Two-layer copper brazed steel pipe forming unit

A technology for brazing steel pipes and forming units, which is applied in the field of production equipment for double-layer brazing steel pipes, can solve the problems of difficulty in meeting the requirements of modern manufacturing, poor technical performance and stability, and low production efficiency, and achieves compact structure and eliminates heat. The effect of expansion and contraction, improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

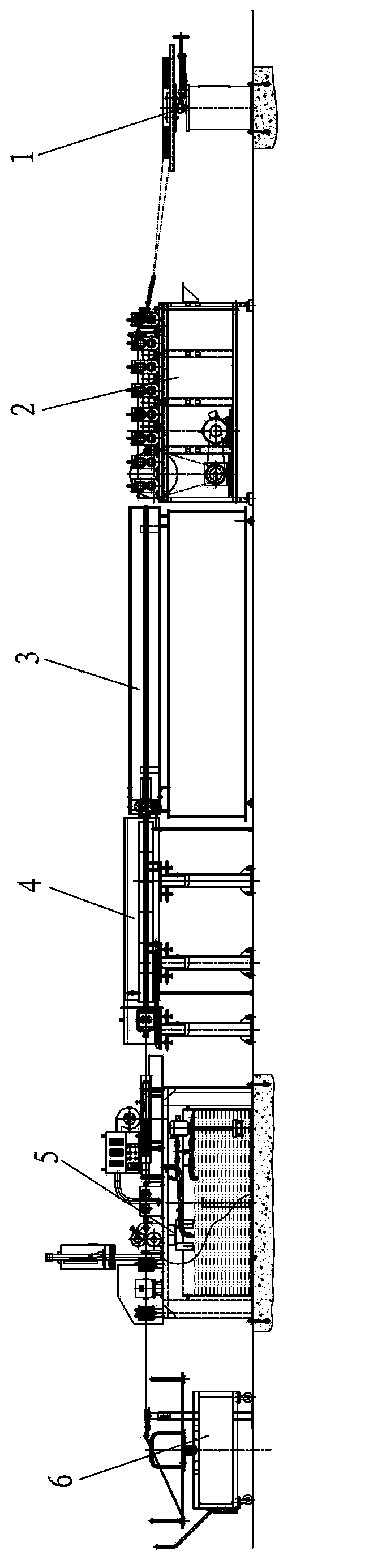

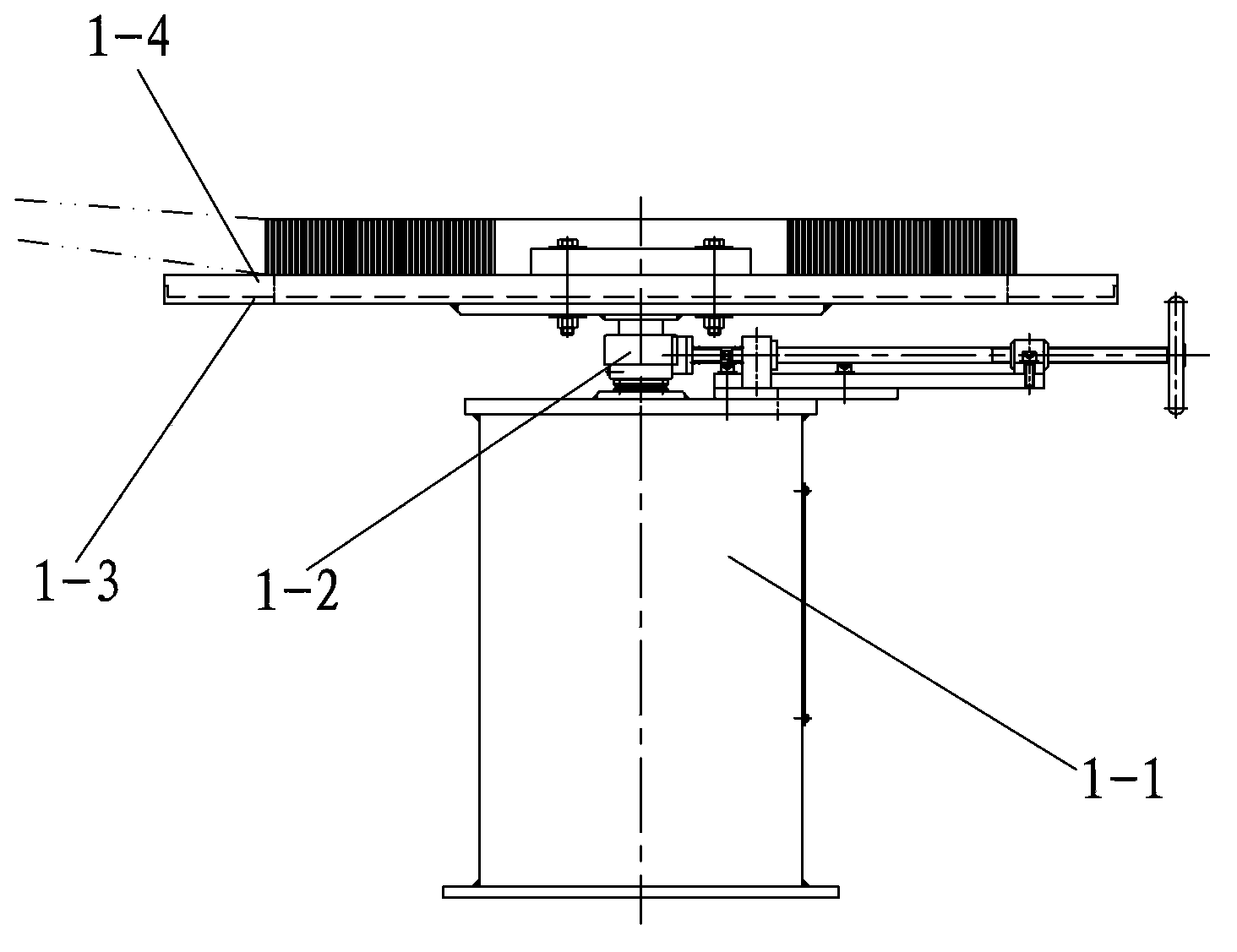

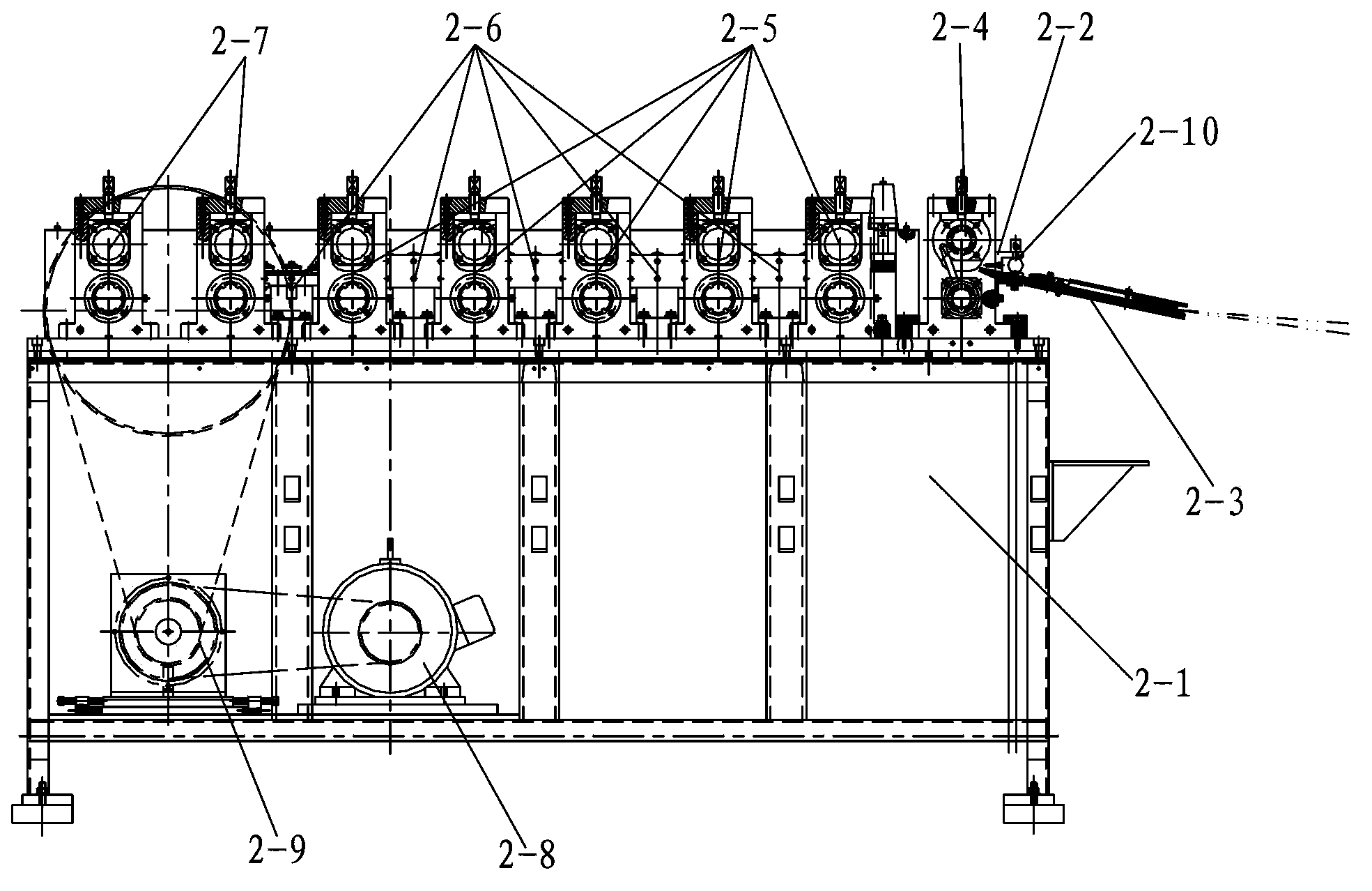

[0054] like Figure 1 to Figure 8 As shown, the present invention includes a horizontal unwinding machine 1, a pipe forming machine 2, an induction heating brazing furnace 3, a cooling device 4, a cleaning air-drying and flaw detection device 5 and a winding device 6 arranged side by side in sequence. The unwinder 1 comprises an unwinder base 1-1, a rotating shaft 1-2 installed on the top of the unwinder base 1-1 and a discharge tray 1-3 installed on the rotating shaft 1-2; 2 Including head box 2-1, strip forming power mechanism installed in head box 2-1 and forming head installed on the top of head box 2-1, mandrel is fixed on the forming head Frame 2-2, mandrel 2-3 is installed on described mandrel fixing frame 2-2; Described induction heating brazing furnace 3 comprises brazing furnace frame 3-1 and is arranged on brazing furnace frame 3- 1 on the brazing furnace cover body 3-2, the brazing furnace cover body 3-2 is filled with protective gas, the brazing furnace frame 3-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com