Rivet nut, method for processing waterproof joint on processed lamp shell and pressing block used in method

A technology for pulling rivet nuts and shells, which is applied to nuts, manufacturing tools, metal processing, etc., can solve the problems of inconvenient installation and manufacture of waterproof joints, easy loosening of the threaded connection between the fixing plate and the inner end of the joint body, and insufficient structural firmness. , to achieve the beautiful effect of the lamp shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

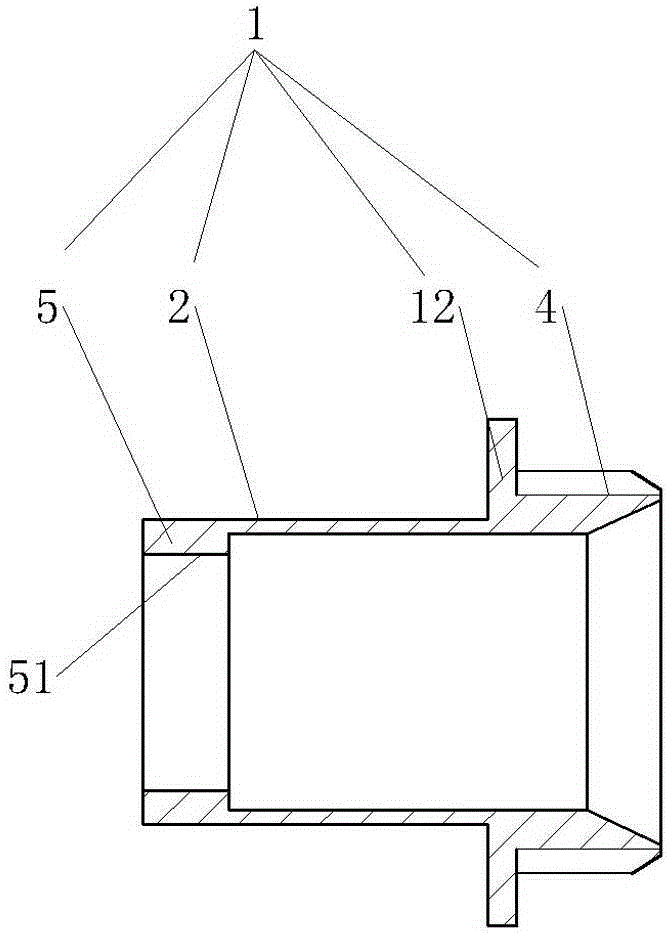

[0015] refer to figure 1 As shown, the blind rivet nut 1 provided by the present invention includes a deformation part 2 and a pressure plate 12, and a tubular threaded connection part 4 protrudes outwards from one end of the pressure plate 12 relative to the deformation part 2, and the threaded connection part 4 with external thread. In this embodiment, the outer end of the deformation part 2 is provided with a pressing part 5 thicker than the deformation part 2 , and the pressing part 5 is thickened inwardly and provided with an inner annular protrusion 51 .

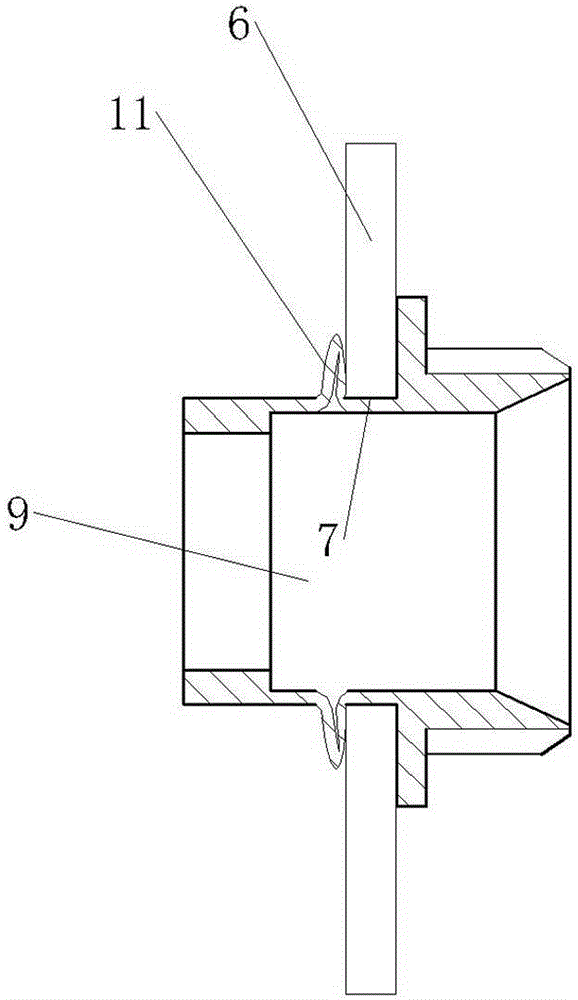

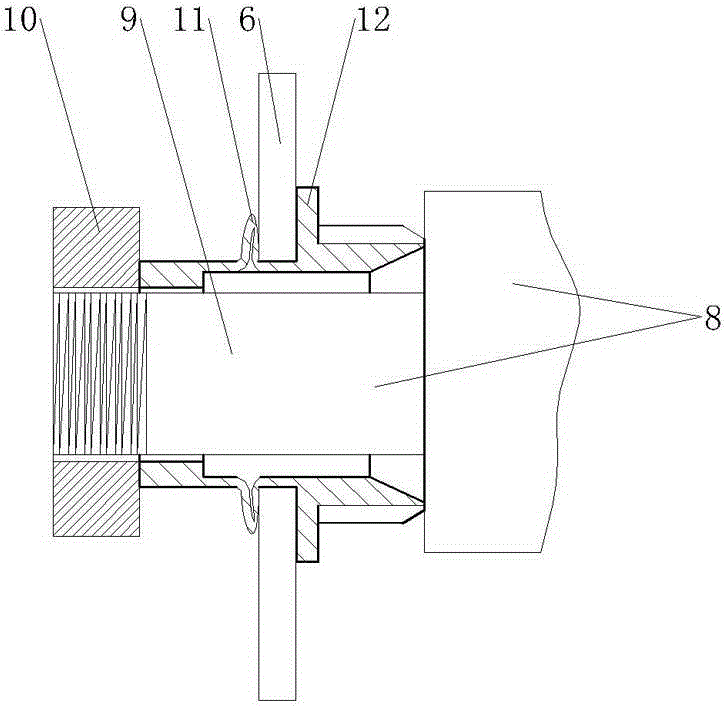

[0016] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the method provided by the present invention for processing the waterproof joint on the lamp housing by using a blind rivet nut includes the following steps: 1. Opening a through hole 7 on the housing 6; 2. Insert the through hole 7; 3. Insert the rivet gun 8 from one end of the threaded connection part 4 into the inner hole 9 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com