Formwork-hanging-free pipeline and casing interior fireproof blocking modular filling device and construction method thereof

A filling device and fire-proof sealing technology, which is applied in the direction of pipes/pipe joints/fittings, pipes, mechanical equipment, etc., can solve the problems of high-elevation operation risk and work efficiency reduction, so as to avoid the risk of high-elevation hanging mold and improve the filling standardization process to improve the effectiveness of the modular specification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

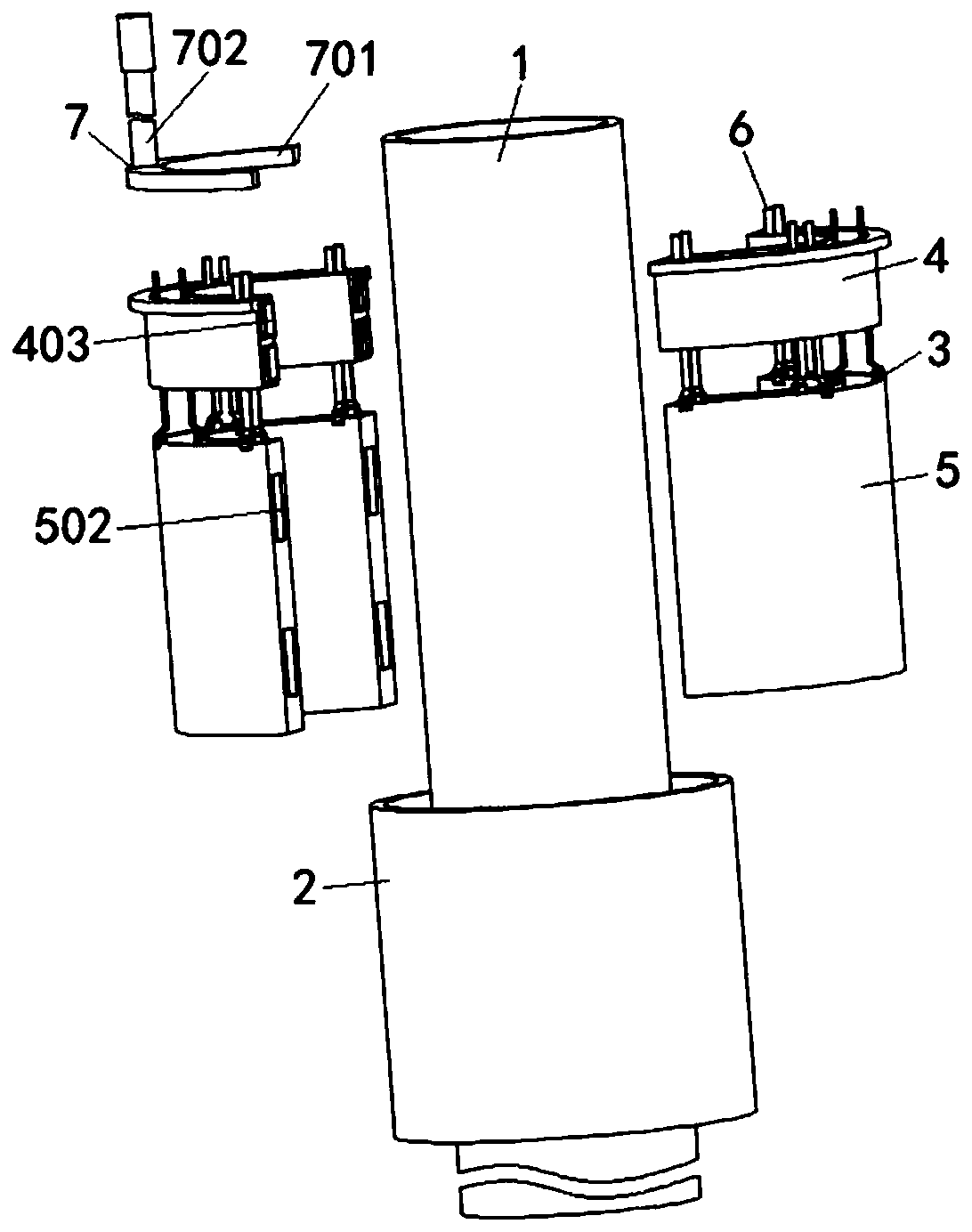

[0039] like Figure 1-3 As shown in the figure, the present invention is a fire-proof blocking modular filling device in a mold-free pipeline casing, comprising a pipeline 1 and a floor casing 2, and a filling device 3 is fixedly installed between the pipeline 1 and the floor casing 2; the filling device 3 is used for Filled with fireproof material, which can be cement mortar or viscous fireproof mud;

