A car sliding door conversion mechanism

A conversion mechanism and sliding door technology, which is applied in vehicle locks, building structures, building locks, etc., can solve the problems of too simple, too simple connection, and impractical connection parts of the connection mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

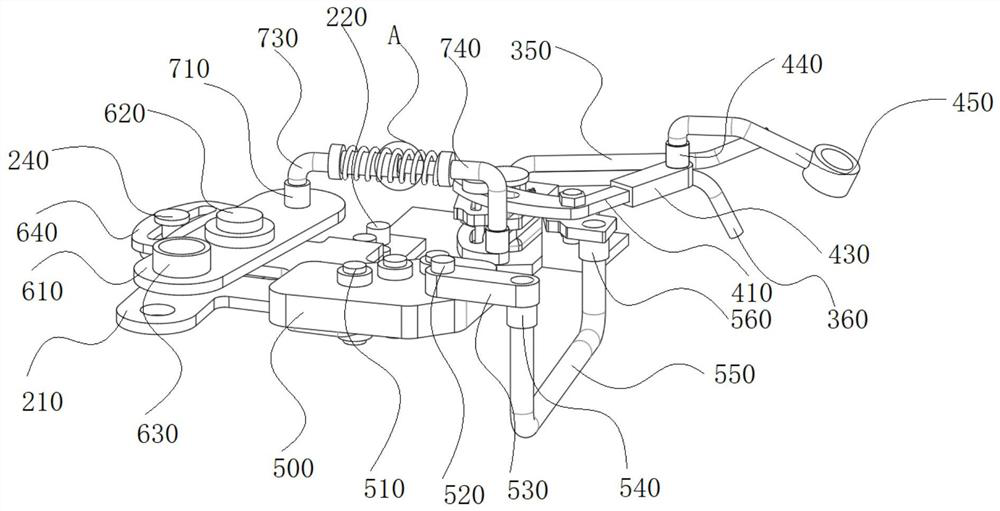

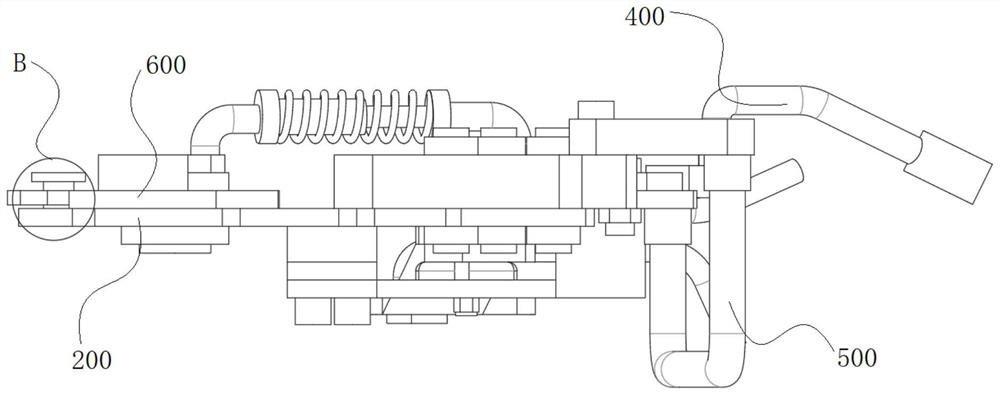

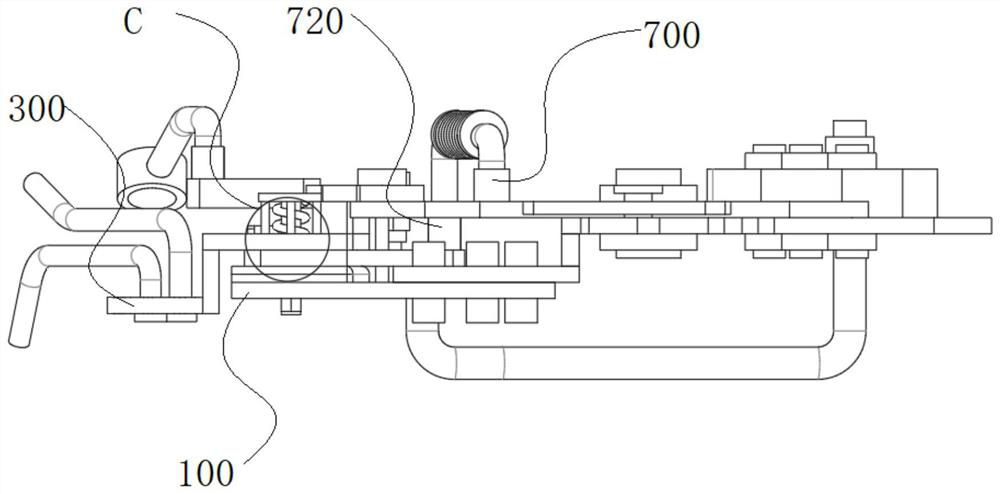

[0033] refer to figure 1-8, the present invention is a kind of automobile sliding door conversion mechanism, comprises conversion plate 100, support mechanism 200, opening mechanism 300, inner locking mechanism 400, stopper 500, opening transmission mechanism 600 and connecting mechanism 700, conversion plate 100 comprises The bottom plate 110, the cover plate 140 and the first connecting column 160, the support mechanism 200 includes a support plate 210 and a pillar 220, the bottom plate 110 and the support plate 210 are connected by three pillars 220, the opening mechanism 300 includes an opening rocker arm 310 and an opening linkage plate 320, the lower surface of the opening rocker arm 310 is connected to the upper surface of the bottom plate 110, one end of the four first connecting columns 160 is connected to the upper surface of the opening linkage plate 320, and the other ends of the four first connecting columns 160 are connected to the lower surface of the cover plate...

Embodiment 2

[0042] The working principle of the present invention is as follows: through holes of the same size are set inside the bottom plate 110, the opening rocker arm 310 and the opening linkage plate 320, the upright post 120 is set in the through hole, and the first spring 130 is set on the side of the upright post 120, so that To achieve the effect of compression and rebound, the first connecting column 160 is set between the opening linkage plate 320 and the cover plate 140, which can ensure that the opening rocker arm 310 and the opening linkage plate 320 are connected firmly, and the slider 340 and the card Sliding fit between the blocks 330 to achieve further stable connection between the opening rocker arm 310 and the opening linkage plate 320, the positioning ring 630 is mainly to increase the redundant connection parts, the positioning plate 640 is provided with a chute inside, and is arranged on the bracket 230 The sliding fit between the second positioning post 240 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com