Patents

Literature

32results about How to "Accurate pull" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

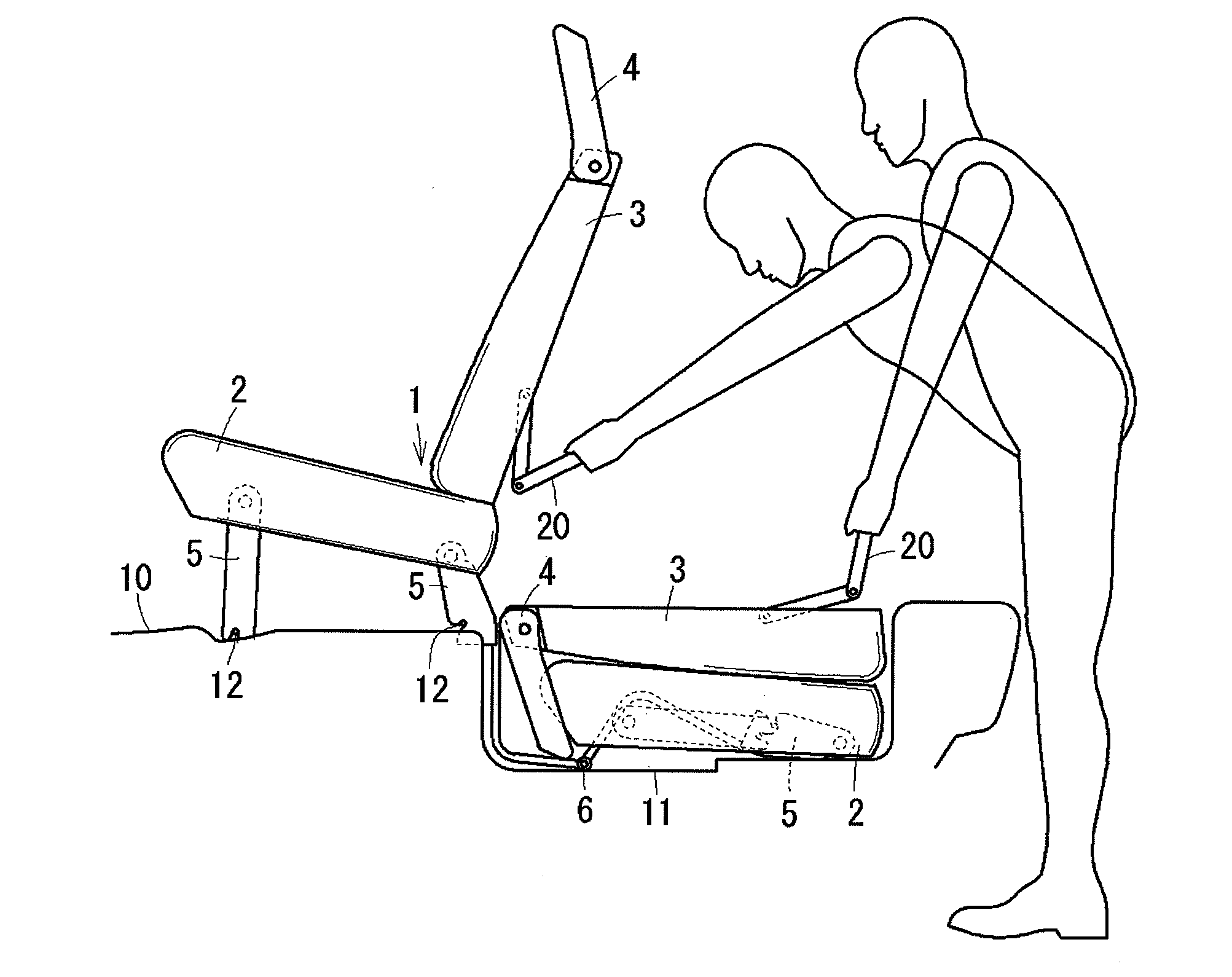

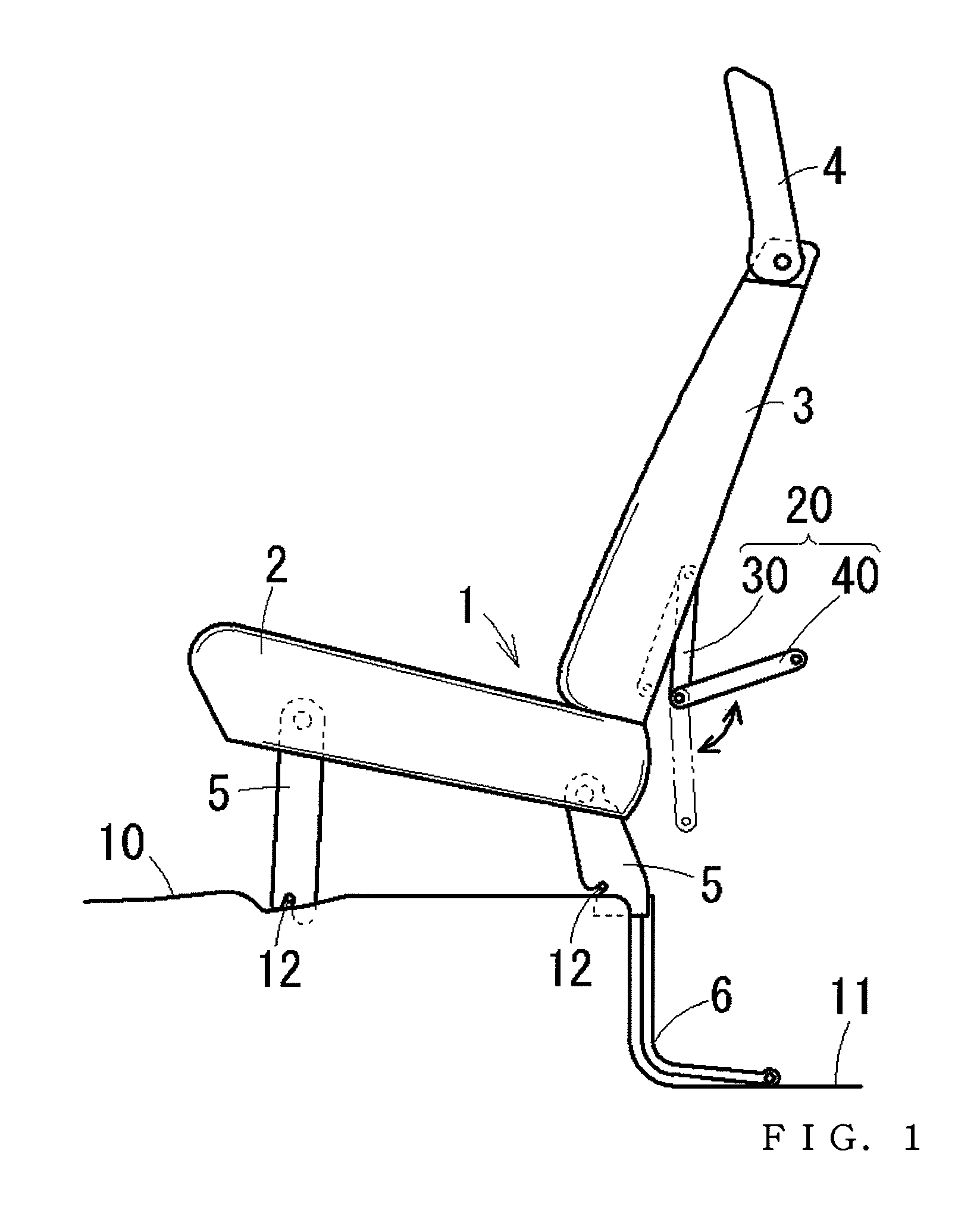

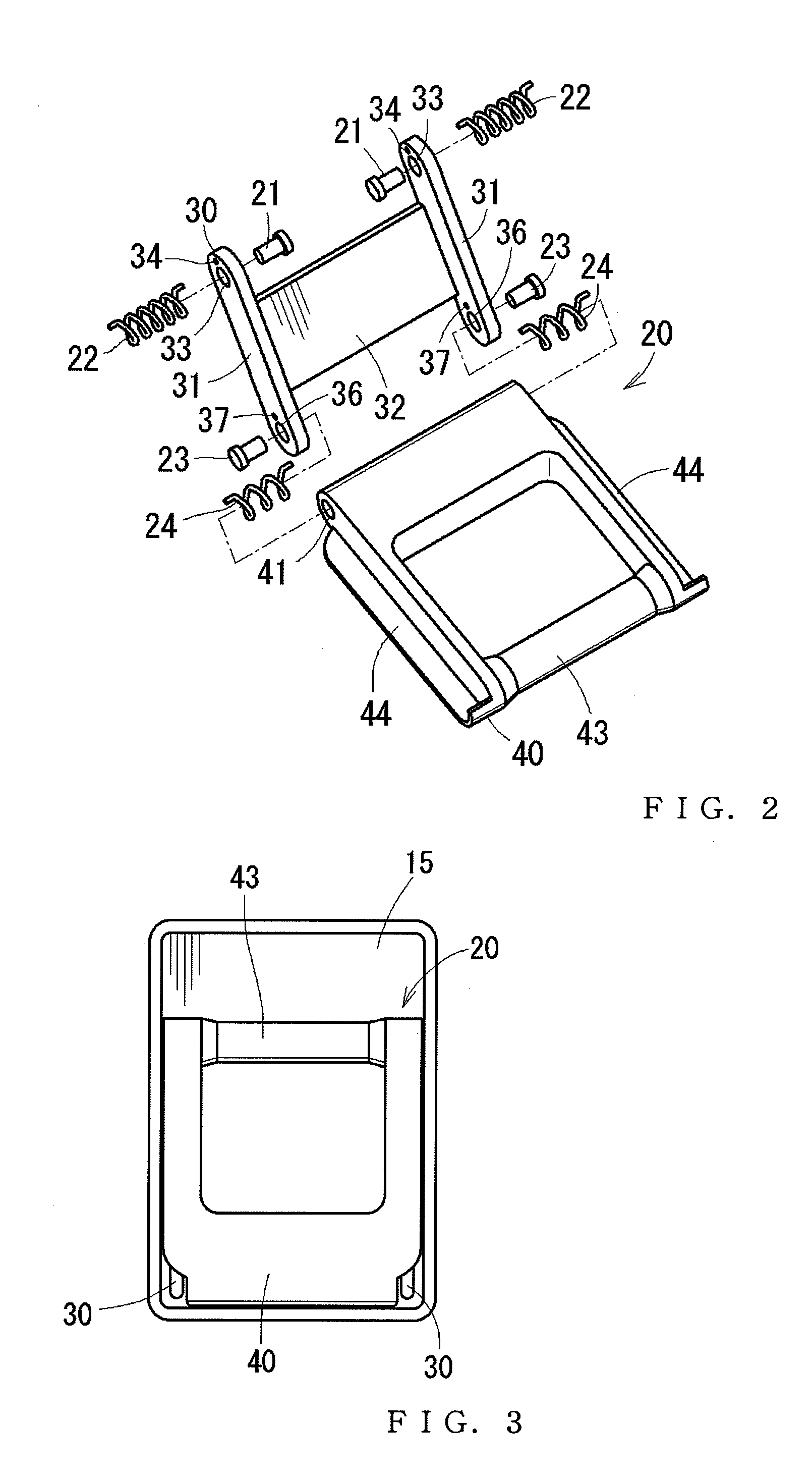

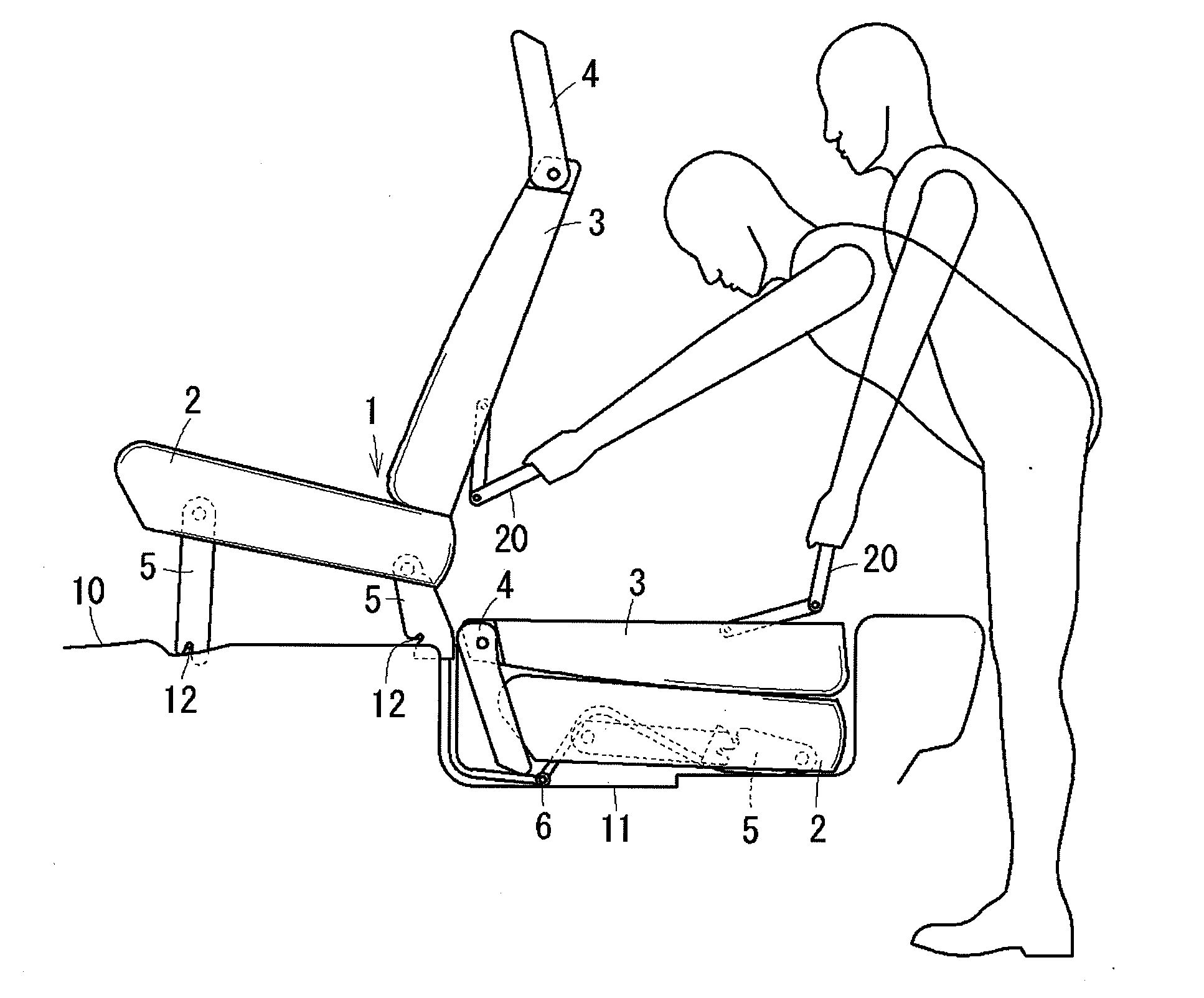

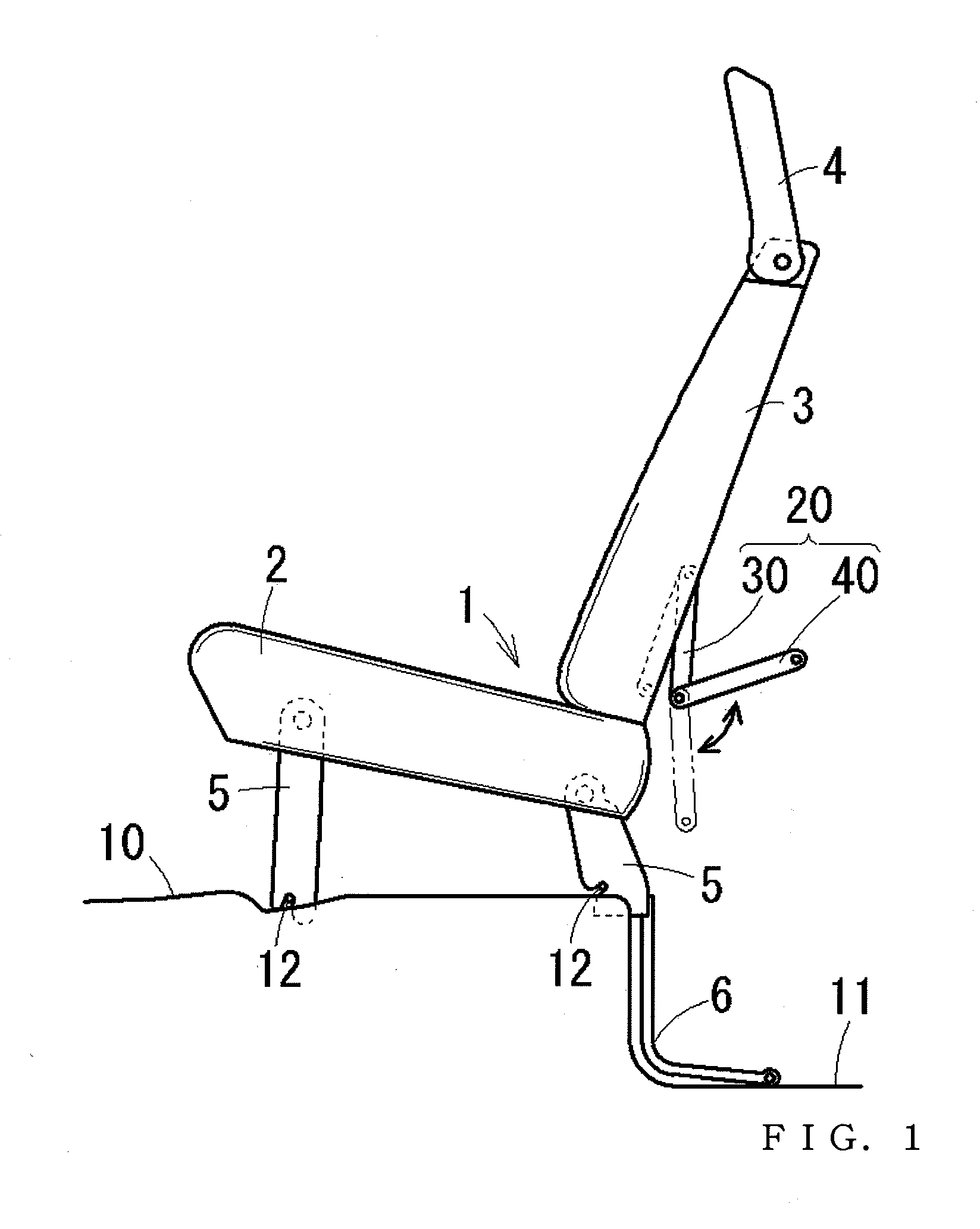

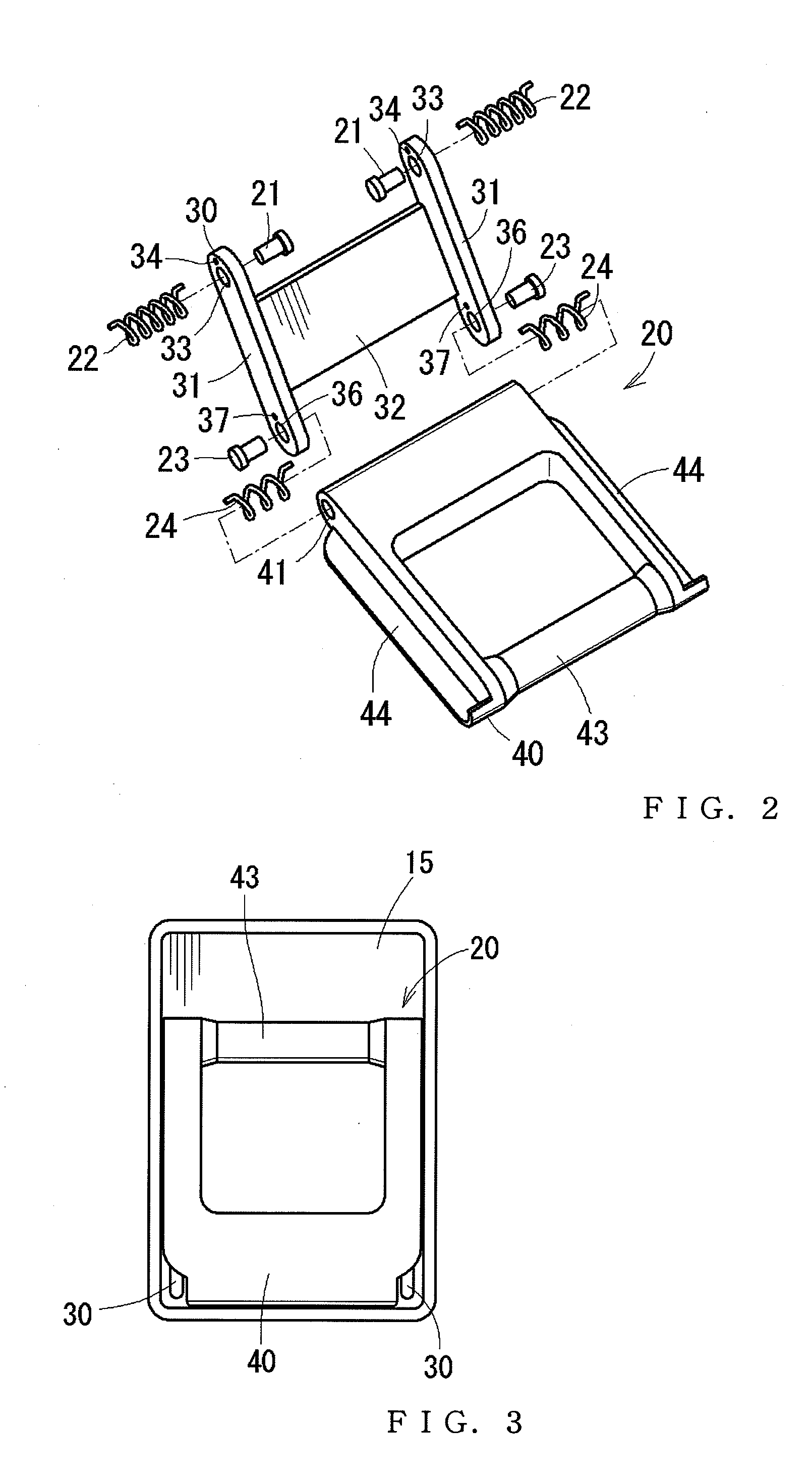

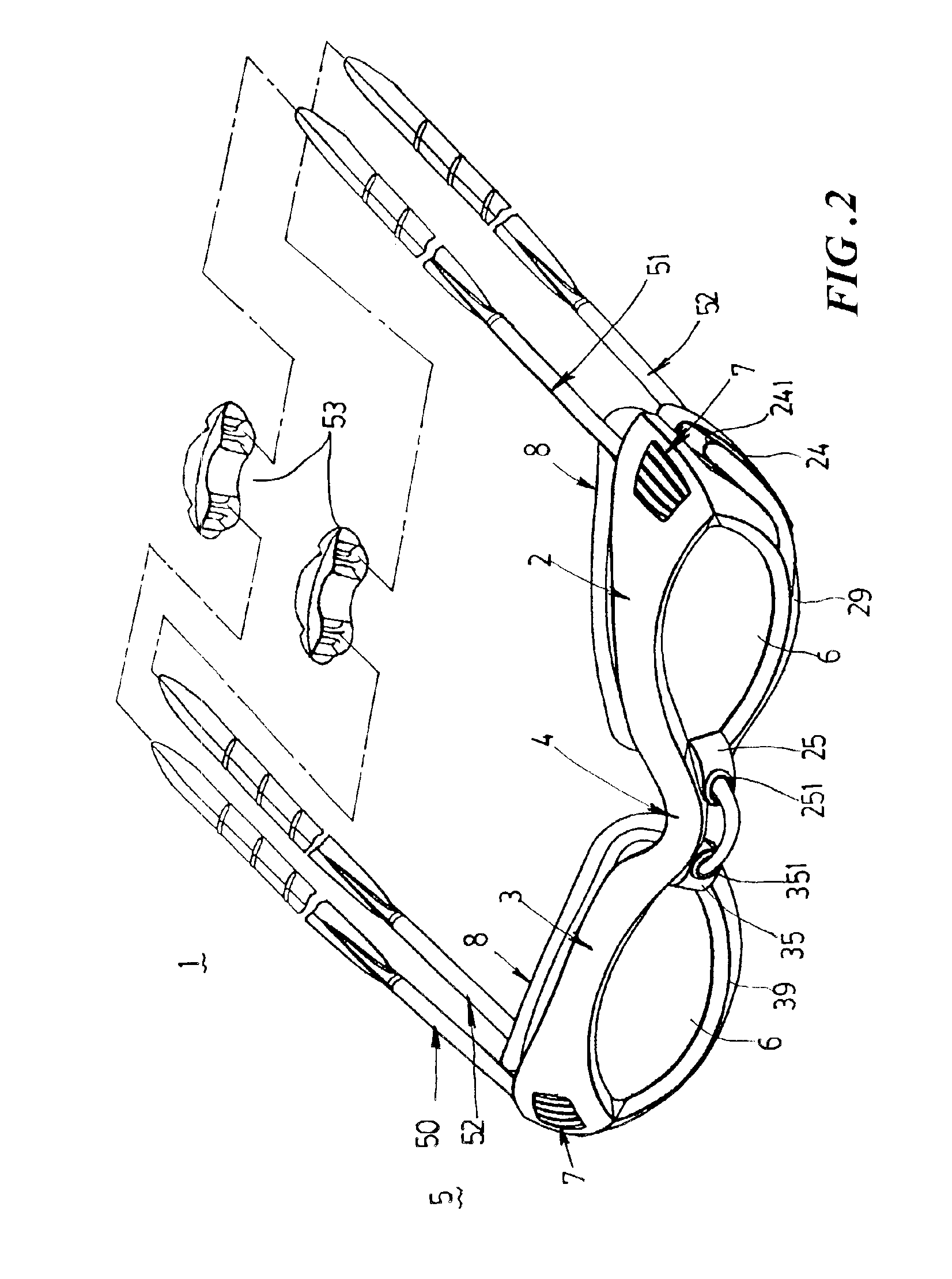

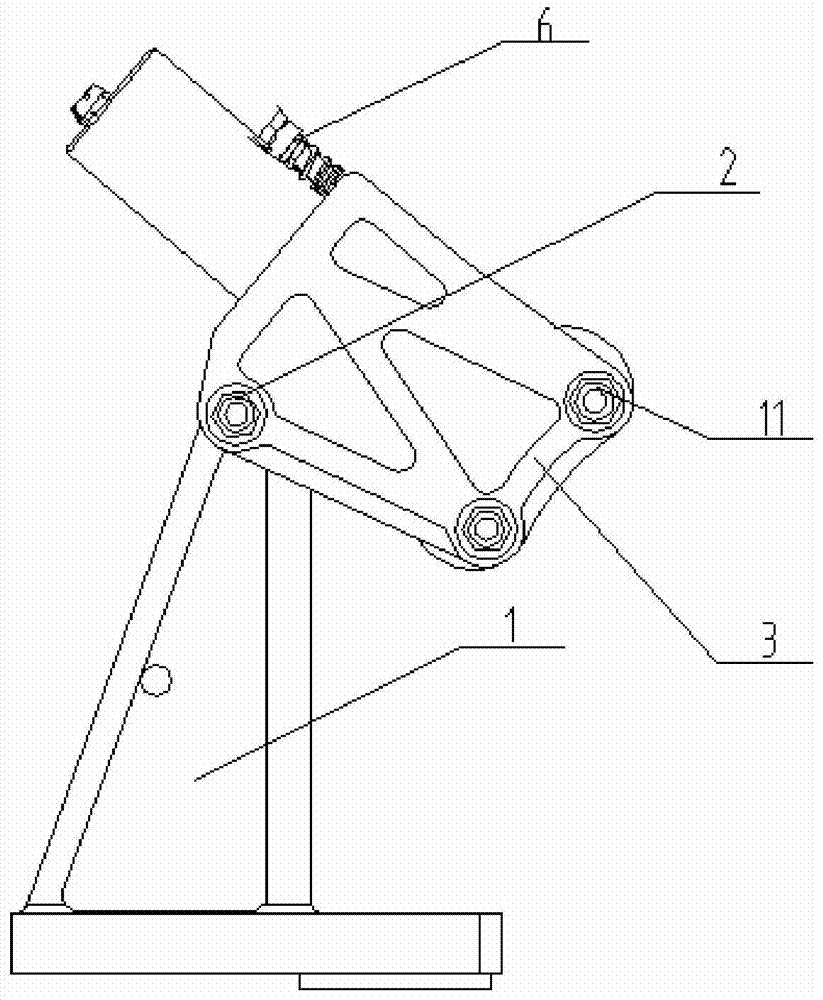

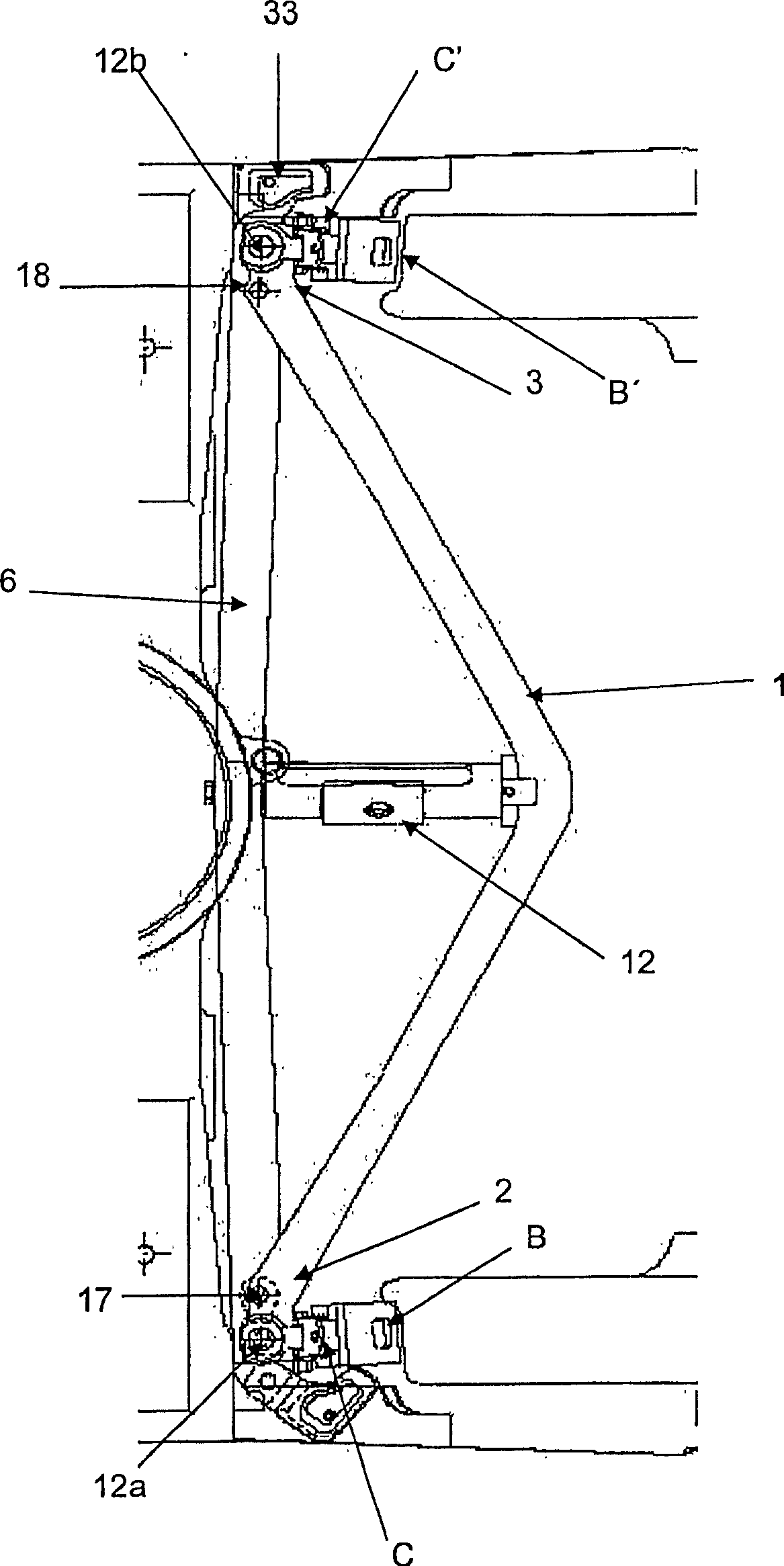

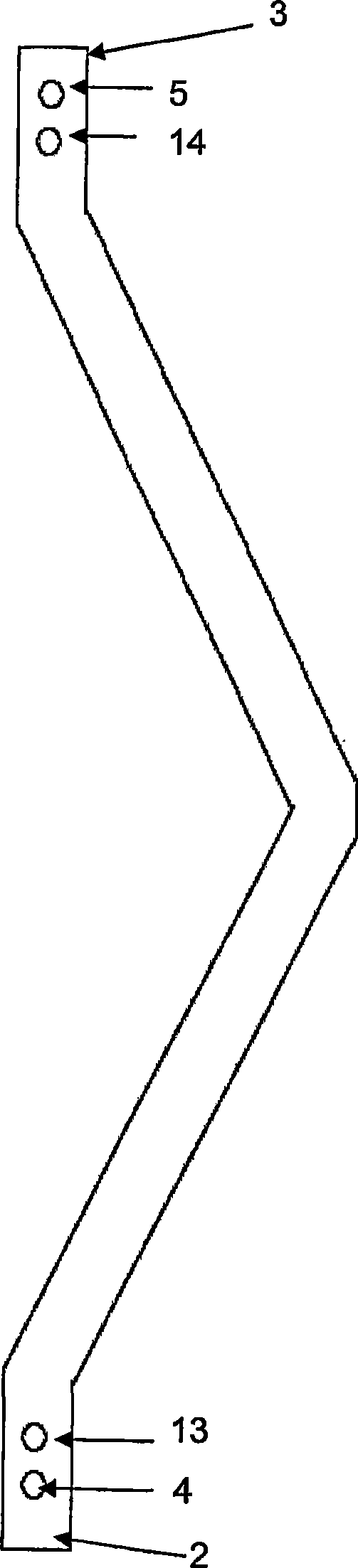

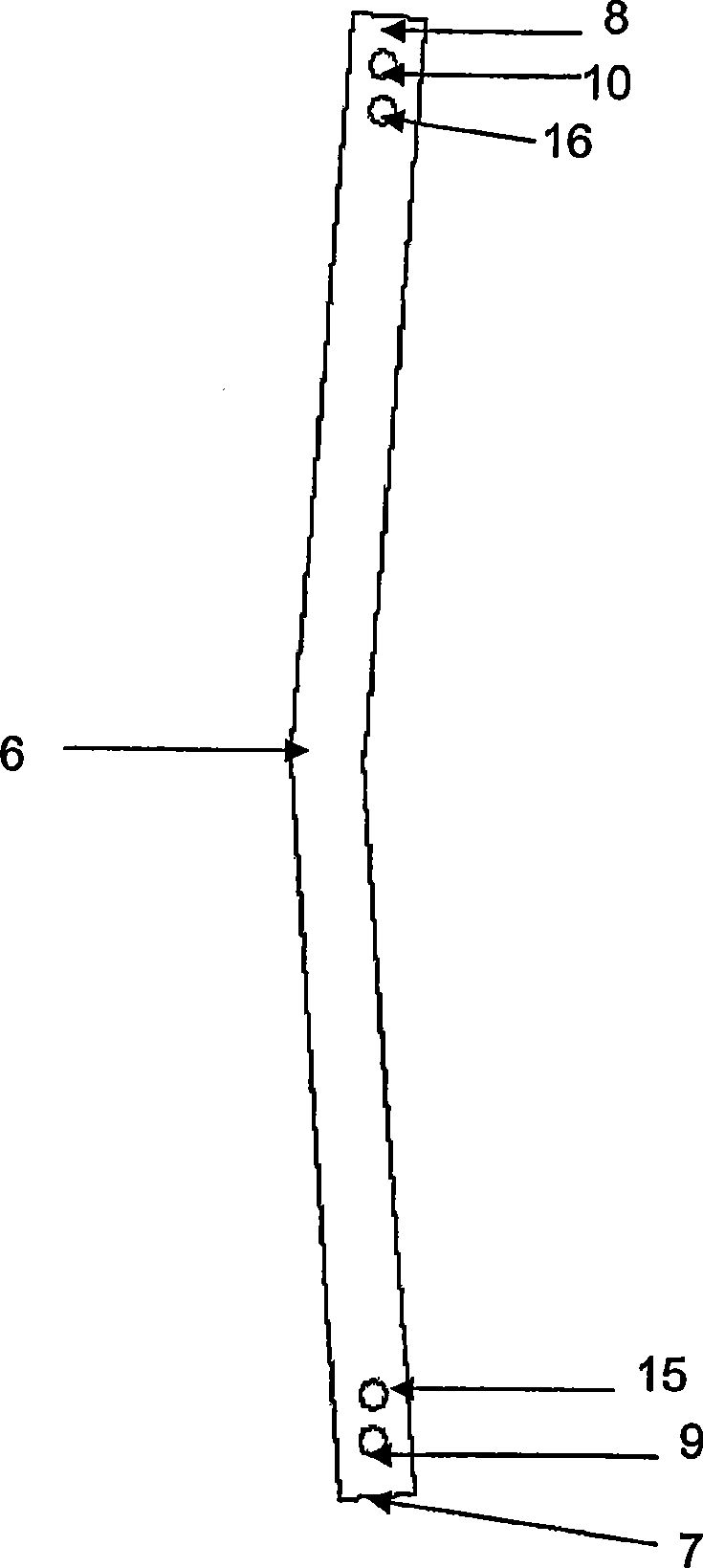

Operating lever of vehicular seat

InactiveUS8038206B2Easy to operateDegree of avoidanceWall stoolsOperating chairsCushionElectrical and Electronics engineering

An operating lever is provided at one of a front face, an upper face, and a back face of a seat including a seat cushion and a seat back. The operating lever may include a first lever having a first end and a second end, and a second lever having a first end and a second end. The second end of the first lever and the first end of the second lever may be pivotably connected to each other, and the first end of the first lever may be pivotably connected to the seat such that the first lever is configured to change an attitude of the seat. In addition, the second end of the second lever may be formed as an operating portion, and when the operating portion is operated in a direction away from the seat, the first lever and the second lever pivot may away from the seat and the attitude of the seat is adjusted.

Owner:TOYOTA BOSHOKU KK +1

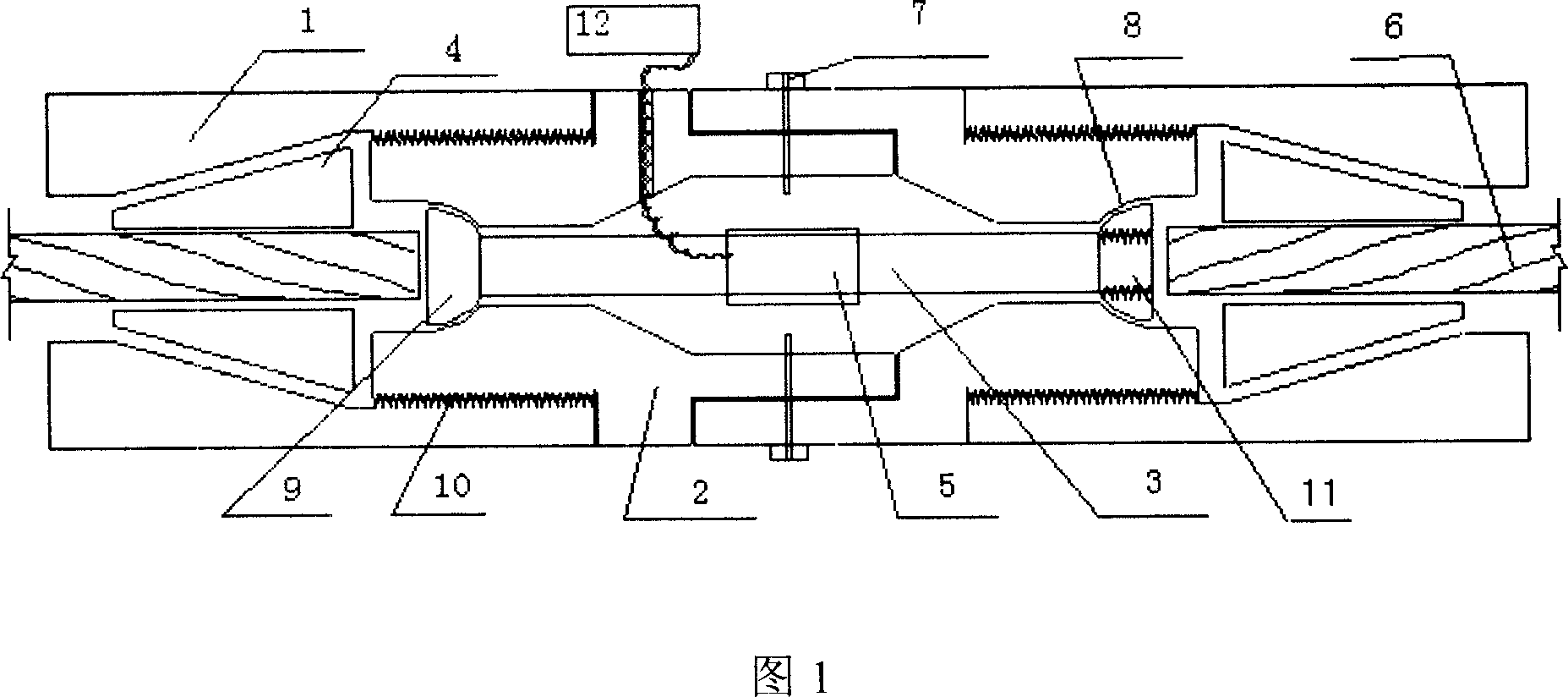

Steel twisted-line tension-force measuring device

InactiveCN1979108AImprove anchoring efficiencyAccurate tensionTension measurementStrain gaugeEngineering

Owner:SOUTH CHINA UNIV OF TECH

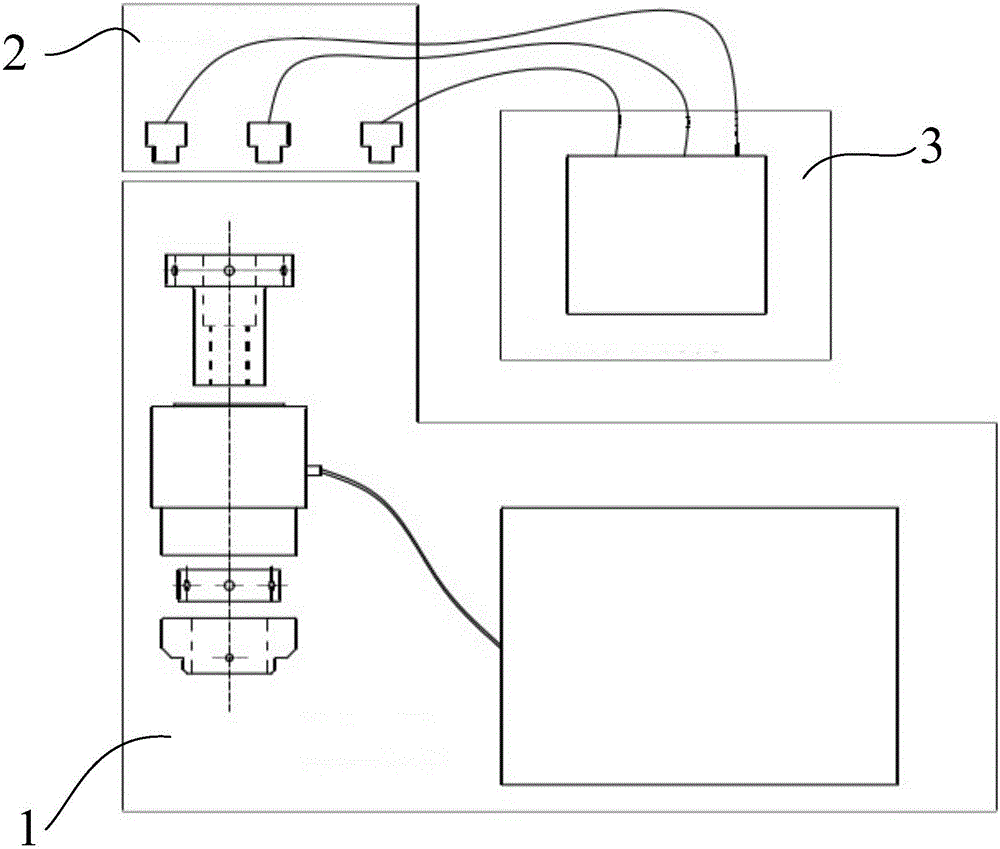

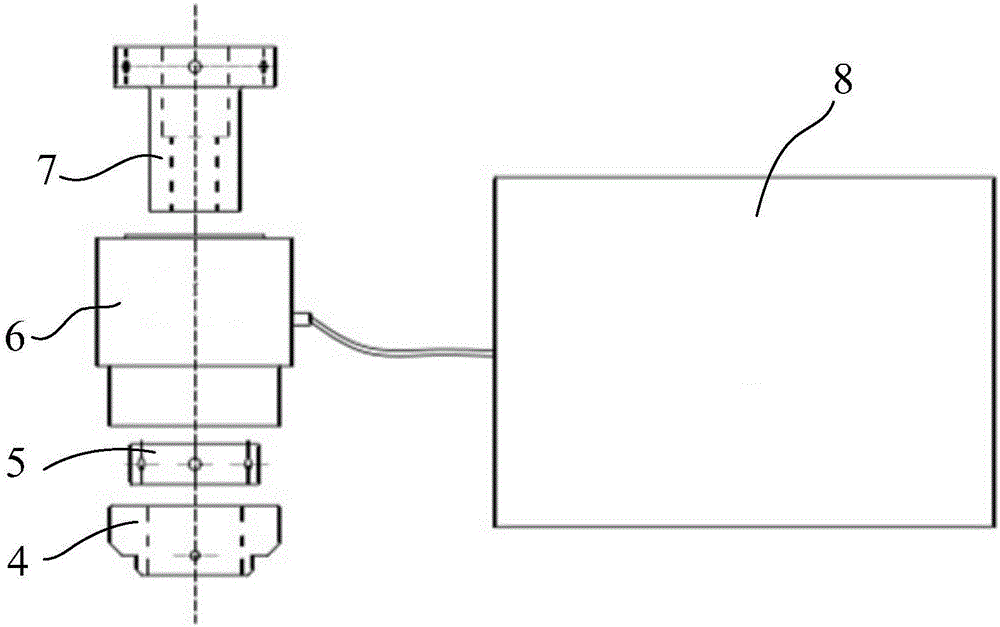

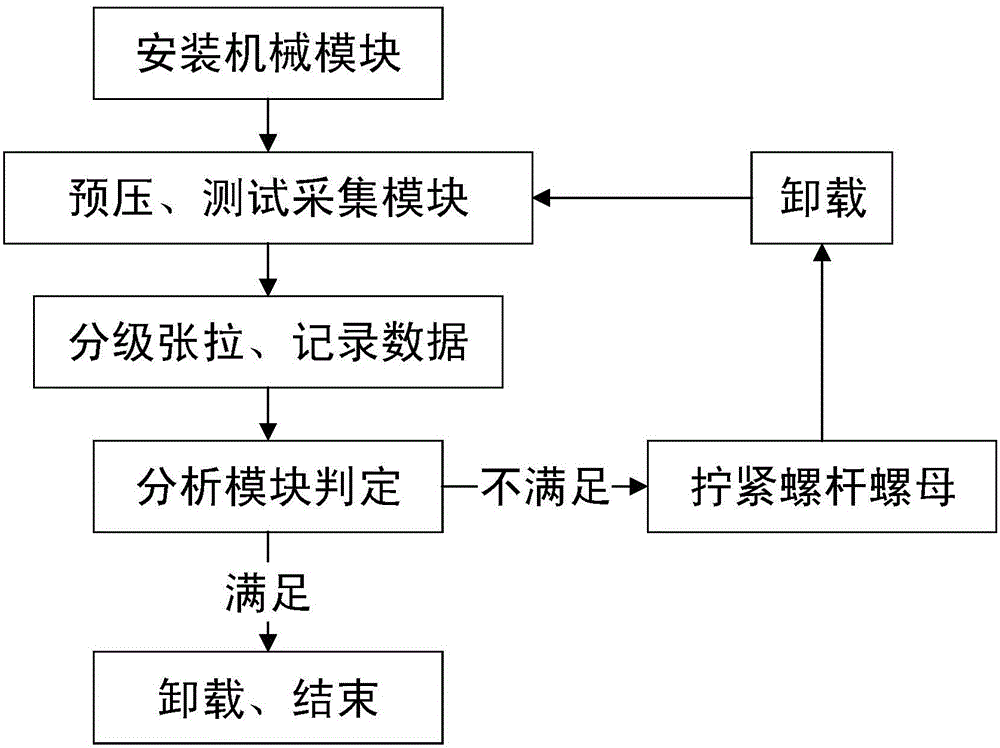

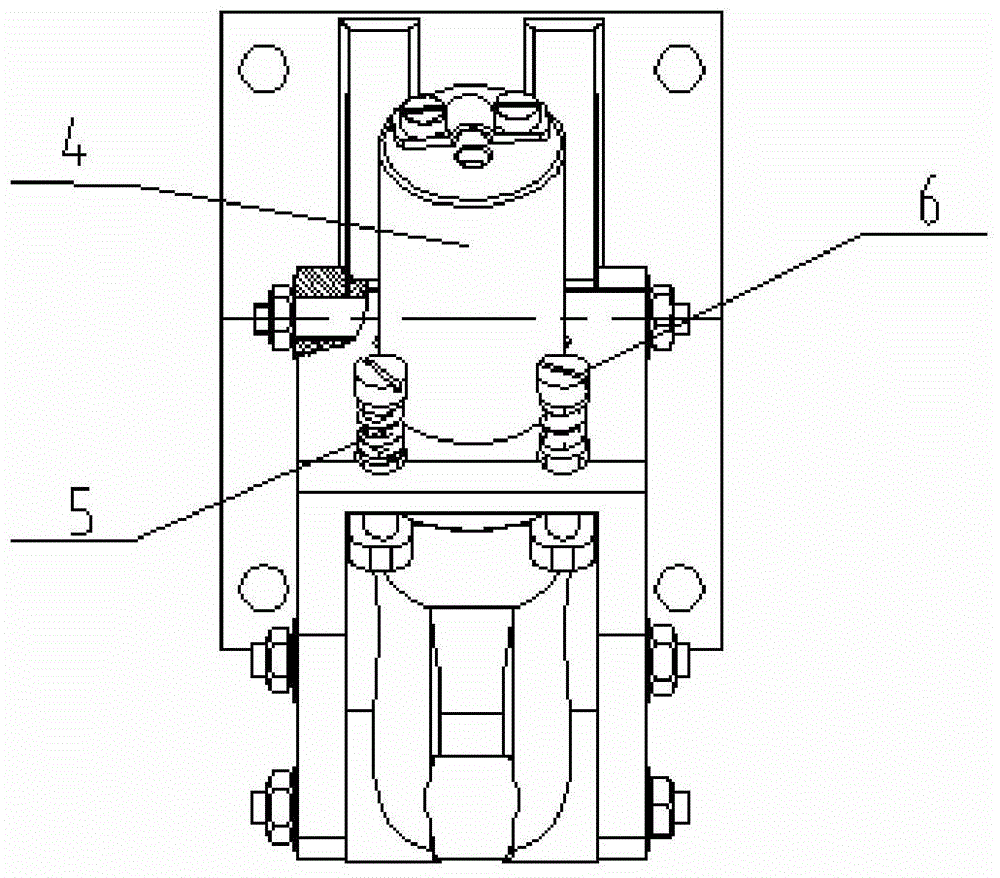

Tensioning instrument for screw detection and application thereof

