Glass bottle opening inner plug capping machine

A capping machine and glass bottle technology, applied in the direction of bottle/container cap, closure plug, bottle filling, etc., can solve the problems of high labor intensity, broken glass bottle mouth, high labor cost, etc., and achieve reasonable structural design and high quality stoppering The effect of stability and high stoppering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

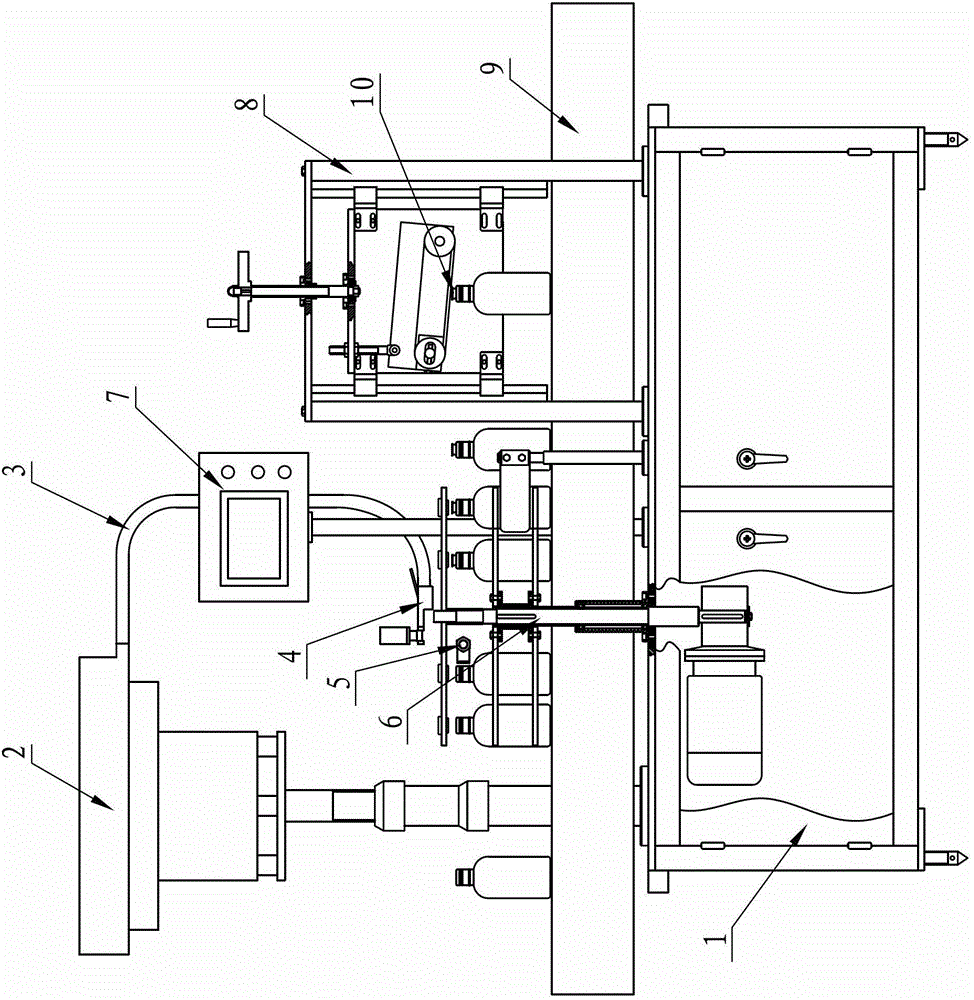

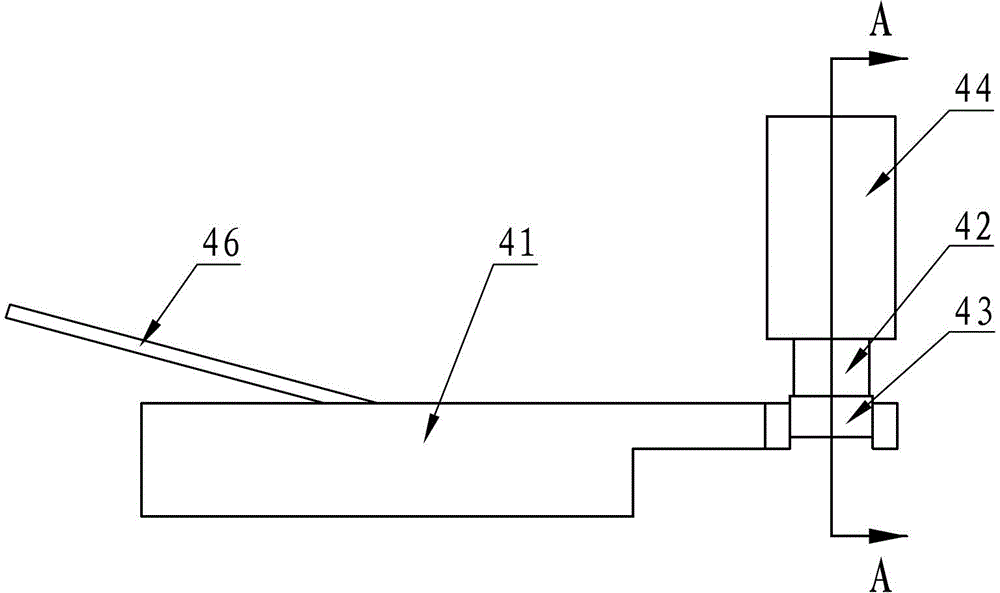

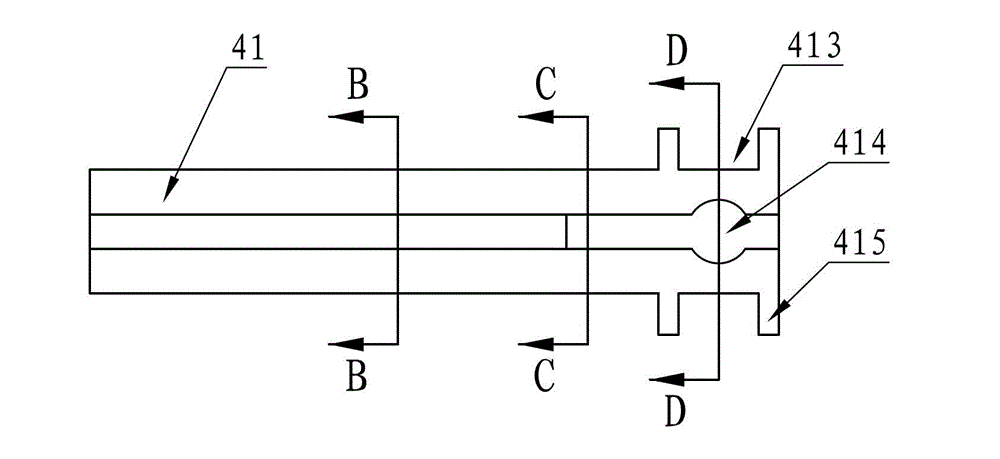

[0023] A glass bottle mouth stopper capping machine, such as Figure 1~Figure 13As shown, it includes a frame 1, a cap unscrambling device 2, a lower cork groove 3, a guide cork drop mechanism 4, a bottle inspection photoelectric sensor 5, a bottle pulling guide mechanism 6, an operation touch screen 7, a cork pressing mechanism 8 and a bottle conveying belt 9, The cap sorting device 2 is fixedly installed on the frame 1, and the lower plug groove 3 is arranged between the cap sorting device 2 and the guide plug drop mechanism 4. One end of the lower plug groove 3 communicates with the cap sorting device 2, and the other end connects with the guide drop mechanism 4. The plug mechanism 4 is connected, and the guide plug drop mechanism 4 is arranged on the top of the bottle-pushing guide mechanism 6. The guide plug drop mechanism 4 includes a body 41, a piston guide sleeve 42, a lower plug movable stopper 43, a plug push cylinder 44, and a stopper. The block pin 45 and the air b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com