Single-handle hand riveter

A riveting gun and handle-type technology is applied in the field of single-hand riveting guns to achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

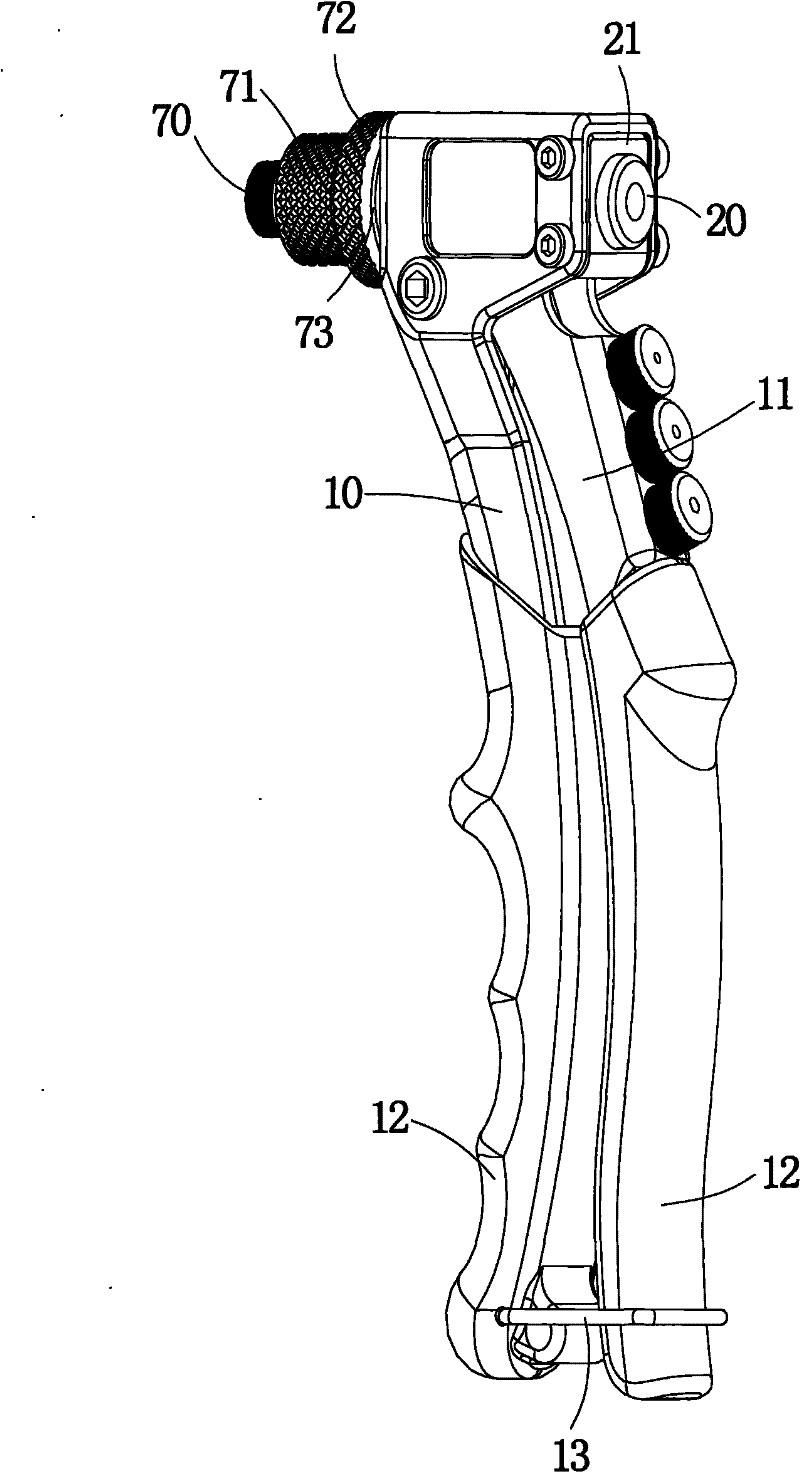

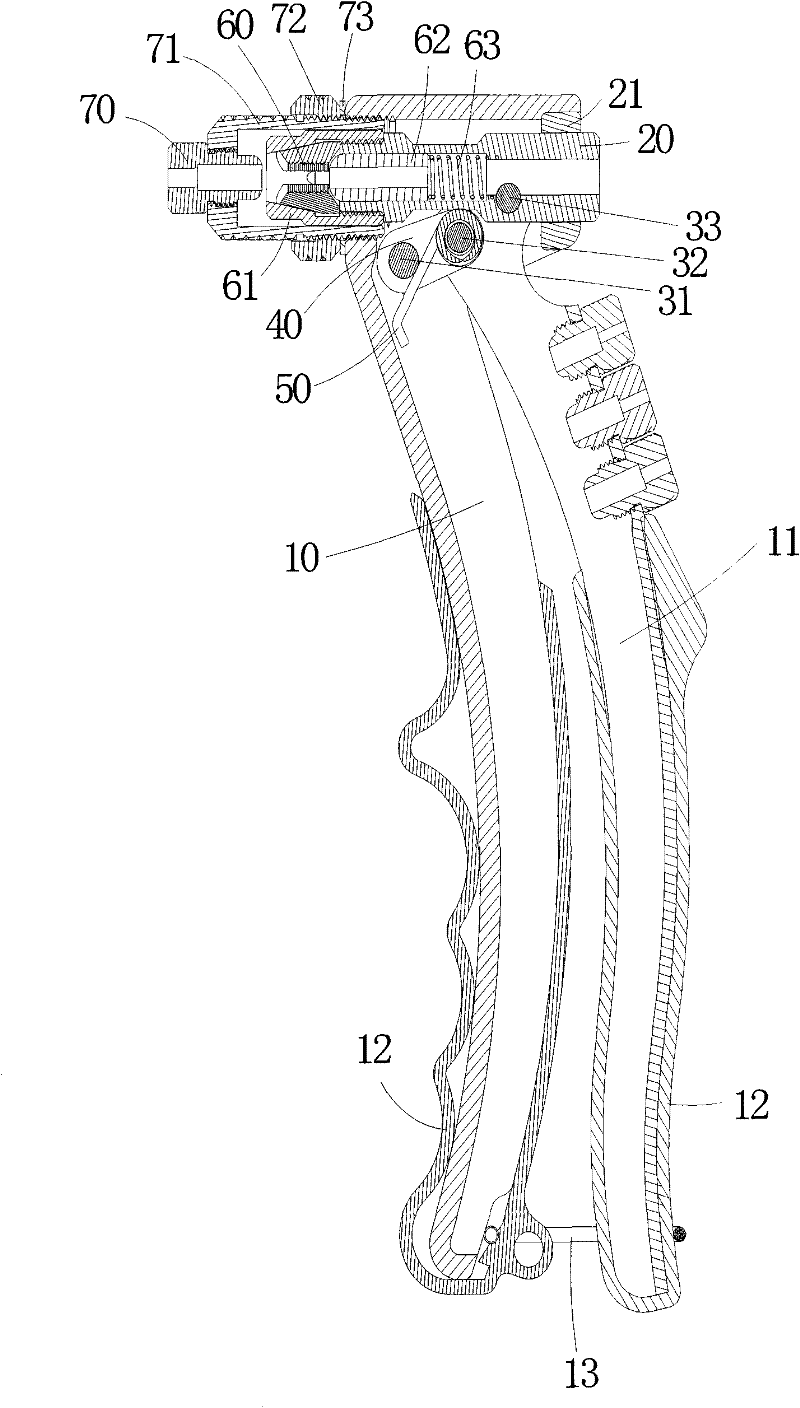

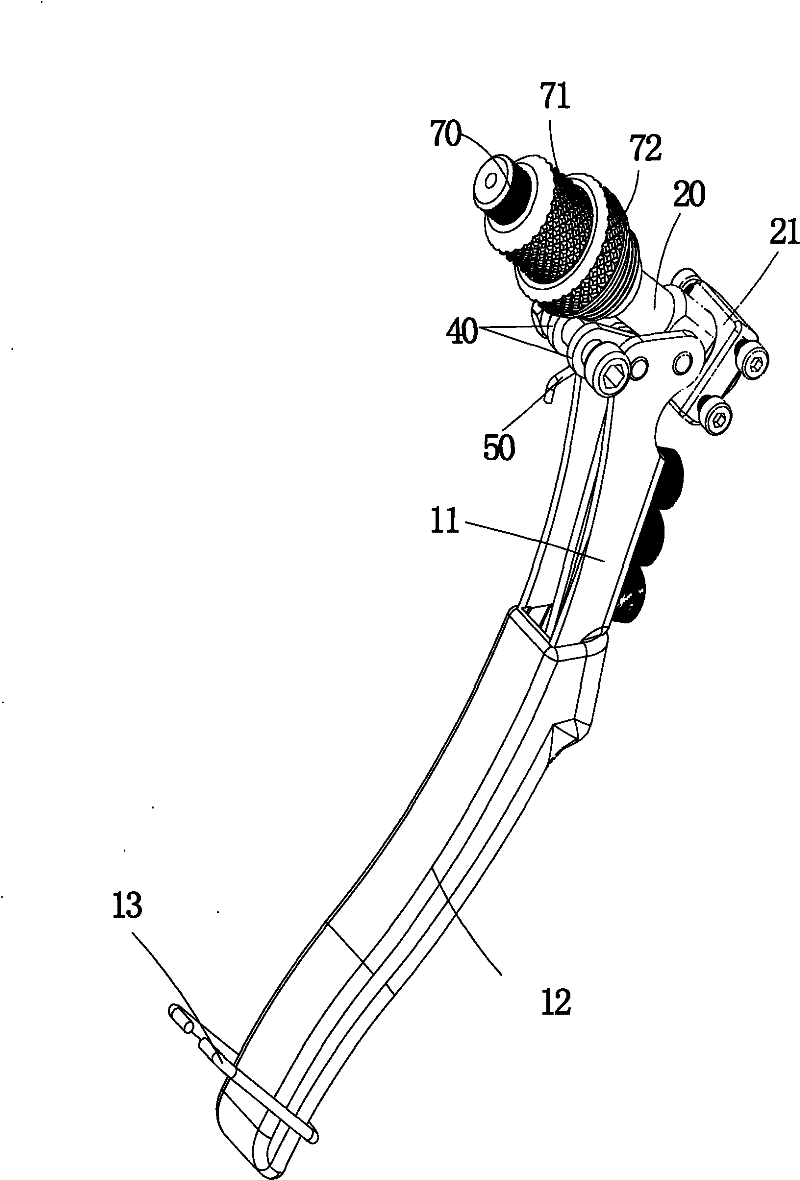

[0026] The structure of a kind of single type riveting gun of the embodiment of the present invention is as figure 1 , figure 2 with image 3 As shown, it includes a body 10, a handle 11, a pull rod 20, a gripping mechanism, and a rivet adjustment mechanism, as well as a first pin 31, a second pin 32, a third pin 33, and a link piece 40; the rivet adjustment mechanism Cooperate with the front end of the body 10; the gripping mechanism is arranged in the cavity of the