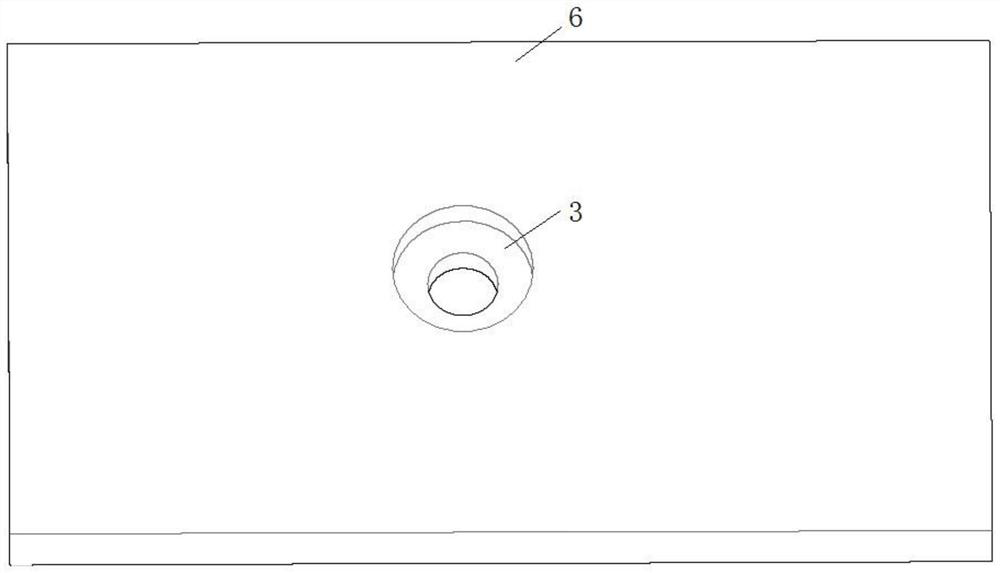

[0054] A non-design reserved hole sealing device, comprising a reserved hole pre-embedded template 1 and a hole sealing plate 2, the hole sealing plate 2 is made according to the reserved hole pre-buried template 1 after removal, and the hole sealing plate The shape of 2 is the same as that of the pre-embedded template 1 of the reserved hole, and the size is the pre-embedded template 1 of the reserved hole minus the size of the installation gap.

[0055] The installation gap size is the plate thickness size of the pre-embedded formwork 1 in the reserved hole. The opening sealing plate 2 is made according to the pre-embedded formwork 1 reserved for the opening, that is, the outer side of the pre-embedded formwork 1 for the reserved opening is the construction formwork for the reserved opening 3, and the inner side of the embedded formwork 1 for the reserved opening is the opening sealing plate 2, when the hole sealing plate 2 processed in this way is installed in the reserved h...

Embodiment 2

[0063] A non-design reserved hole sealing device, comprising a reserved hole pre-embedded template 1 and a hole sealing plate 2, the hole sealing plate 2 is made according to the reserved hole pre-buried template 1 after removal, and the hole sealing plate The shape of 2 is the same as that of the pre-embedded template 1 of the reserved hole, and the size is the pre-embedded template 1 of the reserved hole minus the size of the installation gap.

[0064] The difference between this embodiment and Embodiment 1 is that the reserved hole 3 is a cantilevered outer frame channel steel hole, and the cantilevered outer frame channel steel hole is a distance-shaped hole with three sides that are stepped. The blocking plate 2 is a step-shaped distance-shaped square plate with three sides that is made according to the pre-embedded formwork 1 of the reserved hole and matched with the three-side stepped distance-shaped hole. The three stepped sides of the distance-shaped square plate Anch...

Embodiment 3

[0066] A non-design reserved hole sealing device, comprising a reserved hole pre-embedded template 1 and a hole sealing plate 2, the hole sealing plate 2 is made according to the reserved hole pre-buried template 1 after removal, and the hole sealing plate The shape of 2 is the same as that of the pre-embedded template 1 of the reserved hole, and the size is the pre-embedded template 1 of the reserved hole minus the size of the installation gap.

[0067] The difference between this embodiment and Embodiment 1 is that the reserved hole 3 is a reserved outlet for a closed space, and the reserved outlet for a closed space is a distance-shaped stepped hole, and the hole blocking plate 2 is based on The step-shaped distance-shaped square plate made by the pre-embedded template 1 for the reserved hole is matched with the distance-shaped stepped hole, and the four sides of the distance-shaped square plate are evenly arranged with anchor bolt reserved holes 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com