Transmission structure of blind rivet gun

A technology of transmission structure and rivet gun, which is applied in the field of tools for fixing rivets, can solve problems such as inability to construct angled working surfaces, hidden dangers to the safety of operators, and influence on project quality, and achieve reliable performance, improved installation quality, and simple overall structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

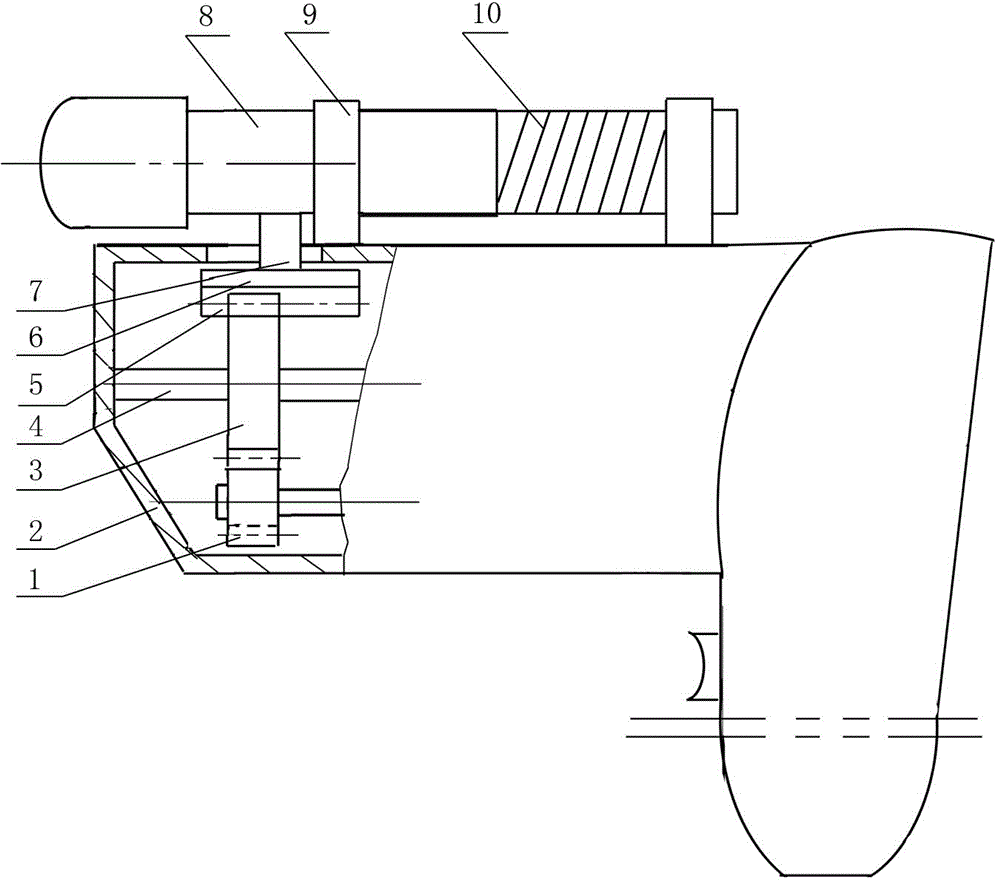

[0014] like figure 1 The transmission structure of a blind riveting gun of the present invention is shown, including: reduction gear 1, outer shell 2, large gear 3, long shaft 4, transmission rack 5, connecting pulley 6, short shaft 7, and push rod of the riveting gun 8, fixed frame 9, spring 10. The outer casing 2 is provided with a major axis 4; the major axis 4 is provided with a large gear 3 meshed with the reduction gear 1; Shaft 7; the large gear 3 meshes with the transmission rack 5 fixed on the connecting puller 6, and the rivet gun push rod 8 between the two fixed brackets 9 of the fixed riveter push rod 8 A spring 10 is provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com