InactiveCN105865688AAccurately reflect the pulling forceSpread fastApparatus for force/torque/work measurementEngineeringFlight time

The invention discloses a tensioning instrument for screw detection and application thereof. The tensioning instrument comprises a mechanical module, a data collection module and a data analysis module; the mechanical module is used for tensioning a screw and adjusting the tightness degree of a nut; the data collection module is used for collecting pressure, ultrasonic flight time and temperature data which are generated when the mechanical module tensions the screw; the data analysis module is used for receiving the data collected by the data collection module and generating a length-tensile force relation curve of the screw. By using the tensioning instrument, current pre-tightening force of the screw can be accurately and conveniently tested out, and a basis is provided for determining whether tensioning supplementing is needed or not subsequently; meanwhile, after tensioning supplementing of tensile force of the screw is completed, the tensioning supplementing effect can be assessed according to a testing result.

Owner:CCCC HIGHWAY CONSULTANTS

Operating lever of vehicular seat

One aspect of the present invention can include an operating lever of a vehicular seat provided at a front face, an upper face, or a back face of a seat, including a seat cushion and a seat back, and a first lever and a second lever. The first lever and the second lever are axially supported pivotably to each other on one end sides in length directions. An other end side in the length direction of the first lever is axially supported pivotably to the seat and is connected to a lock mechanism capable of changing a state of an attitude of the seat. The other end side in the length direction of the second lever is formed as an operating portion. The attitude of the seat can be operated while bending the first lever in two stages around axial shafts on sides of both ends in the length direction of the first lever by operating an operating portion of the second lever in a direction of being remote from the seat.

