Coupler for hand riveter

A technology of couplings and riveting guns, applied in the direction of couplings, rigid shaft couplings, mechanical equipment, etc., can solve the problems of bending, the pins are easy to fall, and break, and the probability of breaking or bending is reduced, Low cost and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

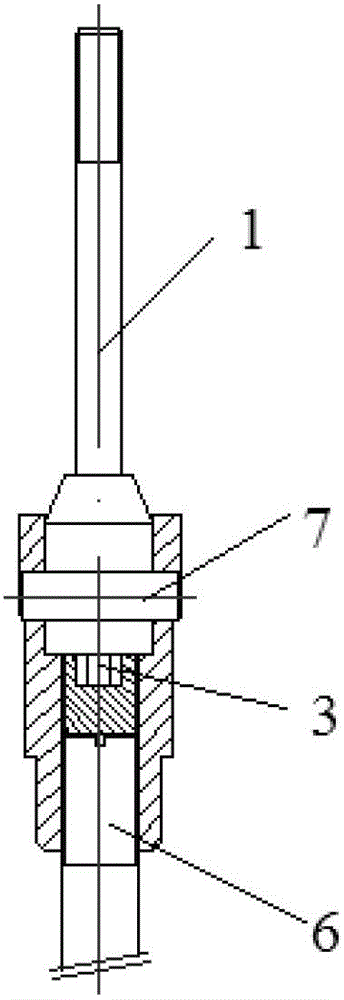

Image

Examples

Embodiment 1

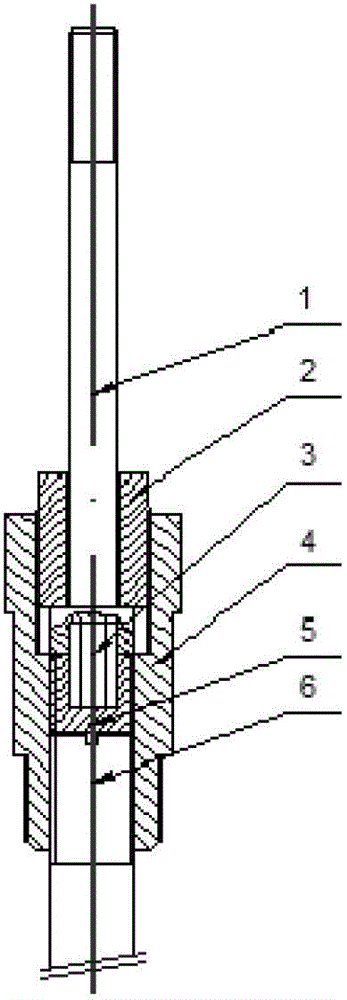

[0019] Embodiment 1 (detailed description with reference to the reference numerals)

[0020] Such as figure 2 As shown, a coupling for a rivet gun includes a rivet head 1, a connecting shaft 3, a shaft sleeve 4, an output shaft 6, and also includes a rivet head pressing block 2 and a support screw 5. The shaft sleeve 4 described above is mounted on the output shaft 6, the support head screw 5 is mounted on the shaft sleeve 4, and abuts against the output shaft 6, and the shaft 4 is respectively connected to the rivet head 1 and the support shaft. Head screw 5, the described rivet head pressing block 2 is provided with fine thread, and the rivet head pressing block 2 compresses the rivet head 1 with fine thread.

[0021] The connecting shaft 3 is an inner hexagonal connecting shaft, which can be replaced by ordinary bolts, and changed from non-standard parts to standard parts. The processing technology of standard bolts is mature, and the probability of fracture or bending is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com