A temporary support for cable erection with automatic adjustment function

An automatic adjustment and temporary support technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of heavy connecting hooks, affecting the construction progress, and being difficult to be found, so as to achieve good equipment versatility, simple and convenient installation, and high equipment utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

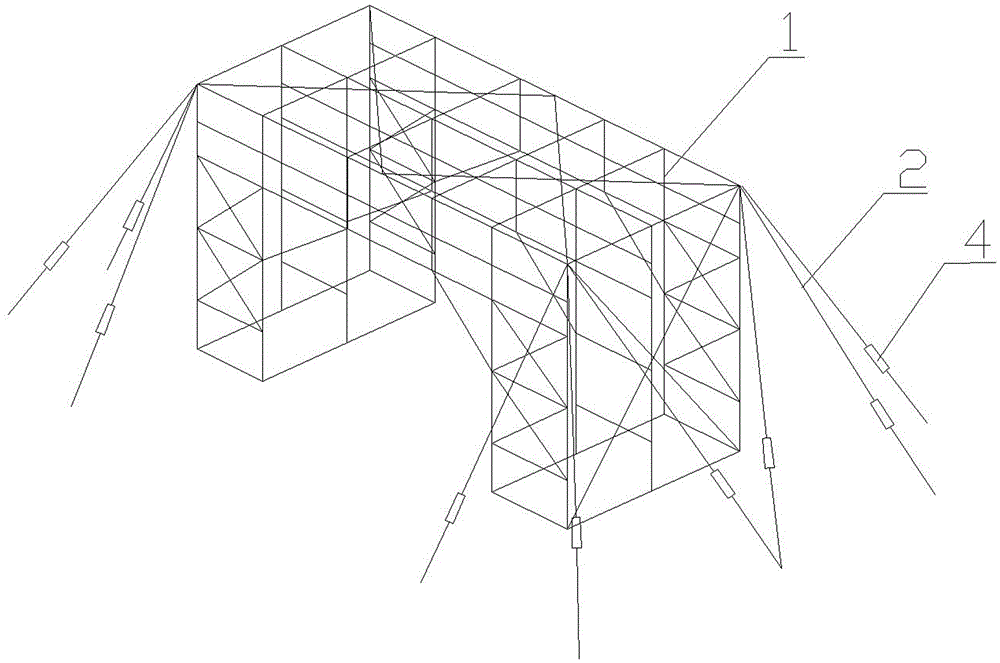

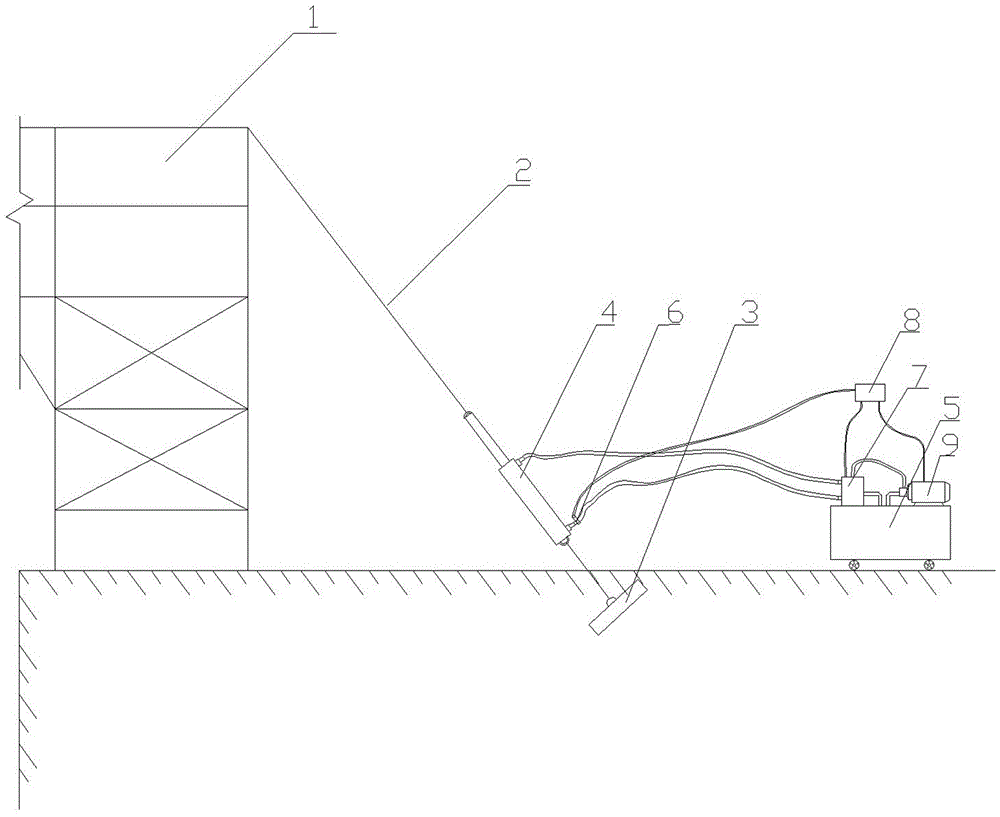

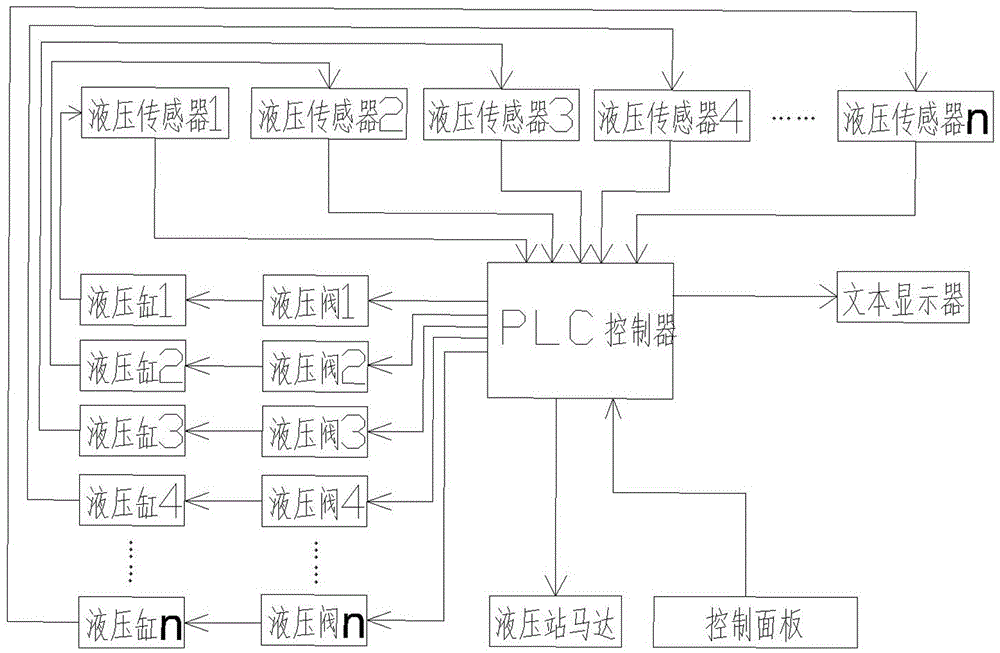

[0026] as attached Figure 1-3 As shown, a temporary support for cable erection with automatic adjustment function, which includes a support body, a hydraulic system and a PLC control system, wherein:

[0027] The support body includes a square arch body 1, a cable stay 2 and a ground anchor 3, the cable stay 2 is connected to the top corner of the square arch frame 1, and the cable stay 2 is connected to the ground through the ground anchor 3. Fixed; the hydraulic system includes a hydraulic station 5 and a hydraulic cylinder 4 arranged between the stay wire 2 and the ground anchor 3, and the hydraulic cylinder 4 is connected to the hydraulic station 5 through a hydraulic valve 7; the The PLC control system includes a PLC controller 8 and a hydraulic sensor 6 arranged on the hydraulic cylinder 4; the hydraulic sensor 6 is connected to the input end of the PLC controller, and the hydraulic valve 7 and the hydraulic station motor 9 are respectively connected to the PLC controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com