Owner:TOYOTA BOSHOKU KK +1

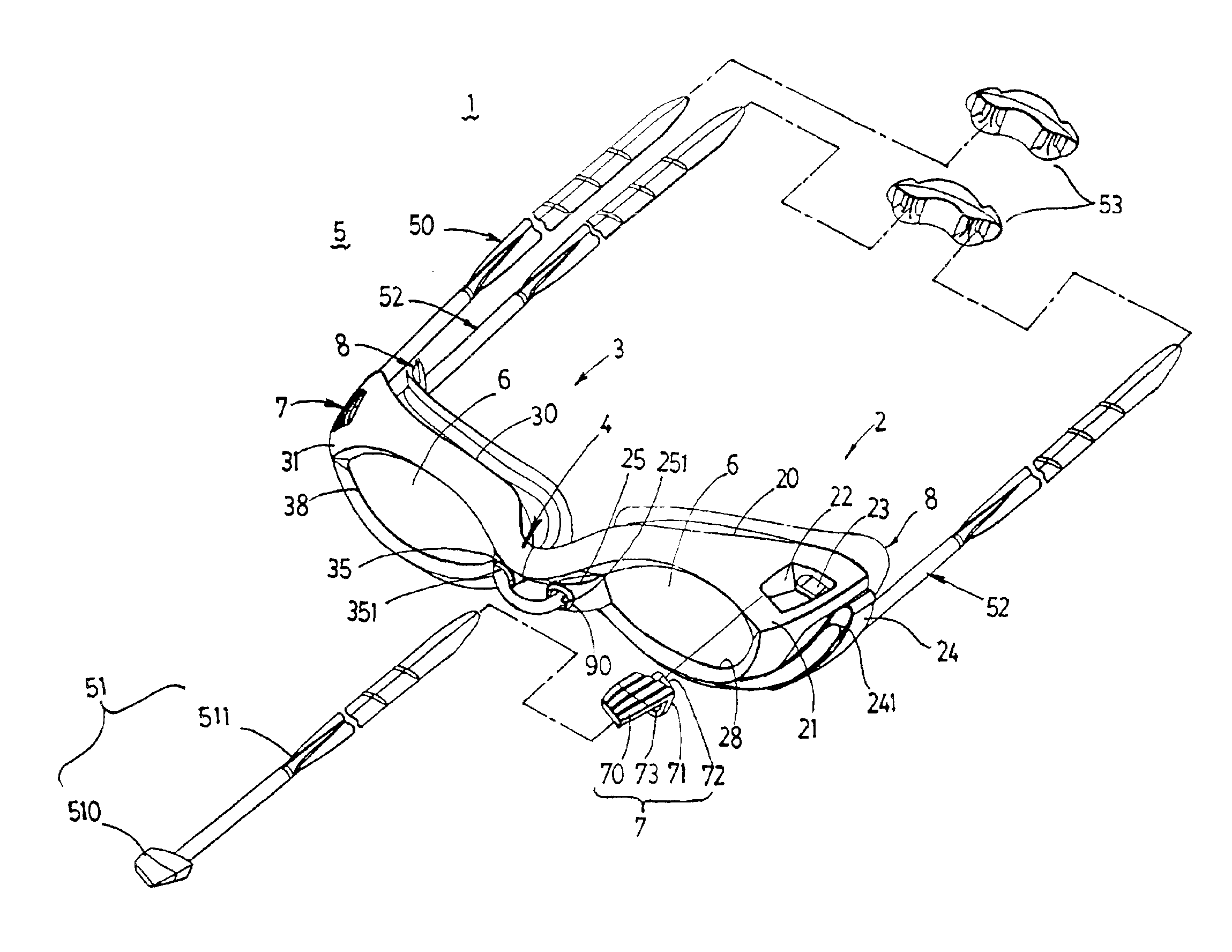

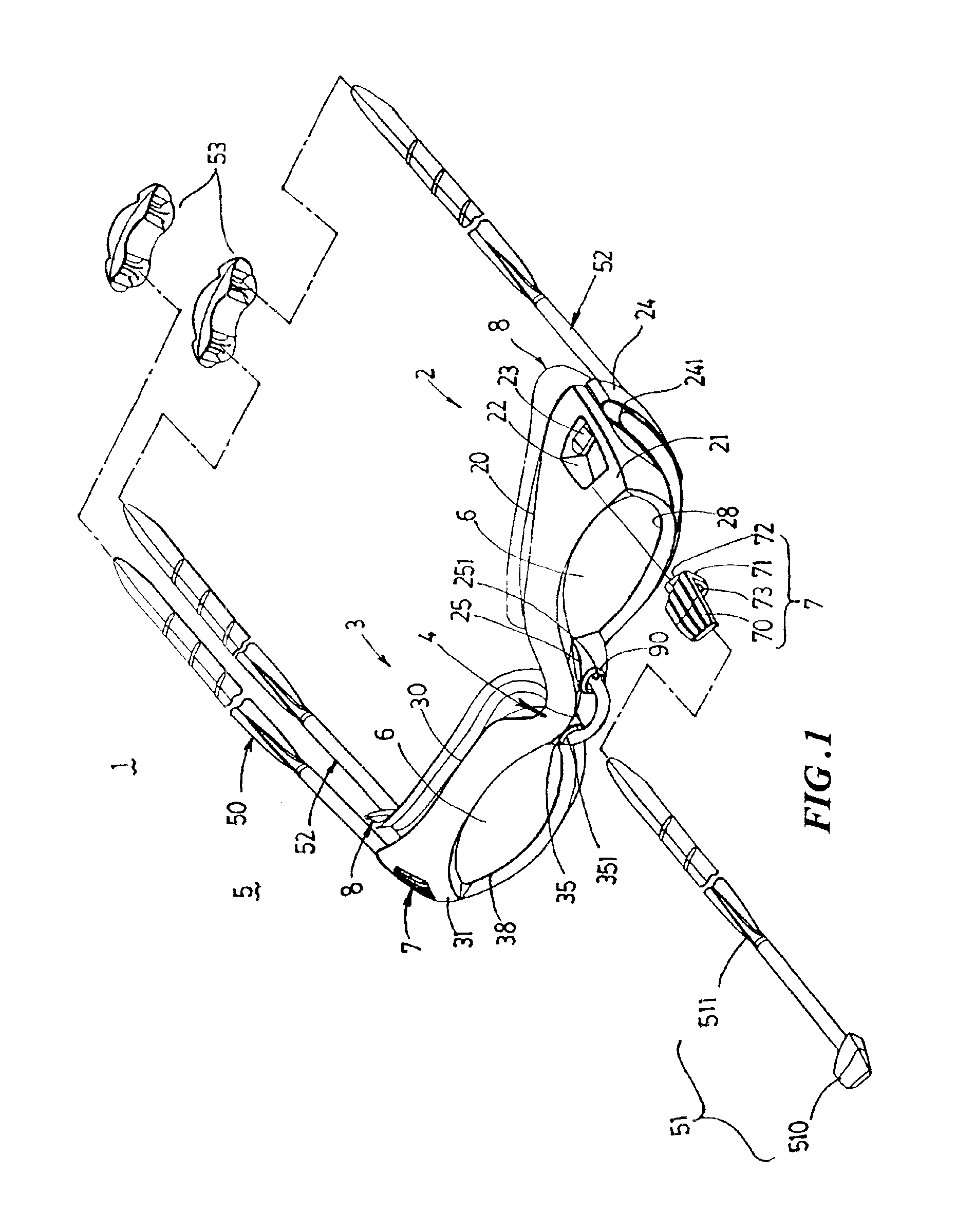

Swimming goggles

A pair of swimming goggles of the present invention comprises a pair of left and right lens frames which respectively include an outer surface and an inner surface and receive a pair of lenses, a bridge member disposed at the upper edges of the inner sides of the left and right lens frames, and a head strap means disposed at the outer sides of the left and right lens frames. The feature of the present invention is that the head strap means at least includes a first thread, a second thread, and a pair of adjustment fasteners disposed at the first and second threads, wherein the first thread is disposed at the upper position of the outer sides of the left and right frames, and the second thread is disposed at the lower position of the outer sides of the left and right frames. Thus, the adjustment fasteners properly adjust the first and second threads thereby providing different application lengths for the first and second threads and providing a desired pull force such that the upper and lower edges of the lens frames are adjusted to comfortably contact with the periphery of the eye holes and a desired refraction effect of the lenses in water is achieved.

Owner:CHIANG HERMAN

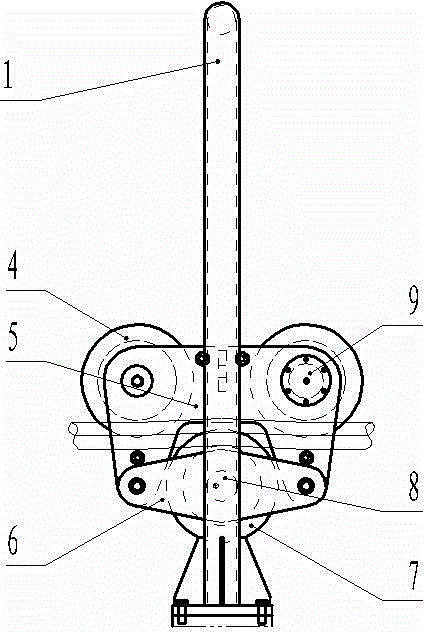

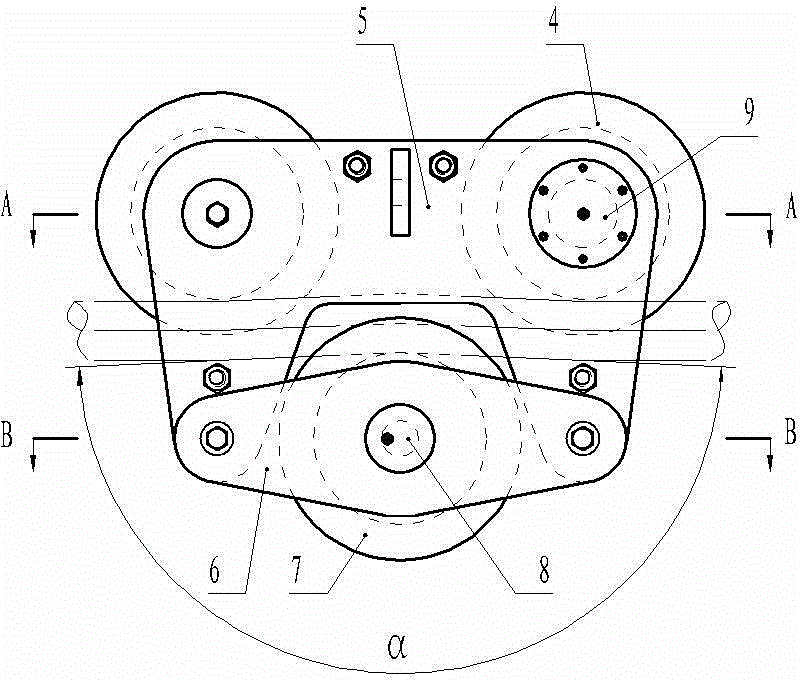

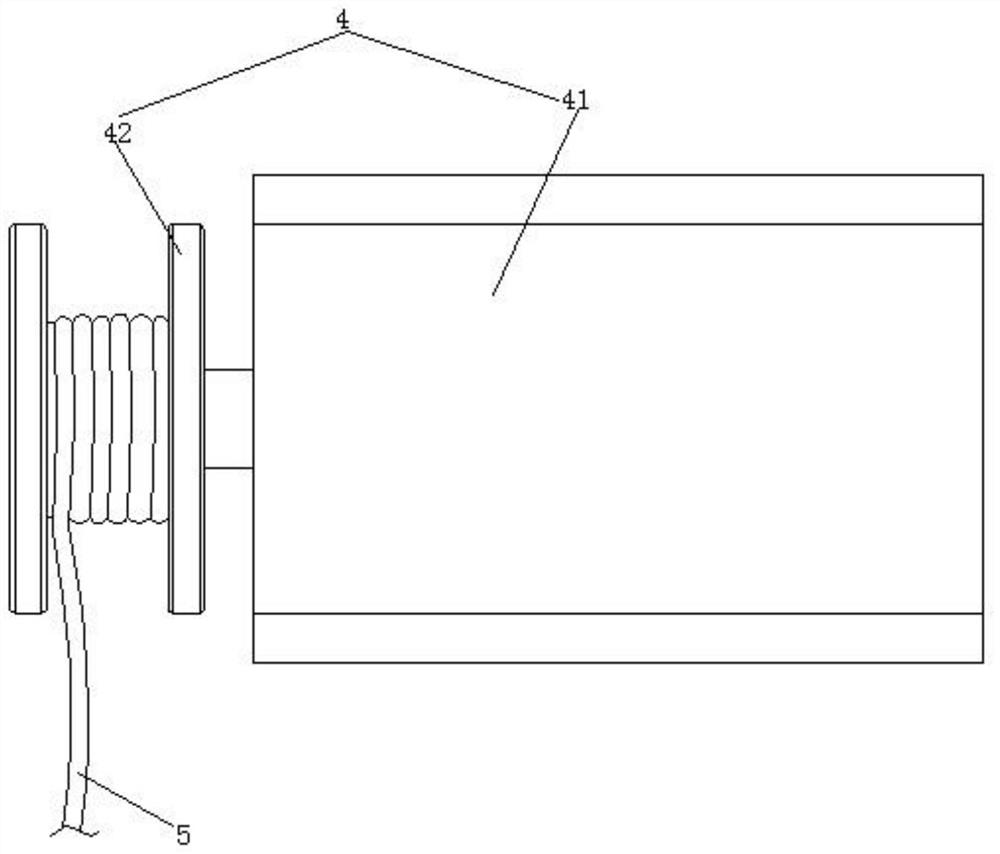

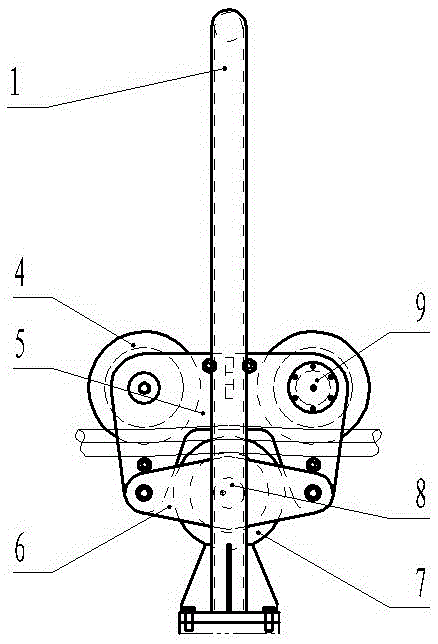

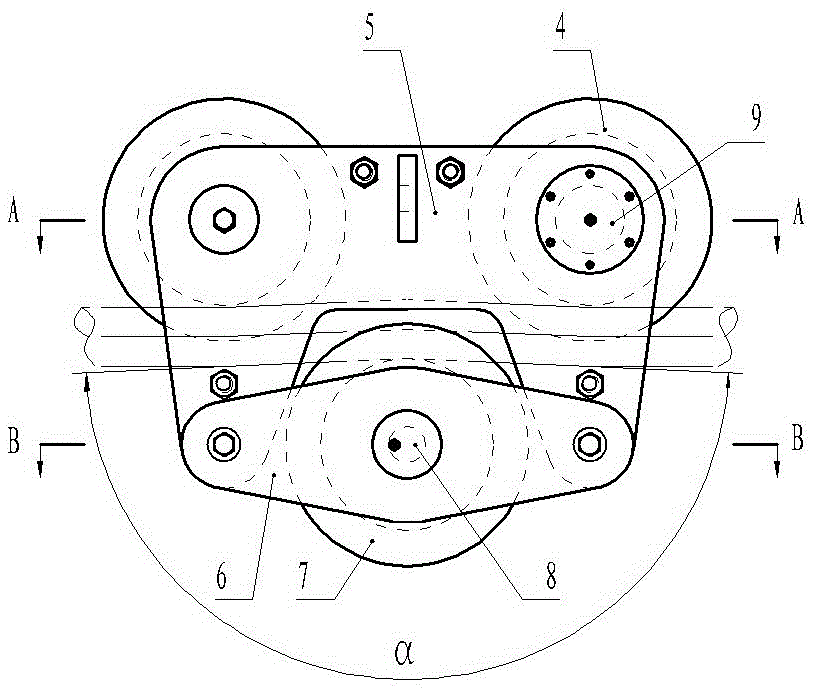

Flexible-installation force and speed measuring device

ActiveCN104614110ACompact structureWork reliablyLinear/angular speed measurementApparatus for force/torque/work measurementMicrocomputerPull force

The invention discloses a flexible-installation force and speed measuring device and relates to the technical field of cable tension and speed detecting devices of winches. The flexible-installation force and speed measuring device comprises a pulley block suspended on a fixing support through cables; the pulley block comprises a force measuring pulley and two speed measuring pulleys, which are mounted on a support rack through a force measuring hinge pin and speed measuring hinge pins respectively, wherein the force measuring pulley is arranged under the two speed measuring pulleys; winch cable passages at a wrap angle of alpha from the force measuring pulley are formed between the two speed measuring pulleys and the force measuring pulley; one of the speed measuring hinge pins is provided with a speed measuring rotary encoder, a stress sensor is arranged inside the force measuring hinge pin, and the speed measuring rotary encoder and the stress sensor are electrically connected with a microcomputer processor. Compared with the prior art, the force measuring pulley and the two speed measuring pulleys can achieve automatic adjustment to adapt to continuous change in output angles and the number of layers of the cable, and monitored tension and cable speed data can be more direct and more accurate.

Owner:SOUTH CHINA MARINE MACHINERY

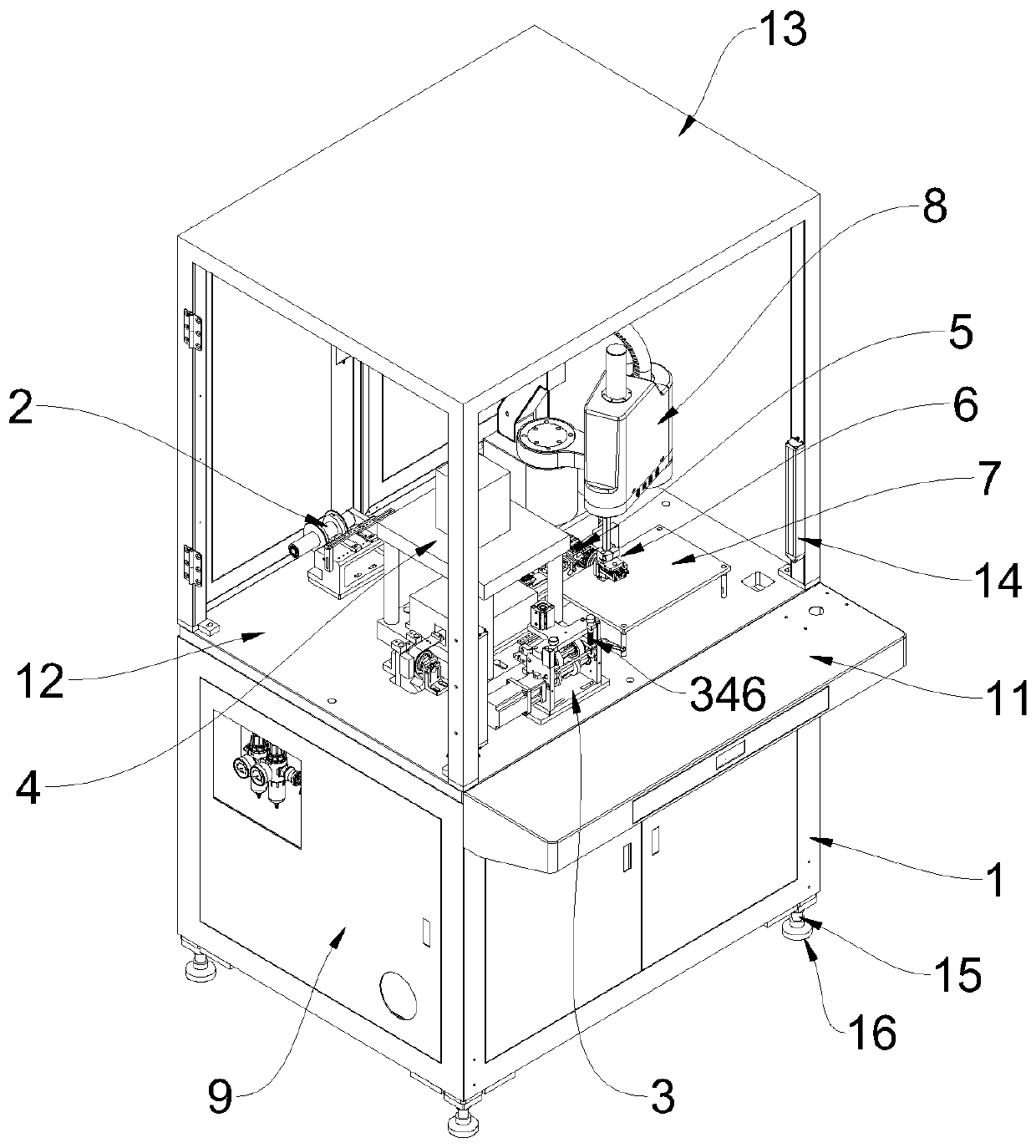

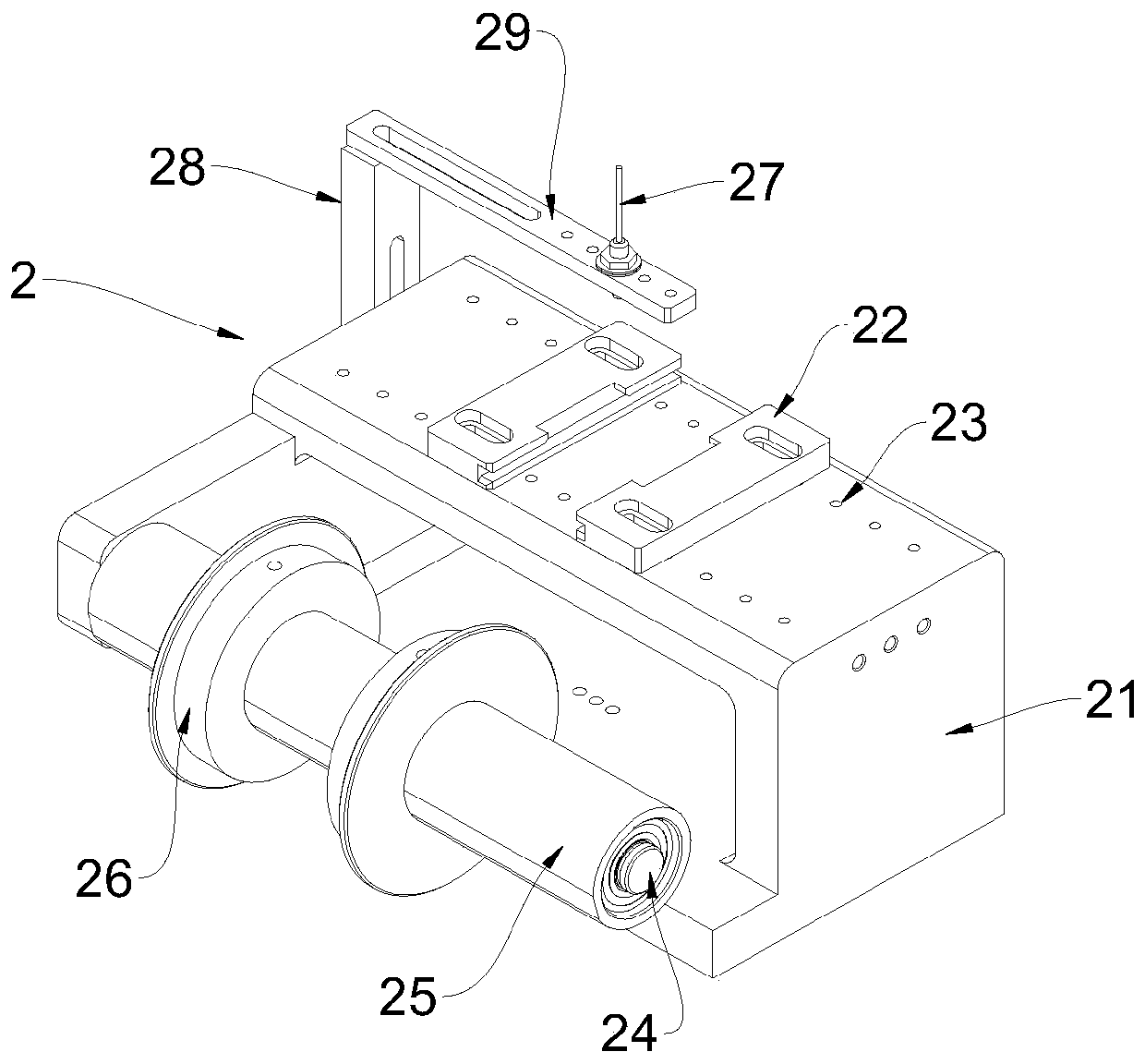

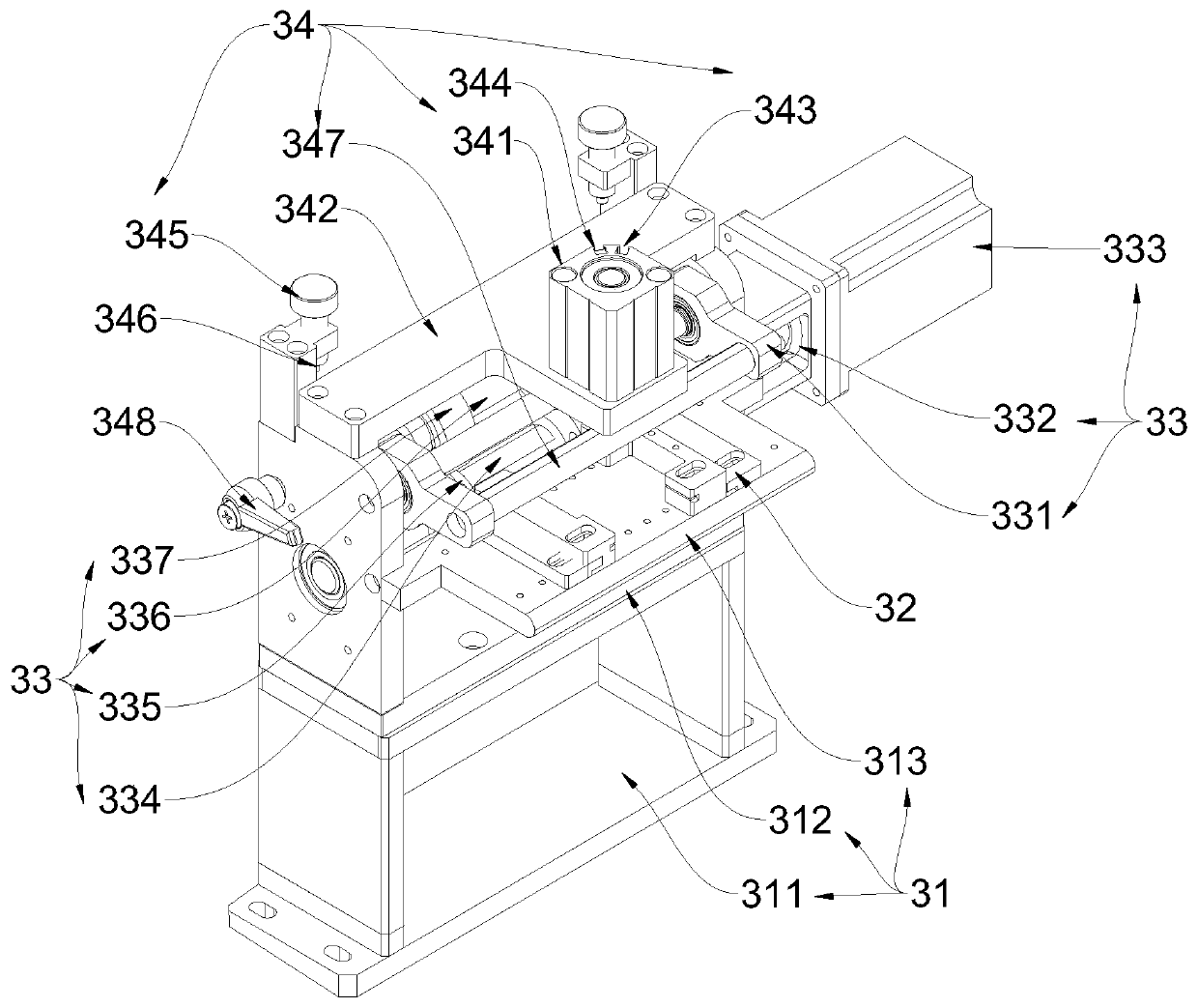

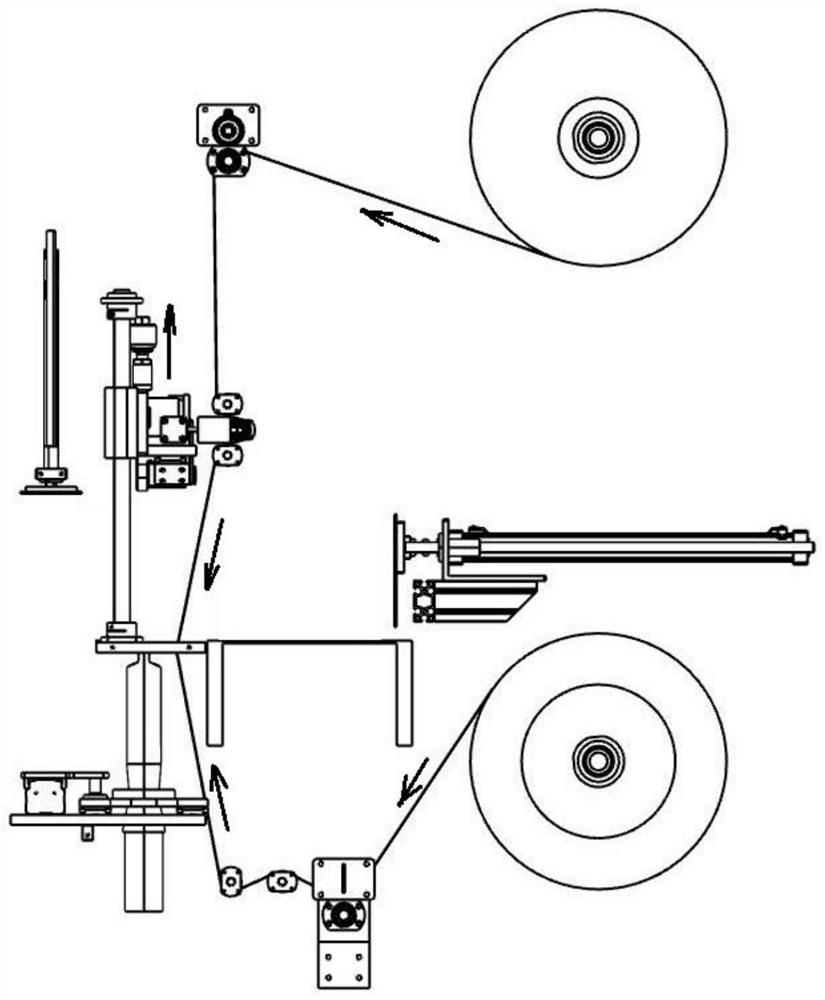

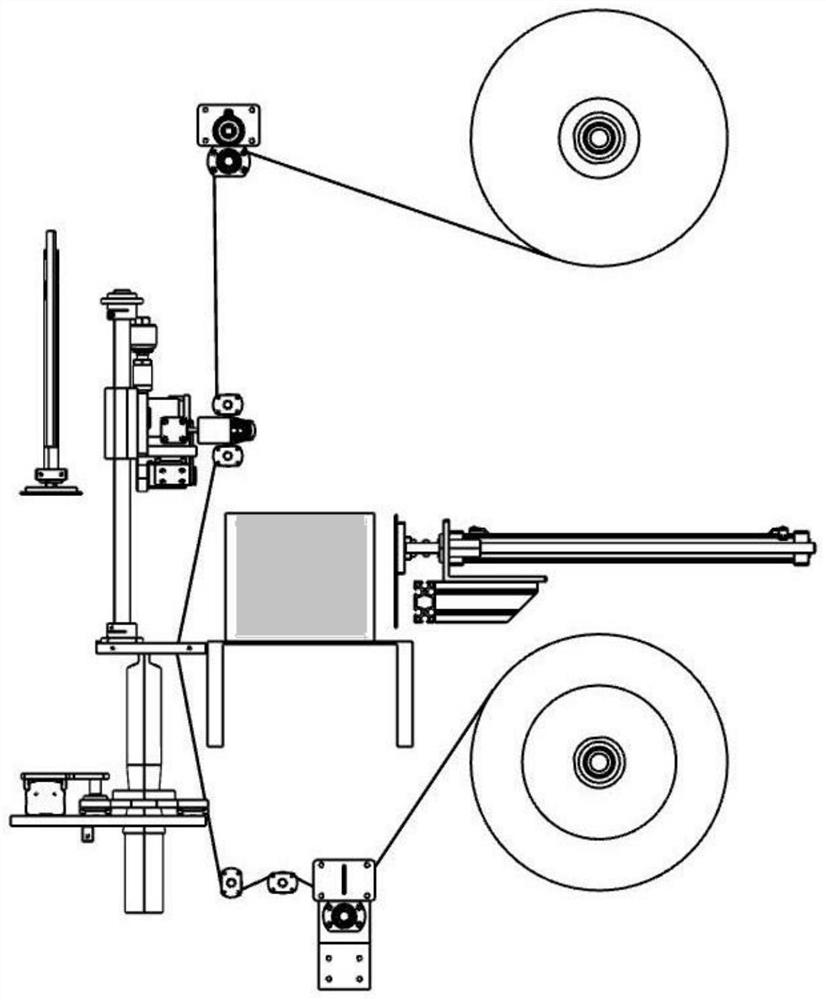

Put-away machine of blanking robot

The invention discloses a put-away machine of a blanking robot. The put-away machine comprises a machine frame, a correcting assembly, a puller assembly, a cut-off die, a conveying assembly, a variable-pitch sucker assembly and a blister box. A material belt is input through the correcting assembly, penetrates through the cut-off die and enters the puller assembly to be pulled out. The correctingassembly can freely adjust the correcting position according to the width of the material belt and can also support the material belt so that the product deformation caused by the drooping of the material belt can be prevented. The puller assembly can automatically send the to-be-stamped material belt into a servo cam stamping die, labor is saved, and the pulling speed is higher and more stable. The conveying assembly is used for conveying out cut-off stamped products from the lower side of the cut-off die and providing the product suction space for the variable-pitch sucker assembly. The variable-pitch sucker assembly moves the products to the blister box, and the put-away efficiency of the put-away machine is improved. By means of the put-away machine, the automatic steel material pulling and sending function and the material belt automatic stamping and put-away function are realized, the automation degree is high, cost is saved, and efficiency is improved.

