Method for collaboratively controlling multi-pollutants produced from waste incineration smokes

A waste incineration and collaborative control technology, applied in separation methods, chemical instruments and methods, air quality improvement, etc., can solve problems such as obstacles to popularization and application, complex processes, high investment and operation costs, and achieve low production and use costs, simple equipment, The effect of low running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The patent No. ZL200810029188.7 and the invention patent titled "Coal-fired flue gas mercury pollutant adsorbent and its preparation method and application" disclose a kind of coal-fired flue gas mercury pollutant adsorbent, and its preparation includes the following specific steps :

[0045] (1) Take a certain amount of dewatered sludge from urban sewage plants, add sawdust additive with a mass fraction of 1.5%, stir evenly, then add solid zinc chloride powder 1 times the weight of dry sludge, stir evenly, and let stand for 24 hours.

[0046] (2) Put the static dewatered sludge into the muffle furnace, heat it under the condition of isolating the air, control the heating rate at 15°C / min, raise the temperature to 175°C and dry for 1.5h, and then heat up to the activation temperature of 550°C, pyrolysis and carbonization for a certain period of 2 hours; after cooling in the system state, the dewatered sludge pyrolysis and carbonization products are obtained.

[0047] (...

Embodiment 2

[0050] The patent No. ZL200810029188.7 and the invention patent titled "Coal-fired flue gas mercury pollutant adsorbent and its preparation method and application" disclose a kind of coal-fired flue gas mercury pollutant adsorbent, and its preparation includes the following specific steps :

[0051] (1) Take a certain amount of dewatered sludge from urban sewage plants, add coconut shell additives with a mass fraction of 1.5%, stir evenly, then add solid potassium hydroxide powder 1 times the weight of dry sludge, mix evenly, and let stand for 24 hours.

[0052] (2) Put the static dewatered sludge into the muffle furnace, heat it under the condition of isolating the air, control the heating rate at 15°C / min, raise the temperature to 175°C and dry for 1.5h, and then heat up to the activation temperature of 550°C ℃, pyrolysis and carbonization for 2.0 hours; after cooling in the system state, the dehydrated sludge pyrolysis and carbonization products are obtained.

[0053] (3) ...

Embodiment 3

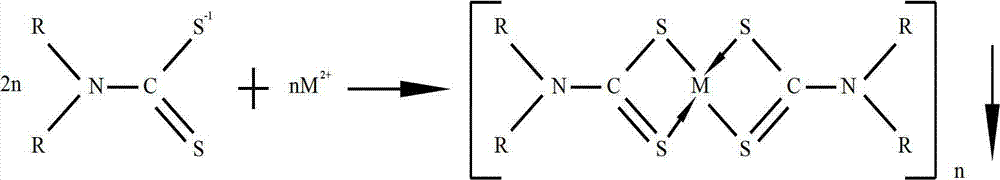

[0056] The preparation of a heavy metal ion complexing agent disclosed in the patent application with the application number "201210100123.3" and the name "a heavy metal ion complexing agent and its preparation method and application" includes the following specific steps:

[0057] (1) Raw materials required for preparing 1Kg of heavy metal ion complexing agent: 100g of triethylenetetramine, accounting for 10% of the total; 200g of sodium hydroxide, accounting for 20% of the total; 50g of epichlorohydrin, accounting for the total 5%; CS2250g, accounting for 25% of the total; deionized water 400g, accounting for 40% of the total.

[0058] (2) During the preparation process, first dissolve 200g of sodium hydroxide in 400g of deionized water to obtain a sodium hydroxide solution, take 1 / 3 of the aforementioned lye of the total volume and place it in a three-necked flask with a stirrer and a reflux condenser. The three-necked flask was placed in a water bath at 28°C and stirred at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com