Casing bottom plugging device and method

A plugging device and casing technology, applied in earthwork drilling, sealing/isolation, wellbore/well parts, etc., can solve the production requirements of holes that are not suitable for the construction parameters of the buried depth of the ore body, the number of times of drilling, and the efficiency Low and other problems, to achieve the effect of shortening the laying time, simplifying the plugging process, and facilitating the laying work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

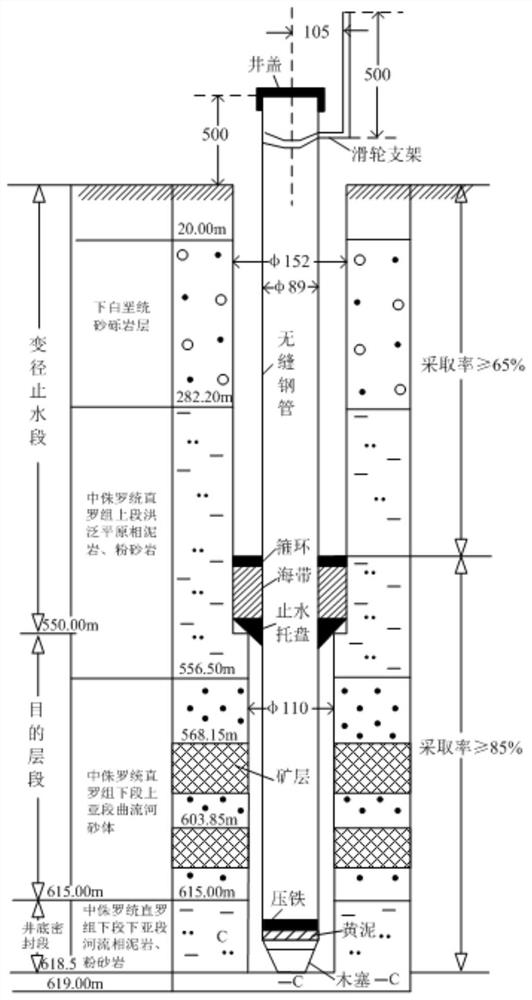

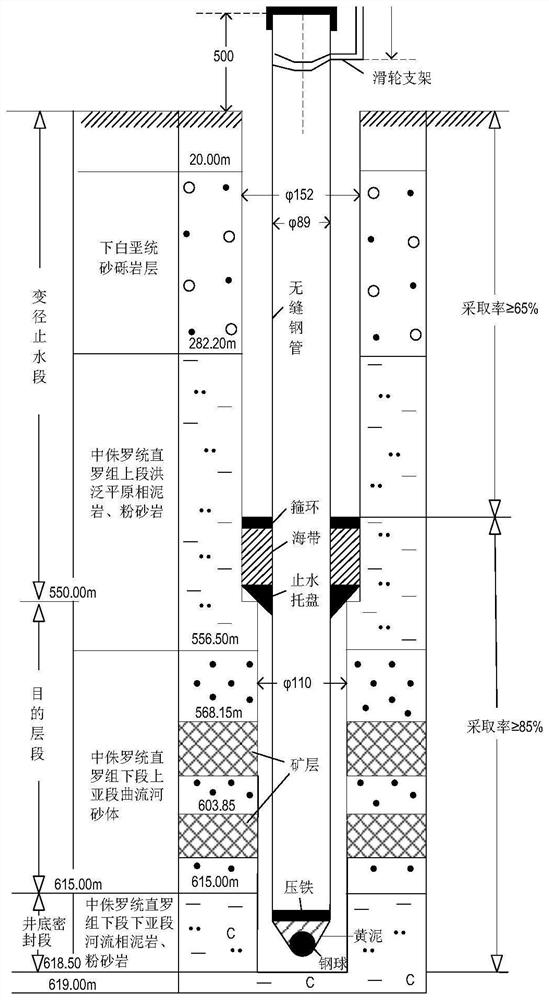

[0035] see Figure 5-8 , a casing bottom plugging device, including a plug and a steel ball; the plug is an integrated structure, including a cylinder 1 and a truncated cone 2; the cylinder is arranged on the top of the plug, and the cone The platform is arranged at the lower part of the plug; the outer surface of the cylinder 1 is provided with a twist turnbuckle suitable for the sleeve, and a circular surface of the cylinder 1 is connected with a larger circular surface of the truncated cone 2. Connected by a common central axis, the cylinder 1 and the truncated cone 2 are both hollow structures, and the hollow structures are circular holes 3 whose diameter is smaller than that of steel balls.

[0036] A method for plugging the bottom of a casing, comprising the following steps: before placing the casing down, screwing the plug to the bottom of the casing in the form of a turnbuckle, and placing a steel ball on the hollow structure, the plug is connected to the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com