A plugging plate and a plugging device for a grouting sleeve communicating chamber

A technology for grouting sleeves and plugging plates, which is applied to buildings, building reinforcements, building components, etc., can solve the problems of inability to ensure the uniformity of grouting, delaying the construction progress, and long construction time, so as to reduce the hidden dangers of grouting quality, Quick installation and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

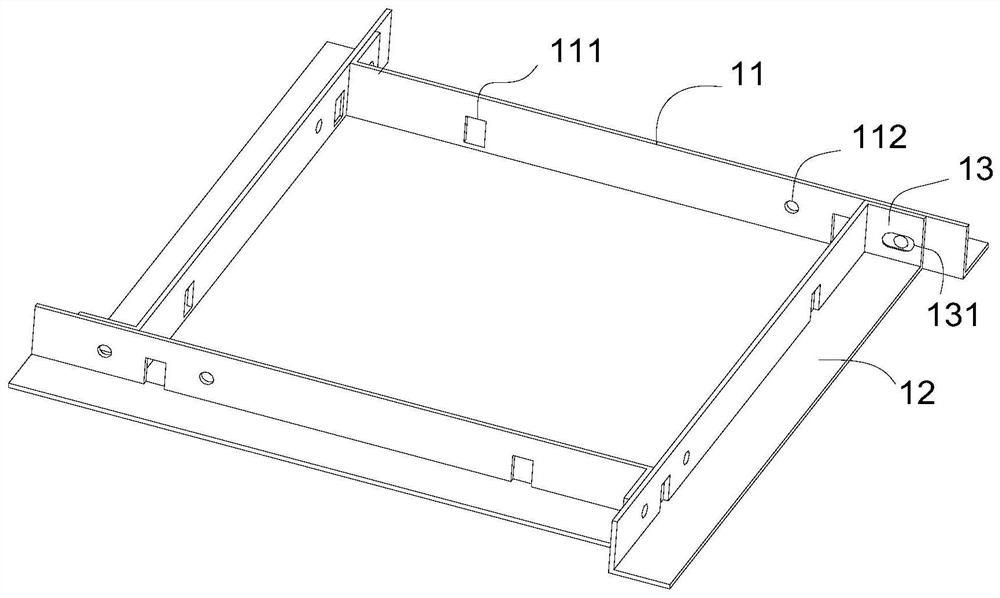

[0030]Reference schematicfigure 1 In this embodiment, the blocking plate includes a baffle 1. The baffle 1 includes two vertical vertical plates 11, a horizontal plate 12, and a fixing plate 13. The vertical plate 11 is provided with a fixing hole 111 and a through hole 112, and the fixing plate 13 A card hole 131 is opened on the top. The baffle 1 is respectively arranged on the periphery of the prefabricated member, wherein the fixing plate 13 and the vertical plate 11 of the adjacent baffle 1 are pressed against each other, and the clip (not shown in the figure) is passed through the through hole 112 and the blocking on the vertical plate 11 The card holes 131 on the board fasten adjacent baffles 1 together. Since the prefabricated component in this embodiment is a prefabricated column, the four baffles 1 surround a rectangle.

[0031]Continue to see the schematicfigure 1 In actual production, the cross-sectional dimension difference of prefabricated columns of different specificati...

