A guiding rope tension measuring device

A tension measurement and rope technology, applied in the field of mechanical measurement, can solve the problems of no rope angle transformation and guidance, difficult to ensure the measurement accuracy of the sensor, and inability to accurately measure the core force, etc., and achieves light weight, fast and reliable operation. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

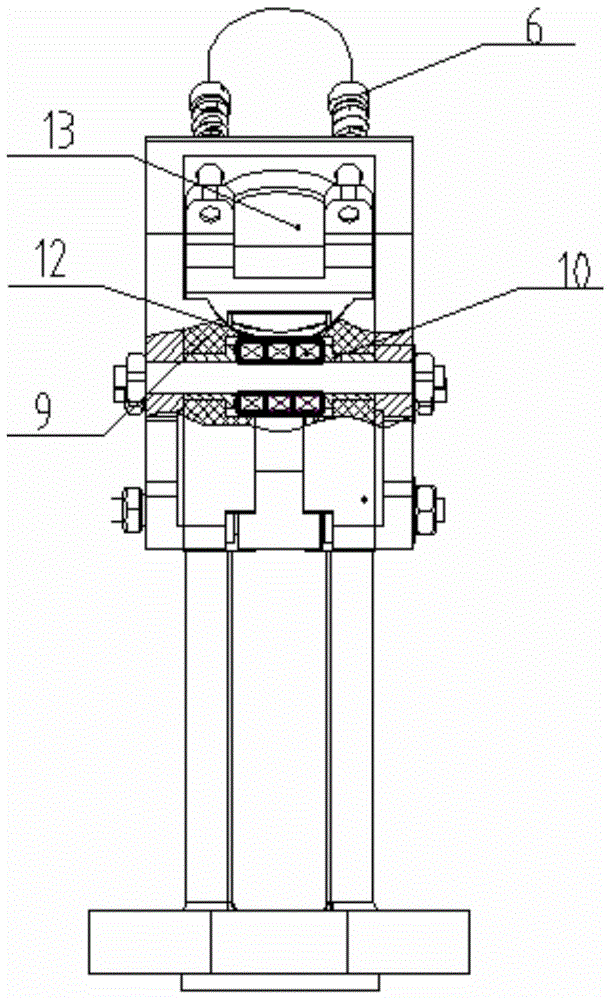

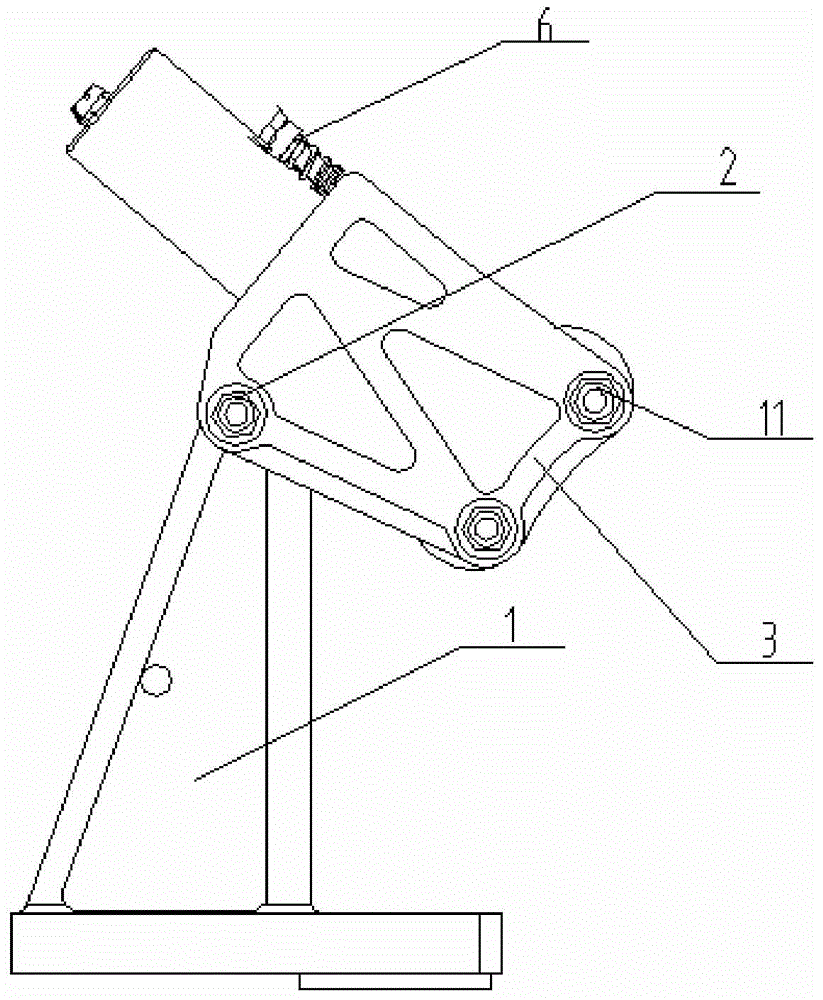

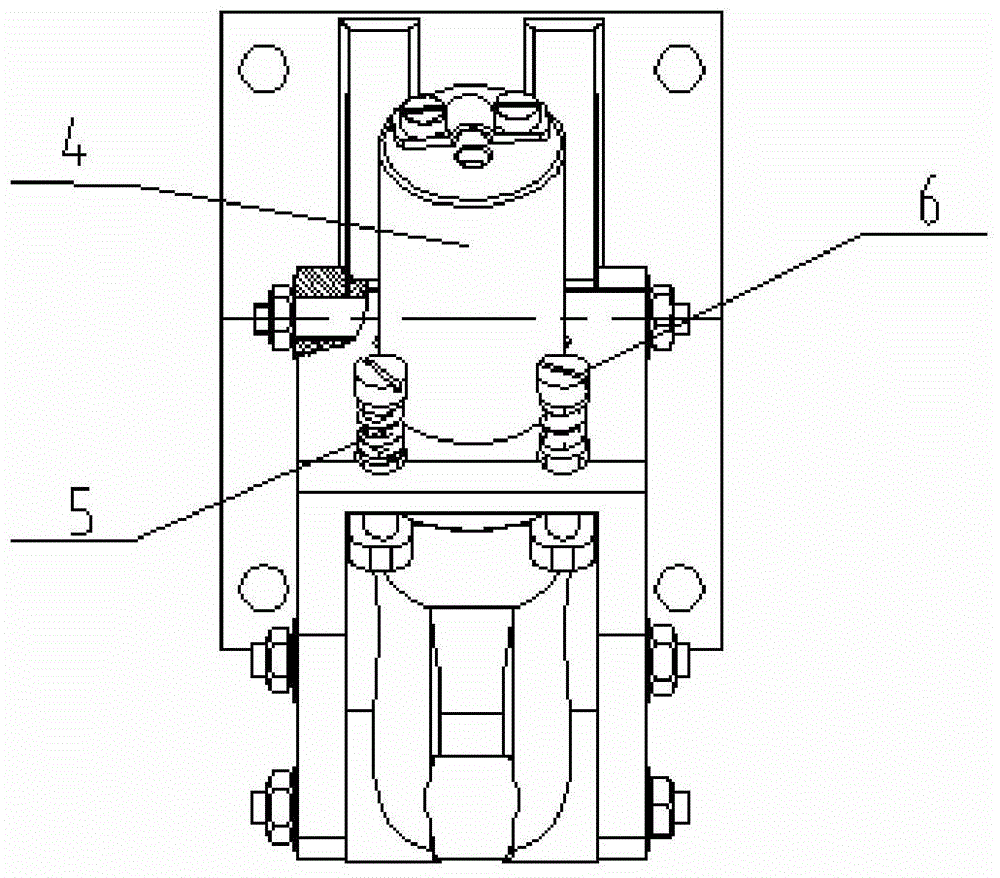

[0011] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, the guide rope tension measuring device of this embodiment is characterized in that it includes a base 1, a rotating shaft 2, a rotating block 3, a pressure sensor 4, a pre-tightening spring 5, a pre-tightening screw 6, a guide sleeve 9, a guide The shaft 11 and the guide rope pass through the hole 12; the base 1 and the side end of the rotating block 3 cooperate with each other through the rotating shaft 2, the upper end surface of the rotating block 3 is fixed on the upper part of the base 1 by two pre-tightening screws 6, and the pre-tightening spring 5 is arranged on the pre-loaded On the tightening screw 6, the pressure sensor 4 is fixed on the upper end surface of the rotating block 3 and is coplanar with the pre-tightening screw 6. The pressure contact of the pressure sensor 4 is in contact with the upper end surface of the base 1, and the opposite sides of the rotating block...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination Figure 1 to Figure 3 To describe this embodiment, the number of the guide shafts 11 in this embodiment is not less than two. The guide shaft 11 is used for guiding and positioning of the guide rope, and its number is determined according to installation requirements. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination Figure 1 to Figure 3 To describe this embodiment, a bearing 10 is provided at the middle position of the guide shaft 11 in this embodiment, and the guide rope is attached to the bearing 10 . Other compositions and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com