Production of modified polysaccharide S-7

a technology of polysaccharide and polysaccharide, which is applied in the field of polysaccharide s7, can solve the problems of not knowing the basis of the change in physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2 (

GENETIC MODIFICATIONS)

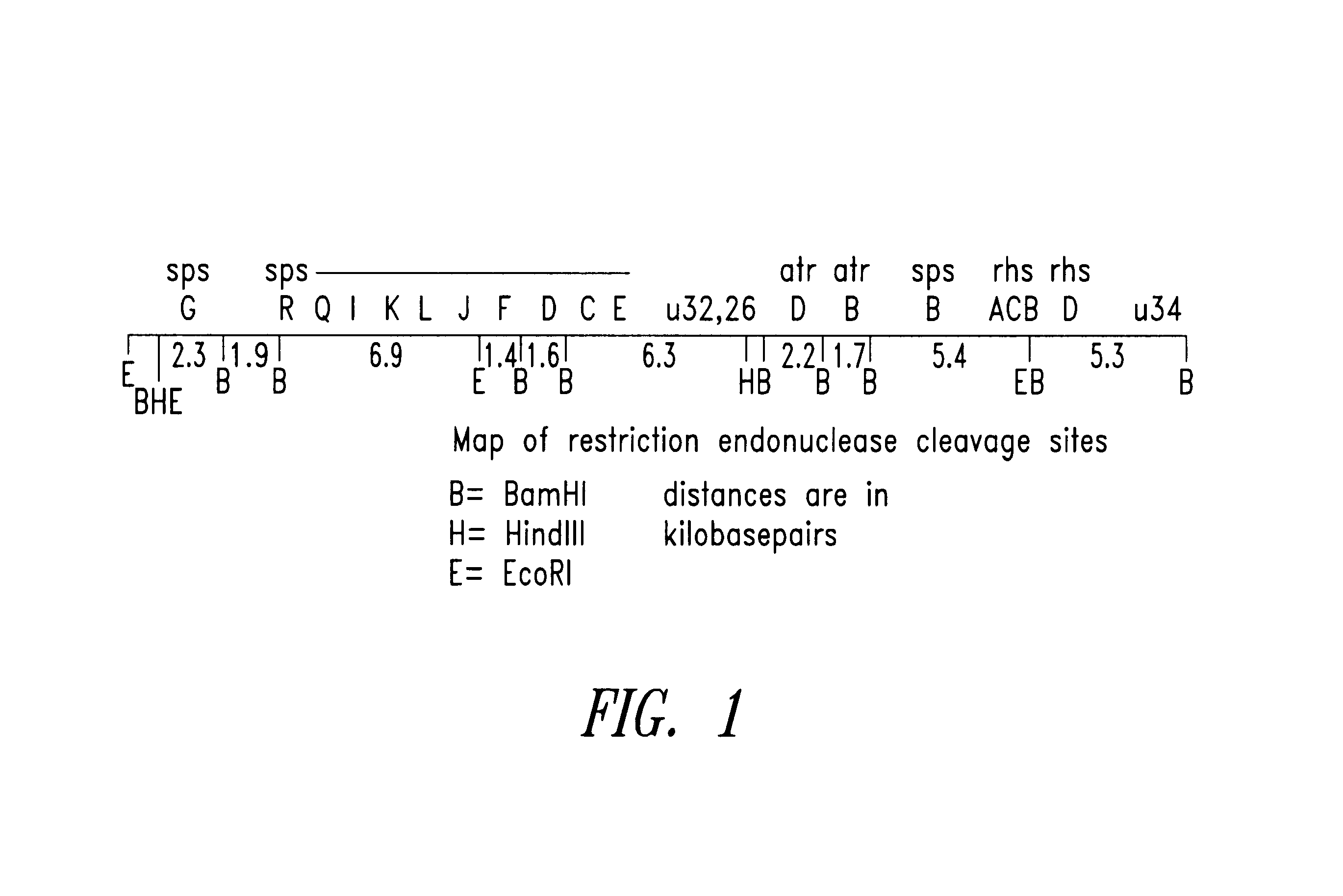

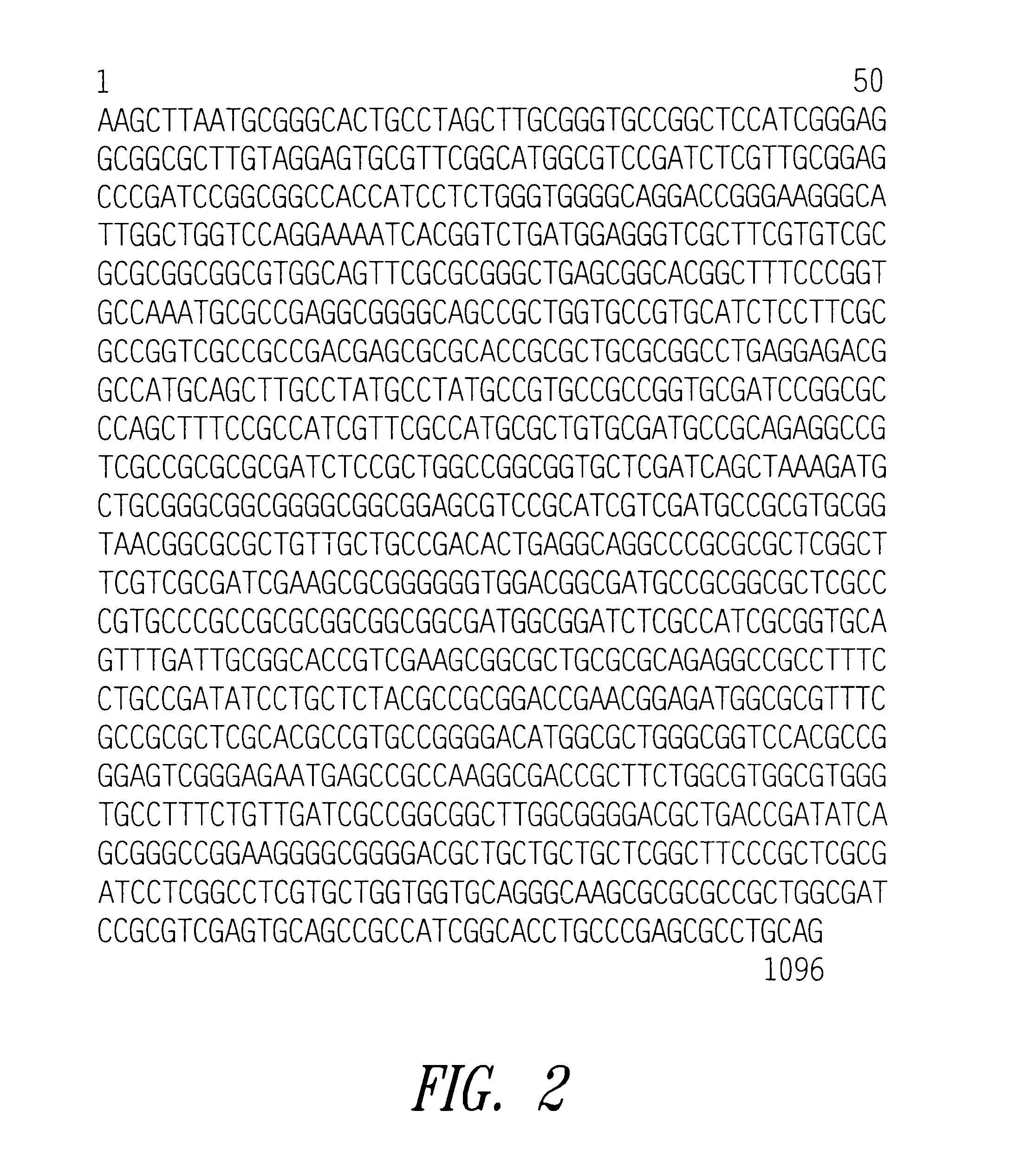

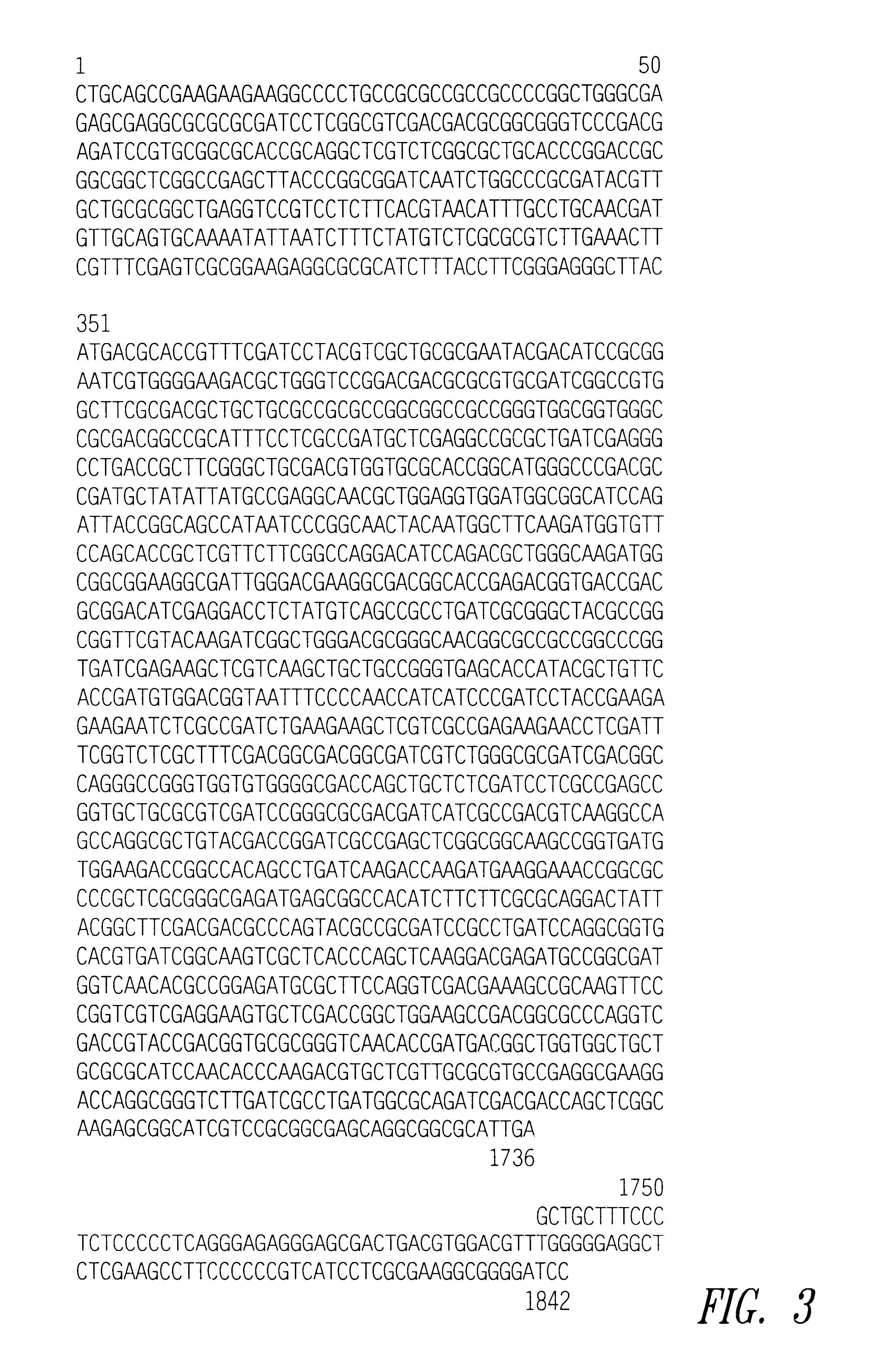

Preparation ofa library of S7 genes. Strain S7 was cultured in 5 ml of YM medium by shaking at 30.degree. C. After adding 0.55 ml of 10.times.TE (100 mM Tris-HCl, 10 mM EDTA, pH 8), 0.3 ml of 10% sodium dodecylsulfate, and 0.03 ml of 20 mg / ml proteinase K, the cultures were incubated with shaking for one hour at 65.degree. C. After adding 1 ml of 5M NaCi and 0.8 ml of 10% CTAB (hexadecyltrimethylammoniumbromide) in 1M