Owner:SHENZHEN LLMACHINECO LTD

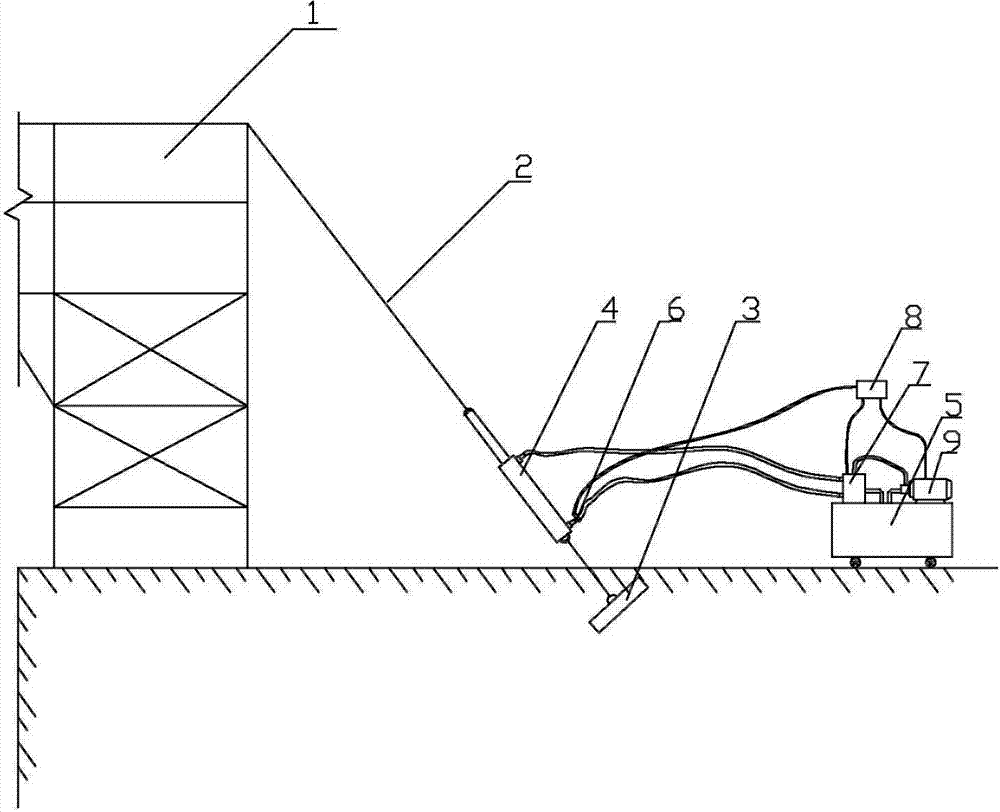

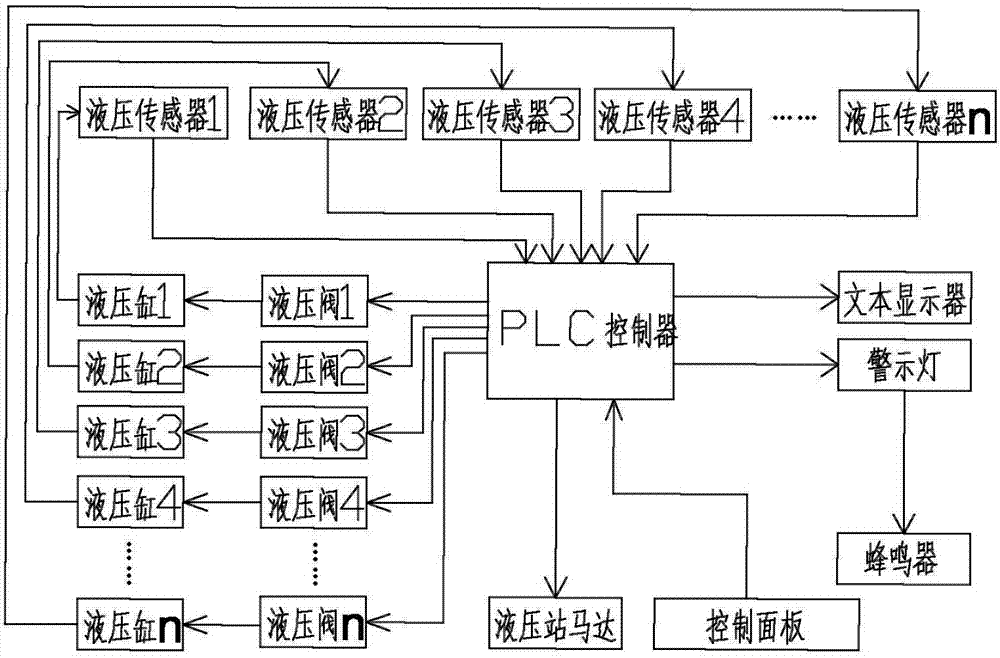

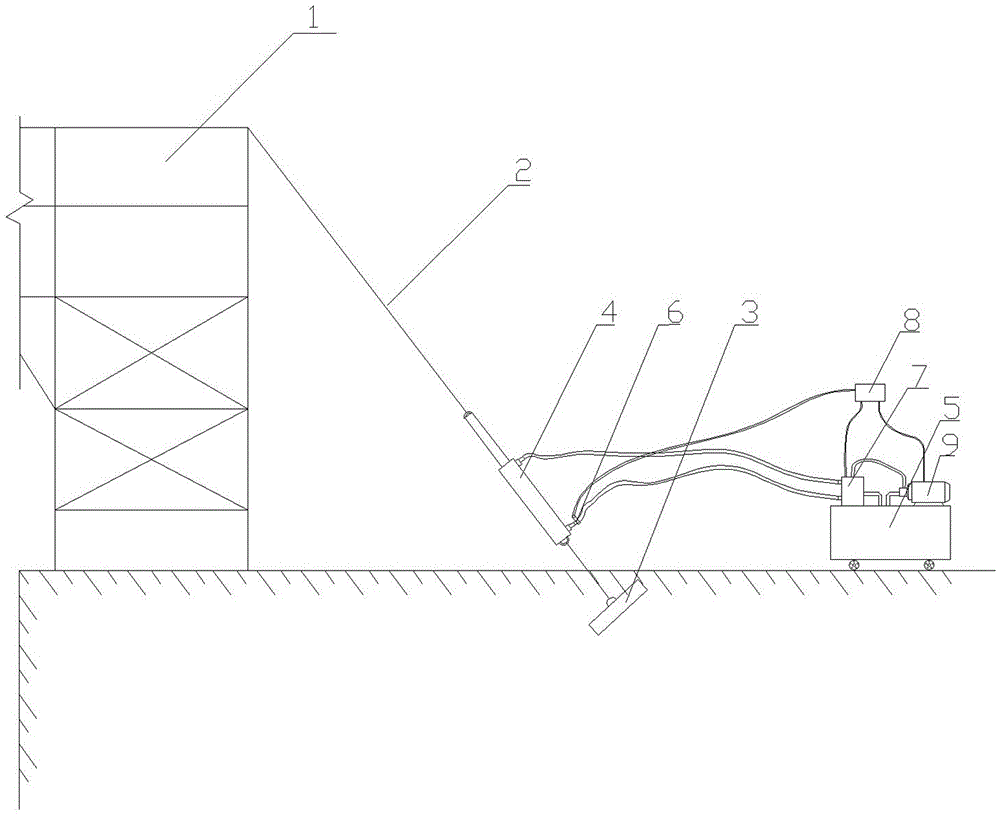

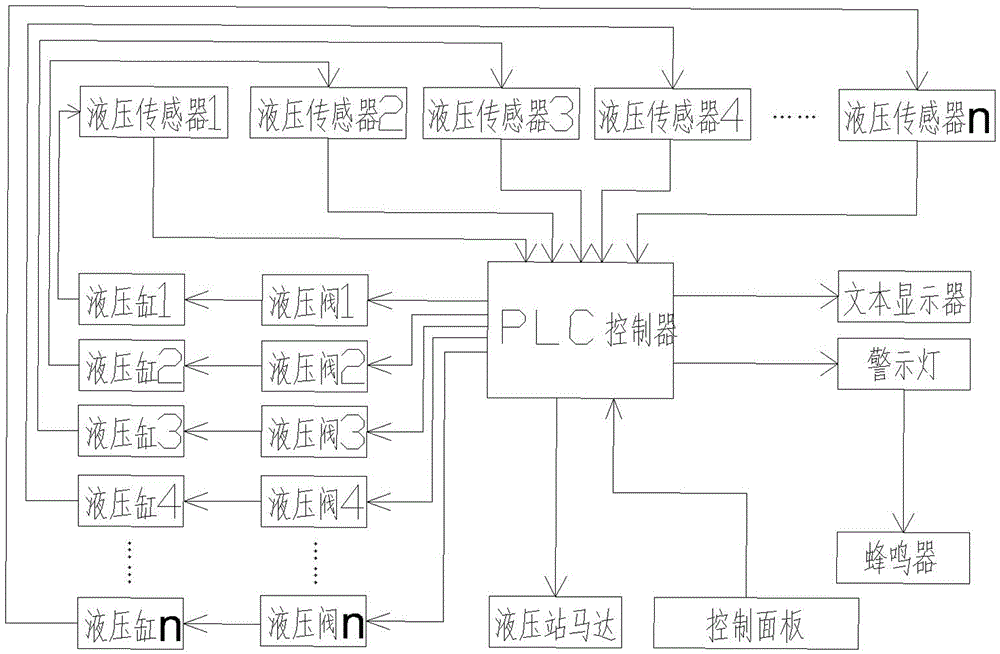

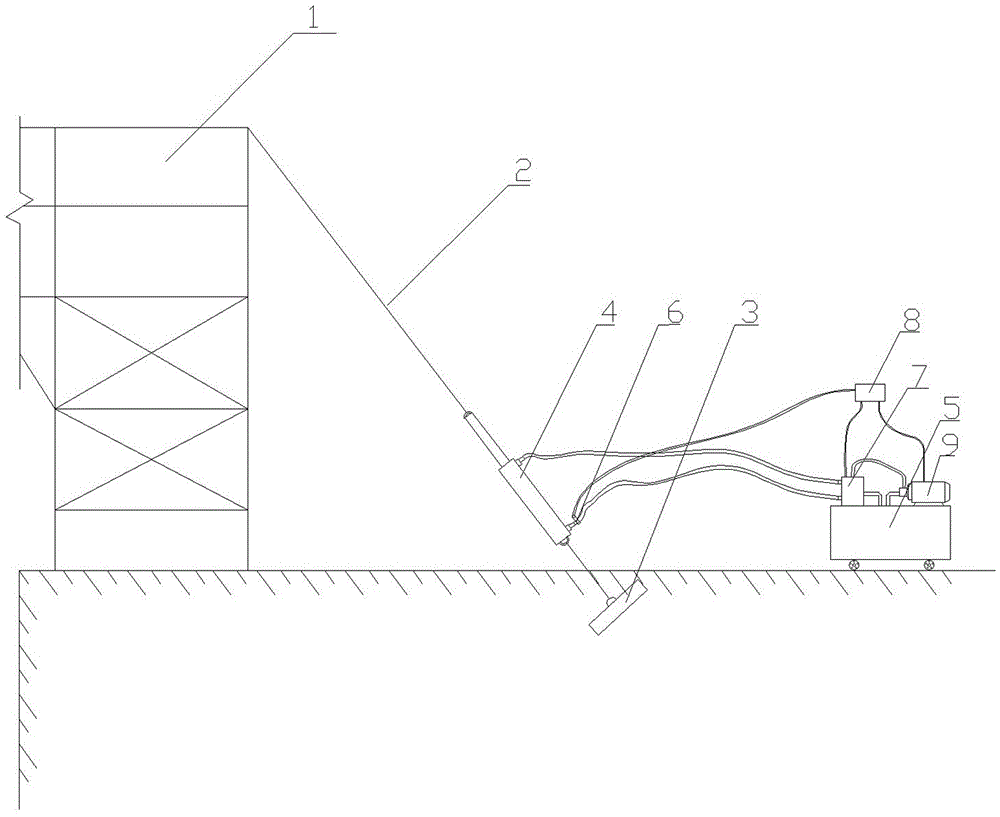

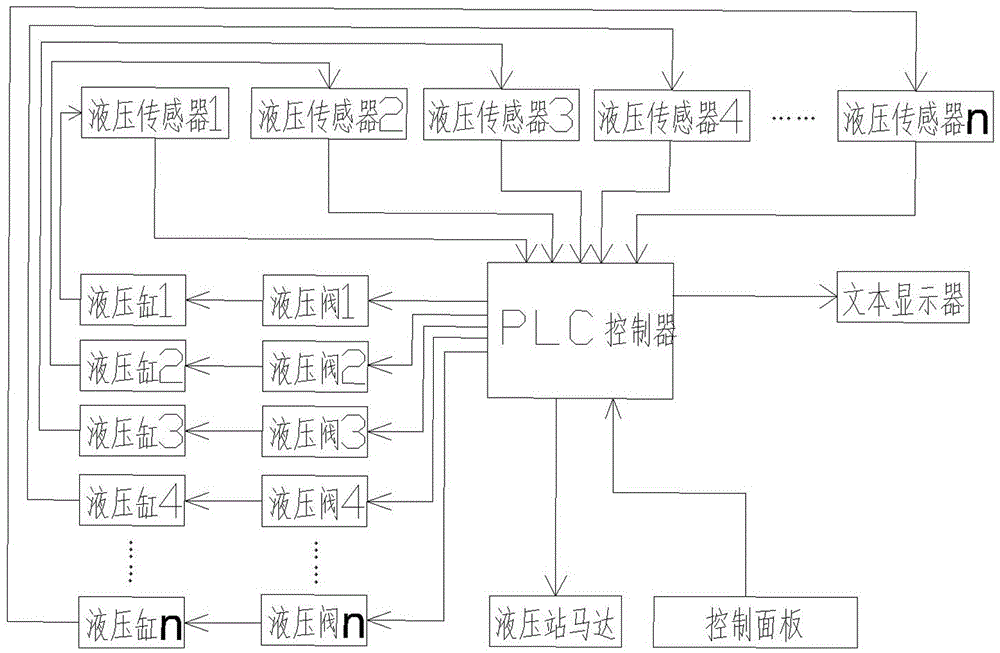

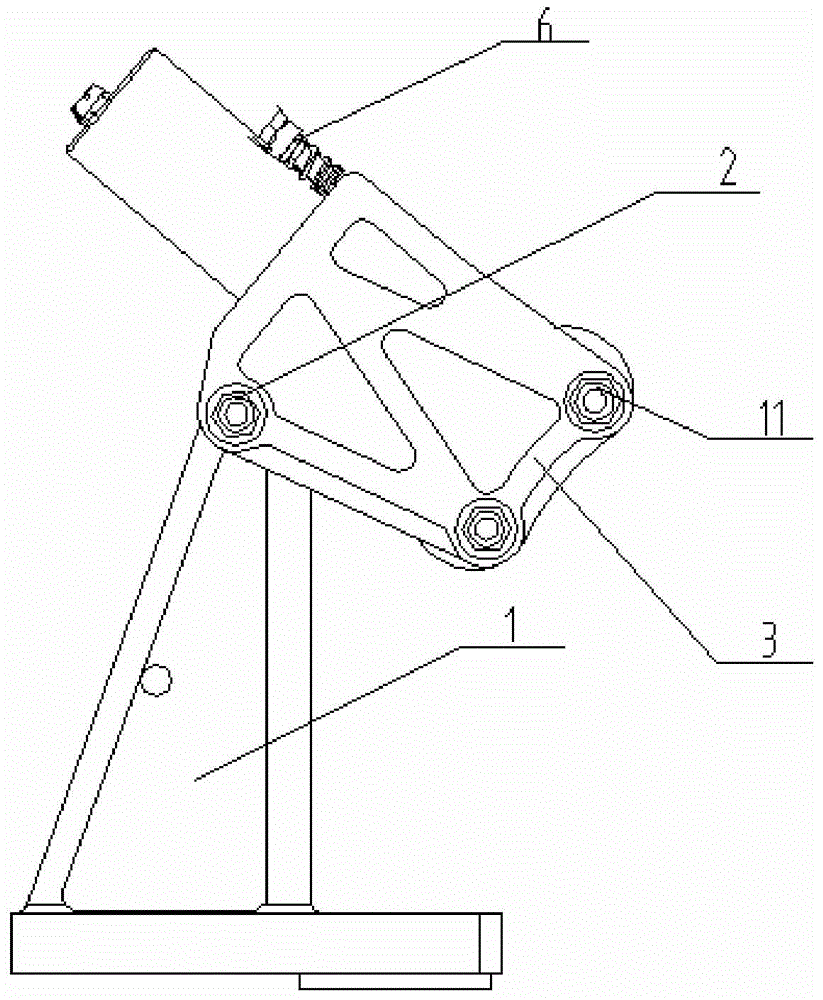

System for automatically controlling stability of temporary cable erection support

ActiveCN103899600APlay the effect of linkage and joint adjustmentEasy to installFluid-pressure actuator safetyPipe supportsHydraulic cylinderPull force

The invention relates to a system for automatically controlling the stability of a temporary cable erection support. The system comprises a support body, a hydraulic system and a PLC control system, all inclined pulling wires are connected through the hydraulic system so that a linkage joint adjustment effect can be achieved, then the tensile force of all the inclined pulling wires can be independently or simultaneously controlled through the PLC control system, the system is easy and convenient to install, the inclined pulling wires and ground anchors can be connected only through a hydraulic cylinder, the hydraulic cylinder is controlled to stretch or retract by a hydraulic valve so that the tensile force of the inclined pulling wires can be adjusted, the responding speed is high, the tensile force is accurately controlled, and the whole set of equipment can be installed fast.

Owner:STATE GRID CORP OF CHINA +2

Method for packaging cigarette carton through non-woven fabric and cigarette carton packaging machine

PendingCN113859613APush for protectionRealize replacementWrapping material feeding apparatusPackaging cigaretteCartonStructural engineering

The invention provides a method for packaging a cigarette carton through non-woven fabric and a cigarette carton packaging machine based on the method. The cigarette carton packaging machine is provided with a rack, a control box, a packaging, sealing and cutting platform, a cigarette side pushing device, a cigarette pressing device, a lower movable ultrasonic device of a movable multi-cutter sealing and cutting device, a tension detection roller set, a fabric pulling roller set and an unwinding roller are arranged on the rack, the cigarette side pushing device running in the horizontal direction is arranged on the right side of the packaging, sealing and cutting platform, two guide columns are arranged on the front side and the rear side of the packaging, sealing and cutting platform, guide sleeves are arranged on the guide columns in a penetrating manner, the guide sleeves are arranged on an upper movable sealing and cutting device of the movable multi-cutter sealing and cutting device, an up-down movable sealing and cutting driving air cylinder is arranged on the upper movable sealing and cutting device, the sealing and cutting driving air cylinder is arranged on the rack, and the cigarette pressing device running in the up-down direction is arranged above the left side of the packaging, sealing and cutting platform. Upgrading that the non-woven fabric is used for replacing a PE shrinkable plastic film to package a cigarette packet is achieved, and contributions are made to restraining white pollution and promoting environmental protection.

