Hand riveter with tension detection function

A technology of tension detection and riveting gun, which is applied in the field of riveting guns, can solve the problems of insufficient installation, time spent more than ten minutes, and the installation of tail teeth being damaged, so as to achieve accurate and instant tension monitoring and improve quality and efficiency, the effect of compact structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below with reference to the embodiments and the accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention. The present invention will be described in detail below with reference to the accompanying drawings.

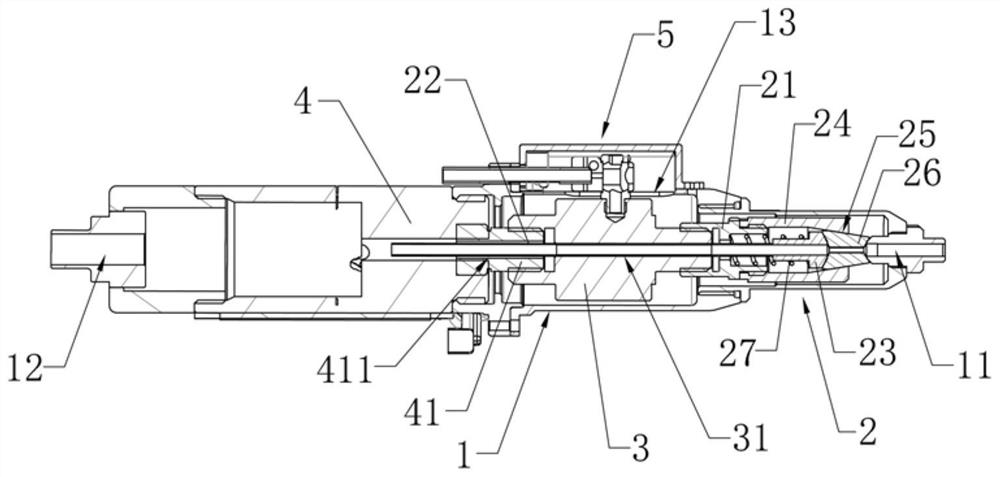