rivet adjustment mechanism, and its tail part is matched with the pull rod 20; the first pin shaft 31 is fixed on the body 10; the The second pin shaft 32 is fixed on the handle 11 and connected to the first pin shaft 31 through the link piece 40 ; the third pin shaft 33 is fixed on the handle 11 and fixedly connected to the pull rod 20 at the same time. The positional relationship between the first pin 31, the second pin 32 and the third pin 33 and the pull rod 20 is as follows: Figure 4 As shown, when the r...

Embodiment 2

[0034] The described rivet adjustment mechanism can also have other structures. For example, a rivet opening with the same size as the rivet outlet in the rivet guide nozzle 70 can be set on the adjustment sleeve 71, so that the rivet guide nozzle 70 is no longer needed, and the riveting stroke can be changed by adjusting the adjustment sleeve 71 , it is also very convenient to use. All the other are the same as embodiment one.

[0035] The single handle riveting gun of the present invention uses three pins to connect the body, the handle and the pull rod, and the second pin fixed on the handle is connected to the first pin fixed on the body through the connecting plate, and is fixed on the handle The third pin shaft is fixed on the pull rod at the same time; when riveting, the second pin shaft is driven by the link plate to approach the pull rod, so that the torque is increased, so that the use is more labor-saving. In addition, in the single-handle riveting gun of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com