Owner:四川省烟草公司广元市公司 +1

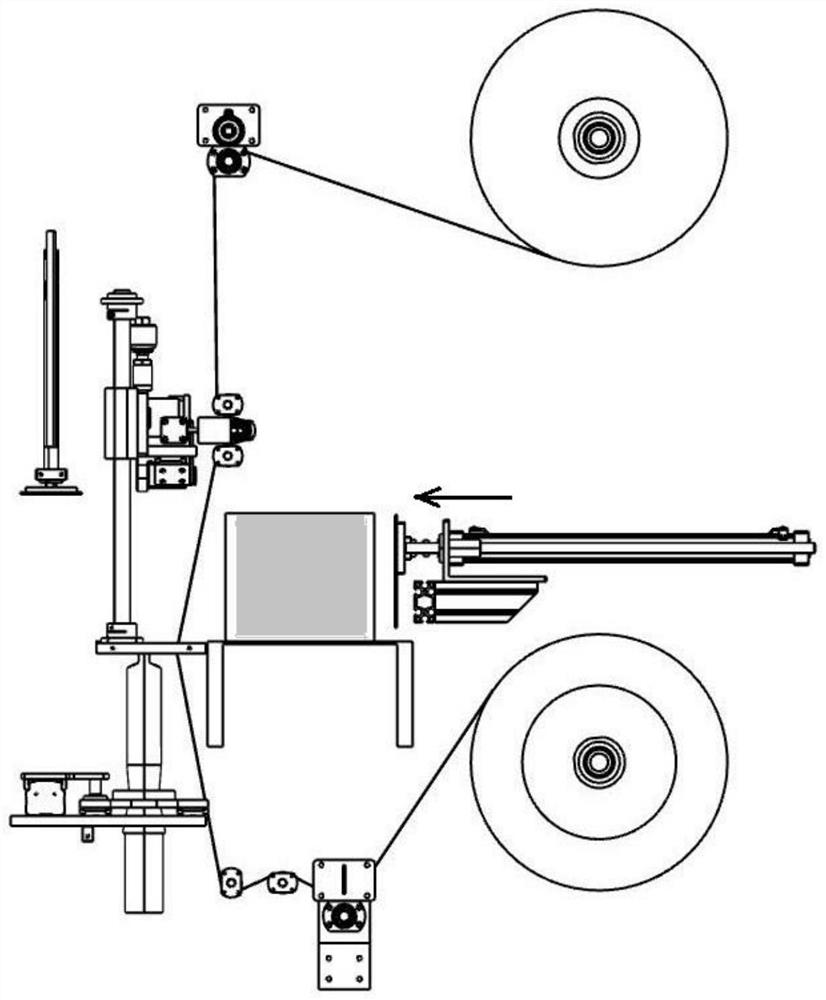

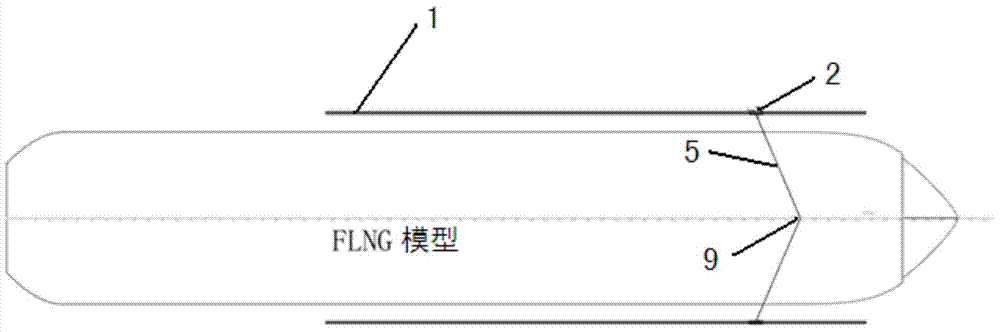

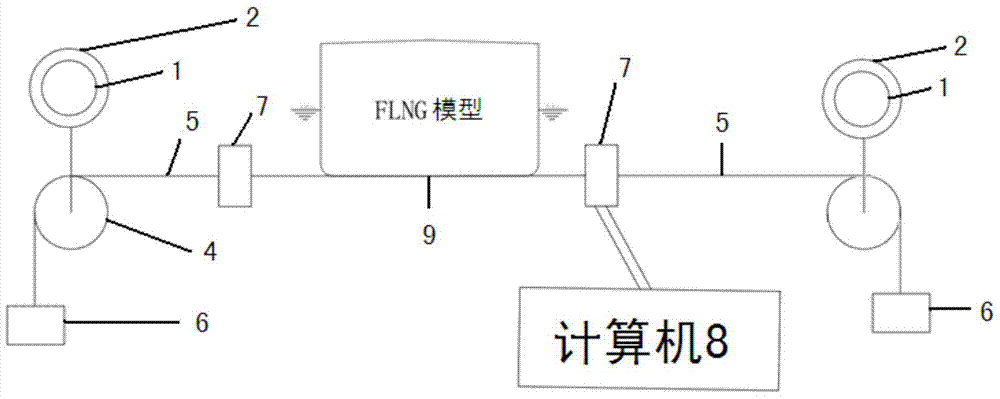

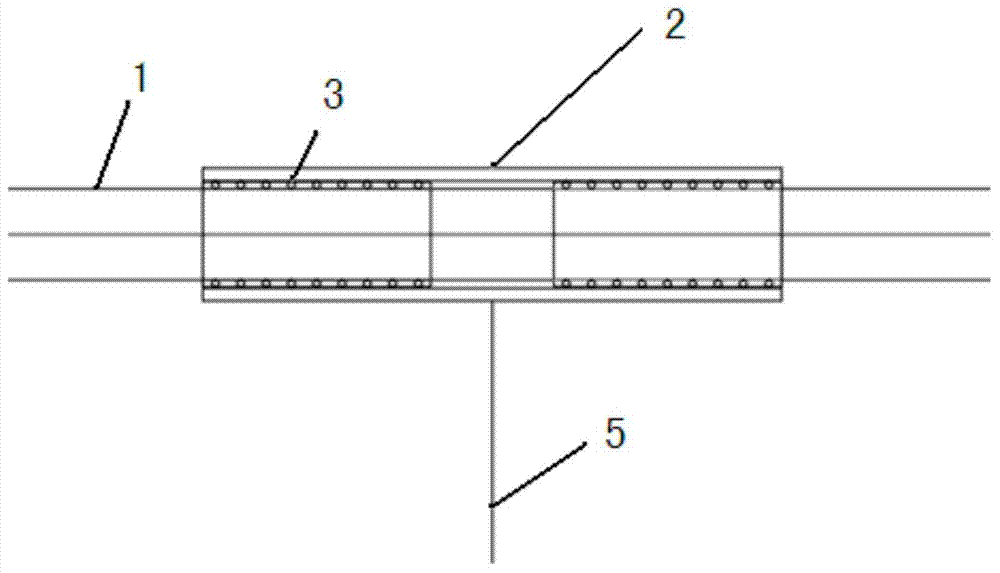

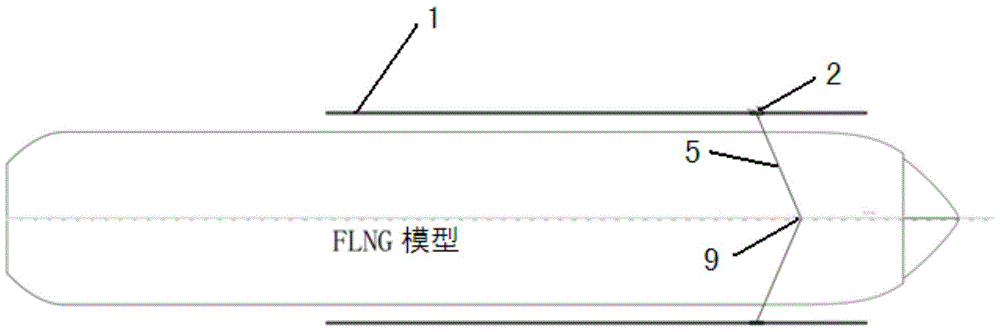

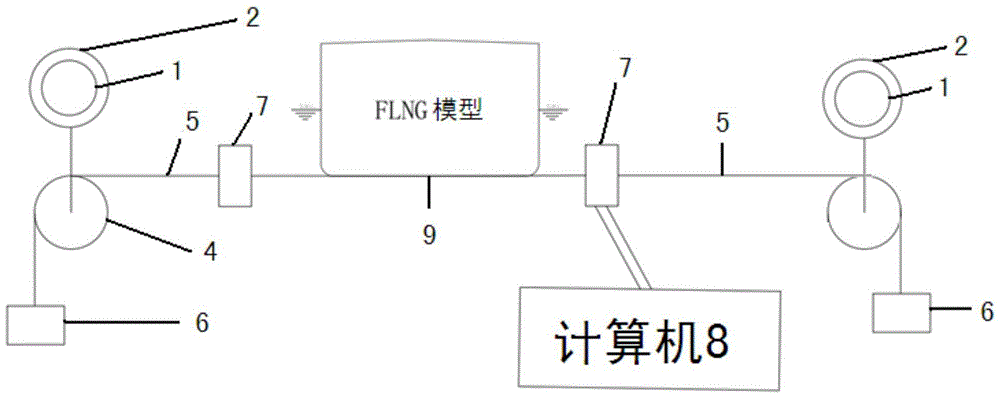

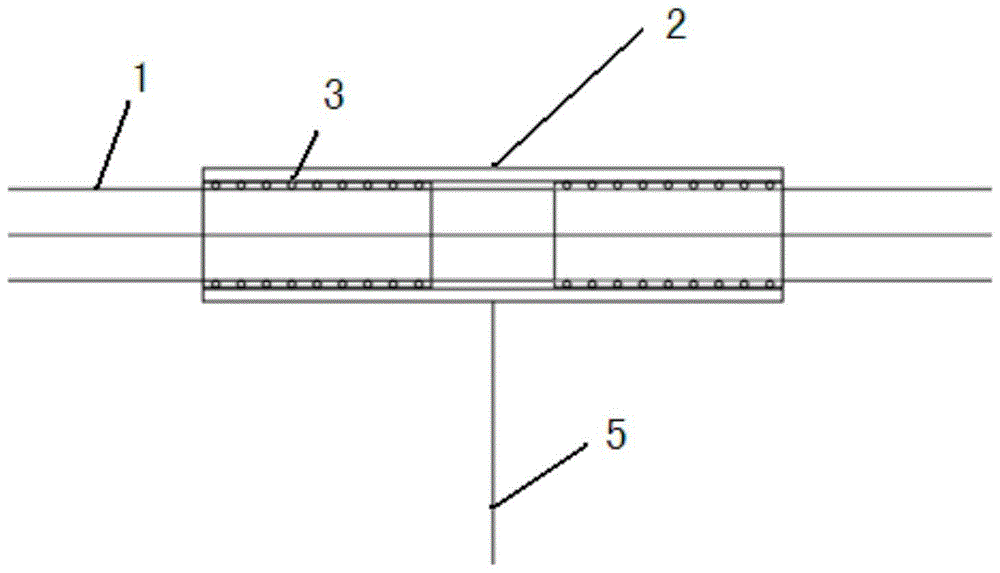

Large liquefied petroleum and natural gas boat pond test horizontal thrusting function simulation device

ActiveCN104764585ATo achieve the function of side pushSimple structureHydrodynamic testingProtractorPetroleum

The invention relates to a large liquefied petroleum and natural gas boat pond test horizontal thrusting function simulation device which comprises four vertical supports, two guide rods, two linings for micro ball guide, balls, two fixed pulleys, two ropes, a plurality of weights with different masses, two tension sensors, a computer and a protractor. Every two vertical support are in a group, the two groups of vertical supports are symmetrically and fixedly arranged on banks on the two sides of an FLNG model. Each guide rod is fixedly installed on the tops of the corresponding two vertical supports on one side of the corresponding bank and is sleeved with one lining for micro ball guide, and each ball is arranged between the corresponding guide rod and the corresponding lining for micro ball guide. Each lining for micro ball guide is fixedly connected with one fixed pulley, each rope is wound on the corresponding fixed pulley, one end of each rope is connected with the weights, and the other end of each rope is connected with a boat bottom horizontal thrusting action point through one tension sensor.

Owner:CHINA NAT OFFSHORE OIL CORP +1

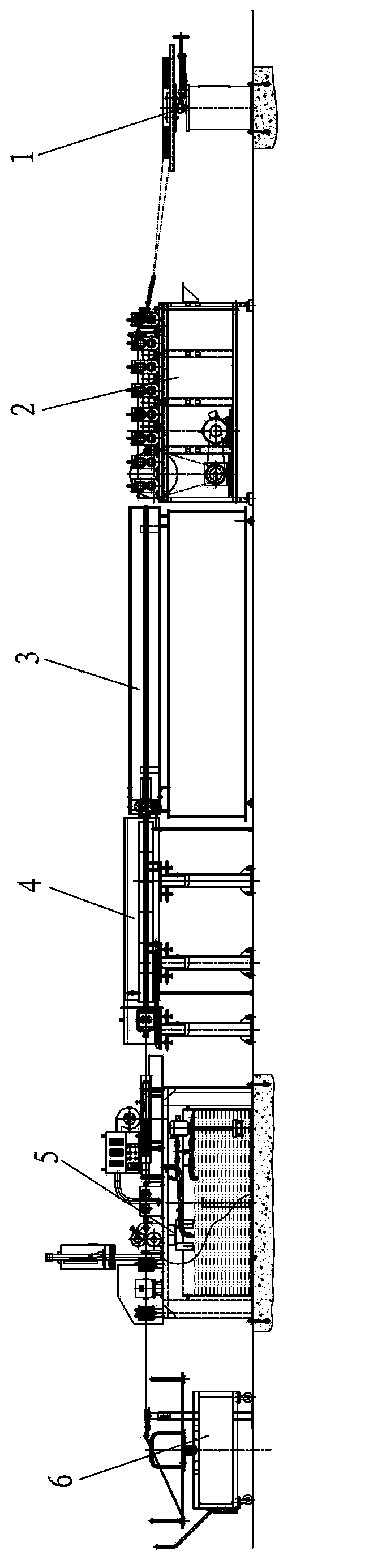

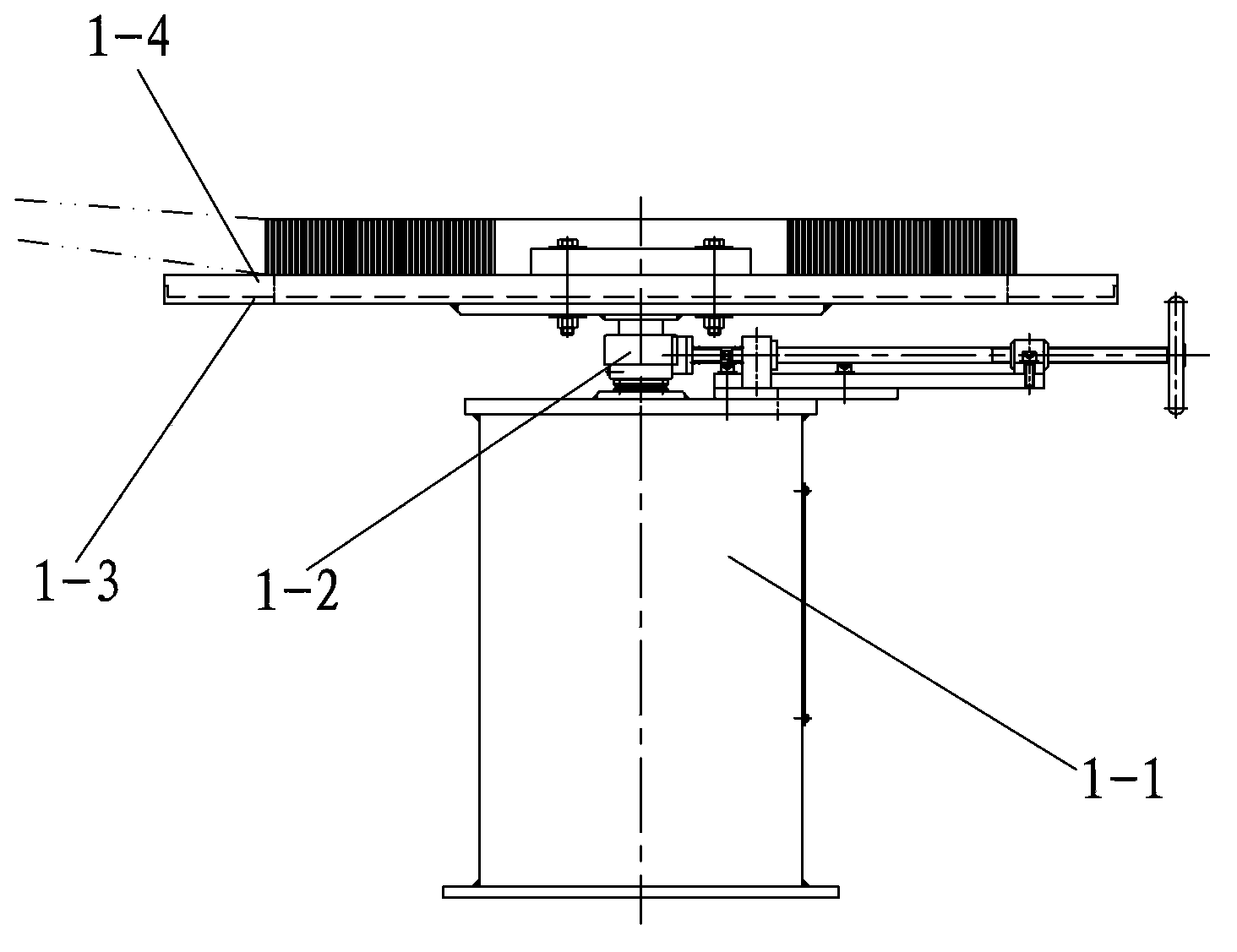

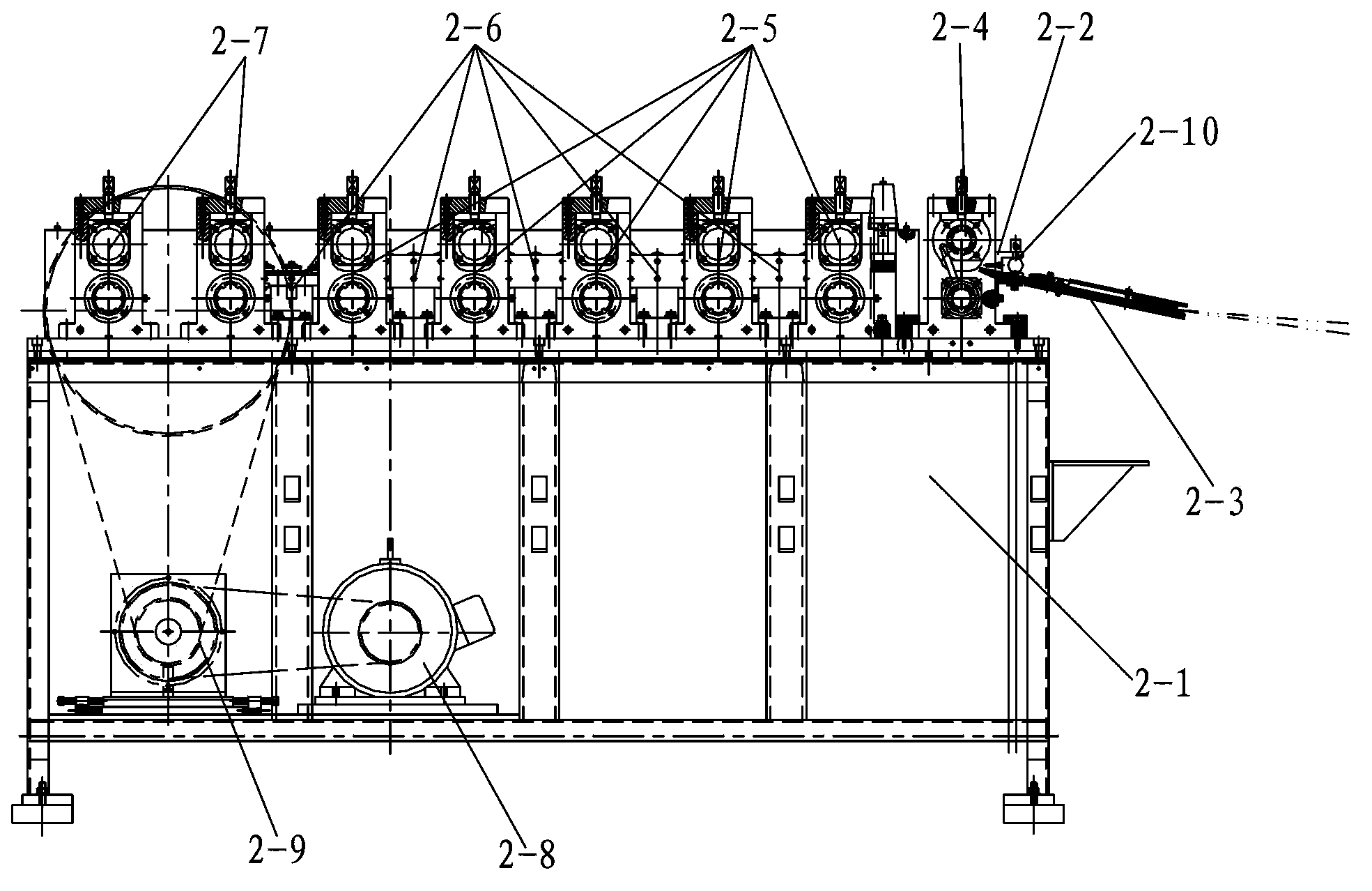

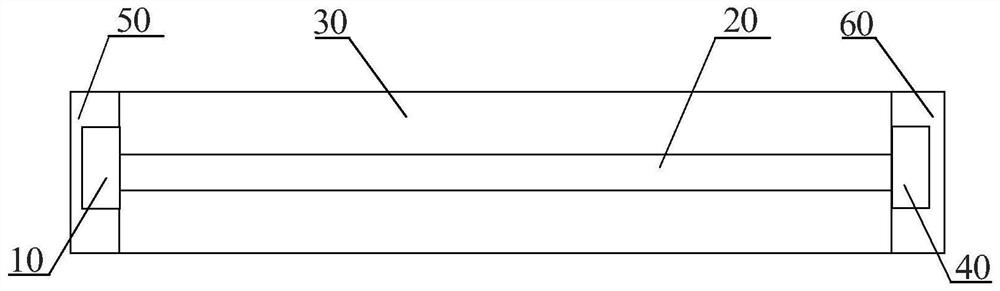

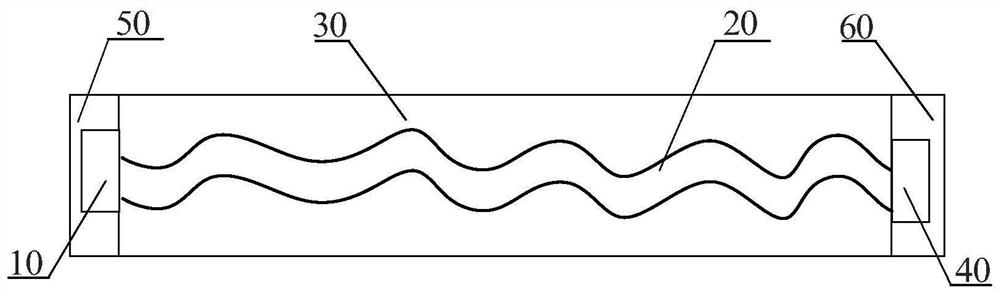

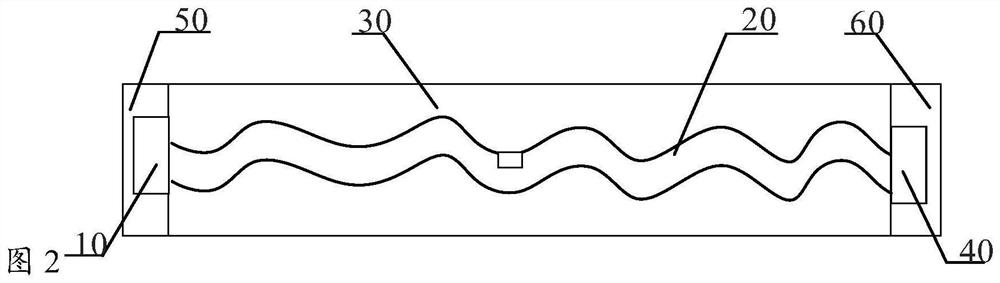

Two-layer copper brazed steel pipe forming unit

The invention discloses a two-layer copper brazed steel pipe forming unit, comprising a horizontal unreeling machine, a pipe-making forming machine, an induction heating brazing furnace, a cooling device, cleaning, air-drying and flaw detection apparatus, and a reeling device, all of which are sequentially arranged parallel to each other, wherein the horizontal unreeling machine comprises an unreeling machine base, a rotating shaft and a discharge disc; the pipe-making forming machine comprises a nose box, a strip forming power mechanism, a forming nose, a mandril holder and a mandril; the induction heating brazing furnace comprises a brazing furnace frame, a brazing furnace cover and an induction heating device; the cooling device comprises a cooling pipe support and a cooling pipe; the cooling pipe is composed of an inner pipe and an outer pipe; the cleaning, air-drying and flaw detection apparatus comprises a cleaning liquid box, a pipe cleaning machine, an air-drying device, a pipe traction device, a flaw detection device and a cleaning liquid circulating pipeline; and the reeling device comprises a reeling trolley with a brake truckle, and a receiving disc. The two-layer copper brazed steel pipe forming unit is novel and reasonable in design, high in working efficiency, high in quality of a product, wide in application range, good in using effect and convenient to popularize and use.

Owner:THE NORTHWEST MACHINE

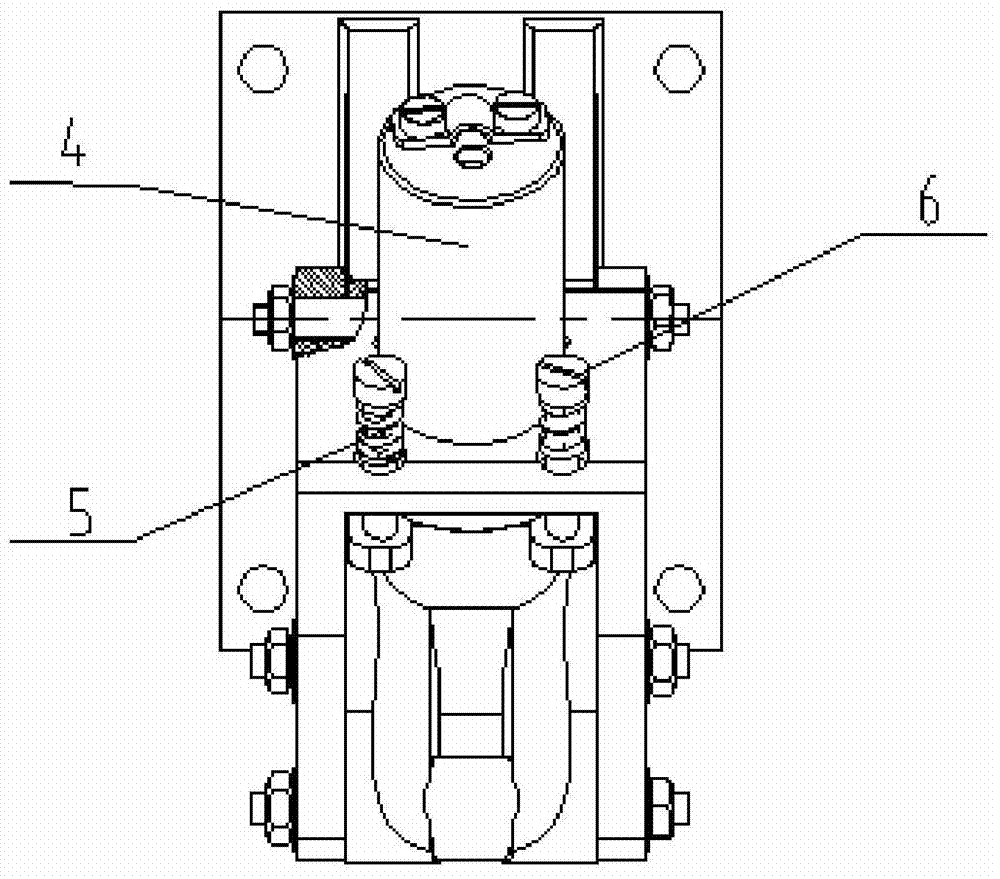

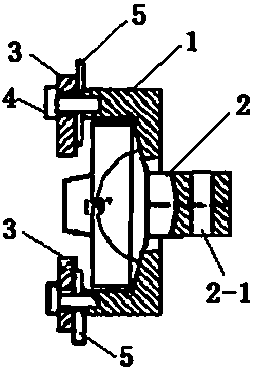

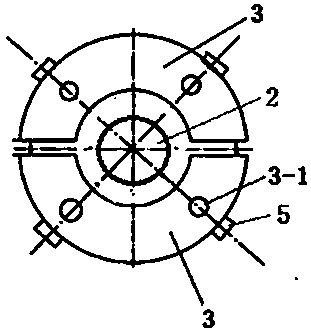

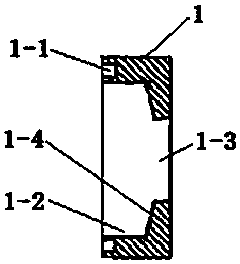

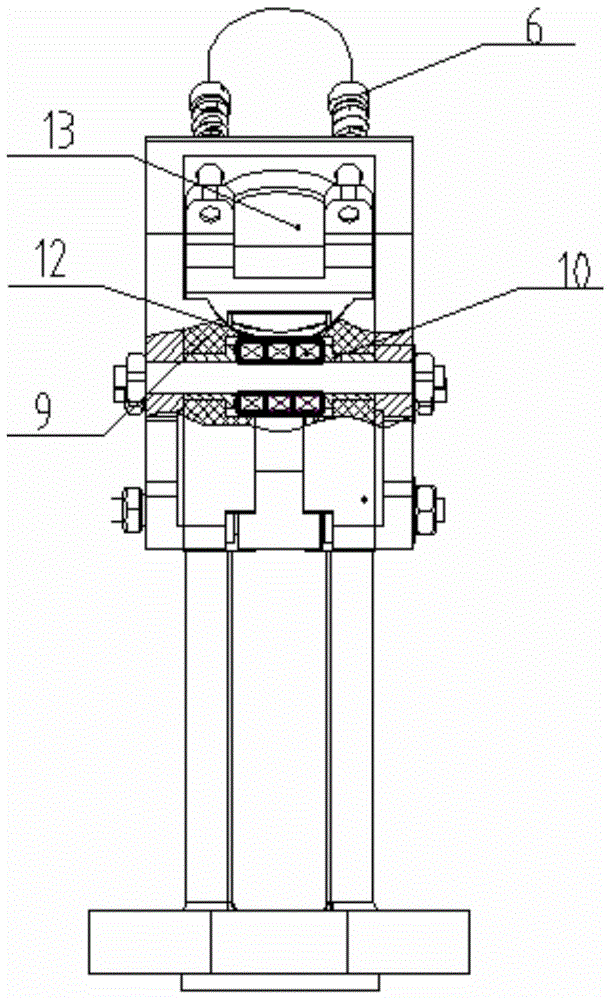

Guide rope tension measuring device

ActiveCN104502012ASimple and reasonable structural designEasy to operateTension measurementMeasurement deviceComposite effect

The invention provides a guide rope tension measuring device, relates to the field of mechanical measurement and aims at solving the problem that the existing measuring device cannot accurately measure coring force and smoothly guide the coring force to a sample under complex selenographic environments and the multi-force composite effect. The guide rope tension measuring device provided by the invention comprises a base, a rotating shaft, a rotating block, a pressure sensor, pretightening springs, pretightening screws, a guide sleeve, a guide shaft and a guide rope through hole, wherein the base and a side end of the rotating block are fit with each other through the rotating shaft, an upper end surface of the rotating block is fixed at an upper part of the base through two pretightening screws, the pretightening springs are arranged on the pretightening screws. The guide rope tension measuring device is used for the mechanical measurement of the guide rope.

