Pigment-free low-molecular weight Welan gum production strain and construction method and application thereof

A low-molecular-weight, strain-producing technology, applied in microorganism-based methods, biochemical equipment and methods, enzymes, etc., can solve the problems of difficult separation of bacterial gum and large amount of ethanol, and achieve the effect of improving fermentation level and good application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

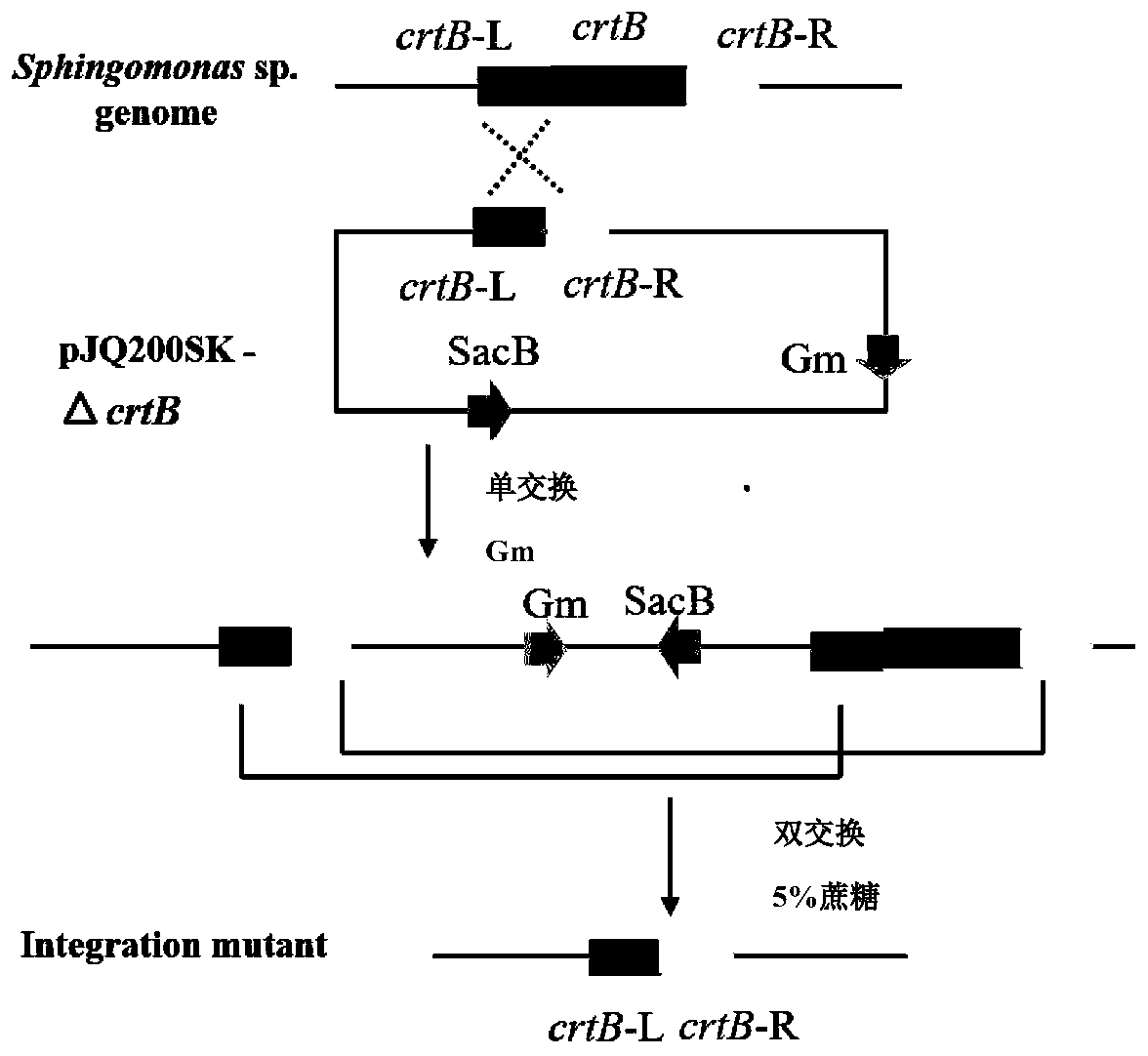

[0059] Example 1 Construction of pigment-deficient recombinant Sphingomonas genetically engineered bacteria.

