Sphingomonas capable of degrading triphenyl phosphate and domestication method and application thereof

A technology of sphingomonas and triphenyl phosphate, which is applied in the field of sphingomonas and its domestication, can solve the problems of low efficiency and achieve low cost and good degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1. Domestication and screening of degrading strains

[0049] (1) Add triphenyl phosphate-contaminated soil (taken from electronic waste-contaminated soil in Guiyu Town, Guangdong, where the content of triphenyl phosphate is 4260-1710000ng / g) into 20mL inorganic salt medium (sterilized) , cultivated in a constant temperature shaker at a temperature of 30° C. and a rotation speed of 160 rpm for 4 hours, then took it out, stood it for stratification, and obtained a supernatant. Each liter of inorganic salt medium includes: 1g / L NH 4 NO 3 , 1.5g / L KH 2 PO 4 , 3g / LK 2 HPO 4 , 2mL / L trace element solution, 1000mL distilled water, pH 7.0. The trace element solution is a solution obtained by adding trace element compounds into water and mixing them uniformly, wherein in the trace element solution, the concentration of each substance is: 4g / L MgSO 4 , 4g / LZnSO 4 , 1g / L CuSO 4 , 1g / L MnSO 4 , 1g / LFeSO 4 ·7H 2 O, 1g / LCaCl 2 ; the same below.

[0050] (2) Take 1 mL of...

Embodiment 2

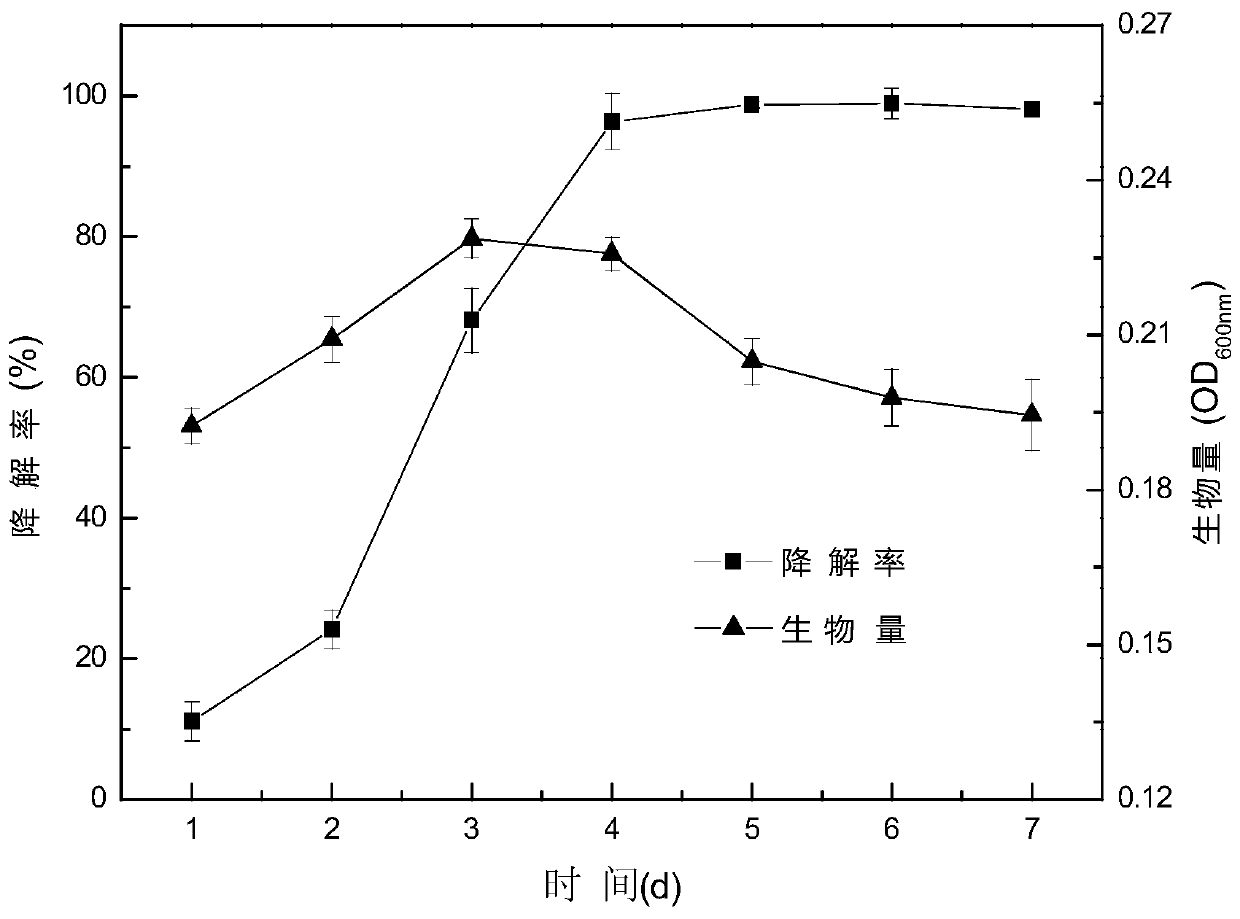

[0059] Example 2 Degradation Analysis of Sphingomonas to Triphenyl Phosphate (Effect Verification)

[0060] (1) Inoculate Sphingomonas sp.GY-1 into a 500mL Erlenmeyer flask containing 200mL of sterilized enrichment medium, and place it in a constant temperature shaker at a temperature of 30°C and a rotational speed of 160rpm, cultivated for 24 hours, to obtain enriched cultured bacterial solution; each liter of enriched medium includes: 3g / L beef extract, 10g / L peptone, 5g / L NaCl, 1000mL distilled water, pH 7.0.

[0061] (2) Put the enriched cultured bacterial solution (20mL) in a 50mL sterilized centrifuge tube, centrifuge at 6000g for 5min, collect the bacteria, wash repeatedly with sterile normal saline and centrifuge for 3 times, and finally add normal saline to prepare into a certain concentration (OD 600 =0.6) of the bacterial suspension, 1mL of the configured bacterial suspension was added to the sterilized degradation medium (triphenyl phosphate degradation medium) co...

Embodiment 3

[0081] Example 3 is the same as Example 2, except that during the enrichment culture process, the pH of the enrichment medium is 6.5, and the culture conditions are as follows: the temperature is 20° C., the rotation speed of the shaker is 120 rpm, and the culture time is 16 hours. Finally, the degradation rate of triphenyl phosphate by Sphingomonas was determined to be 92.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com