Bearing dismounting tool

A technology for disassembling tools and bearings, applied in the field of fixtures, can solve the problems of high labor intensity for operators, inconvenient operation and movement, poor versatility, etc., and achieve the effects of improving disassembly efficiency, improving bearing disassembling efficiency and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

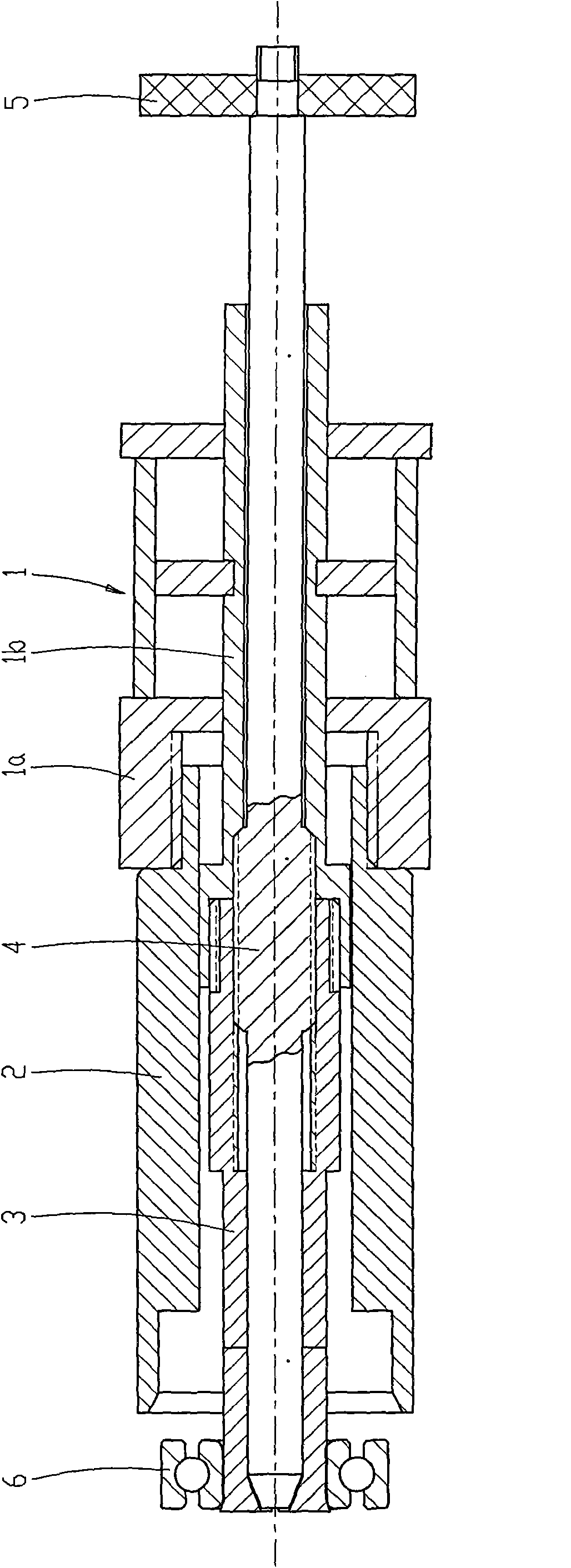

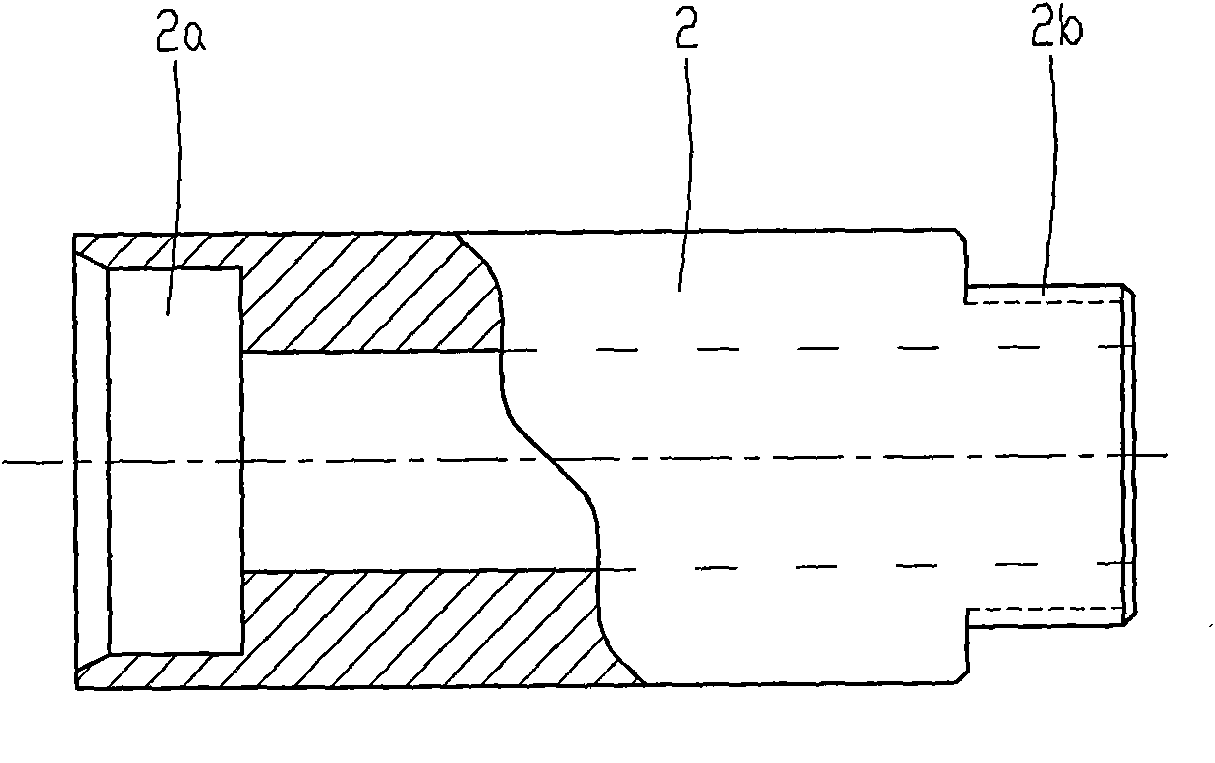

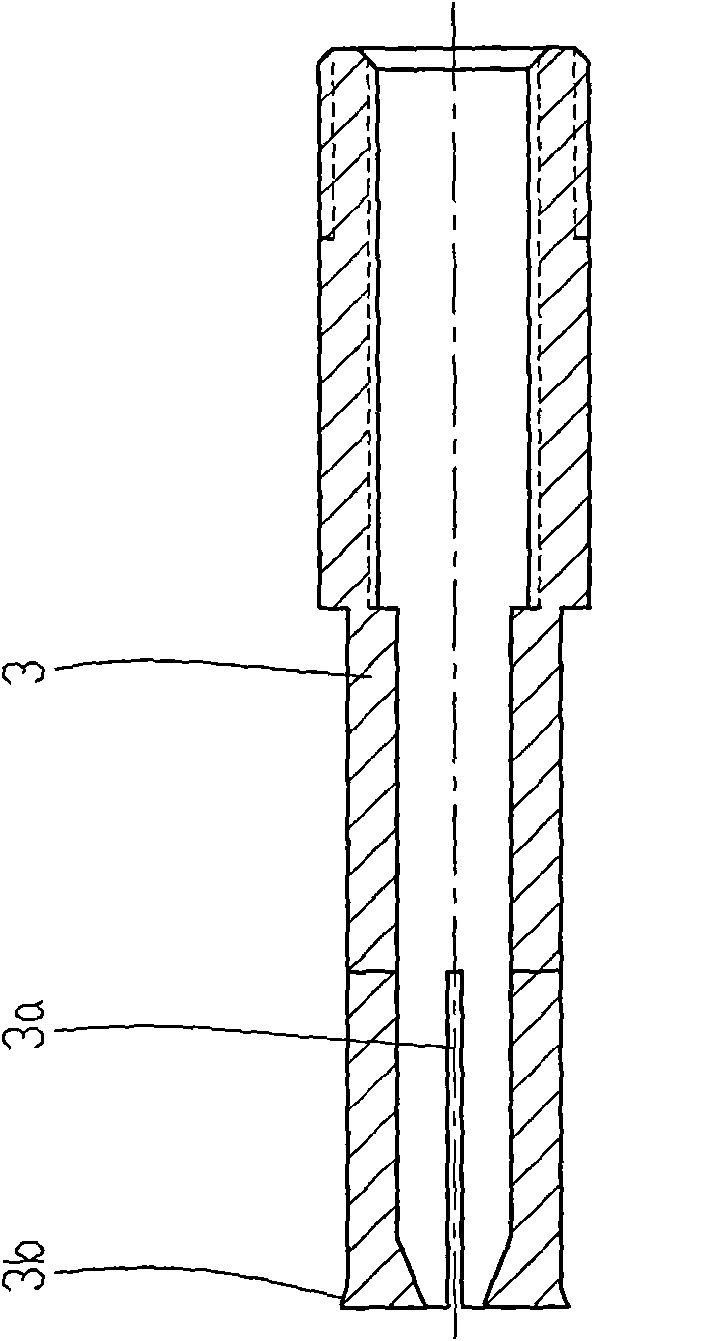

[0017] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention is composed of a riveting gun cylinder 1, a positioning cylinder 2, a pull pipe 3, a push rod 4 and an adjusting disc 5, wherein the riveting gun cylinder 1 is a prior art, and its structure will not be repeated here. On the left side of the riveting gun cylinder 1 cylinder 1a as shown in the figure, a positioning cylinder 2 is provided. The positioning cylinder 2 is a straight-through pipe structure. The left end of the central hole of the positioning cylinder 2 expands into a circular accommodation groove 2a, and the right end of the positioning cylinder 2 is integrated. A threaded head 2b with a slightly smaller diameter is formed, and the threaded head 2b extends into the cylinder body 1a of the riveting gun cylinder 1, and the two are screwed together. The ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com