[0060] Step 1. Identification of key enzyme genes of carotenoid synthesis pathway in S.sp.HT-1

[0061] (1)Degenerate primer design

[0062] According to the whole genome sequence of two strains with high homology, Sphingomonas sp.ATCC31555 (producing welan gum) and Sphingomonas elodea ATCC31461 (producing gellan gum). The gene sequences related to key enzymes in the carotenoid synthesis pathway of the two strains were searched in GenBank, and degenerate primers were designed by Vector NTI 11.5.1 software (Table 1).

[0063] Table 1 Degenerate primers for PCR amplification of genes related to key enzymes in carotenoid synthesis pathway

[0064]

[0065] (2) Cloning and identification of key enzyme genes

[0066] Genome extraction kit from TaKaRa Company was used for S.sp.HT-1 genome extraction. For specific methods, please refer to the instruction manual. Using...

Embodiment 2

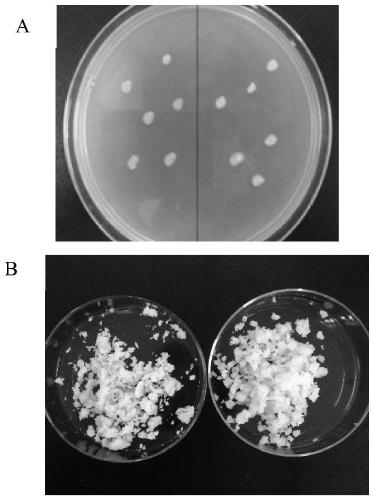

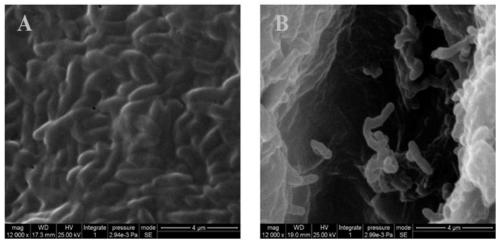

[0092] Example 2 Construction of Pigment-Deficient and Encapsulation-Removed Recombinant Sphingomonas Genetically Engineered Bacteria

[0093]The construction method is the same as in Example 1, except that the recipient strain is S.sp.-△crtB in Example 1, the knockout gene is the srtW gene, the nucleotide sequence is shown in SEQ ID NO: 2, and the primer sequence is shown in In Table 7 and Table 8, the sequence of the upstream / downstream genes of the sortase srtW gene was overlapped by PCR and constructed on the suicide vector pJQ200SK, and transformed into E.coli S17-1 competent cells. Using the method of conjugative transfer, under the action of the helper bacteria E.coli HB101(pRK2013), the suicide plasmid pJQ-△srtW carrying the upstream and downstream gene fragments of srtW was transformed into the welan gum producing strain S.sp.-△crtB . Single exchange clones were picked for expansion. In the second step, single exchange clones were inoculated into welan gum seed medi...

Embodiment 3

[0099] Example 3 Construction of recombinant sphingomonas genetic engineering bacteria with pigment deficiency and degradative enzyme gene knockout.

[0100] The construction method is the same as in Example 1, except that the recipient strain is S.sp.-△crtB in Example 1, the knockout gene is the gelR gene, the nucleotide sequence is shown in SEQ ID NO: 3, and the primer sequence list See Table 9, the obtained S.sp.-ΔcrtB-ΔgelR strain was named S.sp.WG-2.

[0101] Table 9 Primers required for constructing gelR knockout strains

[0102]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com