Put-away machine of blanking robot

A technology of robot and swinging machine, applied in the field of blanking robot swinging machine, can solve the problems of product defects, easy to damage products, easy to knock off, etc., to achieve the effect of high degree of automation, fast material pulling speed, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings.

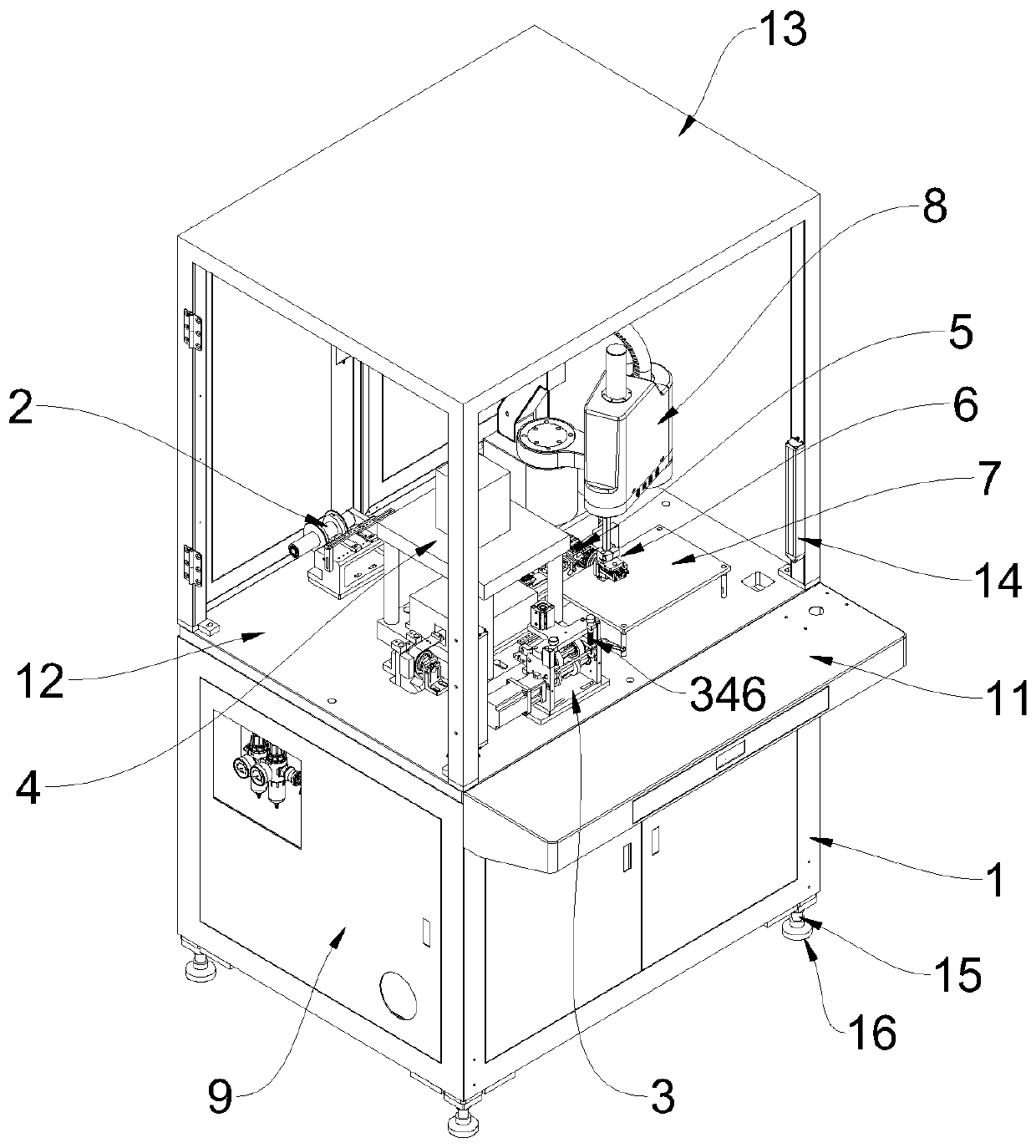

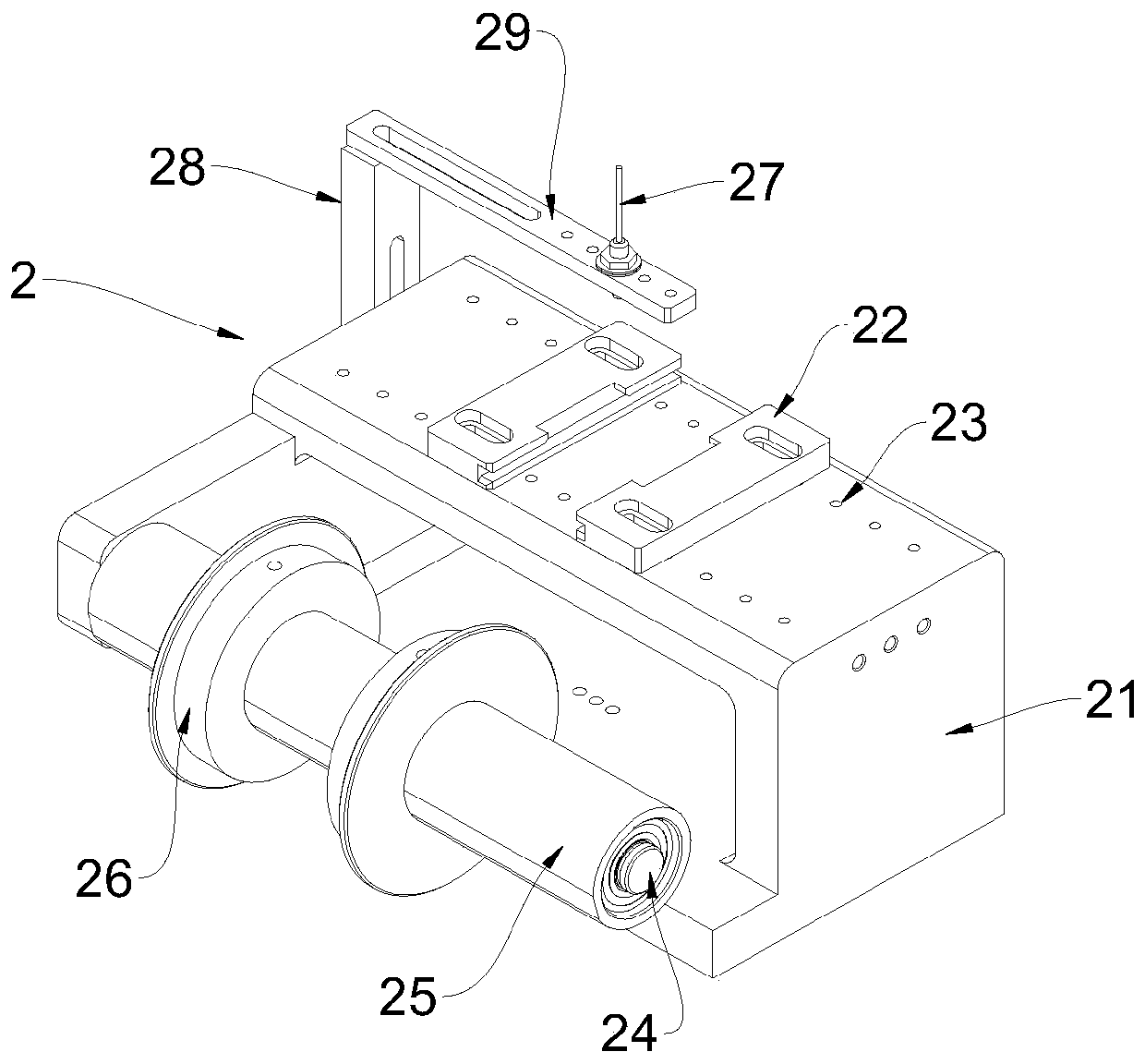

