Tensioning instrument for screw detection and application thereof

A screw and tensioning technology, applied in the field of the tension meter for testing large-section screws, can solve the problems of time-consuming and laborious, inability to determine whether the screw tension meets the requirements, and inability to guarantee the tensioning quality, etc., and achieves high accuracy and high test accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

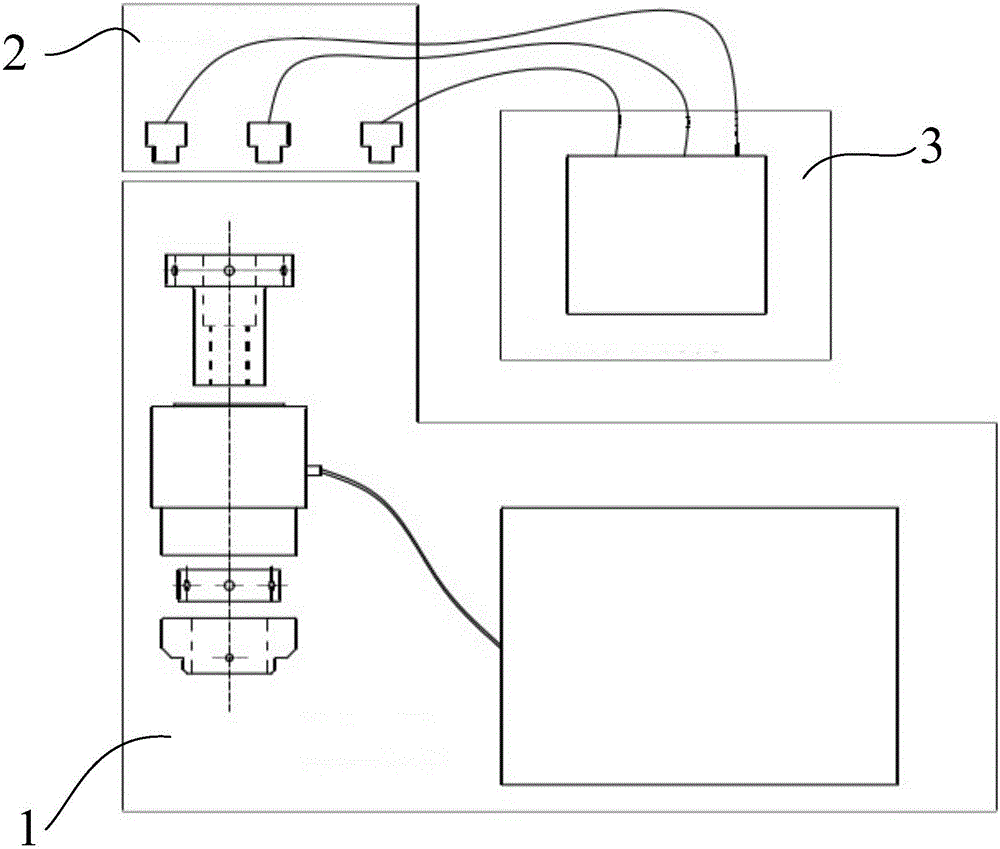

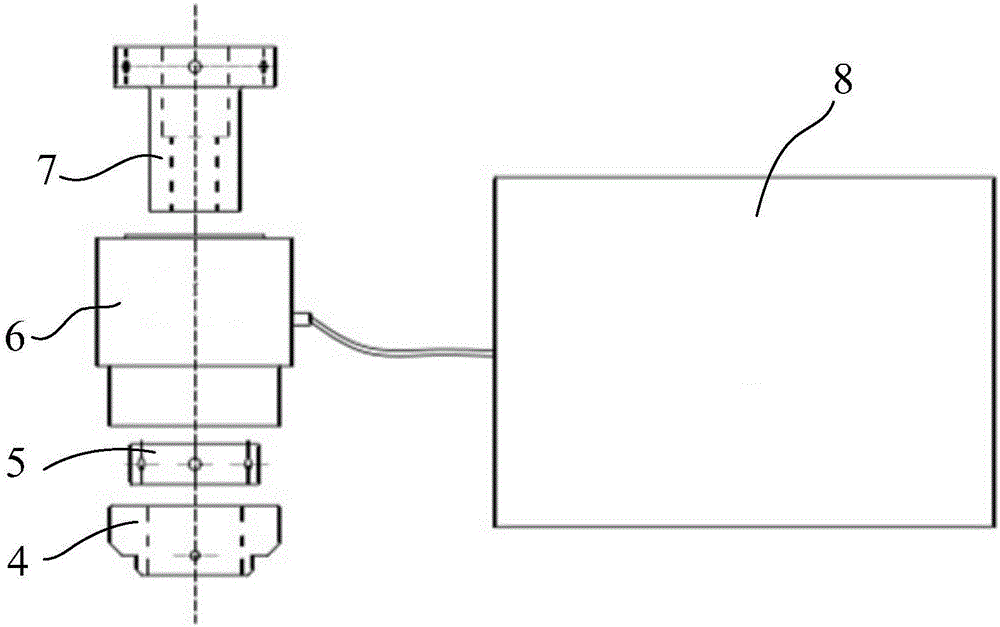

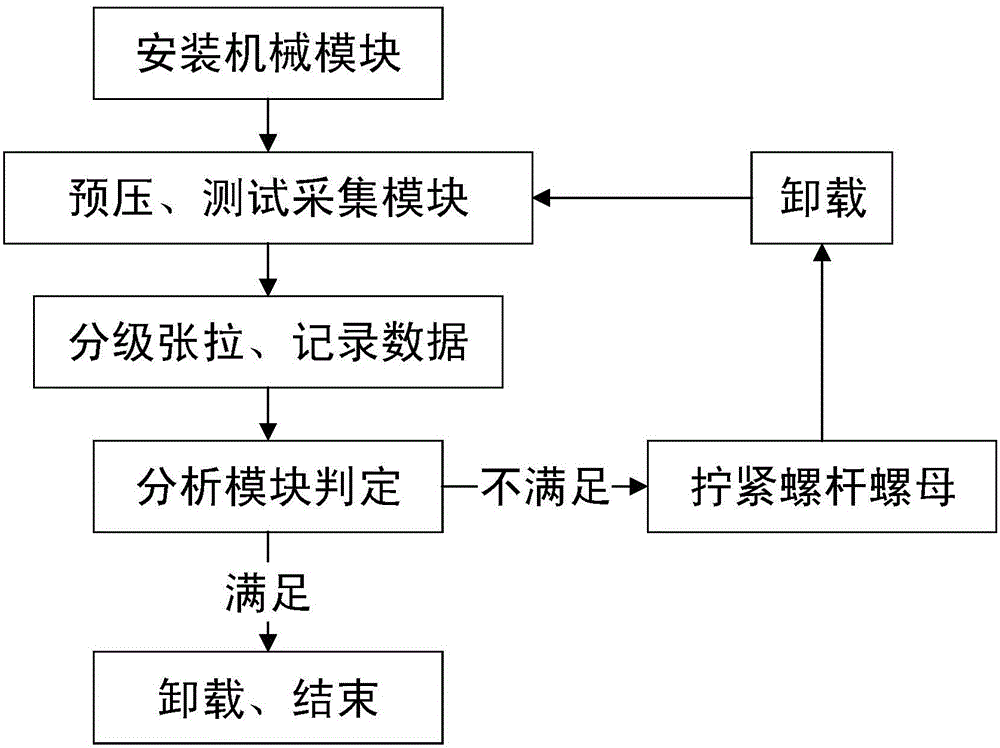

[0051] This embodiment provides a tensiometer for screw detection, such as figure 1 and figure 2 As shown, it includes a mechanical module 1 , a data acquisition module 2 and a data analysis module 3 . The mechanical module includes spacer 4, nut adjustment block 5, jack 6, tension nut 7 and oil pump 8; the oil pump 8 in this embodiment is a light manual high-pressure oil pump, which is convenient for high-altitude operations.

[0052] The data acquisition module 2 includes a pressure sensor, an ultrasonic sensor and a temperature sensor; during operation, one end of the pressure sensor is connected to the oil pump 8, and the other end of the pressure sensor is connected to the data analysis module 3 One end of the ultrasonic sensor is connected to the end of the screw, and the other end of the ultrasonic sensor is connected to the data analysis module 3; one end of the temperature sensor is connected to the end of the screw, and the other end of the temperature sensor is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com