Method for packaging cigarette carton through non-woven fabric and cigarette carton packaging machine

A non-woven and packaging machine technology, applied in the field of tobacco packaging, can solve the problems of inability to wrap cigarette packs tightly, the impact of transportation and distribution, and high energy consumption, and achieve the effects of curbing white pollution, being easy to popularize and using, and having a simple force-measuring structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

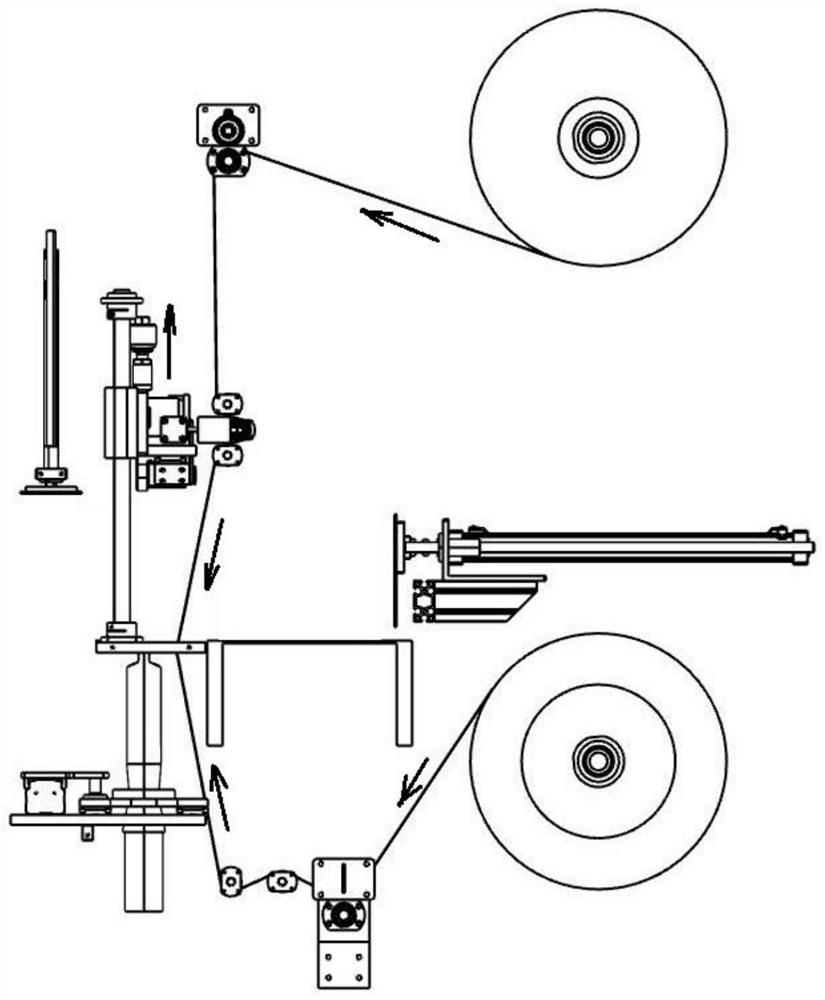

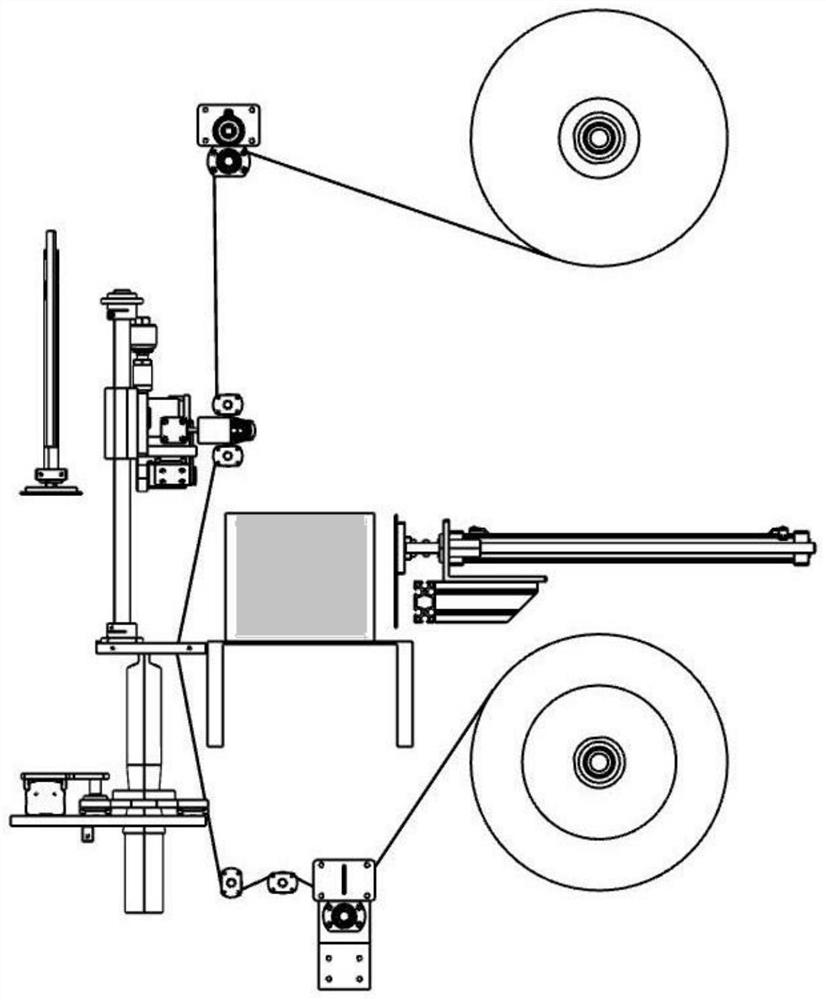

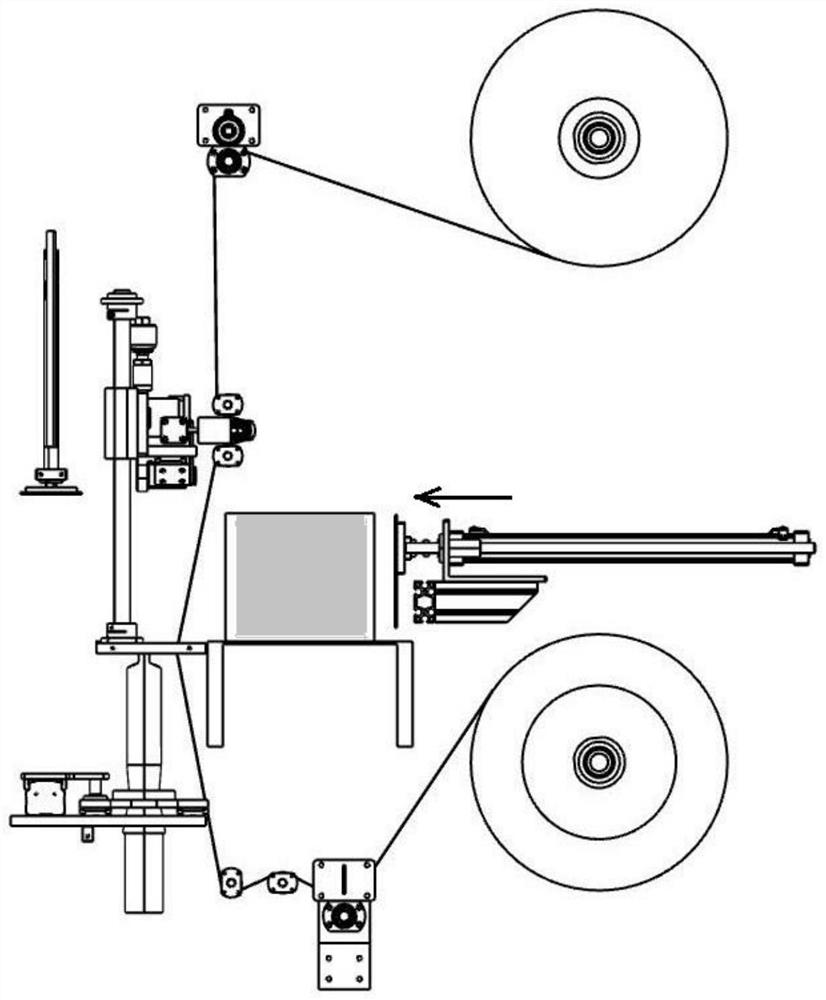

[0064] In this embodiment, according to the size of the GDX carton of domestic cigarettes, the size is 86.45 mm high × 54.4 mm wide × 22.5 mm thick, and a high-strength non-woven roll with a width of 276 mm is used as the packaging material, and the width of the two non-woven rolls is the same. And the thickness is the same, both are 70g / m 2 According to the test method of GB / T 24218.3-2010 "Test Method for Textiles and Nonwoven Fabrics - Determination of Breaking Strength and Elongation at Break", the average breaking force (breaking strength) measured with a standard breaking force test block of 50mm×200mm The value is 155N. Therefore, the breaking force of a non-woven fabric with a width of 276mm is greater than 850N, and there are 50 cigarettes in a box of cigarettes, and its weight is 20kg. Usually, the number of cigarettes in a cigarette pack after sorting is less than The weight of a box is less than 20kg, so the use of this non-woven fabric can fully withstand the pull...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking force | aaaaa | aaaaa |

| breaking force | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com