Fermentation process for production of welan gum via Sphingomonas sp.WG

A technology of sphingomonas and fermentation technology, which is applied in the field of high-yield welan gum fermentation technology, can solve the problems of limiting the fermentation yield of welan gum, and the lack of understanding of optimal culture conditions and nutritional conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Initial fermentation medium composition (g / L): glucose 40, yeast powder 2, dipotassium hydrogen phosphate 4, potassium dihydrogen phosphate 2, magnesium sulfate 0.1, deionized water to volume.

[0023] The initial culture conditions are as follows: the inoculum size is 5% (v / v), the filling volume is 50mL (250mL Erlenmeyer flask), the medium pH is natural pH, the culture temperature is 28°C, the shaking table speed is 150rpm, and the fermentation cycle is 72h.

Embodiment 2

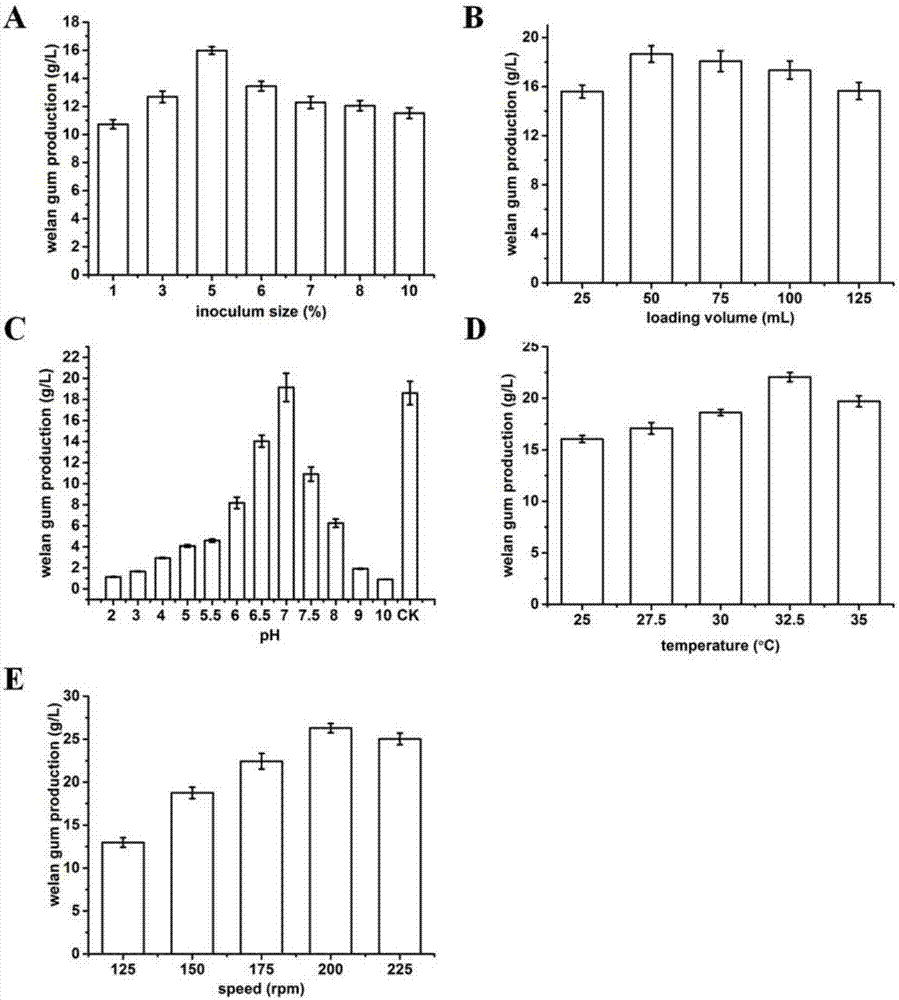

[0025] The culture conditions (such as inoculum size, liquid volume, initial pH of medium, temperature, rotation speed) that may affect the yield of welan gum were optimized by single factor experimental design. It is specifically set as: inoculum size 1%, 3%, 5%, 6%, 7%, 8%, 10% (v / v); , 150mL, the culture temperature is 25, 27.5, 30, 32.5, 35°C, the initial pH of the medium is 2-10, and the shaker speed is 125, 150, 175, 200, 225rpm. The culture medium is the initial fermentation medium.

[0026] Detect the yield of welan gum under different fermentation conditions, the results are as follows: figure 1 As shown, the following conclusions can be drawn: 1. With the increase of inoculation amount, the yield of welan gum showed a trend of rising first and then decreasing, and the optimal inoculation amount was 5%. 2. When the liquid volume is 50mL, it is most beneficial to the production of Welan gum. 3. The initial pH of the medium had a great influence on the production of ...

Embodiment 3

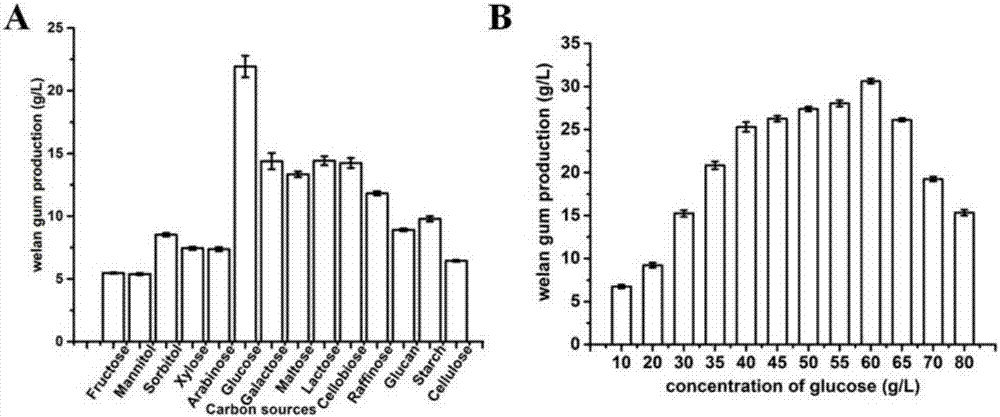

[0028] In the initial fermentation medium, 4% (w / v) of different sugar substances were used to replace glucose as carbon source: fructose, mannitol, L-sorbose, D-xylose, D-arabinose, glucose, D - Galactose, maltose, lactose, cellobiose, raffinose, dextran (T5), soluble starch and cellulose. The selected sugars replaced glucose as the single carbon source, and the culture conditions were optimal fermentation conditions. After 72 hours of fermentation, the yield of welan gum in the fermentation broth was measured.

[0029] For the production of welan gum corresponding to different carbon sources, see figure 2 . It can be seen from the figure that when the carbon source is glucose, the yield of welan gum is the highest, so the single factor design is used to optimize the concentration of glucose, the selected glucose concentration is 10-80g / L, and the yield when the glucose concentration is 60g / L Highest.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com