Spherical dual-seal plugging device

A occluder, spherical technology, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., can solve the problem of no spherical double-occluder structure or occluder principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in more detail below in conjunction with accompanying drawing:

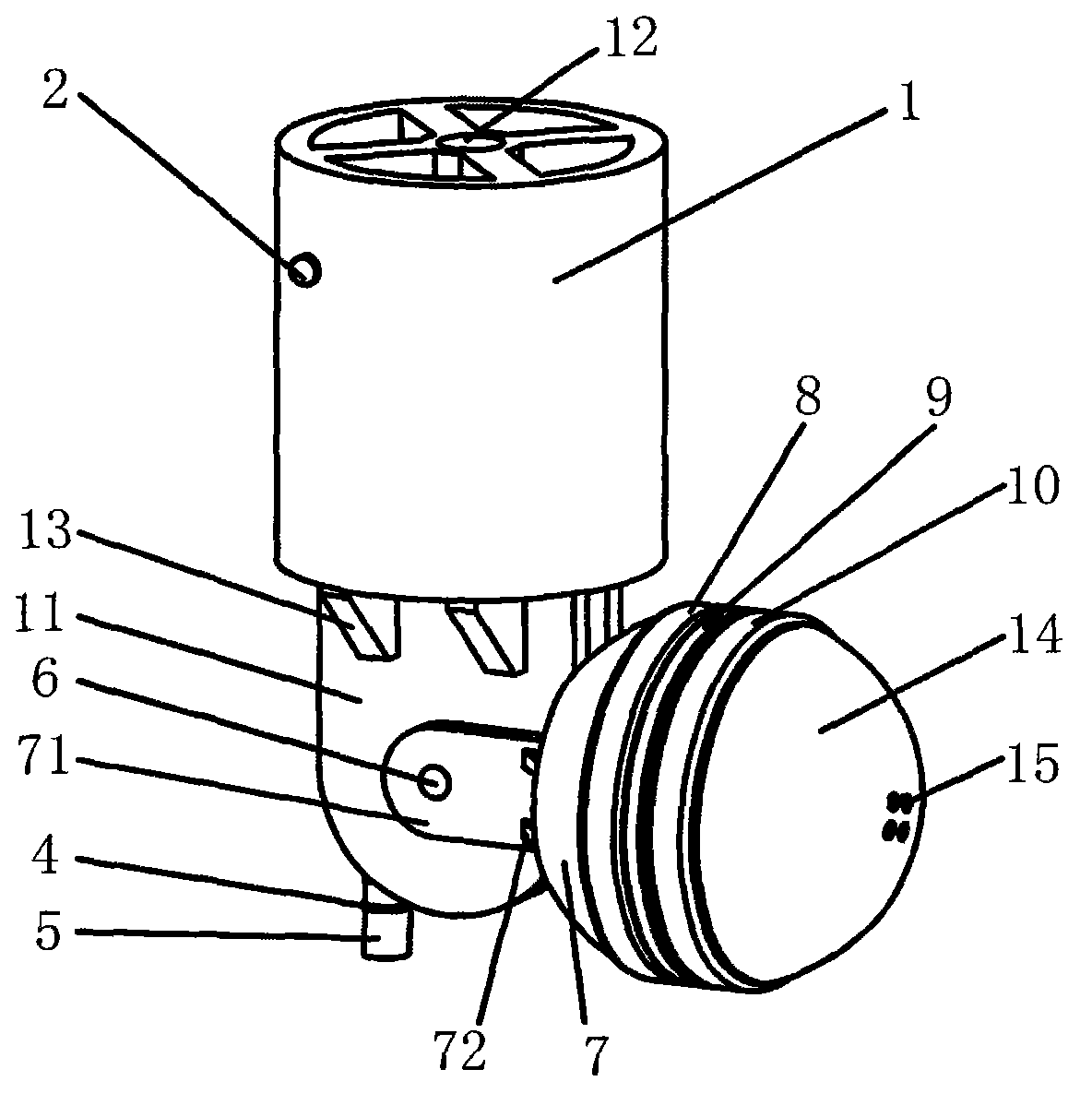

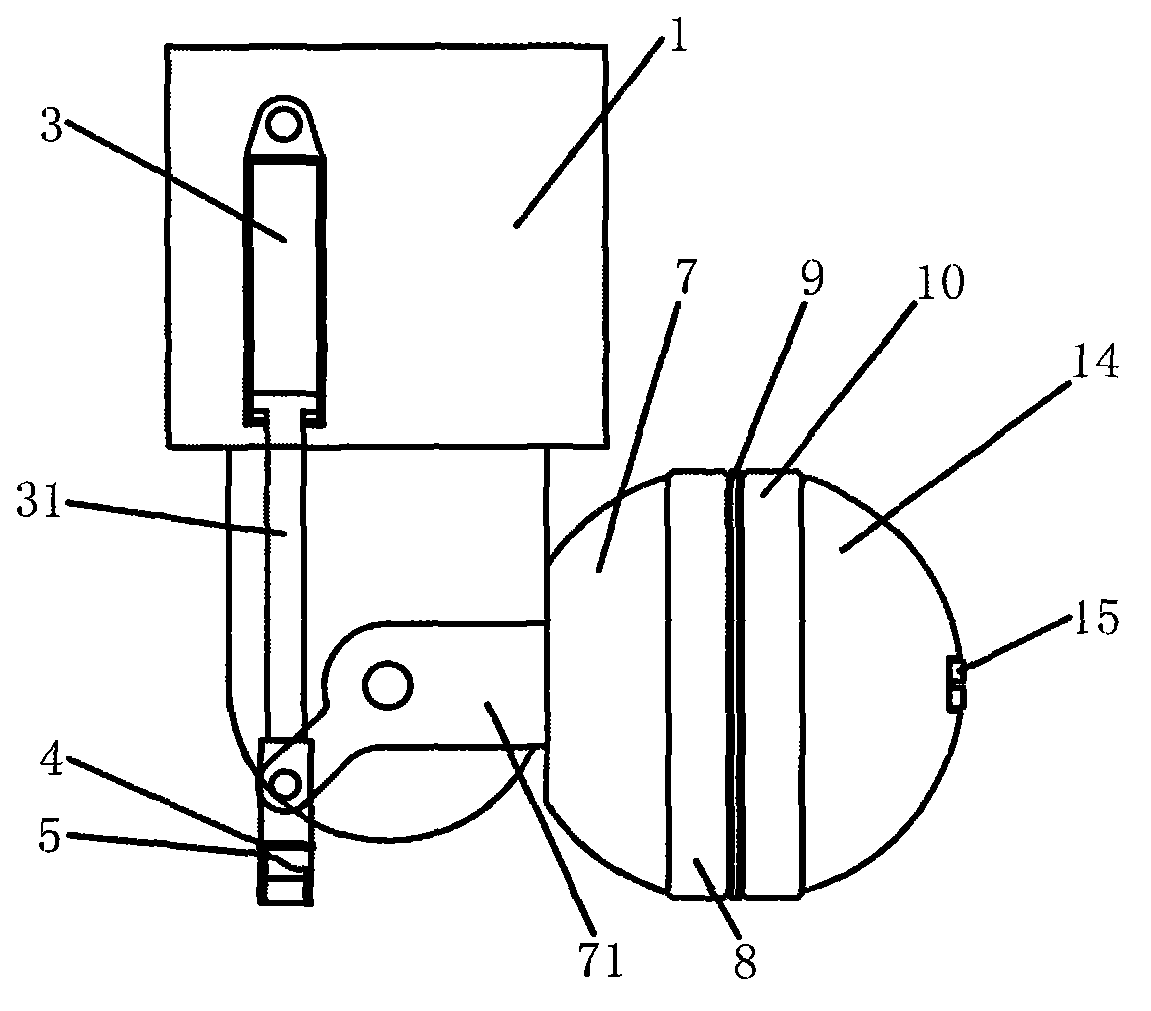

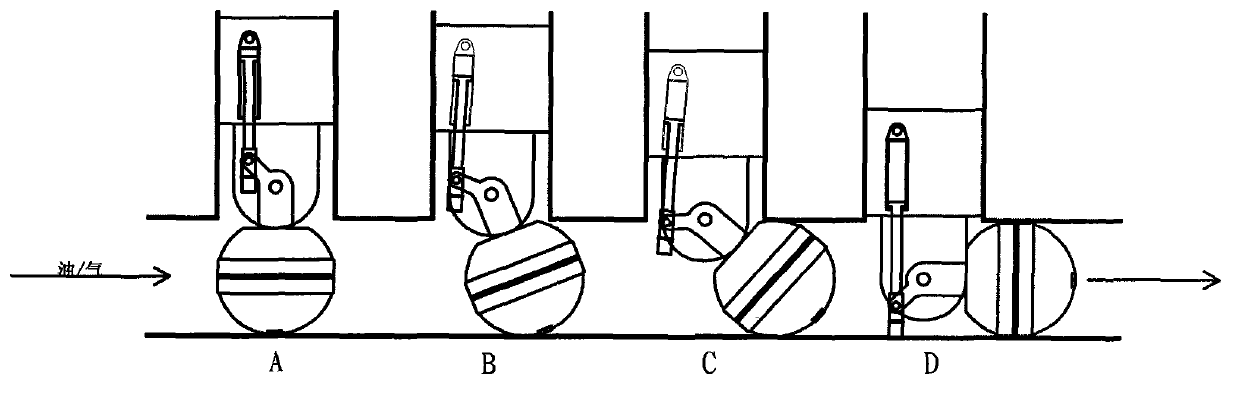

[0018] Such as figure 1 , 2 As shown, the spherical double-seal occluder consists of a main support cylinder 1, a small rotating shaft 2, a rotating hydraulic cylinder 3, a gasket 4, an anchor sleeve 5, a rotating mandrel 6, an occluder housing 7, and a rear sealing rubber cylinder 8. An isolation ring 9, a front sealing rubber cylinder 10, a occluder ball cover 14, an inner hexagon screw 15, and a driving hydraulic cylinder 16 are composed. The main support cylinder 1 mainly acts as a guide and support during the process of the plugging device being lowered into the pipeline. The main support cylinder 1 is designed with a plugging machine coupling hole 12 for the plugging machine, and the plugging machine passes through the coupling hole 12 of the plugging machine. Connect, send the spherical occluder through the splint valve into the pipeline.

[0019] Such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com