Root rotting prevention angle steel plugging device for shear wall and construction method

A plugging device and shear wall technology, applied in protection devices, walls, infrastructure engineering and other directions, can solve the problems of insufficient mortar strength, loss of mortar, and unclean base cleaning, so as to achieve safe and reliable construction and improve anti-seepage performance. , the effect of excellent construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

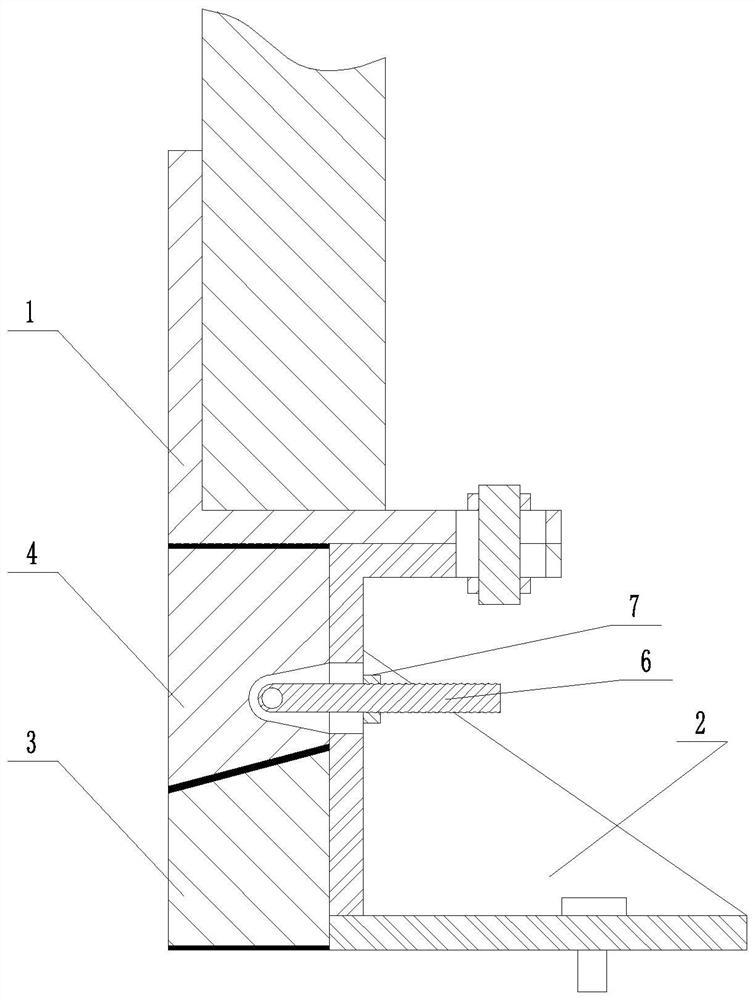

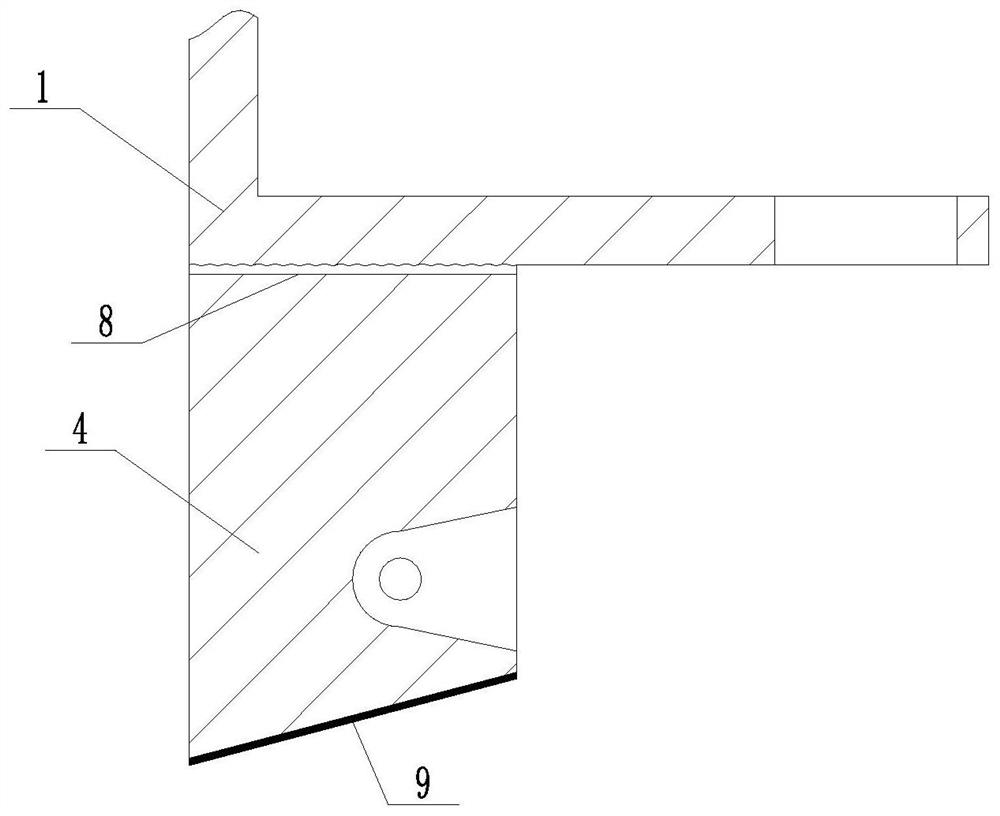

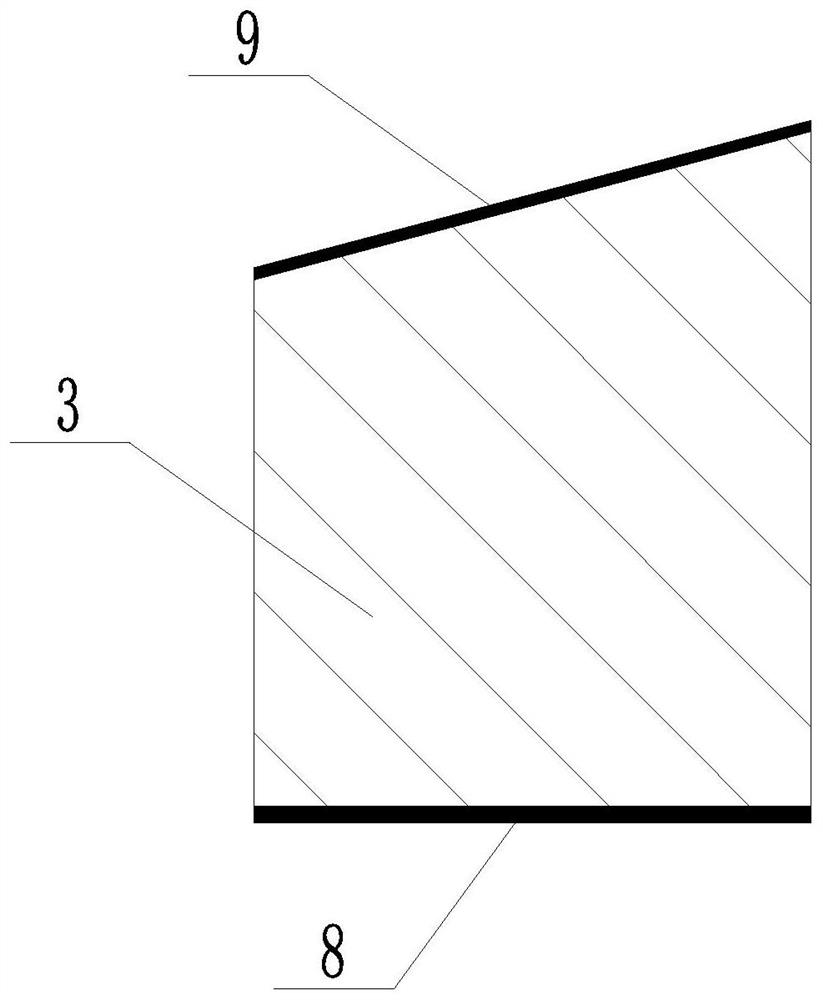

[0029] Such as Figure 1 to Figure 3 As shown, a shear wall anti-rotting root angle steel plugging device, the device includes a positioning angle steel 1, a fixed support 2, an anti-seepage installation block 3 and an anti-seepage moving block 4, and the positioning angle steel 1 is fixedly connected to the bottom of the formwork by screws. The top of the fixed support 2 is fixed with a fixed angle steel 5, and the fixed angle steel 5 is arranged at the bottom of the positioning angle steel 1. The fixed angle steel 5 and the positioning angle steel 1 are detachably connected by bolts, and the fixed support 2 is fixed on the ground through anchor bolts. The fixed support 2 An anti-seepage installation block 3 is installed at the bottom of one side opposite to the shear wall. 4 is rotatably connected with an adjustment rod 6, and the end of the adjustment rod 6 away from the anti-seepage moving block 4 freely passes through the fixed support 2 and extends to the side of the fix...

Embodiment 2

[0035] A construction method of a shear wall anti-rot root angle steel plugging device, comprising the following steps:

[0036] A. The spring line at the root of the shear wall, chiseling, cleaning, and welding limit steel bars. The spring line at the root of the shear wall includes the wall position line and the control line 200mm away from the wall on both sides;

[0037] B. Binding and acceptance of the steel bars in the shear wall. The installation position of the steel bars is correct and the binding is firm. At this time, concrete supports should be installed;

[0038] C. The shear wall formwork is closed. The formwork must be firm, sealed, flat, and have sufficient strength, rigidity and stability. Steel nails are used to fix the positioning angle steel 1 and the formwork at the joints of the formwork;

[0039]D. Place the corner sealing device at the root of the shear wall, first install the anti-seepage installation block 3 on the side of the fixed support 2 facing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com