Owner:HARBIN INST OF TECH

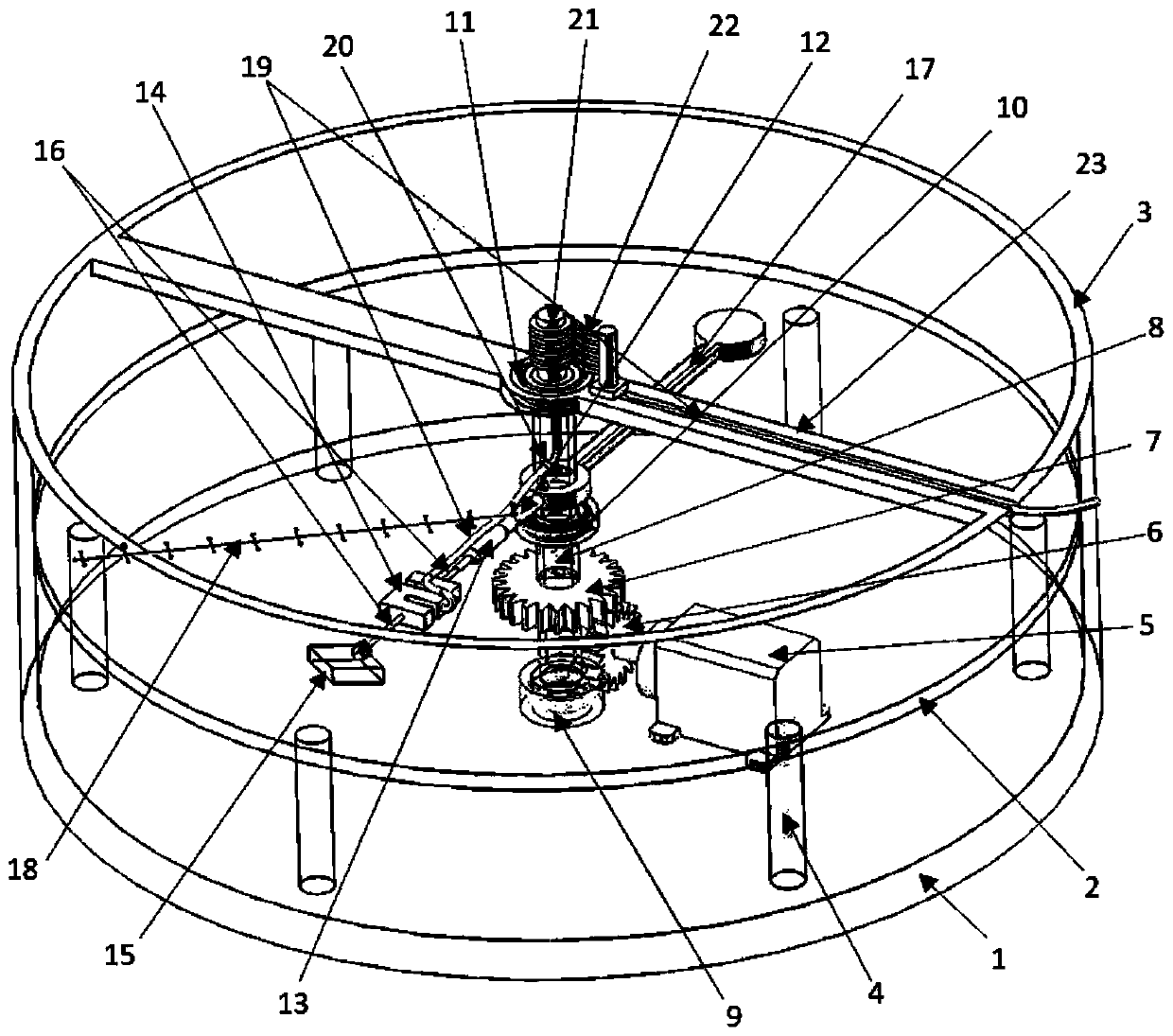

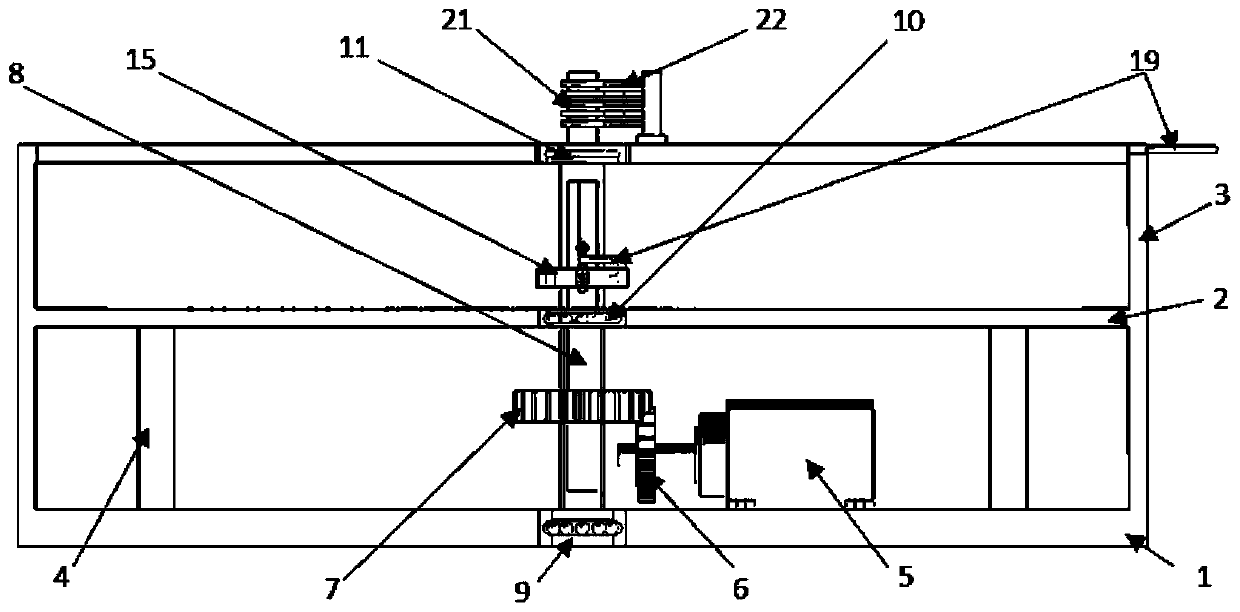

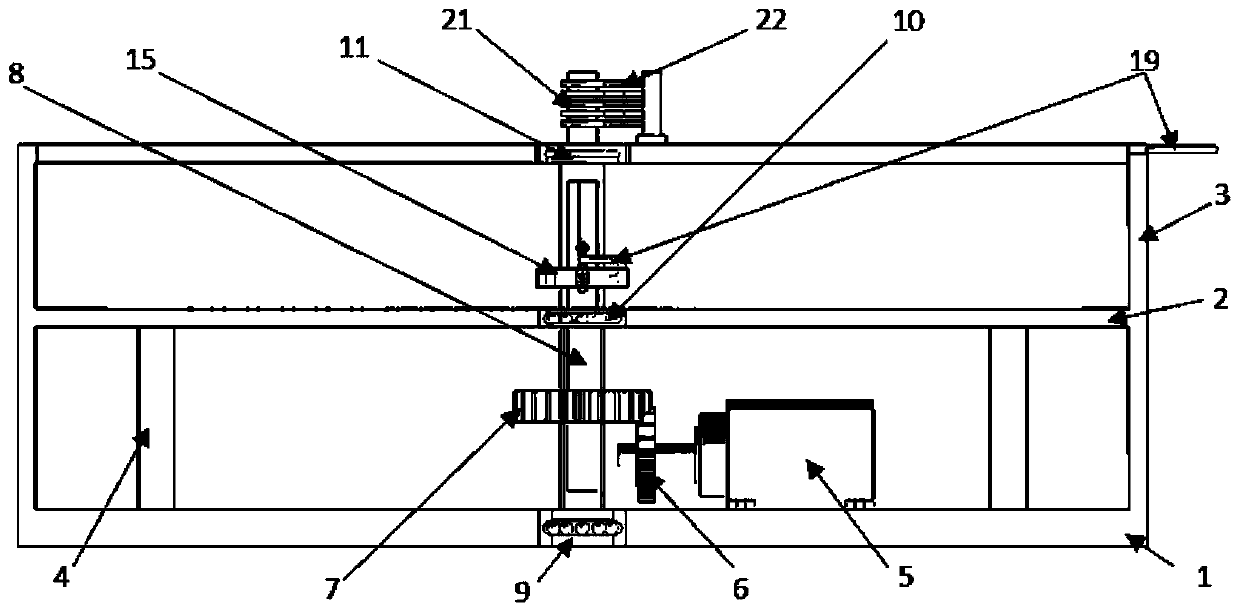

Tension sensor static calibration device and method in weightless environment

InactiveCN109696274APrevent weightlessnessAccurate calibrationForce/torque/work measurement apparatus calibration/testingMass balanceEngineering

The invention discloses a tension sensor static calibration device and method in weightless environment. The device comprises a chassis and a shell mounted on the chassis; a dial is fixed on the chassis through a supporting column, and a graduated scale is arranged on the upper surface of the dial; a rotating shaft penetrates through the chassis and the dial and is connected with the chassis and the dial through bearings; the lower end of the rotating shaft is provided with a first gear; a servo motor is mounted on the chassis, a second gear is arranged on an output shaft of the servo motor, and the second gear is perpendicular to and meshed with the first gear; the rotating shaft is connected with a fine tuning arm; the fine tuning arm is positioned above the dial, and a distance is formed between the fine tuning arm and the dial; one end of the fine tuning arm is connected with one end of a tension sensor to be calibrated through a string, the other end of the tension sensor is connected with a standard mass balance weight through a string, a fine tuning knob for adjusting the telescopic length of the fine tuning arm is arranged on the fine tuning arm, and a balance beam is arranged on the opposite side of the fine tuning arm. The problem that a conventional calibration method is not suitable for a weightless environment is solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

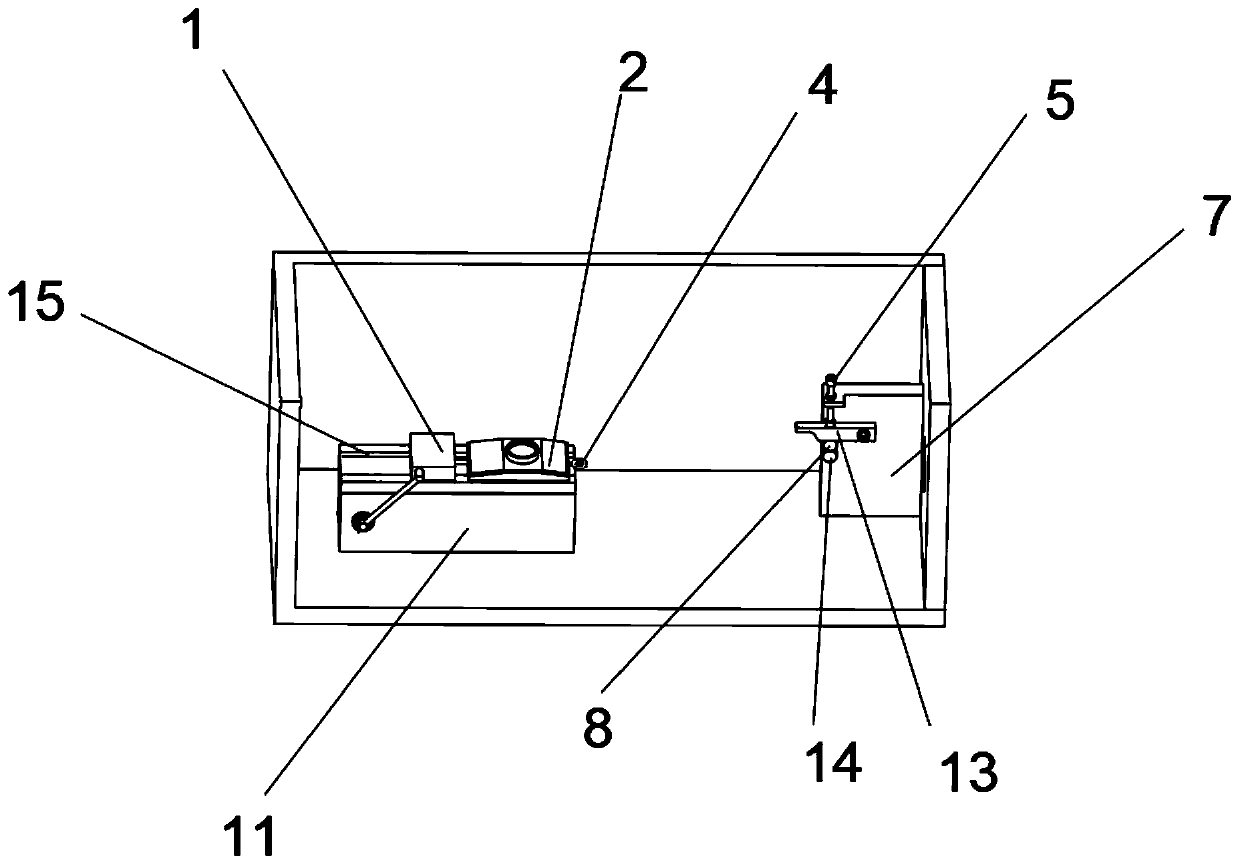

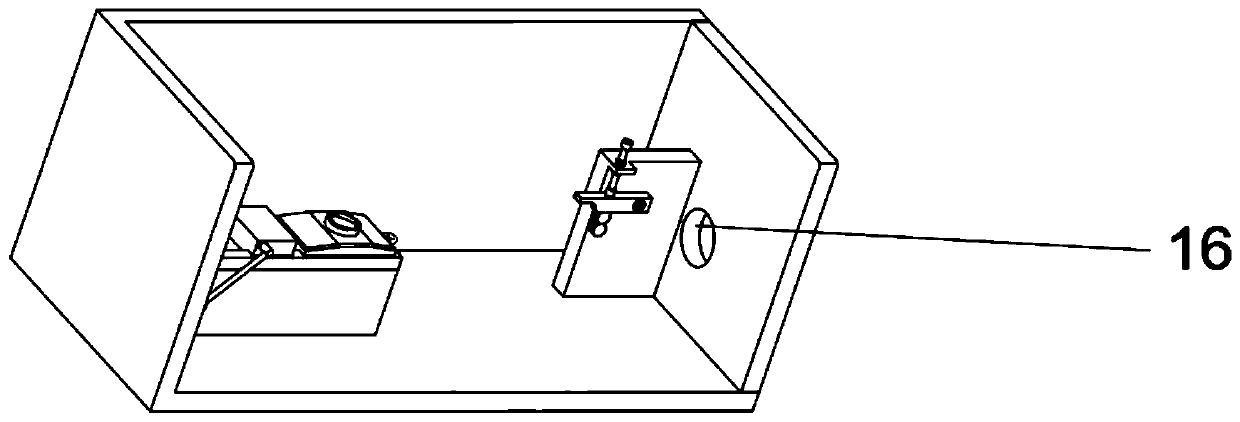

Test piece mechanical strength fixtures used for manufacturing high-strength structural adhesive and application method

ActiveCN105818015AGuaranteed pass rateAccurate pullWork holdersUsing mechanical meansHigh intensityEngineering

The invention relates to test piece mechanical strength fixtures used for manufacturing a high-strength structural adhesive and an application method. The first set of fixture is taken, a short column body of a base is inserted into a center hole of a first test piece, a long column body of the base is inserted into a hole of an outer sleeve, two pressing plates are fixed to the outer sleeve, and the first test piece is fixed to the base through the two pressing plates. The second set of fixture is taken, a short column body of a base is inserted into a center hole of a second test piece, a long column body of the base is inserted into a hole of an outer sleeve, two pressing plates are fixed to the outer sleeve, and the second test piece is fixed to the base through the two pressing plates. The long column body on the first set of fixture is fixed into an upper sleeve of a stretching force measuring machine, and the long column body on the second set of fixture is fixed into a lower sleeve of the stretching force measuring machine. The stretching force measuring machine is started to test the strength of the tensile force or torque of the whole test piece, that is, the bonding strength of the high-strength structural adhesive is tested. According to the test piece mechanical strength fixtures used for manufacturing the high-strength structural adhesive and the application method, not only can tensile force testing be conducted, but also torque testing can be conducted, and the adhesive thickness can be controlled; the tested tensile force and torque data are accurate; and the effect that the qualified rate of the automobile adhesive leaving a factory reaches 100% can be ensured.

Owner:三友(天津)高分子技术有限公司

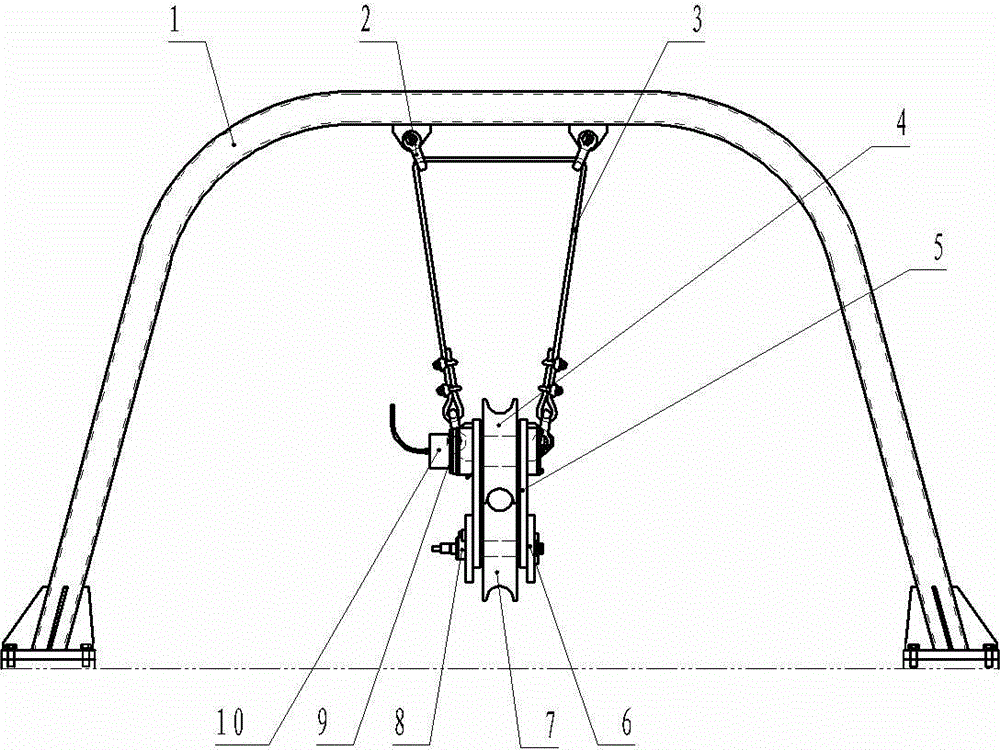

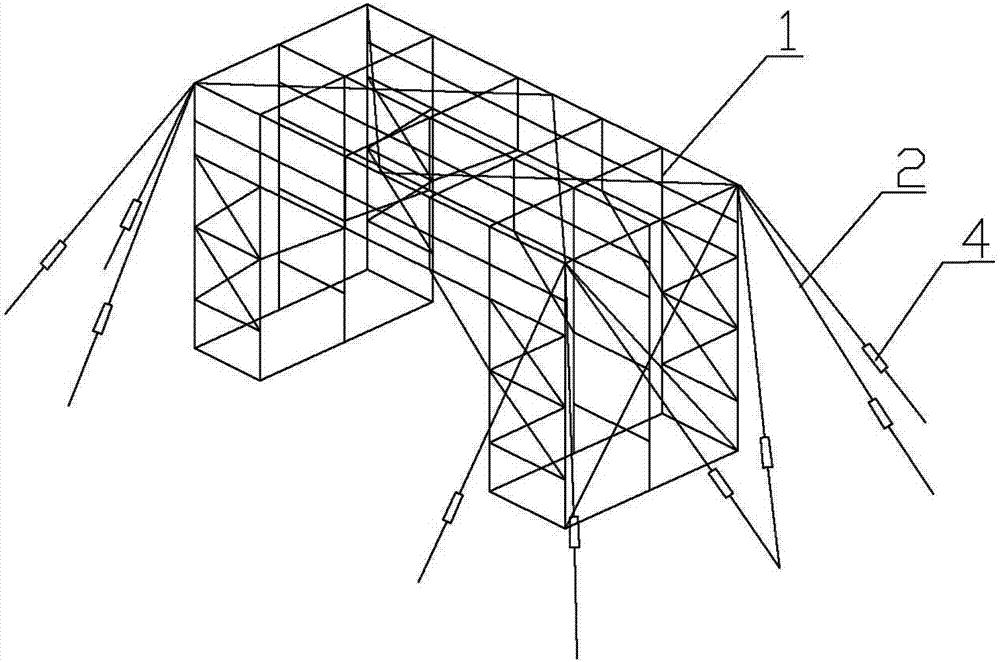

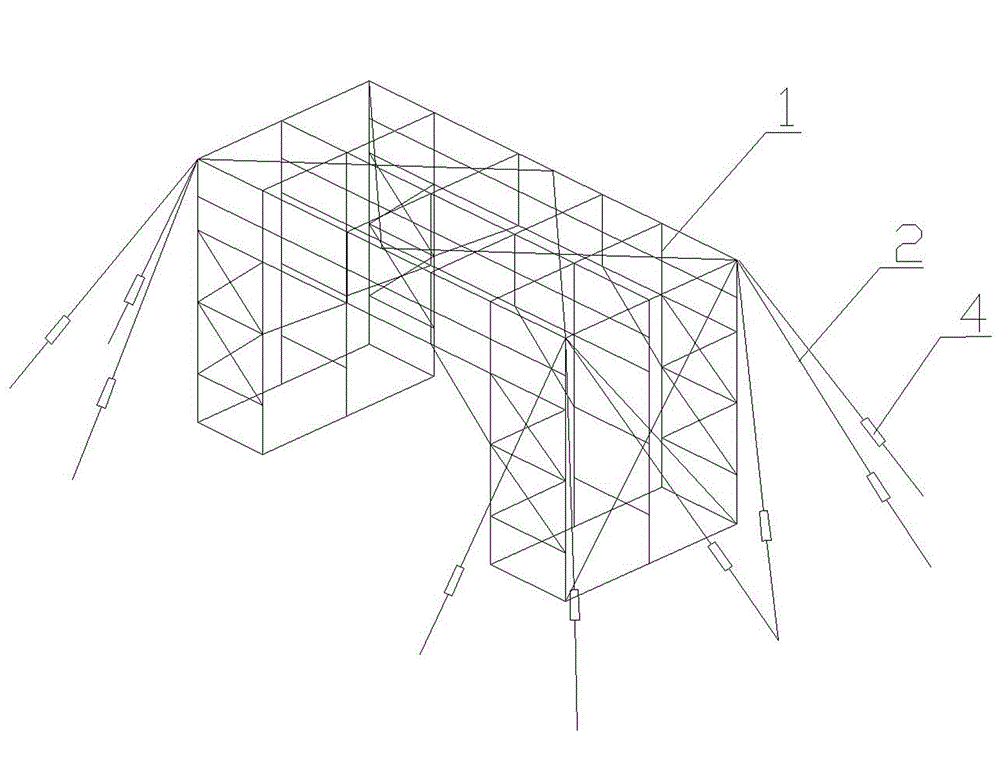

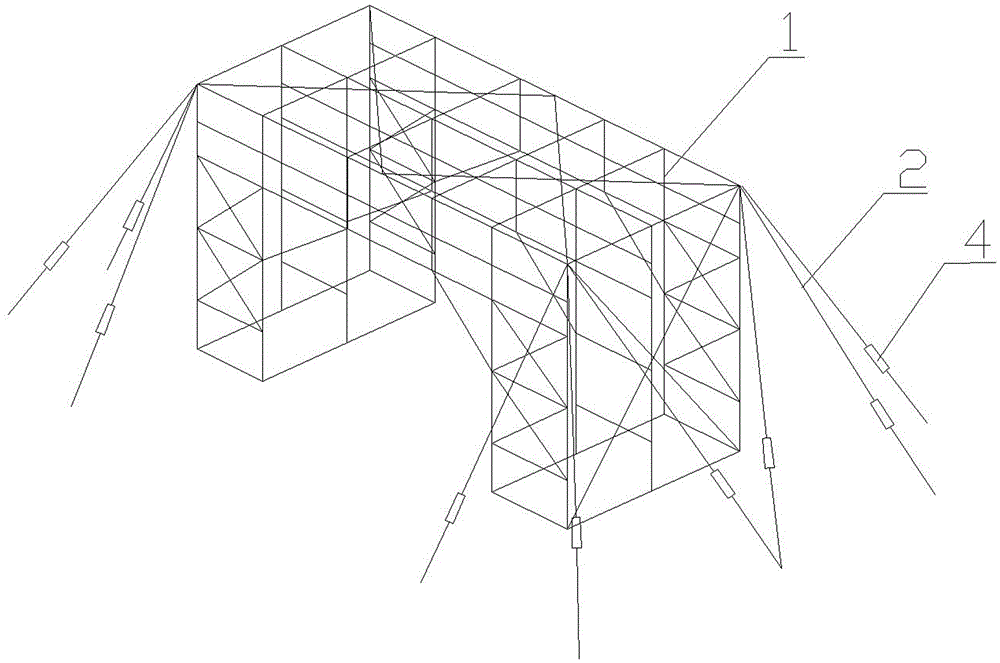

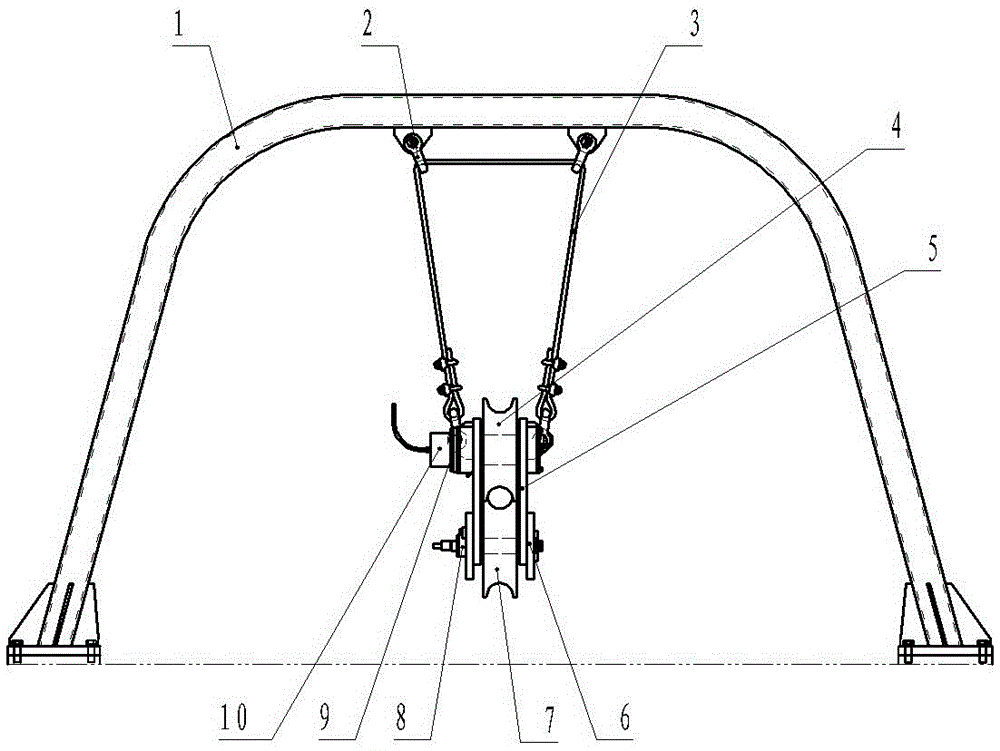

Temporary rapid installing support for cable erection

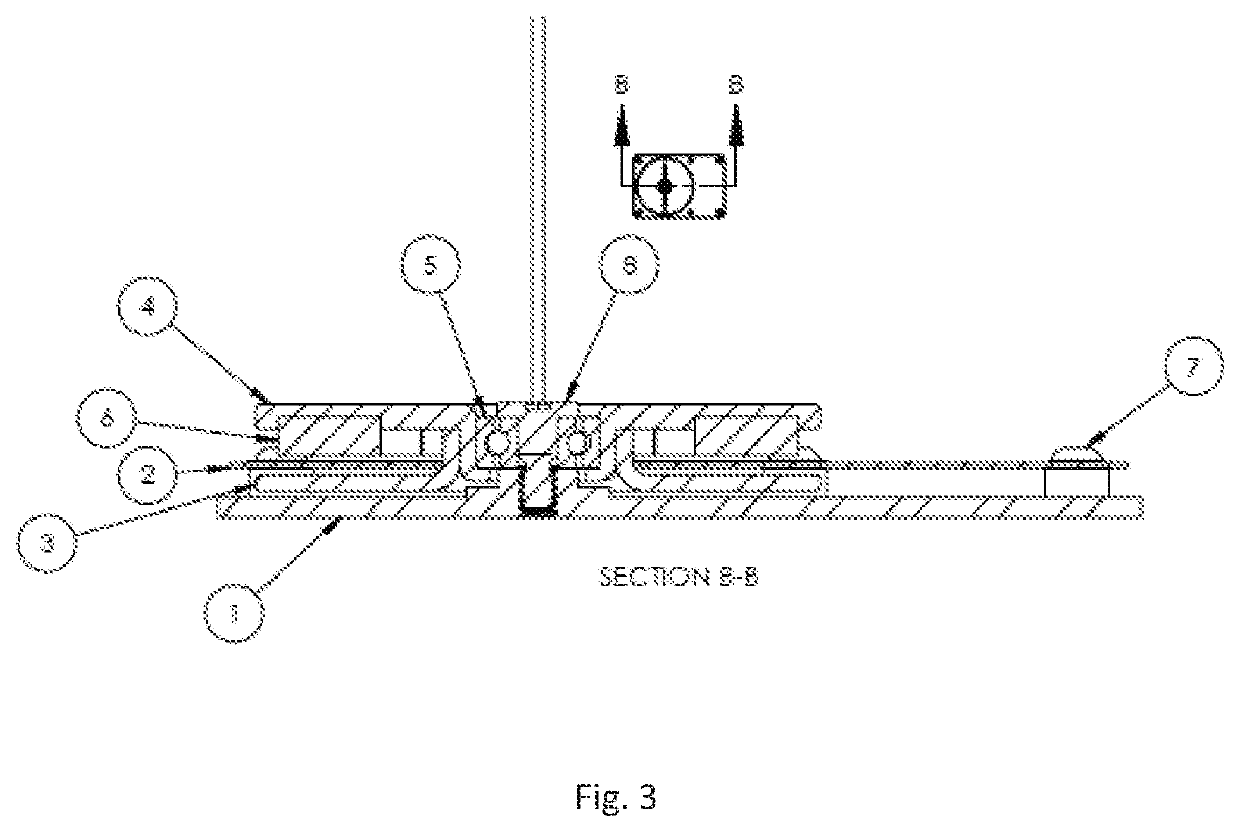

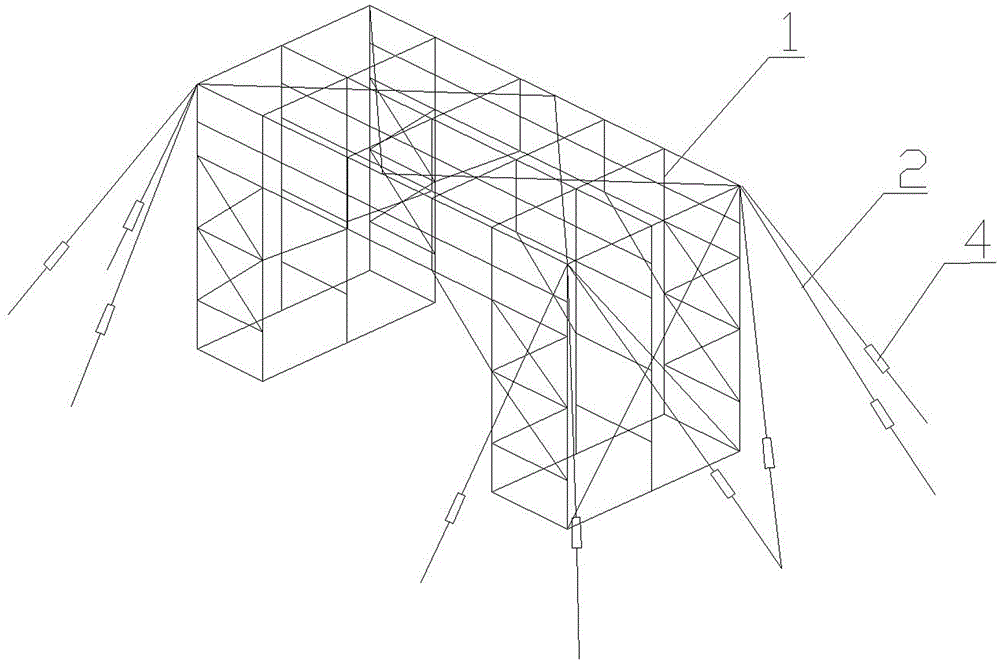

InactiveCN103915784APlay the effect of linkage and joint adjustmentEasy to installApparatus for overhead lines/cablesHydraulic cylinderPull force

The invention discloses a temporary rapid installing support for cable erection. The temporary rapid installing support for cable erection comprises a square-arch-shaped frame body, inclined pull wires, ground anchors, hydraulic cylinders, a multi-way valve and a hydraulic station, wherein the inclined pull wires are connected with the top corners of the square-arch-shaped frame body and are fixed to the ground through the ground anchors, and the hydraulic cylinders are arranged between the inclined pull wires and the ground anchors 3 and are connected with the hydraulic station through the multi-way valve. The pull force of each pull wire can be independently controlled, it is only required that the pull wires and the ground anchors are connected together through the hydraulic cylinders and the hydraulic cylinders are controlled by the multi-way valve to stretch or contract to adjust the pull force of the pull wires, and the whole temporary rapid installing support for cable erection is easy, convenient and fast to install, high in corresponding speed and accurate in pull force control.

