Glue injection device for insulating glass molecular sieve filling machine

A technology of glue injection device and molecular sieve, which is applied in the field of glue injection device of hollow glass molecular sieve canning machine, can solve the problems of affecting sealing, low glue blocking quality, affecting glue filling quality, etc., so as to achieve convenient disassembly and assembly and avoid glue pushing. The pressure is too large or too small, and the effect of improving the quality of glue blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

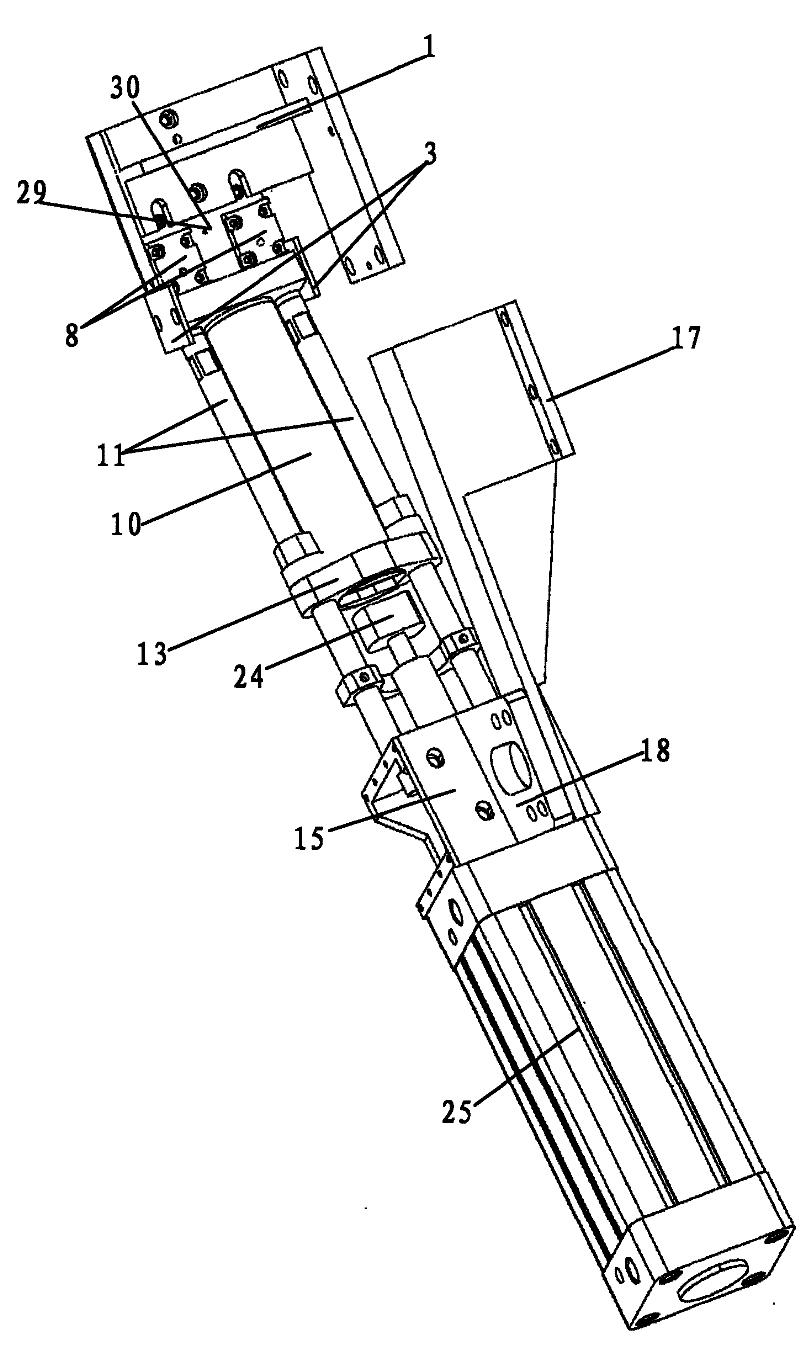

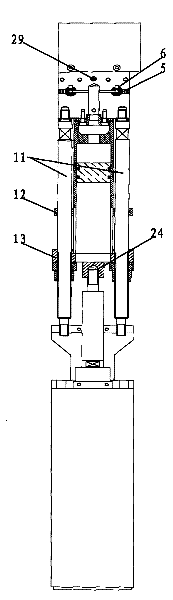

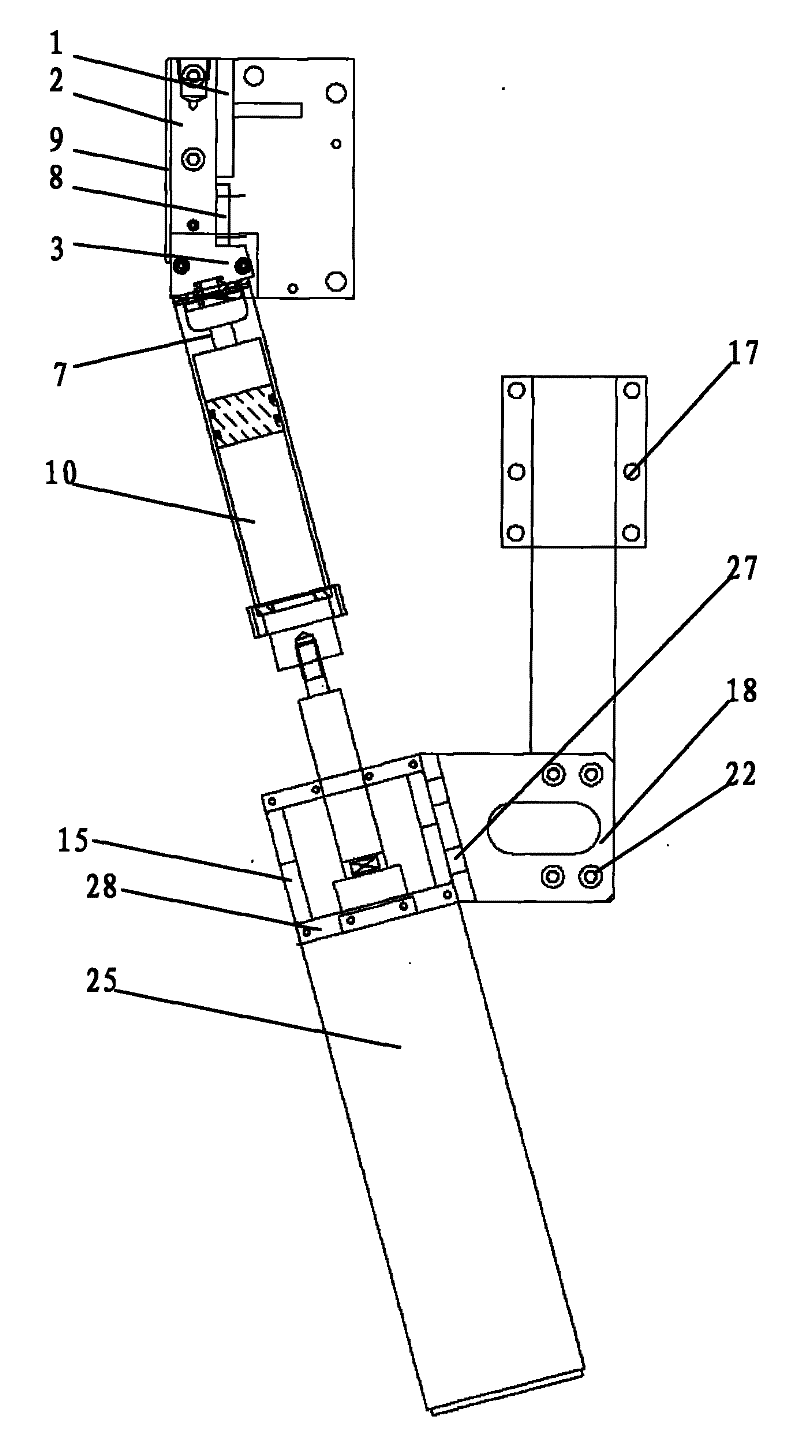

[0020] Such as figure 1 As shown, the glue injection device of the hollow glass molecular sieve can filling machine of the present invention consists of a hot mold bracket 1, a hot mold 2, a side baffle 3, a connector 7, a cover plate 8, a flat plate 9, a rubber cylinder 10, a pull rod 11, and a splint 12. Rubber base 13, cylinder support 15, connecting plate 17, inclined connecting plate 18, cylinder ejector rod 24, cylinder 25, resistance wire 29 and thermocouple sensor 30; thermal mold support 1 is fixed on the front of thermal mold 2 Upper surface; side baffles 3 are provided on both sides of the lower part of the thermal mold 2; a connector 7 is connected to the lower part of the thermal mold 2, and communicates with the rubber cartridge 10 through the connector 7; two covers are symmetrically arranged on the lower surface of the front of the thermal mold 2 plate 8; two flat plates 9 are symmetrically arranged on the back of the hot mold 2; a pull rod 11 is arranged on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com