NaCl the lysates were incubated 30 min at 65.degree. C., and then extracted once with chloroform and once with phenol:chloroform (1:1). The upper aqueous phase was removed and added to 0.6 volumes of isopropylalcohol and then dried. The precipitate was resuspended with a mixture of 0.6 ml of 1.times.TE containing 0.7 M NaCl and 0.1 ml of 10% CTAB in 1M NaCl, incubated 30 min at 65.degree. C., extracted once with chloroform, and then precipitated with two volumes of ethanol. After drying the pellet was resuspended in 0.1 ml of 1.times.TE. High mole...

example 4 (

NEW COMPOSITION)

As shown in Table 1, the broth viscosity for strain S7 carrying additional copies of the plasmid pRK-S7c6 was increased compared to that of unmodified strain S7. After purification of the exopolysaccharide from the broth, the EPS S7c6 retained its high viscosity as indicated in Table 2. EPS S7c6 is the exopolysaccharide produced by the Sphingomonas strain S7 carrying plasmid pRK-S7c6. The increased viscosity per gram of purified EPS suggested a new composition for the S7c6 polymer. The carbohydrate compositions for each of the exopolysaccharides from S7 and the genetically modified derivatives were determined following acid hydrolysis. The ratio of glucose to rhamnose is given in Table 2. The S7c6 EPS has a unique sugar composition with relatively less glucose residues. Table 2 shows that the new composition is linked to the high viscosity.

The carbohydrate compositions were determined for samples of the culture broths after precipitation of the EPS with 2 volumes of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Bond length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com