Cable pit ash sluicing water treatment method

A treatment method and gray water flushing technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of acidity in desulfurization wastewater, achieve long service life and rapid reproduction , the effect of large biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A treatment method for flushing gray water in a cable trench, characterized in that it comprises the following steps:

[0027] (1) Put the gray water into the sedimentation tank for sedimentation: the gray water of the power plant enters the sedimentation tank for sedimentation, remove suspended matter, and adjust the pH value to 7-8

[0028] (2) Put the biological agent into the wastewater treated in step (1), wherein the weight ratio of the biological agent to the wastewater is 1:1000, and let it stand for a week.

[0029] The biological preparation is prepared as follows:

[0030] (1) Put the corn stalks into the pulverizer and pass through a 100-mesh sieve to obtain corn stalk powder;

[0031] (2) Culture Thiobacillus ferrooxidans, Thiobacillus thiooxidans, Pseudomonas aeruginosa and Sphingomonas to a concentration of 1×10 7 cells / ml of bacterial liquid, and then mixed according to the volume ratio of 3:1:2:2 to obtain the mixed bacterial liquid; the mixed bacteri...

Embodiment 2

[0042] The sewage treatment test of the biological agent prepared by the embodiment of the present invention 1:

[0043] The gray water of a power plant exceeds the index mainly due to ph, suspended solids, COD, ammonia nitrogen compounds, etc.

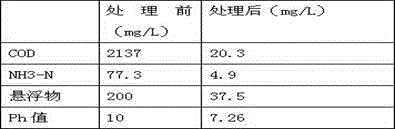

[0044] According to the method described in Example 1, the results of the detection and treatment of the gray water are shown in Table 1.

[0045] Table 1

[0046]

[0047] In conclusion, the treated wastewater complies with the GB / T18921-2002 urban anhydrous recycling standard, and fully meets the national first-level discharge standard

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com