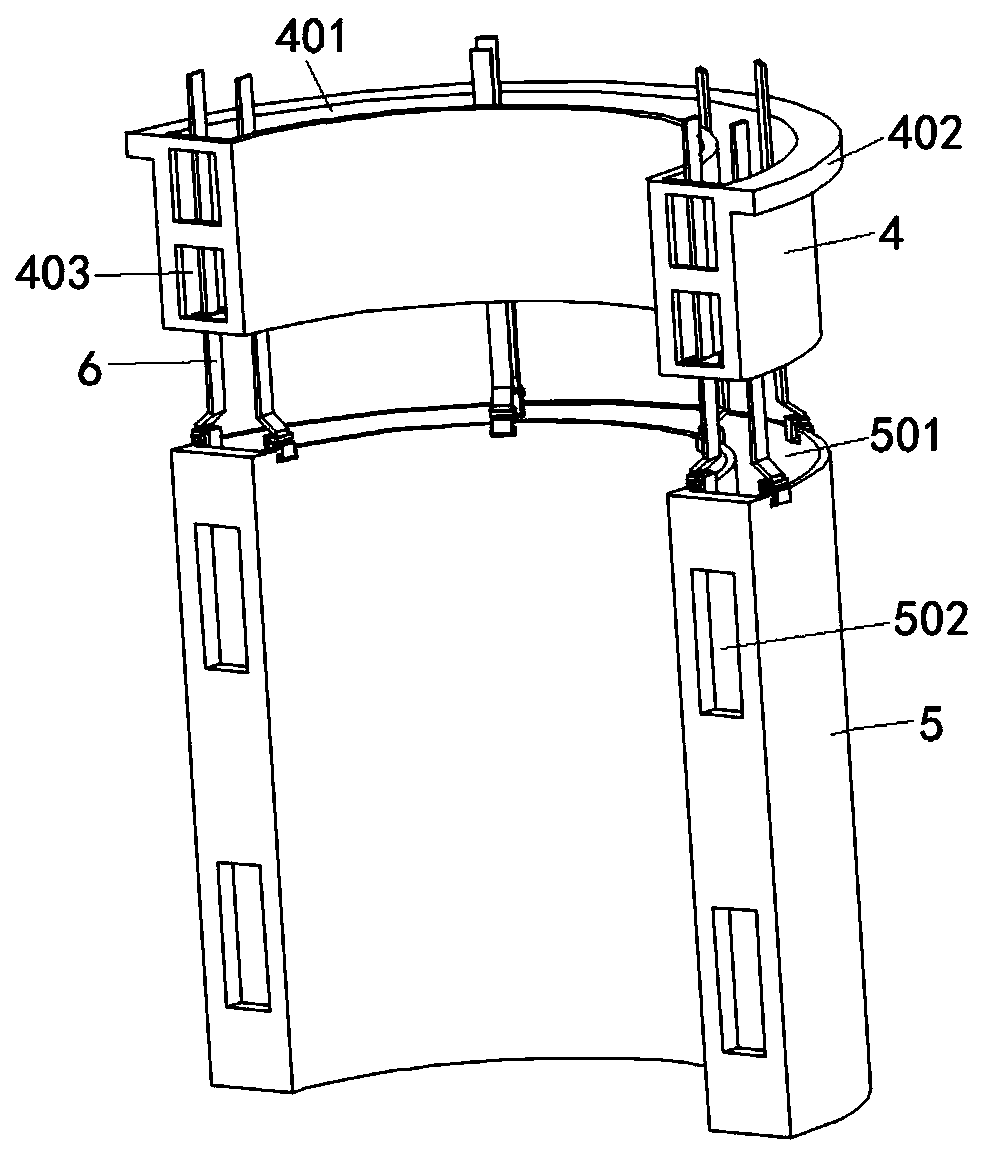

[0040] The filling device 3 includes two half blanking sleeves 4, two semi-lifting sleeves 5 and a cable tie 6. The half blanking sleeve 4 is connected with the half lifting sleeve 5 through the cable tie 6; the half blanking sleeve 4 There is an extrusion tool 7 on it; the extrusion tool 7 is used to compact the fireproof material in the semi-cutting sleeve 4 and the semi-lifting sleeve 5, so as to improve the blocking quality of the fireproof material; The lifting sleeve 5 can be made of flame retardant PVC material;

