T type two spout hand riveter

A riveting gun and handle-type technology, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of inconvenient packaging, transportation and carrying, increased production costs, laborious use, etc., and achieve the effect of solving the problem of functional limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

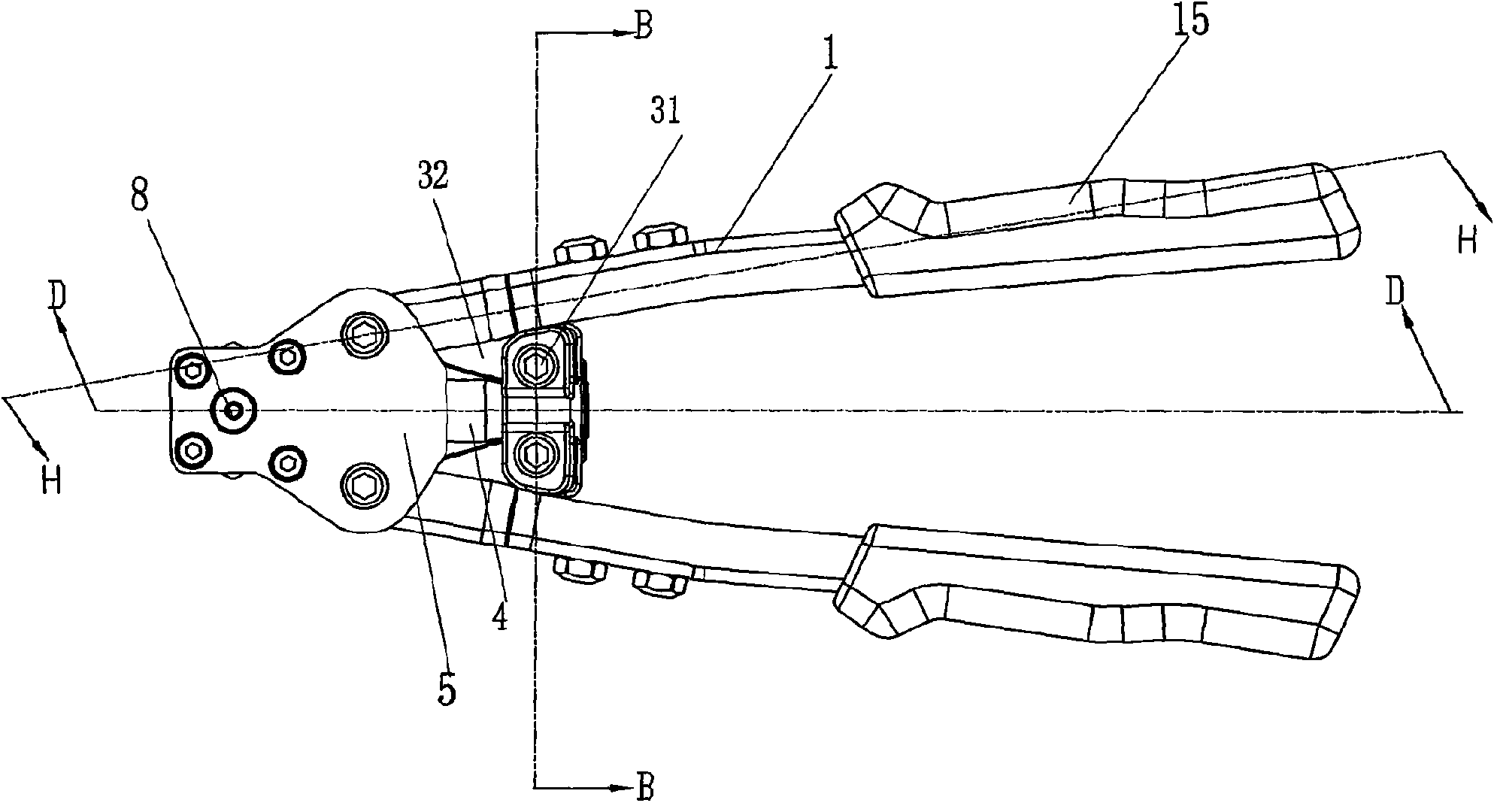

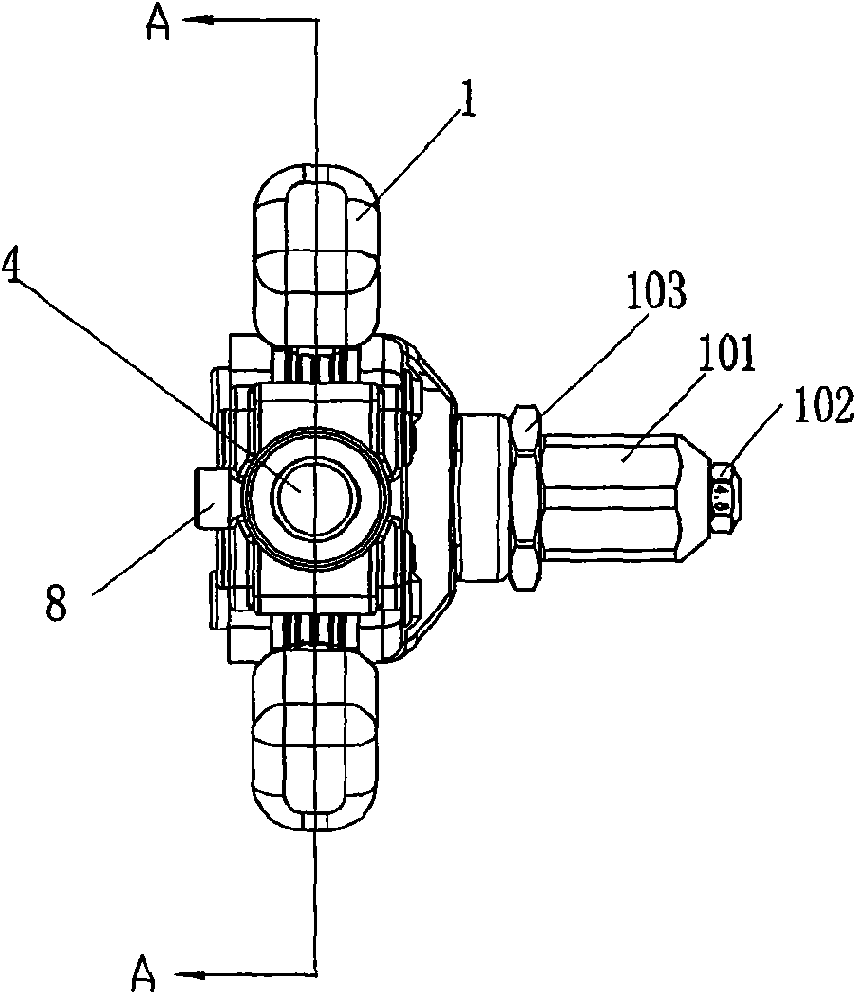

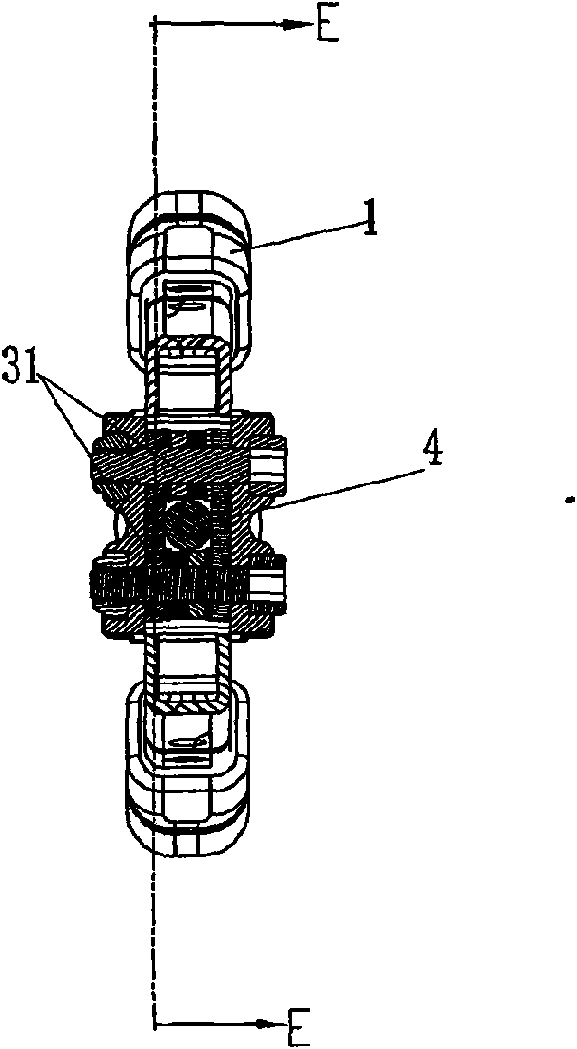

[0042] Such as Figure 1 to Figure 8 Shown, a kind of T-shaped double handle type riveting gun, comprises riveting gun seat 12 ( Figure 5 ), the left and right handles 1 hinged with the riveter base 12 on the left and right sides of the riveter base, the horizontal pull rod 4 that is movably inserted in the riveter base 12, and the horizontal pull rod 4 is arranged between the left and right handles 1 The horizontal tie rod stretching mechanism 3, the adjustment mechanism 10 and the blind rivet grasping mechanism 11 provided inside the adjustment mechanism 10; it is characterized in that: a vertical pull rod 8 pulled by the horizontal pull rod 4 is also provided in the rivet gun seat 12 