Hand riveter device connected with manual drill and capable of automatically loading rivets

A riveting gun and hand-drilling technology, applied in the field of rivets, can solve the problems of carrying many tools in riveting operations, increasing the number of tool replacements, and easily slipping teeth in tapping internal threads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The present invention will be further described in detail below with reference to the accompanying drawings and examples. The same components are indicated by the same reference numerals. It should be noted that the words "prior", ",", "left", "right", ",", "left", ",", ",", ",", ",", ",", ",", "," first "and" top " "," Inner "and" outside "refer to the direction or away from the direction of the specific component geometry.

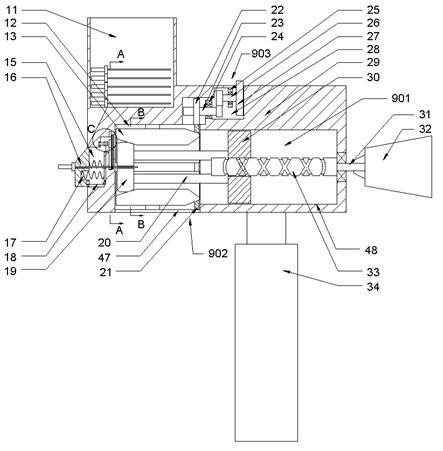

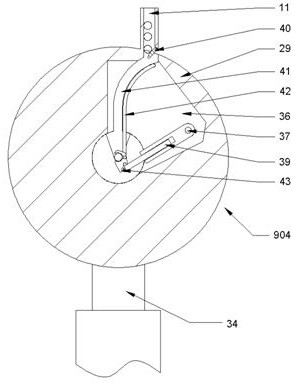

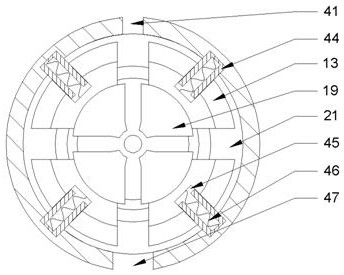

[0022]Such asFigure 1 to 5As shown, a rivenunter device that is connected manually and automatically nail, including a riveting gun 29, and a reciprocating device 901 capable of reciprocating a reciprocating means 901 is provided on the left side of the reciprocating device 901. Pull the clamping device 902 of the rivet core, the nail nail device 904 is provided on the right side of the clamping device 902, and the nail device 904 further includes a nail claw 43, and the nail claw 43 is hinged. There is a rotary lever 39, and the nail claw 43 grabs the rive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com