Flexible-installation force and speed measuring device

A speed-measuring device and force-measuring technology, which is applied in the field of cable tension and speed detection devices of hoisting winches, can solve problems such as the inability to automatically adjust the cable exit angle, the constant change of the number of layers, and the data error of tension and cable speed data, etc. Achieve the effect of simple and compact structure, reliable operation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

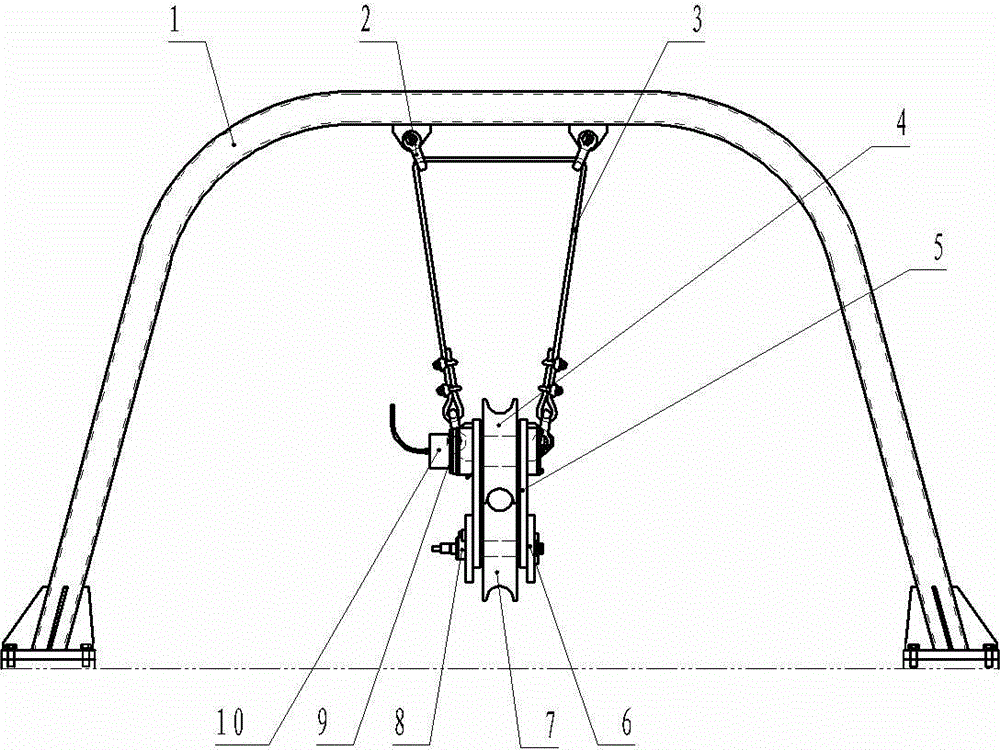

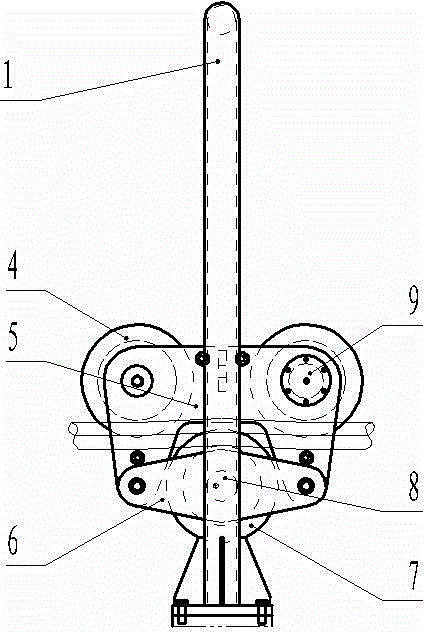

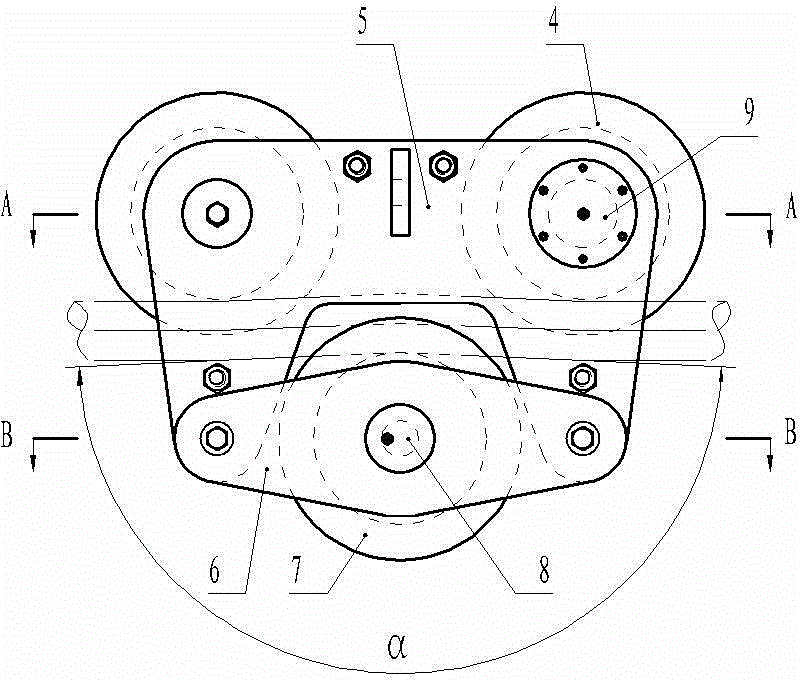

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 The shown one kind of flexible installation dynamometer and speed measuring device includes a pulley block suspended on the fixed bracket 1 by cables 3 for force measurement and speed measurement, the fixed bracket 1 is installed on the working plane by bolts, and the cables 3 are worn on the fixed bracket On the two lifting lugs 2 of 1, adjust the length according to the swing range when it is working; the pulley block includes a force measuring pulley 7 and two speed measuring pulleys installed on the support frame through the force measuring pin 8 and the speed measuring pin 9 respectively 4. The support frame includes two opposing support plates 5 connected by four bolts, two speed measuring pulleys 4 are respectively installed between the two support plates 5, and each support plate 5 is provided with two downward protruding Connecting part, between the two connecting parts, there is an installation ear plate 6...

Embodiment 2

[0026] The difference between this embodiment and Embodiment 1 lies in that the wrapping angle α formed by the cable channel of the winch and the force-measuring pulley 7 is 175 degrees.

[0027] All the other features are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com