Owner:STATE GRID CORP OF CHINA +2

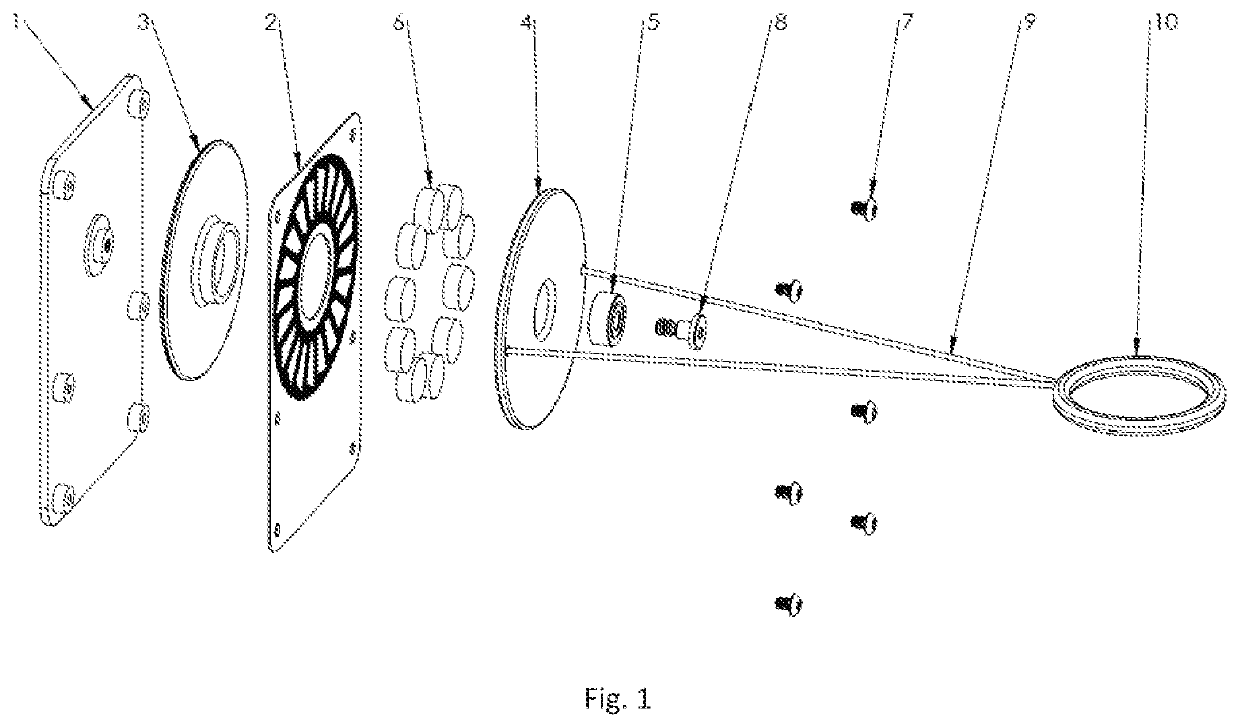

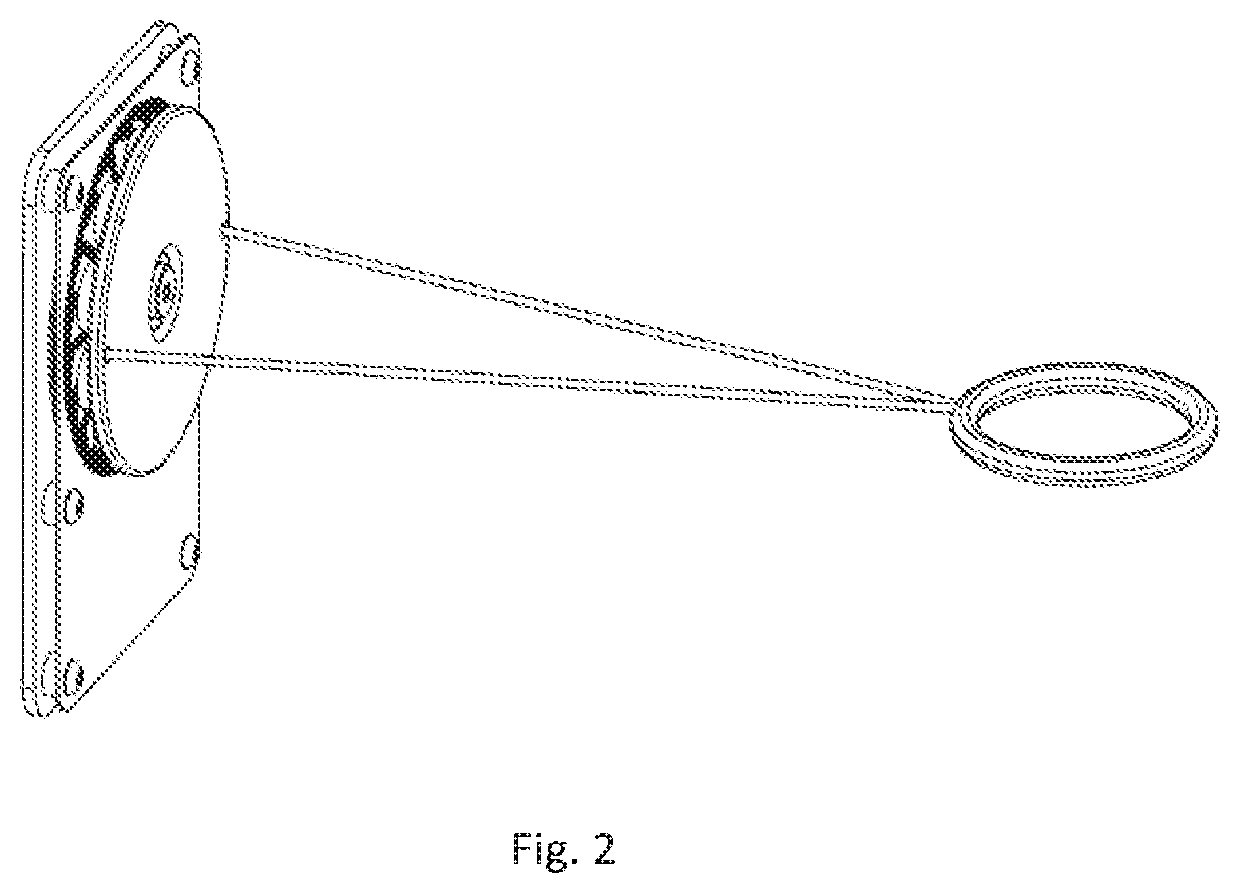

Personal Electromechanical Hand Driven AC to DC Generator to Charge Mobile Devices

InactiveUS20200059132A1Accurate pullRelieve stressMagnetic circuit rotating partsMachines/enginesFlywheelElectric generator

An efficient compact form factor for the hand powered mechanically driven flywheel electric generator for charging a smartphone or other personal device, in which the electric generator including a rotor and a stator, in which said rotor includes a plurality of alternating permanent magnetic fields arranged in a circular array such that a series of poles are established about the rotors circumference.

Owner:NUYTKENS MARK H

An automatic control system for the stability of temporary cable erection brackets

ActiveCN103899600BPlay the effect of linkage and joint adjustmentEasy to installFluid-pressure actuator safetyPipe supportsHydraulic cylinderAutomatic train control

The invention relates to a system for automatically controlling the stability of a temporary cable erection support. The system comprises a support body, a hydraulic system and a PLC control system, all inclined pulling wires are connected through the hydraulic system so that a linkage joint adjustment effect can be achieved, then the tensile force of all the inclined pulling wires can be independently or simultaneously controlled through the PLC control system, the system is easy and convenient to install, the inclined pulling wires and ground anchors can be connected only through a hydraulic cylinder, the hydraulic cylinder is controlled to stretch or retract by a hydraulic valve so that the tensile force of the inclined pulling wires can be adjusted, the responding speed is high, the tensile force is accurately controlled, and the whole set of equipment can be installed fast.

Owner:STATE GRID CORP OF CHINA +2

A temporary support for cable erection with automatic adjustment function

ActiveCN103904584BPlay the effect of linkage and joint adjustmentEasy to installApparatus for overhead lines/cablesHydraulic cylinderControl system

Owner:STATE GRID CORP OF CHINA +2

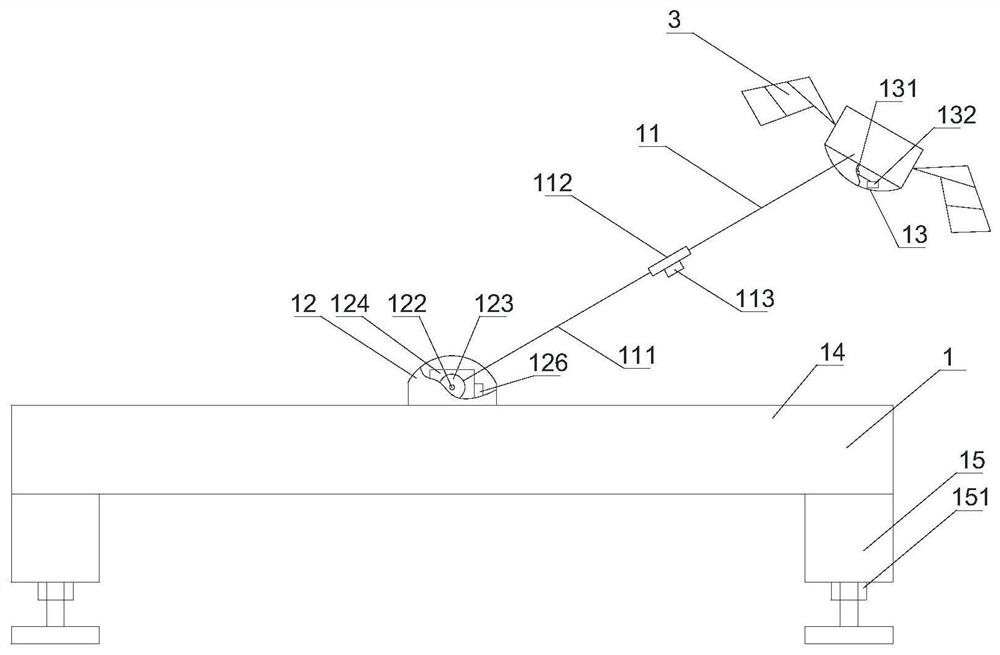

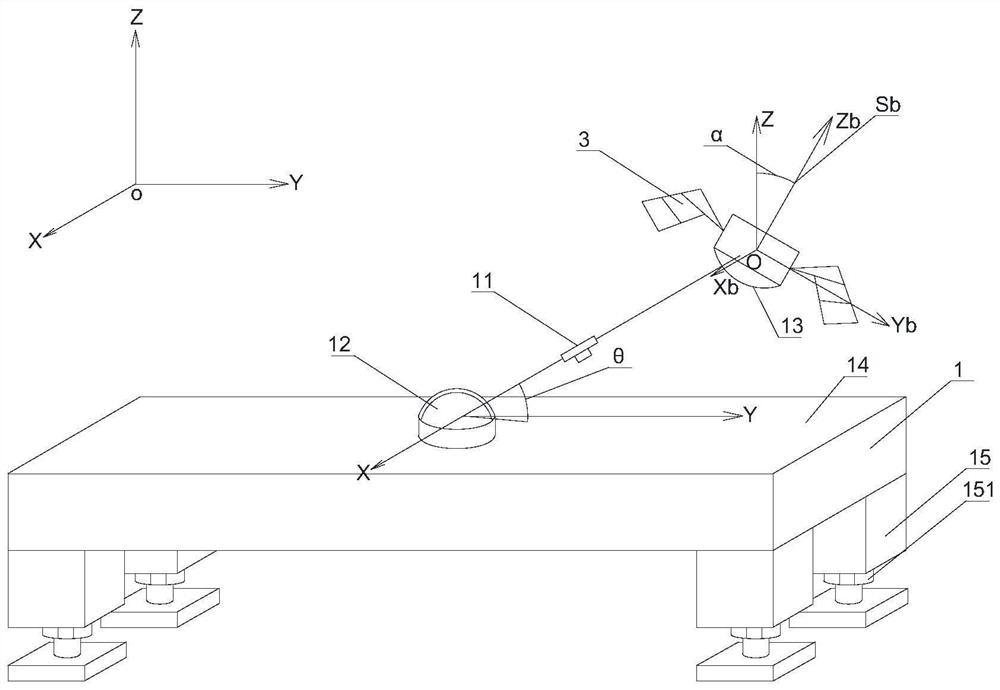

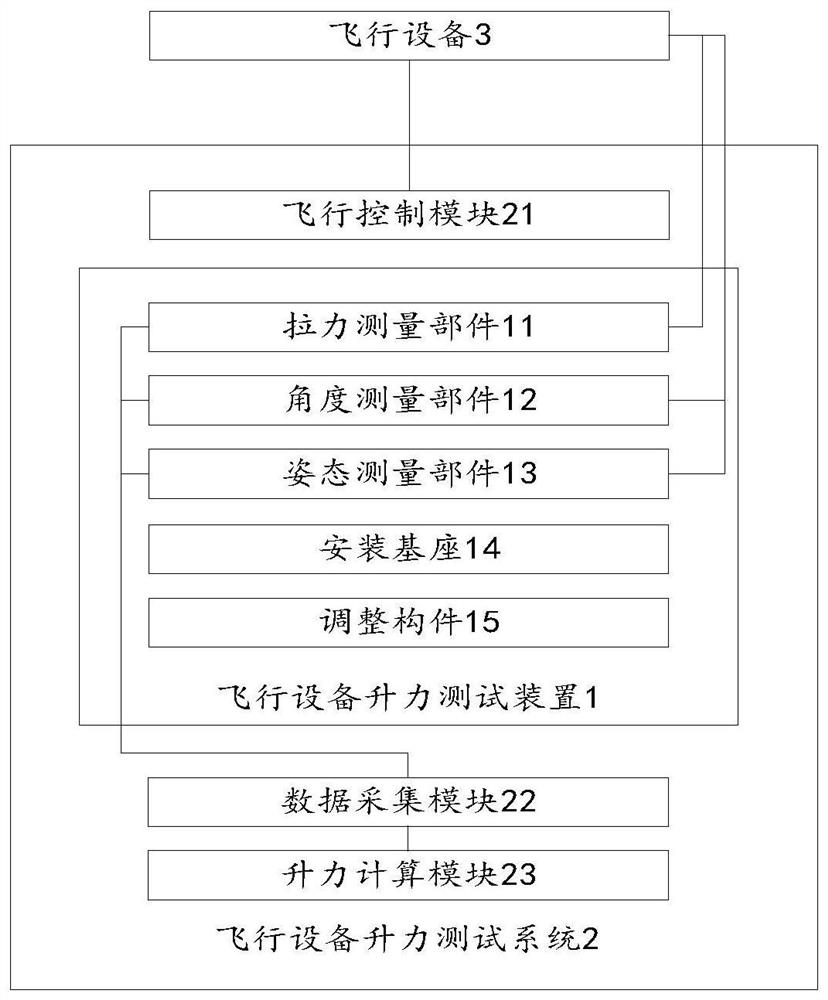

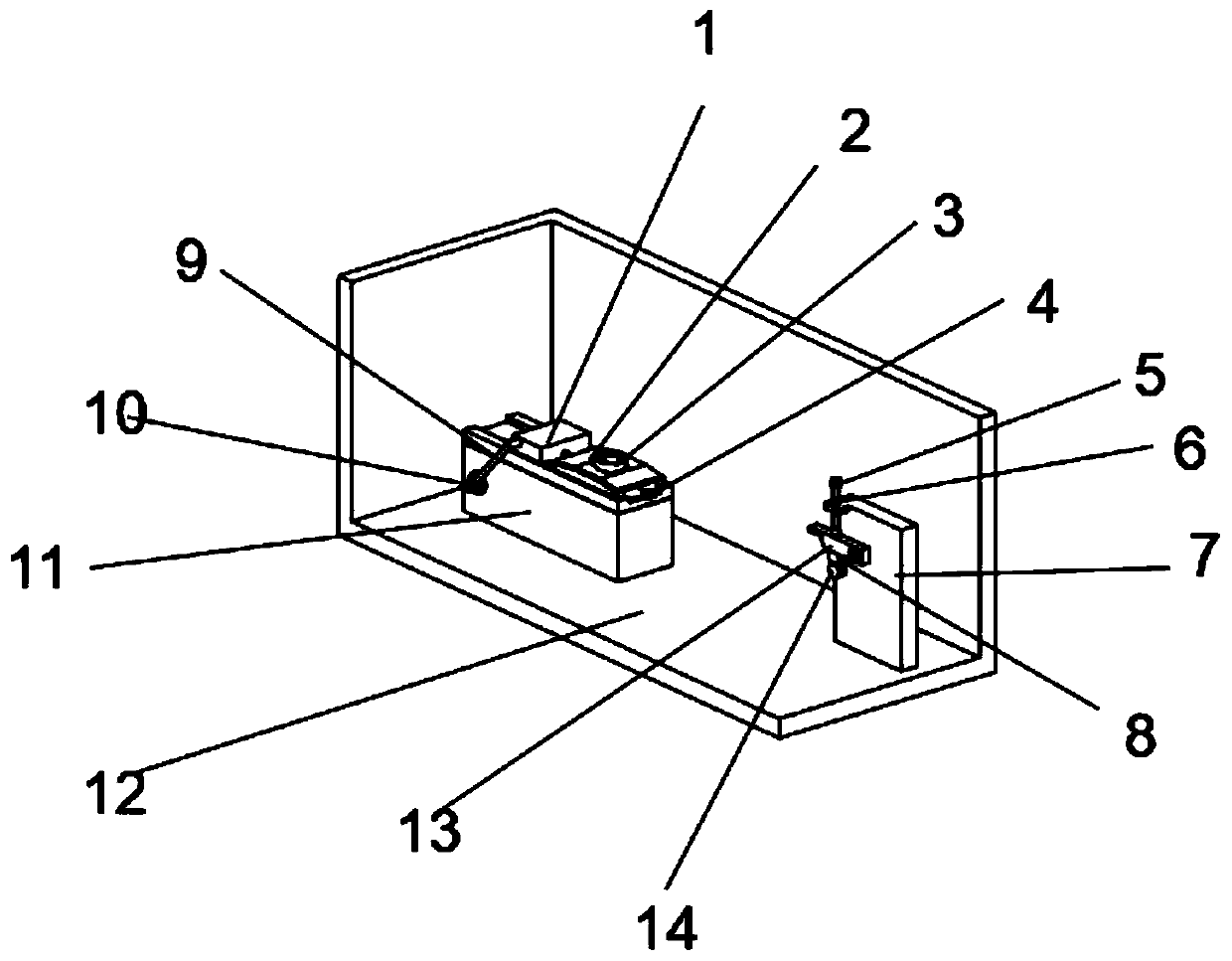

Flight equipment lift force testing device, system and method

PendingCN113071707ATensile measurementAccurate liftAircraft components testingAviationFlight vehicle

The invention relates to the technical field of mechanical measurement in the aviation field, in particular to lift force testing of small and miniature bionic flapping-wing aircrafts, and discloses a flight equipment lift force testing device, system and method. The device comprises a tension measuring part which is used for measuring data which are generated by the flight equipment in a flight state and are used for representing tension; an angle measuring part which is used for measuring data used for representing a tension angle when the flight equipment is in a flight state, and the tension angle is an included angle between the direction of the tension measuring part subjected to the tension of the flight equipment and the measuring reference surface of the angle measuring part; and an attitude measurement component which is used for measuring data for representing a roll angle and / or a pitch angle of the flight equipment in a flight state. According to the device, the accuracy of lift force measurement and calculation work is ensured, and the situation that the lift force test is inaccurate and unreliable due to the fact that a rigid connection scheme cannot reflect the flight state due to over-constraint of the degree of freedom is eliminated.

Owner:上海前瞻创新研究院有限公司

Spare brake beam having replaceable brake heads

ActiveCN101484345AQuick installationEasy to installRail brake actuationBrake padAutomotive engineering

