Cationic chemical plugging agent and preparation method thereof

A plugging agent and cationic technology, which is applied in the field of cationic chemical plugging agent and its preparation, can solve the problems of low plugging success rate, poor plugging effect, little change in viscosity, etc., so as to achieve easy operation of plugging construction, improve Pressure-bearing capacity, the effect of a simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

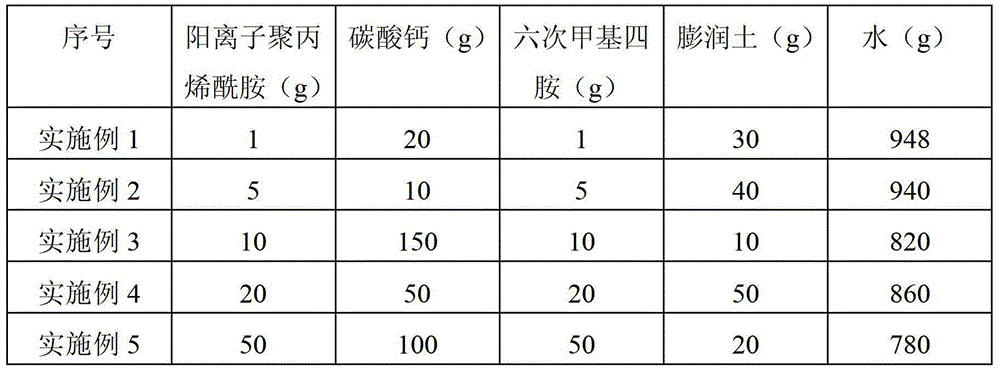

[0027] According to the formula shown in Table 1, configure 5 parts (respectively corresponding to Examples 1 to 5) of 1000g cationic chemical plugging agent, the specific operation steps are as follows: Take a 2500ml beaker and install a cantilever stirrer; Add water in an appropriate amount, start stirring, and the rotation speed is 450r / min; add cationic polyacrylamide (CP-9, produced by Shanghai Hengli Water Treatment Material Co., Ltd.) in the amount shown in Table 1, and stir for 2 hours to make the cationic polyacrylamide Dissolve; then add bentonite and calcium carbonate (average particle size: 0.06 μm) in sequence, and continue to stir to disperse evenly; then add hexamethylenetetramine, and continue to stir for 1 hour to obtain the viscous cations of Examples 1 to 5 Chemical plugging agent.

[0028] Table 1

[0029]

[0030] (2) Preparation of drilling fluid

[0031] 1000ml of conventional anionic polysulfide drilling fluid was prepared to measure the pressure-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com