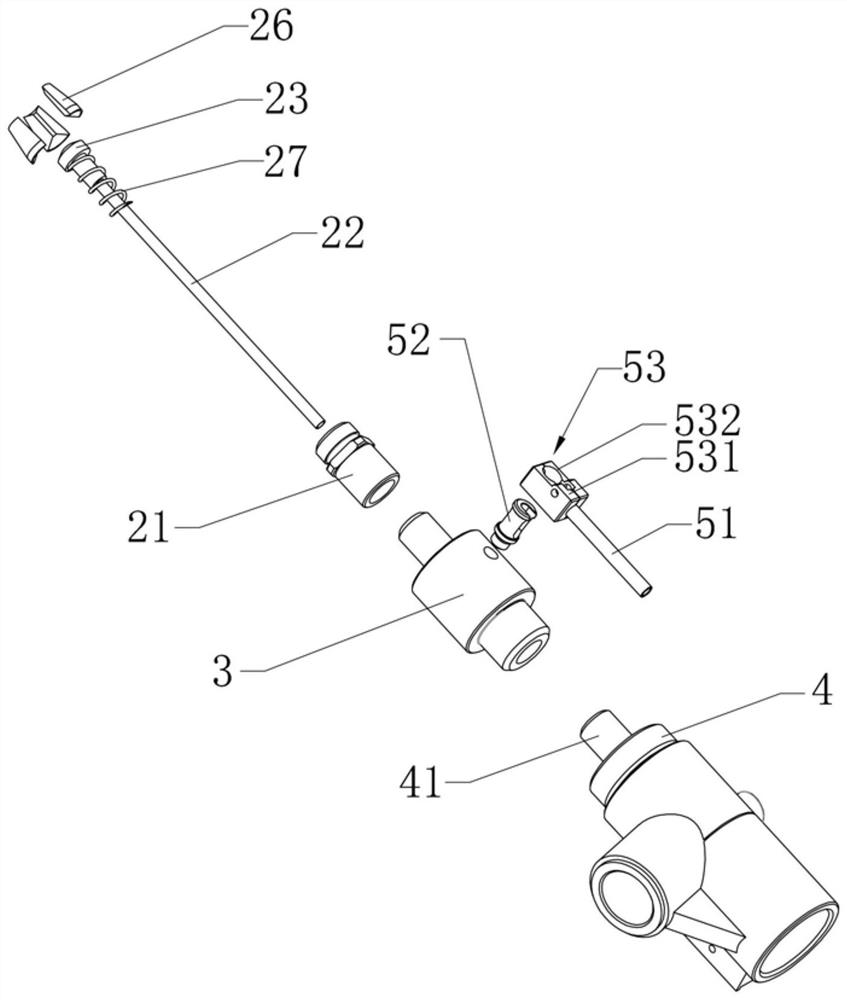

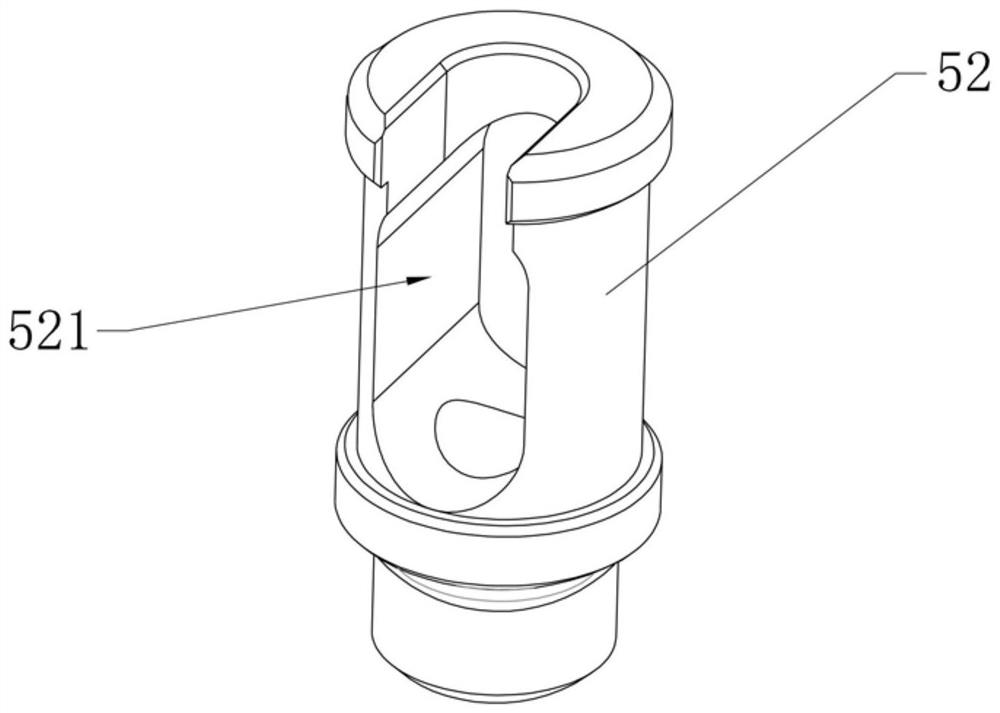

[0026] like Figure 1 to Figure 5 As shown, the present invention provides a pull riveting gun with a tension detection function, which includes a gun body 1, a nail clamping mechanism 2, a tension detector 3 and a driving mechanism 4, and one end of the gun body 1 is provided with a muzzle 11 , the nail clamping mechanism 2, the tension detector 3 and the drive mechanism 4 are arranged in sequence along the direction of the gun body 1 away from the muzzle 11; the drive mechanism 4 is provided with a telescopic rod 41, and one end of the tension detector 3 is connected to the The nail clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com