The lower end of the rivet gun seat 12 at one end of the vertical pull rod 8 is provided with the adjustment mechanism 10, and the inside of the adjustment mechanism 10 is provided with a rivet gripping mechanism 11 at the head of the vertical pull rod 8; The connection between the vertical p...

Embodiment 2

[0055] The structure of embodiment 2 is basically the same as that of embodiment 1, the only difference between the two is that the fixing groove 41 provided at the tail end of the transverse tie rod 4 is an annular groove (the figure of embodiment 2 is omitted). The tail end of the transverse tie rod is provided with a circular fixing groove whose diameter is less than its cross-sectional diameter for easy processing, but it is also very convenient and firm to be connected with the transverse connecting rod 4 after the fixing plate 35 is installed. Embodiment 2 has all the advantages of Embodiment 1.

[0056] Figure 9 , 10 It is the other two structures of the "L" type connecting rod. Figure 9 The "L" type connecting rod is provided with "L" type connecting rod central hole 72, connecting hole 73, also is provided with an oval hole in the other end 71 places of " L " type connecting rod. When using this "L" type connecting rod, the connecting portion of the "L" type conn...

Embodiment 3

[0059] The product structure of embodiment 3 is close to embodiment 1 and 2. Such as Figure 11-15 as shown, Figure 11 and figure 1 similar Figure 12 , 13 , 14, 15 and Figure 5 , 6 , 7, and 8 are similar, or even the same. In Embodiment 3, the components of the vertical pull-rod pulling mechanism 6 , the transverse pull-rod stretching mechanism 3 and the adjustment mechanism 10 have the same connection relationship. The difference between Embodiment 3 and Embodiments 1 and 2 is that in the adjustment mechanism 10 of Embodiment 3, a blind rivet nut gripping mechanism 11' is installed on the head of the vertical pull rod 8 to replace the pulling mechanism 11' of Embodiment 1. Rivet gripping mechanism 11. The blind rivet nut grasping mechanism 11' is mainly composed of a blind rivet screw 111'. The rear end of the vertical pull rod 8 is provided with a knob 17 capable of rotating the vertical pull rod. In order to facilitate the rotation of the knob 17 to rotate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com