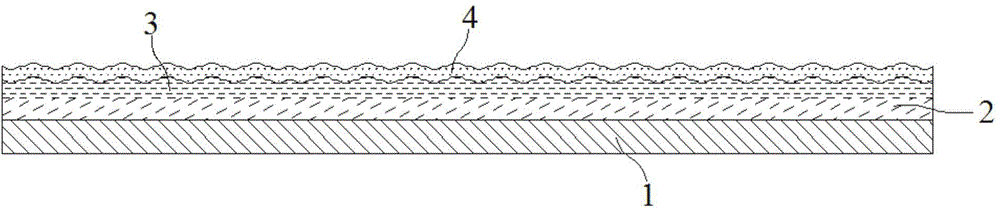

Exhaust type embossed substrate applied to release paper

A release paper and embossing technology, applied in the directions of lamination, lamination device, lamination auxiliary operation, etc., can solve the problems of unsatisfactory beautification effect of glue surface, low tear strength, and easy water absorption of release paper. , to achieve the effect of improving residual bonding rate, improving anti-static performance and uniform distribution line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

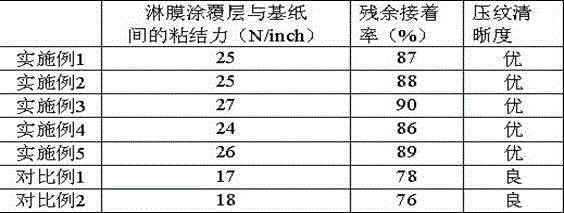

Embodiment 1~5

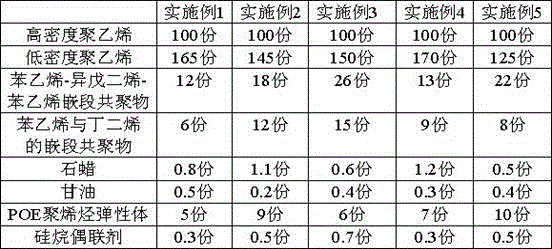

[0020] Embodiment 1~5: a kind of manufacturing method for embossed release paper, comprises the following steps:

[0021] Step 1: The preparation process of the film coating layer is as follows:

[0022] Step 1, 100 parts of high-density polyethylene, 120-180 parts of low-density polyethylene, 10-30 parts of styrene-isoprene-styrene block copolymer, block copolymerization of styrene and butadiene Put 5~15 parts of compound, 0.5~1.5 parts of paraffin, 0.1~0.5 parts of glycerin, 5~10 parts of POE polyolefin elastomer, 0.3~0.8 parts of silane coupling agent into the mixer and mix and stir for 20~30min to form a mixture ;

[0023] Step 2. The mixture obtained in step 1 is heated and bridged by the twin-screw at the feed port of the laminating machine to obtain the melted mixture. The temperature of the heating bridge is 150-200°C;

[0024] Step 3. The molten mixture obtained in step 2 is further heated to 220~250°C at the feeding screw to obtain a fluid mixture, and pressurized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com