Plugging prefabricated part and plugging method for assembled flue hanging hole

A technology for prefabricated components and flues, which is applied in the preparation of building components and building components on site, vertical pipes, etc. Slurry and other problems, to avoid the possibility of water leakage and slurry leakage, prevent horizontal smoke leakage and water leakage, and save labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

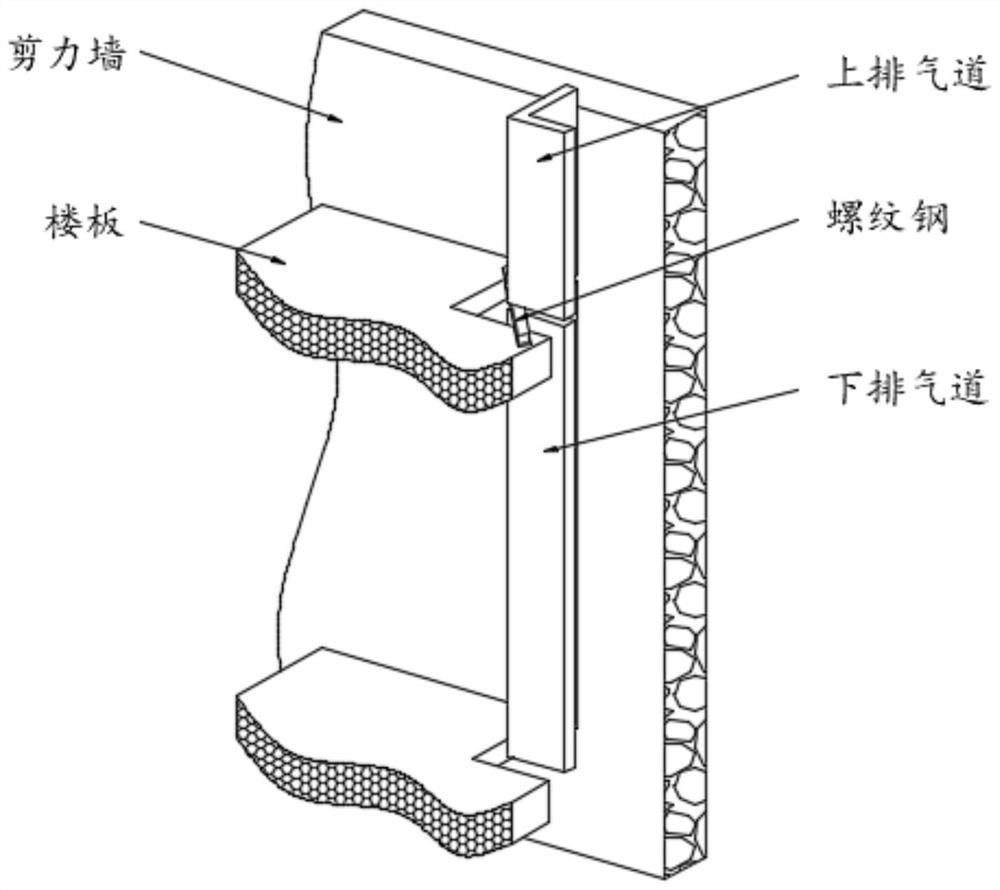

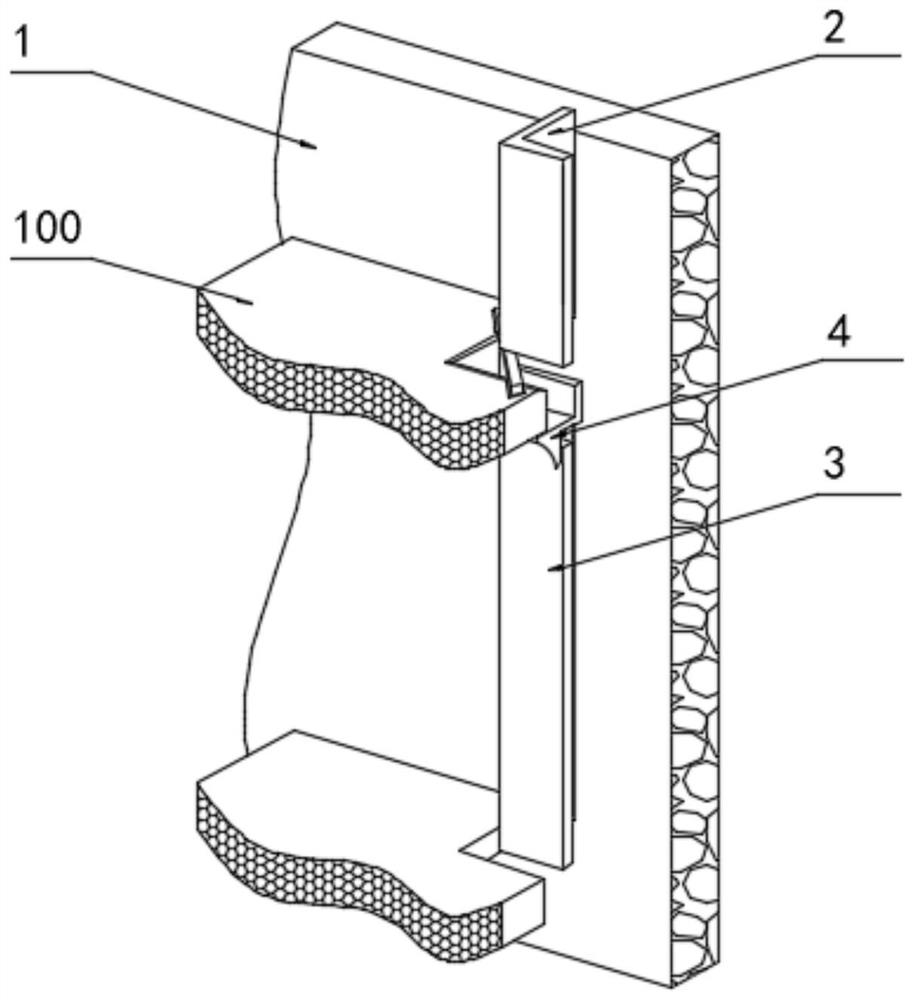

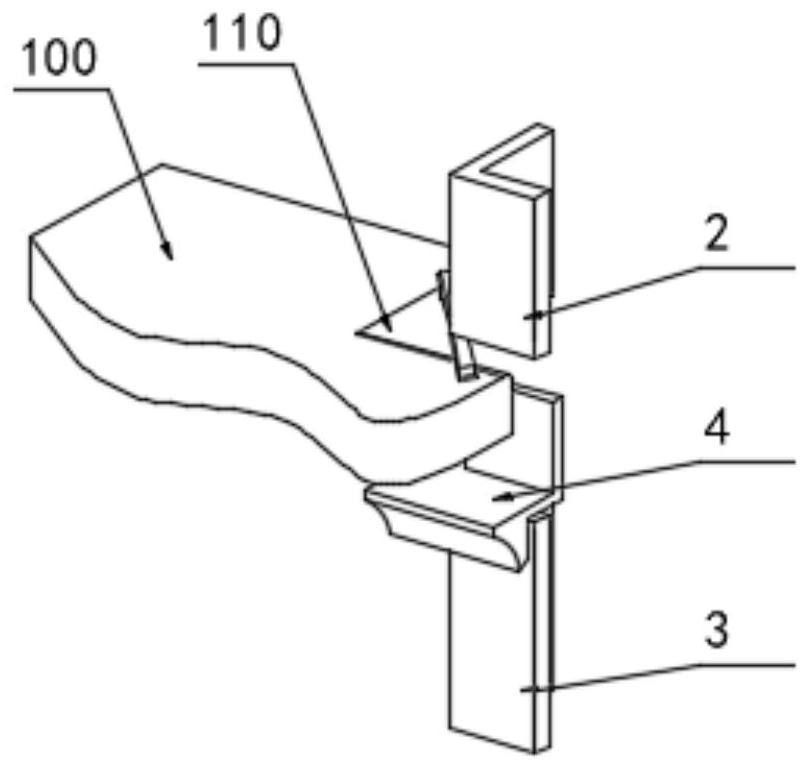

[0031] see Figure 2-Figure 7 As shown, a prefabricated component for assembling flue hanging hole sealing includes two vertically connected walls 1, and the wall surface of the wall 1 is fixedly connected with a plurality of floor slabs 100, and the surface of the floor slabs 100 is close to two adjacent walls. 1 is provided with a hole 110, the inside of the hole 110 is provided with an upper exhaust flue 2, and the lower exhaust flue 3 is arranged below the upper exhaust flue 2, and the upper exhaust flue 2 and the lower exhaust flue The junction of the road 3 is fitted with a prefabricated component block 4, the prefabricated component block 4 is installed in the hole 110 provided on the floor 100, the prefabricated component block 4 includes a horizontal template 400 used in conjunction with the bottom surface of the hole 110, and the prefabricated component block 4 also includes The upper fastener 410 is socketed with the inner wall of the upper exhaust flue 2 and the lo...

Embodiment 2

[0038] see Figure 6-Figure 7As shown, below the opening 110, there is also an anti-leakage sealing mechanism 5 that is attached to the bottom of the prefabricated component block 4. The anti-leakage sealing mechanism 5 includes an anti-seepage plate 500 that is attached to the bottom of the floor 100 and the fillet 440, and prevents leakage. The bottom end of seepage plate 500 is hinged with telescopic ejector rod 510, and the bottom end of telescopic ejector rod 510 is movably connected with anti-skid reinforcement seat 520. The connected telescopic rod, the telescopic rod and the sleeve rod move up and down through the piston push plate.

[0039] In order to prevent the possibility of seepage, when the gap of the hole 110 is too large, an anti-seepage board 500 is pasted under the hole 110, and the design height of the telescopic ejector rod 510 is greater than the height between two adjacent floors 100. The length of the telescopic push rod 510 and the sum of the lengths ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com