Method for preparing methyl parathion degradation bacterium and enzyme preparation thereof

A technology of methyl parathion and degrading bacteria, applied in the high biological field, can solve problems such as products that are not cost-effective, and achieve the effects of thorough removal of pesticide residues, protection of the ecological environment, and protection of people's lives and health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

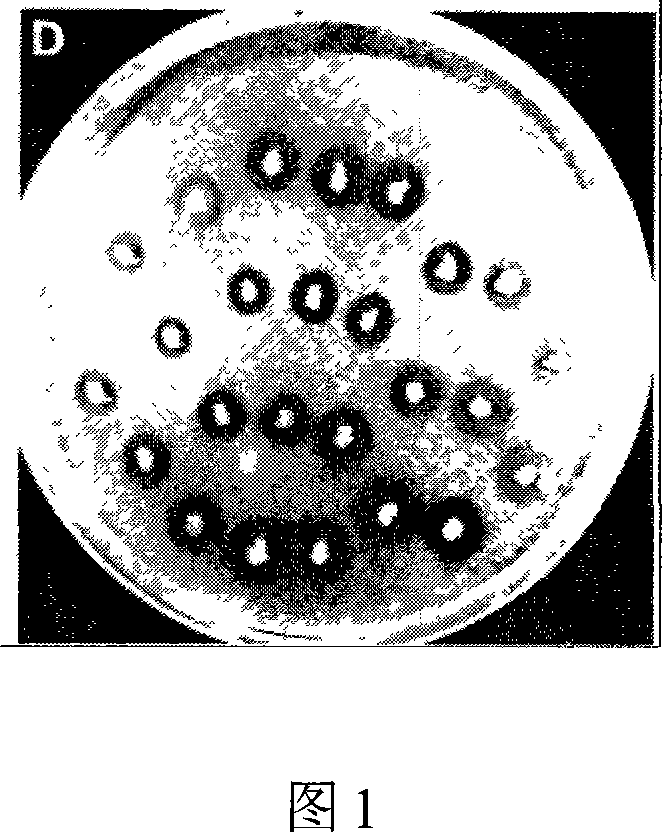

Image

Examples

Embodiment 1

[0031] The surface soil of soybean fields that had been treated with methyl parathion for 10 consecutive years at the Shenyang Ecological Station of the Chinese Academy of Sciences was collected. Get 10g soil, add 90ml distilled water, make soil suspension, insert in the inorganic salt culture medium of methyl parathion only carbon source (methyl parathion concentration is 100mg / L) with 10% volume ratio, inorganic salt The formula of culture medium is (both mass ratio): NH 4 NO 3 0.2%, KH 2 PO 4 0.3%, K 2 HPO 4 0.15%, CaCl 2 0.001%, MgSO 4 ·7H 2 O0.2%, FeSO 4 ·7H 2 O0.001%, the balance is water, pH7.0-7.2, 30 ° C, 200rpm enrichment culture for 5 days, use the enrichment culture solution for the first time to insert in the corresponding medium in a volume ratio of 10%, and simultaneously The concentration of methyl parathion is increased to 200mg / L, cultivated under the same conditions, and the second enrichment culture solution is also inserted into the corresponding...

Embodiment 2

[0034] Get in Example 1 or the slant of P. shigella-like P. shigella with Negative Gram staining in the market and inoculate in 200ml LB medium, by mass percentage, LB medium formula is as follows: yeast extract 0.5%, NaCl1%, peptone 1%, the balance is water; constant temperature shaking culture to logarithmic phase, to obtain seed liquid, ready to inoculate a small fermenter. Fermentor 10L, feeding capacity is 8L, and medium formula is (both mass ratio): glucose 0.8%, (NH 4 ) 2 SO 4 1%, K 2 HPO 4 0.2%, MgSO 4 0.05%, NaCl0.01%, CaCO 3 0.3%, yeast extract 0.02%, the balance is water, pH7.2-7.5. After the feeding is completed, 121°C high-pressure damp heat sterilization, after cooling to 35°C, the above-mentioned cultivated shake flask seed liquid is transferred to a fermenter according to the 10% volume inoculation amount, and cultivated to the logarithmic growth phase; during the cultivation of the fermenter, The stirring speed is 220 rpm, the ventilation rate of steril...

Embodiment 3

[0036] 3000g of the fermented liquid cultivated in the above-mentioned Example 2 was centrifuged for 10 minutes to collect the thalline, and the precipitate was suspended in PBS (40mmol / L, pH7.0) buffer solution. The preparation method of PBS buffer solution was as follows: dissolve 8gNaCl in 800ml distilled water, 0.2gKCl, 1.44gNa 2 HPO 4 , 0.24gKH 2 PO 4 , adjust the pH to 7.4 with HCl, add water to make up to 1L. The bacterial cells were disrupted mechanically, centrifuged at 12000 g for 10 minutes, and the supernatant was collected. 20%~80% mass concentration (NH 4 ) 2 SO 4 Fractional precipitation, collecting 80% mass concentration (NH 4 ) 2 SO 4 Precipitation, dissolved in HEPES buffer solution (20mmol / L, pH7.5), and dialyzed to the above buffer solution for 16-18 hours (dialysis with distilled water or deionized water), to remove ammonium sulfate, to obtain crude enzyme solution, the recovery was 97.8% are bottled and packaged as liquid enzyme preparations.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com