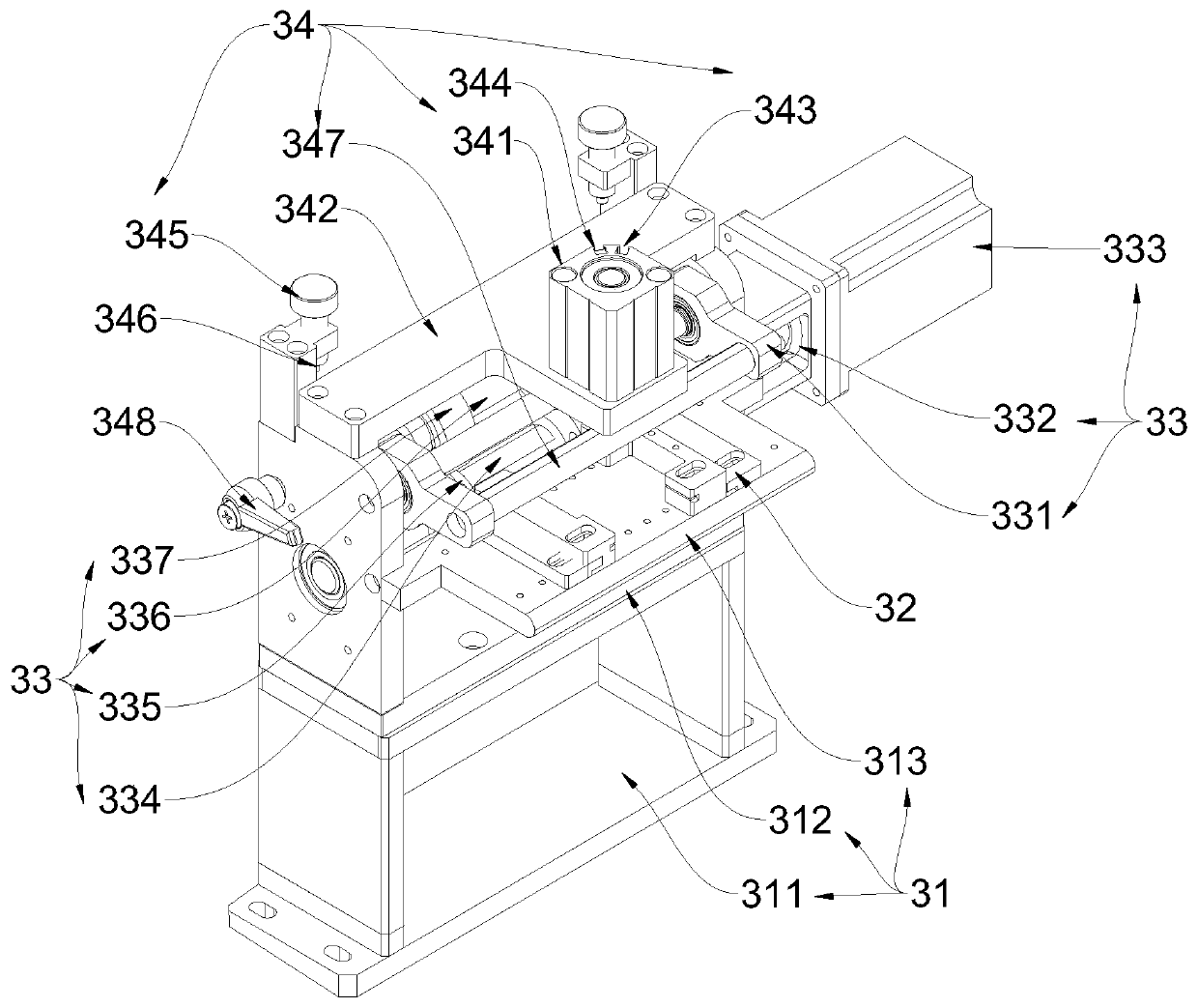

[0053] Figure 1-5 It schematically shows a plate-setting machine for a blanking robot according to an embodiment of the present invention. The device of the present invention can be used for processing various material strips, and in this embodiment, the frequently processed steel strip is taken as an example. like figure 1 As shown, the device includes a frame 1 , a guiding assembly 2 , a puller assembly 3 , a cutting die 4 , a conveying assembly 5 , a variable-pitch suction cup assembly 6 and a blister box 7 . The guiding assembly 2 , the puller assembly 3 , the cutting die 4 , the conveying assembly 5 , the variable-pitch suction cup assembly 6 and the blister box 7 are all arranged on the frame 1 .

[0054] Among them, a control cabinet 9 is provided, and the control cabinet 9 is arranged on the frame 1. The guide assembly 2, the puller assembly 3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com