Embodiment 2

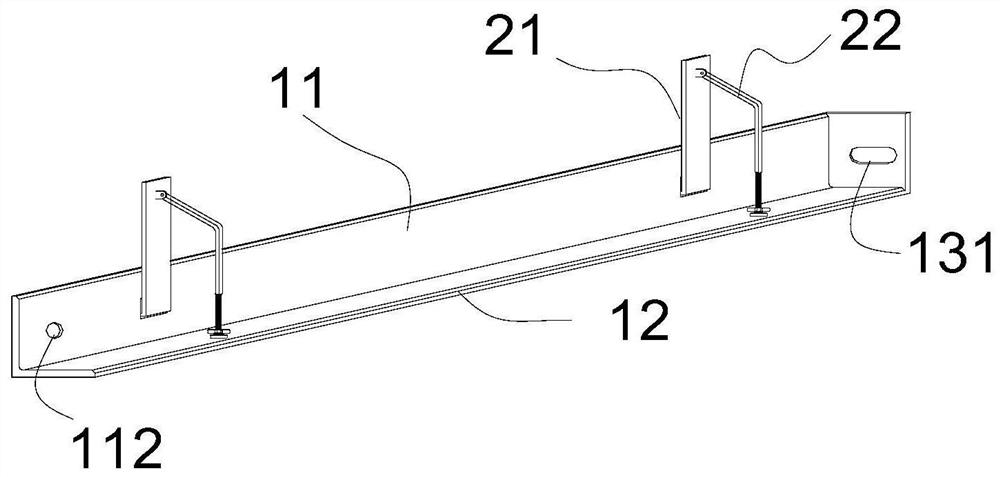

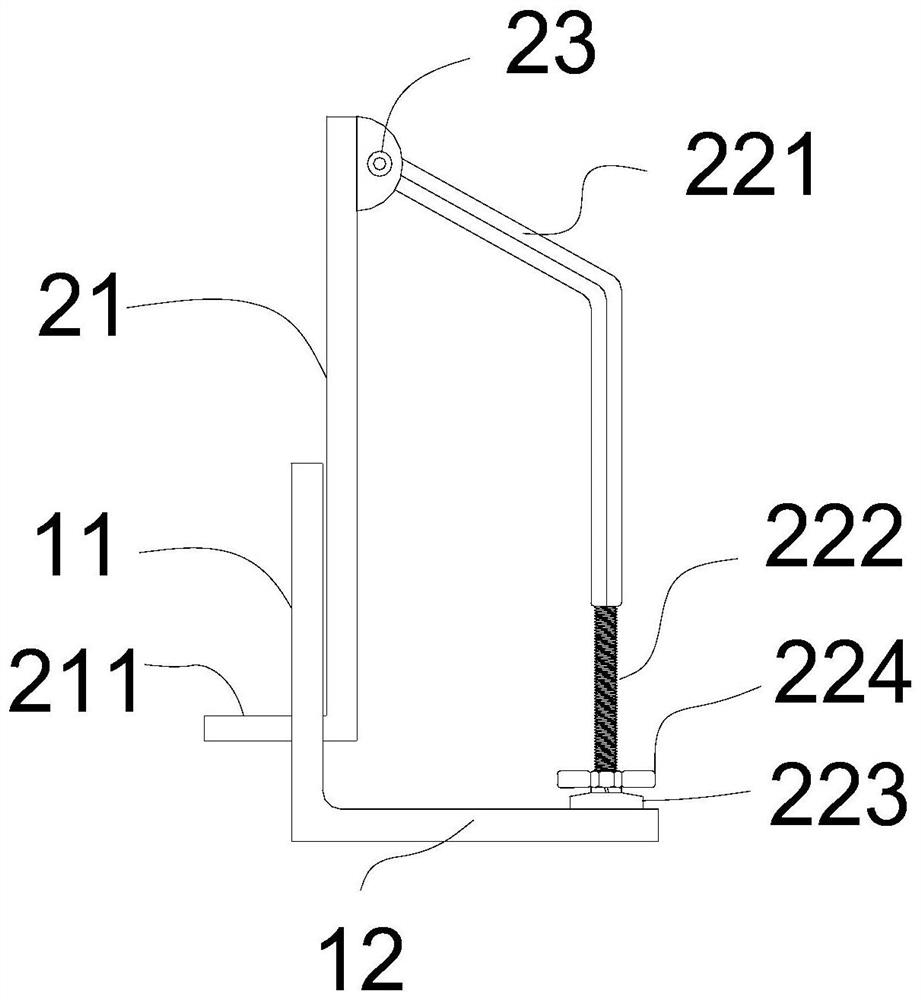

[0033]See schematicfigure 2 with3In this embodiment, the blocking plate includes a baffle 1 and a vertical fastening assembly 2, and the vertical fastening assembly 2 includes an L-shaped support plate 21 and an adjusting rod 22, which are hingedly connected by a hinge 23. The end of the L-shaped pallet 21 is provided with a fixing portion 211, and in this embodiment, the fixing portion 211 and the L-shaped pallet 21 are perpendicular to each other. The adjusting rod 22 includes an outer rod 221 and an inner rod 222. The outer rod 221 is provided with an inner thread, the inner rod 222 is provided with an outer thread, and the outer rod 221 is sleeved on the inner rod 222 and connected by a thread structure. When the outer rod 221 or the inner rod 222 is rotated, the overall length of the adjusting rod 22 is adjusted. The fixing portion 211 of the L-shaped pallet 21 extends into the fixing hole 111 of the vertical plate 11, the end of the inner rod 222 is pressed on the horizontal p...

Embodiment 3

[0037]In this embodiment, a plugging device for connecting a grouting sleeve to a bin is introduced, which is formed by a combination of four plugging plates shown in Embodiment 2. The plugging plate includes a plugging plate 1 and a vertical fastening component 2. In other embodiments, the number of blocking plates can be selected for combination according to specific conditions. For example, a circular prefabricated column, the blocking plate 1 is set in a shape that matches the outer circumference of the circular prefabricated column, and the bottom side of a circular prefabricated column Only 2 matching blocking plates can be provided.

[0038]SeeFigure 4 As shown, the use method and working principle of the plugging device of this embodiment are introduced:

[0039]The upper component is a prefabricated column 3, the internal anchoring column reinforcement 31, and the end of the column reinforcement 31 is provided with a grouting sleeve 32. The lower member is the foundation 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com