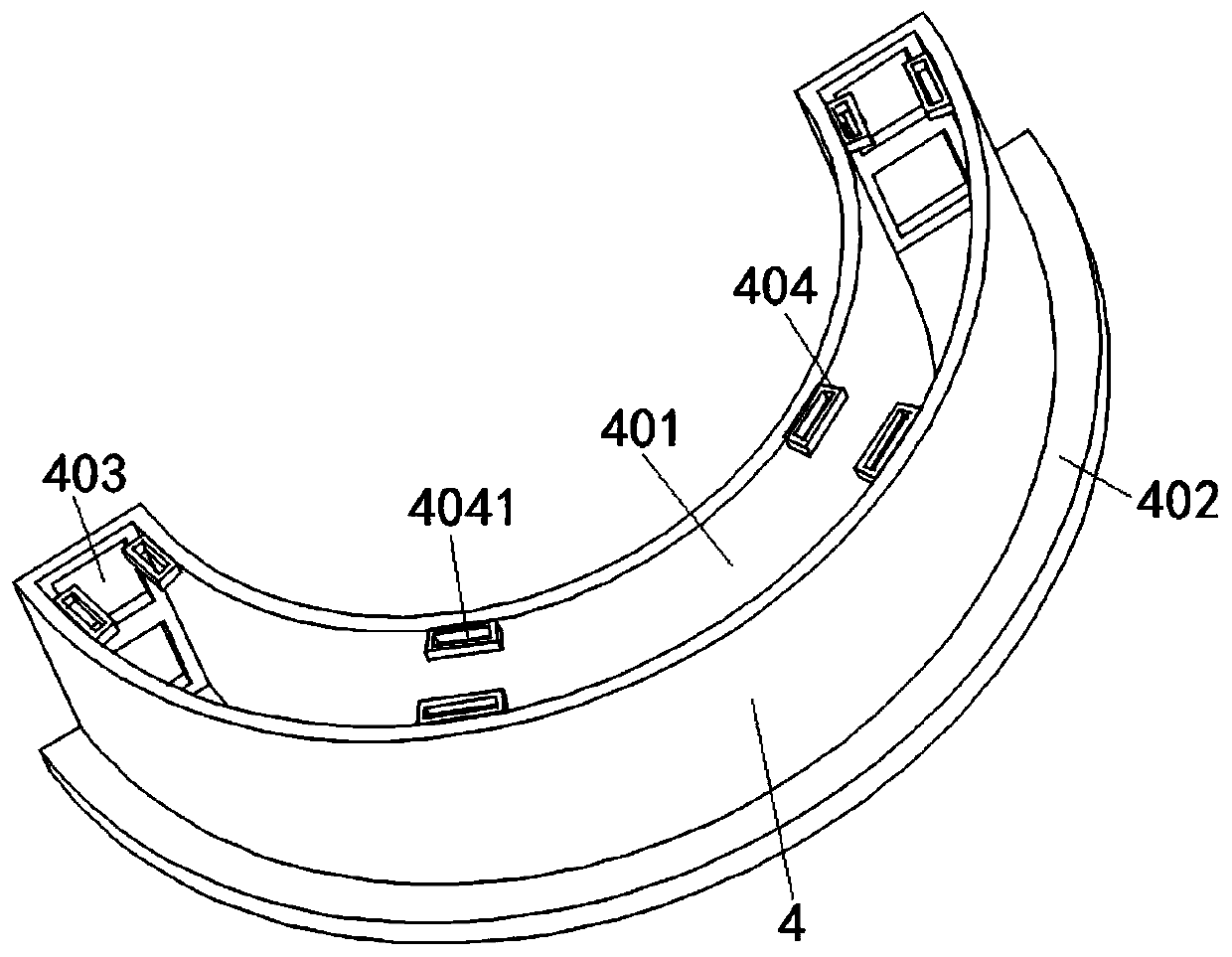

[0041] The end face of the semi-cutting sleeve 4 has an...

Embodiment 2

[0056] The construction method of the fire-proof plugging modular filling device in the pipe casing without the lifting formwork comprises the following steps:

[0057] Step 1: penetrate and fix the floor casing 2 in the floor; pipe 1 penetrates the floor casing 2 and is fixedly installed on the wall; perform concentricity correction on the floor casing 2 and the pipe 1;

[0058] Step 2: Measure the thickness of the floor slab, and adjust the matching position of the cable tie 6 on the one-way bayonet 4041, so that the distance between the top surface of the semi-cutting sleeve 4 and the bottom surface of the semi-lifting sleeve 5 is equal to the thickness of the floor slab;

[0059] Step 3: Put the semi-cutting sleeve 4 and the semi-lifting sleeve 5 connected by the tie 6 into the gap between the floor sleeve 2 and the pipeline 1, and make the arc-shaped outer edge 402 overlap the floor sleeve. The top end face of the tube 2;

[0060] Step 4: Put the other half of the blanki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com