Owner:STUCKI DE MEXICO S DE R L DE C V

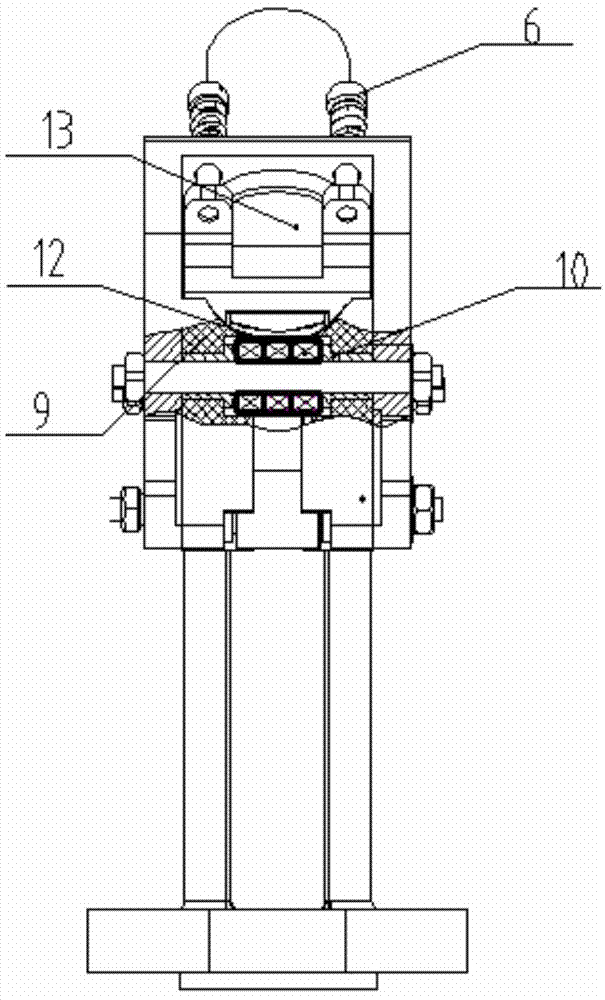

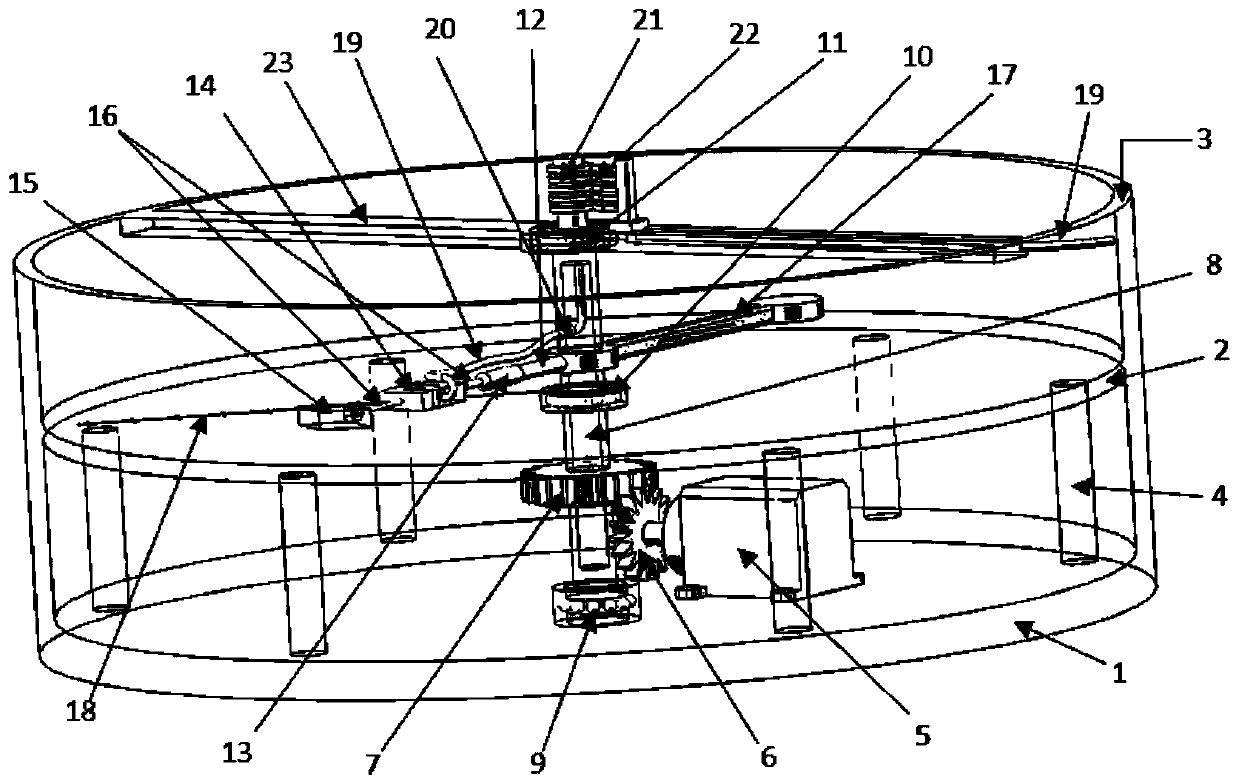

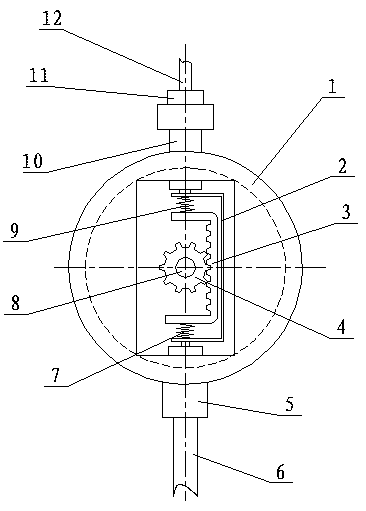

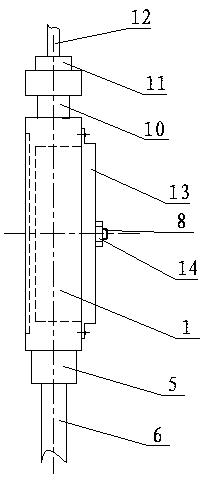

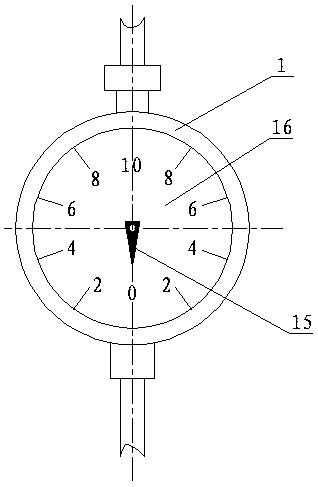

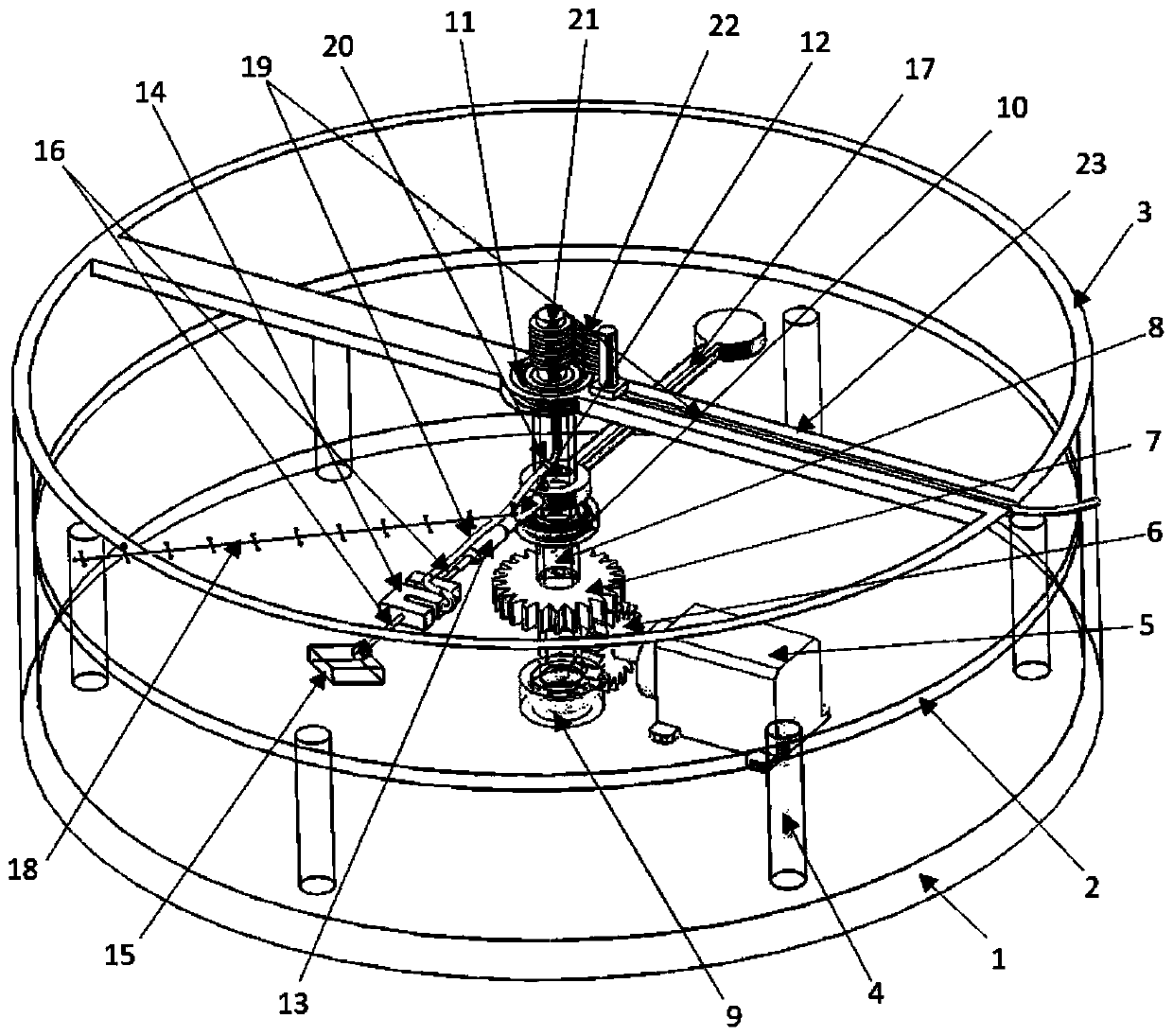

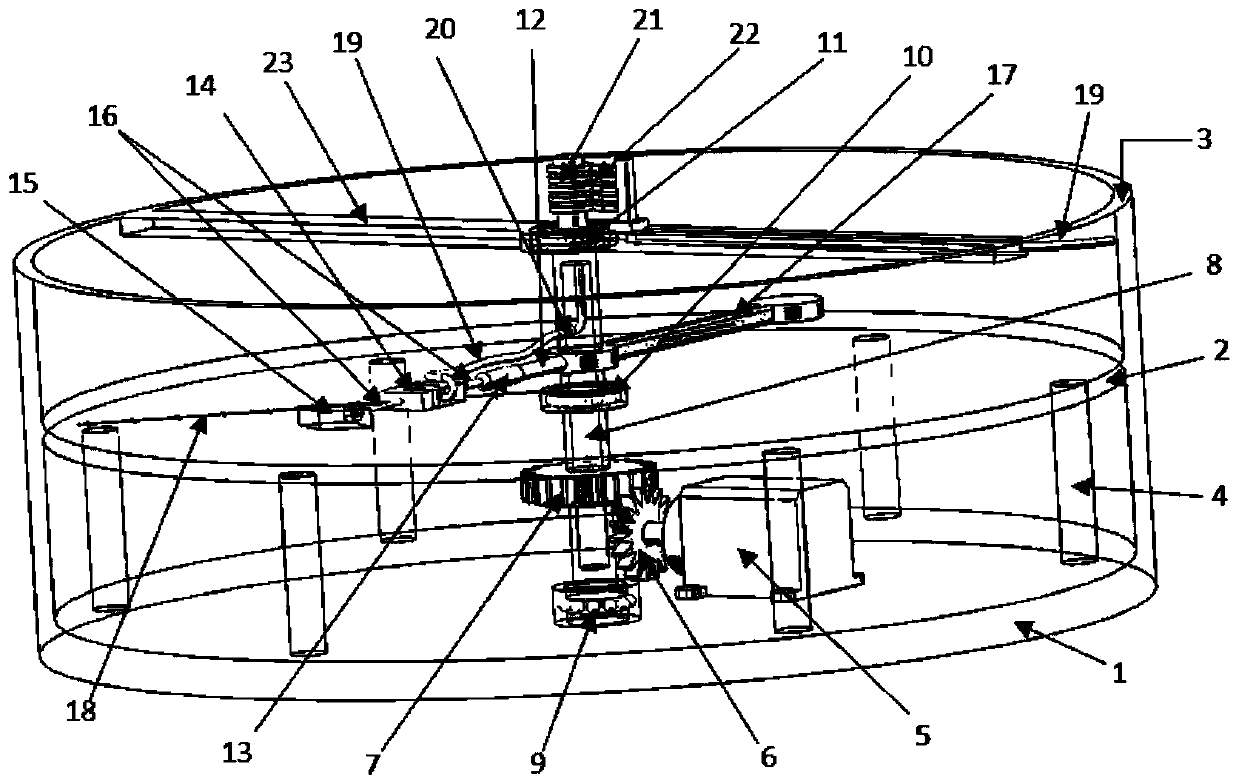

Spring force measuring device for high school physical mechanics experiment and force measuring method

InactiveCN109300369AReduce gapExtended service lifeEducational modelsDirect effectsPhysical laboratory

The invention relates to a spring force measuring device for a mechanics experiment in high school physics and a force measuring method. At present, the teaching tool for a high school physics laboratory is relatively single, especially for the experiment device for force measurement, force measurement in multiple directions can not be done, that is, the pressure and the tension in each directioncan not be measured, and effects of the mechanics experiment are directly influenced. The device comprises a disc (1); the middle part of the disc is provided with a square groove; the square groove is internally provided with a gear (4); the gear is engaged with a rack in a groove rack (3) with a rack; the upper surface and the lower surface of the groove rack are fixed with an upper spring (9) and a lower spring (7); the upper spring and the lower spring are connected with the inner side surface of a support frame (2) and are fixed; the top of the support frame is connected with an upper sliding rod (12); the upper sliding rod sequentially passes through a given-force adjusting sleeve (11) and a zero reset adjusting sleeve (10); and the zero reset adjusting sleeve is connected with the disc through thread. A spring force measuring device for a mechanics experiment in high school physics is provided.

Owner:黄汇彤

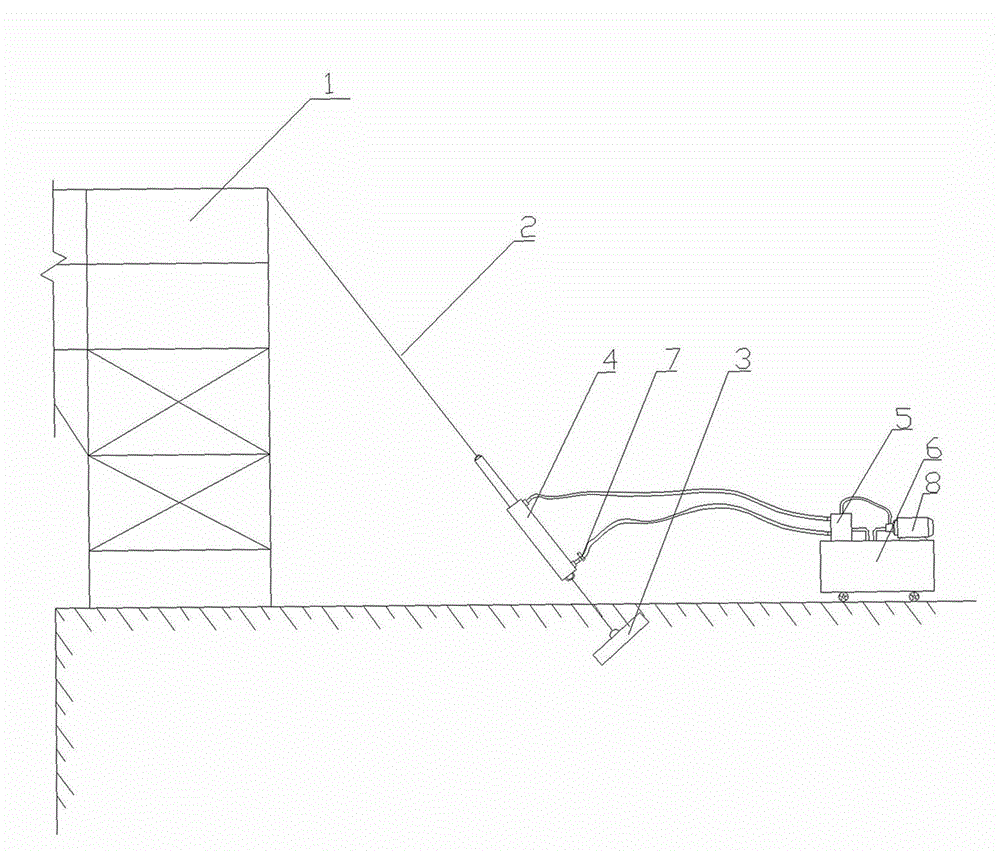

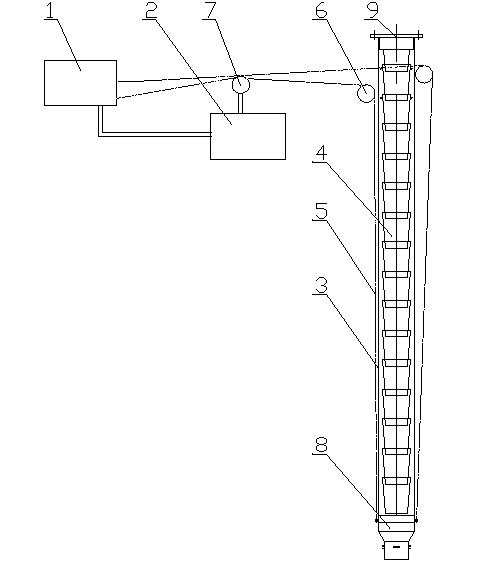

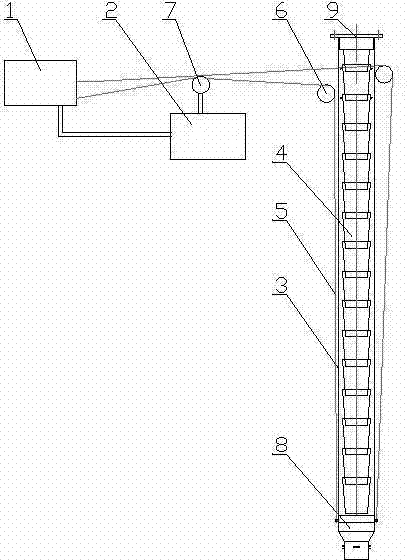

Ship position tracking system capable of being used for long-distance transporting and shipping equipment

The invention relates to a ship position tracking system capable of being used for long-distance transporting and shipping equipment. The ship position tracking system comprises a falling pipe lifting control device (1), a telescopic falling pipe (3), a lifting cable (5) and a lifting pulley (6), wherein a lower end discharge port (8) of the telescopic falling pipe (3) is hermetically connected with a ship cabin; the lower end of the lifting cable (5) is connected with the discharge port (8); and a tension sensor (2) is also arranged between the falling pipe lifting control device (1) and the telescopic falling pipe (3) and is connected with a sensing pulley (7). According to the ship position tracking system, the height of the lifting cable is controlled by using the tension sensor according to variation in tension of the lifting cable during variation in ship position, so that the lower end discharge port of the telescopic falling pipe is hermetically connected with the ship cabin all the time, and material loss and dust pollution caused by separation of the discharge port and the ship cabin due to variation in water level and wind wave and the bumping of the ship cabin are prevented.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

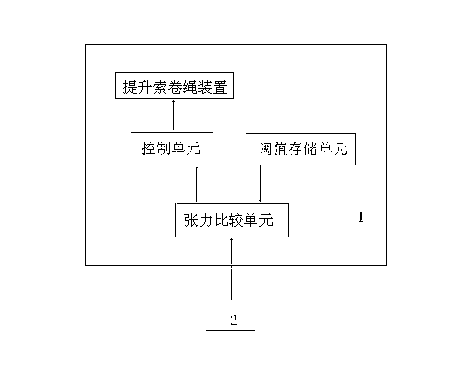

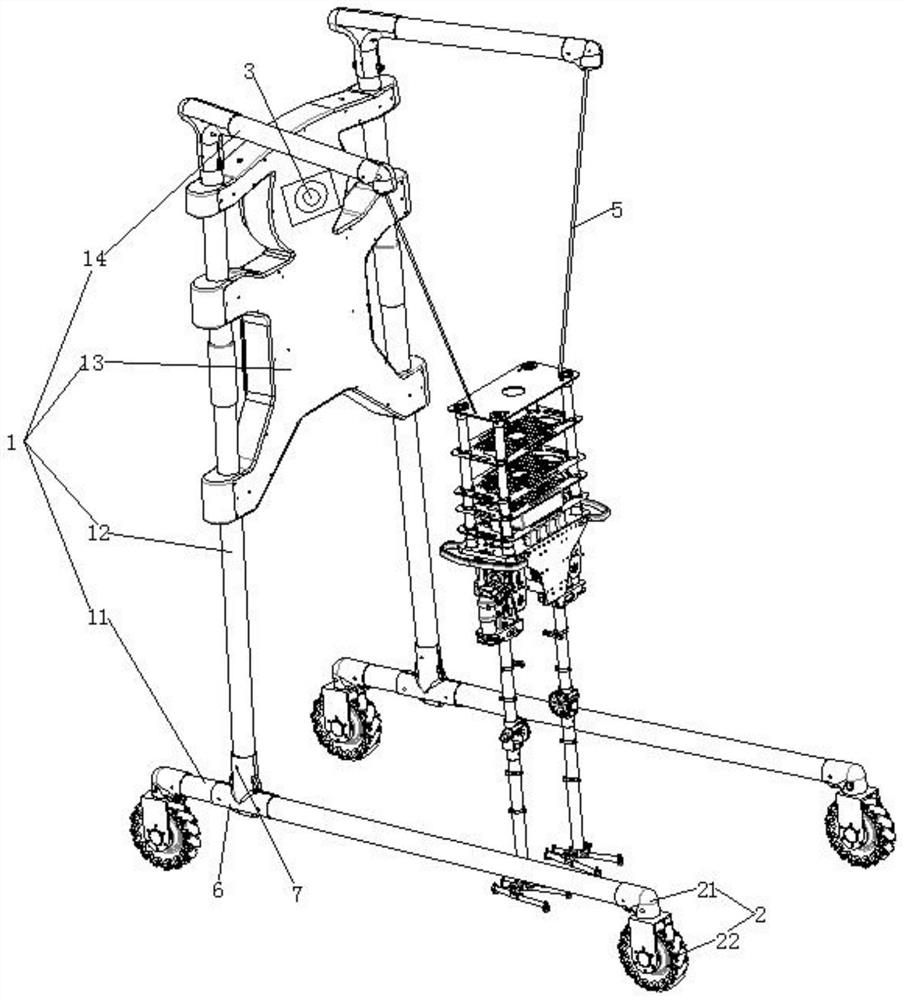

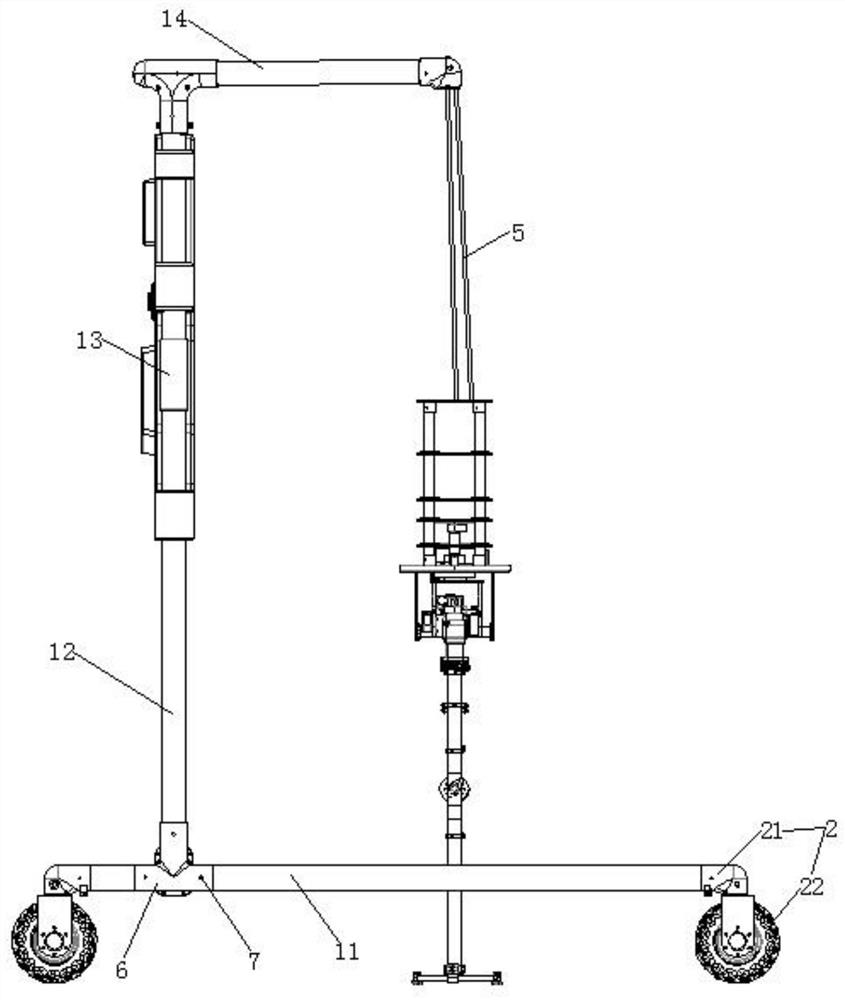

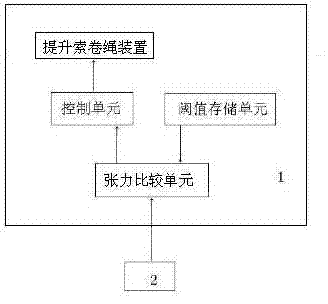

Movable microgravity environment simulation device

PendingCN112079258AMove and adjust in timeLow costBase supporting structuresBraking devices for hoisting equipmentsMicrogravity SimulationClassical mechanics

The invention relates to the technical field of low-gravity simulation devices, and discloses a movable microgravity environment simulation device. The movable microgravity environment simulation device comprises a suspension bracket, an automatic guide moving device, a route acquisition device, a hoisting device, a traction rope and a strength parameter feedback device, wherein the automatic guide moving device is arranged at the bottom end of the suspension bracket and is used for driving the suspension bracket to move; the route acquisition device is arranged on the suspension bracket and is further electrically connected with the automatic guide moving device; the hoisting device is arranged on the suspension bracket; the traction rope is connected with the hoisting device; the hoisting device drives the traction rope to be expanded or contracted; and the strength parameter feedback device is arranged on the suspension bracket and is further electrically connected with the hoistingdevice. The movable microgravity environment simulation device provided by the invention can move along with a tracked target in a full-automatic manner, can conduct various sorts of microgravity simulation on the pulled target, and is simple in structure, flexible, variable, high in using efficiency and low in cost.

Owner:中原动力智能机器人有限公司

A guiding rope tension measuring device

ActiveCN104502012BAccurate pullPrecise tension measurementTension measurementComposite effectPull force

Owner:HARBIN INST OF TECH

Optical fiber tension measuring device and system

InactiveCN113758616APull changeAccurate pullForce measurement by measuring optical property variationOptical detectorsOptical detector

The invention relates to an optical fiber tension measuring device and system, and in particular relates to the field of tension detection. The optical fiber tension measuring device comprises a light source, a first stress part, a second stress part, an elastic part, an optical fiber and an optical detector, when tension needs to be detected, the tension acts on the first stress part and the second stress part of the optical fiber tension measuring device, under the action of the first stress part and the second stress part, the elastic part deforms, the elastic part acts tension and pressure on the optical fiber to enable the optical fiber to deform, and then the transmission loss of the optical fiber is changed, so that the light intensity of an optical signal emitted through the optical fiber is changed, and the emergent light intensity of the optical signal is detected through the optical detector; and according to the corresponding relationship between the light intensity and the to-be-measured tension, the to-be-measured tension is acquired.

Owner:西安柯莱特信息科技有限公司

Consumable tensile detection equipment

PendingCN109991076AEasy to pull testAccurate pullMaterial strength using tensile/compressive forcesEngineeringTensile testing

The invention discloses consumable tensile detection equipment. The consumable tensile detection equipment comprises a force measurement driver, a force meter, a force gauge, a force measurement pullring, a compression screw, a fixed nut, a fixed plate, an upper roll groove bearing, a connection shaft, a motor rotation shaft, a base, a housing, a locking block, a lower roll groove bearing, a sliding table, a feed inlet, a fixed block and a sliding seat. The consumable tensile detection equipment has the beneficial effects that the consumable tensile detection equipment is reasonable in design; the upper roll groove bearing is rotationally connected to a locking block set screw by the locking block; when a consumable is inserted between the upper roll groove bearing and the lower roll groove bearing, the upper roll groove bearing follows up the locking block to move upwards; when passage of the consumable is completed, the upper roll groove bearing follows up the locking block to be descended to compress the consumable; the force measurement driver and the force meter are in sliding connection to the sliding table by the sliding seat; the force meter is driven by the force measurement driver to move backwards so as to carry out tensile testing on the consumable; a compression block is arranged at the head part of the compression screw; the compression block is in contact connection to the upper surface of the locking block; and when the screw is operated to rotate forwards, the locking block compresses the consumable under the action of the compression block.

Owner:HENAN ZHUCHENG ELECTRONICS TECH CO LTD

A static calibration device and method for a tension sensor in a weightless environment

InactiveCN109696274BAccurate pullAvoid the effects of weightlessnessForce/torque/work measurement apparatus calibration/testingEngineeringFine-tuning

The invention discloses a tension sensor static calibration device and method in weightless environment. The device comprises a chassis and a shell mounted on the chassis; a dial is fixed on the chassis through a supporting column, and a graduated scale is arranged on the upper surface of the dial; a rotating shaft penetrates through the chassis and the dial and is connected with the chassis and the dial through bearings; the lower end of the rotating shaft is provided with a first gear; a servo motor is mounted on the chassis, a second gear is arranged on an output shaft of the servo motor, and the second gear is perpendicular to and meshed with the first gear; the rotating shaft is connected with a fine tuning arm; the fine tuning arm is positioned above the dial, and a distance is formed between the fine tuning arm and the dial; one end of the fine tuning arm is connected with one end of a tension sensor to be calibrated through a string, the other end of the tension sensor is connected with a standard mass balance weight through a string, a fine tuning knob for adjusting the telescopic length of the fine tuning arm is arranged on the fine tuning arm, and a balance beam is arranged on the opposite side of the fine tuning arm. The problem that a conventional calibration method is not suitable for a weightless environment is solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Flexible Mounting Force Measuring Velocity Device

ActiveCN104614110BCompact structureWork reliablyLinear/angular speed measurementMicrocomputerPull force

The invention discloses a flexible-installation force and speed measuring device and relates to the technical field of cable tension and speed detecting devices of winches. The flexible-installation force and speed measuring device comprises a pulley block suspended on a fixing support through cables; the pulley block comprises a force measuring pulley and two speed measuring pulleys, which are mounted on a support rack through a force measuring hinge pin and speed measuring hinge pins respectively, wherein the force measuring pulley is arranged under the two speed measuring pulleys; winch cable passages at a wrap angle of alpha from the force measuring pulley are formed between the two speed measuring pulleys and the force measuring pulley; one of the speed measuring hinge pins is provided with a speed measuring rotary encoder, a stress sensor is arranged inside the force measuring hinge pin, and the speed measuring rotary encoder and the stress sensor are electrically connected with a microcomputer processor. Compared with the prior art, the force measuring pulley and the two speed measuring pulleys can achieve automatic adjustment to adapt to continuous change in output angles and the number of layers of the cable, and monitored tension and cable speed data can be more direct and more accurate.

Owner:SOUTH CHINA MARINE MACHINERY

A side thrust function simulation device for large-scale liquefied petroleum and natural gas tank test

ActiveCN104764585BTo achieve the function of side pushSimple structureHydrodynamic testingProtractorLiquefied petroleum gas

Owner:CHINA NAT OFFSHORE OIL CORP +1

A ship position tracking system that can be used for long-distance transportation of shipping equipment

ActiveCN103183242BInstant lift handlingGuaranteed airtight connectionLoading/unloadingOn boardMarine engineering

The invention relates to a ship position tracking system capable of being used for long-distance transporting and shipping equipment. The ship position tracking system comprises a falling pipe lifting control device (1), a telescopic falling pipe (3), a lifting cable (5) and a lifting pulley (6), wherein a lower end discharge port (8) of the telescopic falling pipe (3) is hermetically connected with a ship cabin; the lower end of the lifting cable (5) is connected with the discharge port (8); and a tension sensor (2) is also arranged between the falling pipe lifting control device (1) and the telescopic falling pipe (3) and is connected with a sensing pulley (7). According to the ship position tracking system, the height of the lifting cable is controlled by using the tension sensor according to variation in tension of the lifting cable during variation in ship position, so that the lower end discharge port of the telescopic falling pipe is hermetically connected with the ship cabin all the time, and material loss and dust pollution caused by separation of the discharge port and the ship cabin due to variation in water level and wind wave and the bumping of the ship cabin are prevented.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com