Automatic hand riveter and automatic hand riveting nut assembling machine

A riveting nut and riveting gun technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of manual assembly that cannot guarantee quality and high labor costs, achieve assembly speed blocks, reduce labor costs, and failure rates. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

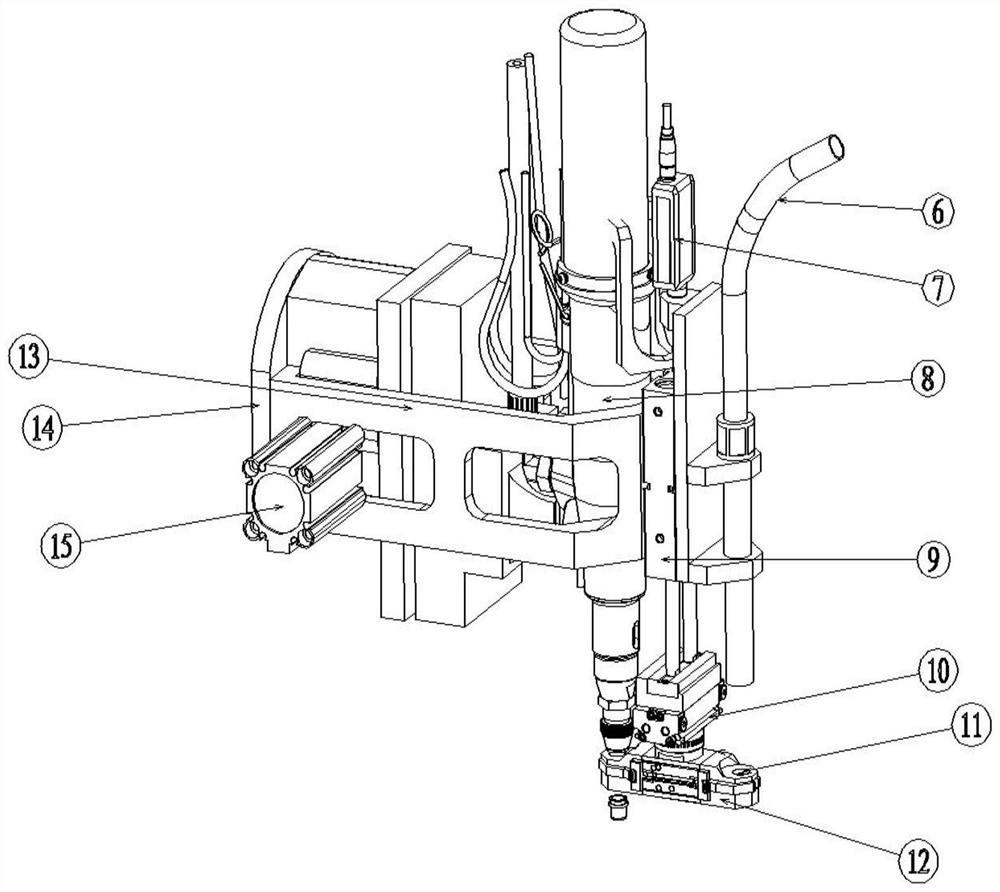

[0025] Such as figure 1 As shown, the automatic riveting gun according to the embodiment of the present invention includes a pulling installation frame, a blanking pipe 6 and a riveting gun body 8, and the blanking pipe 6 extends vertically and is fixedly connected to the mounting frame , the riveting gun body 8 extends in the vertical direction and is fixedly connected to the installation frame, and also includes a first structure for rotating the rivet from the blanking pipe 6 to the riveting gun body 8 and for A second structure for locking the riveting gun on the mounting frame. Specifically, the pressure sensor and the displacement sensor can be electrically connected to the rivet gun body 8. The present invention adopts a fully automatic robot mode, which automatically loads nuts and automatically rivets, completely replaces manual work, improves production efficiency and production quality, and greatly reduces manual labor. It is the only choice in the field of intelli...

Embodiment 2

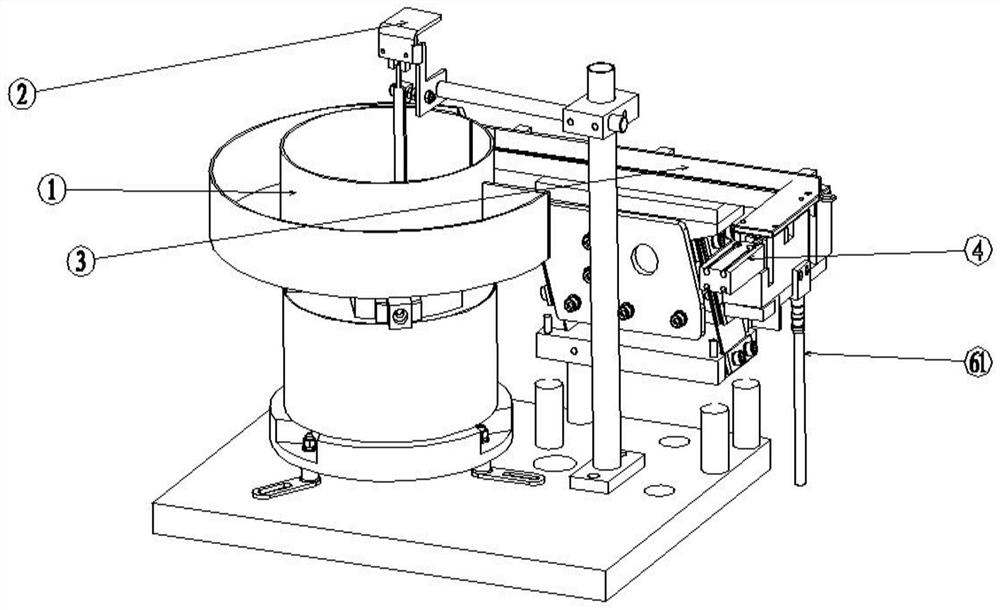

[0031] Such as figure 2 As shown, the difference between the embodiment of the present invention and embodiment 1 is that this embodiment also discloses an automatic rivet nut assembly machine, including an automatic rivet gun and an automatic feeding structure, and the automatic rivet gun is the one described in embodiment 1. An automatic riveting gun, the automatic riveting gun is connected to the automatic feeding structure through the blanking pipe 6 .

[0032] Specifically, it includes a vibrating plate 1, a linear track 3, a material distribution cylinder 4 and a feeding pipe 61. Set at one end, the distribution cylinder 4 is used to open or close the linear track 3, one end of the feeding pipe 61 communicates with the linear track 3, and the other end of the feeding pipe 61 communicates with the discharge pipe 6.

[0033] It is easy to understand that a video unit 2 can be installed on the vibrating plate 1 to detect material shortage, so as to stop the vibrating pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com