Sphingomonas sp. T-3 and method for producing biological polysaccharide and poly-beta-hydroxy-butanoic acid by co-fermentation

A sphingomonas, biopolysaccharide technology, applied in the field of biotechnology and biomaterials, can solve the problem of limiting the application of gellan gum and dieter gum, affecting the properties of gellan gum and dieter gum, poly-beta hydroxybutyric acid Problems such as low output, to achieve the effect of good shear thinning performance and temperature resistance, low cost and good industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

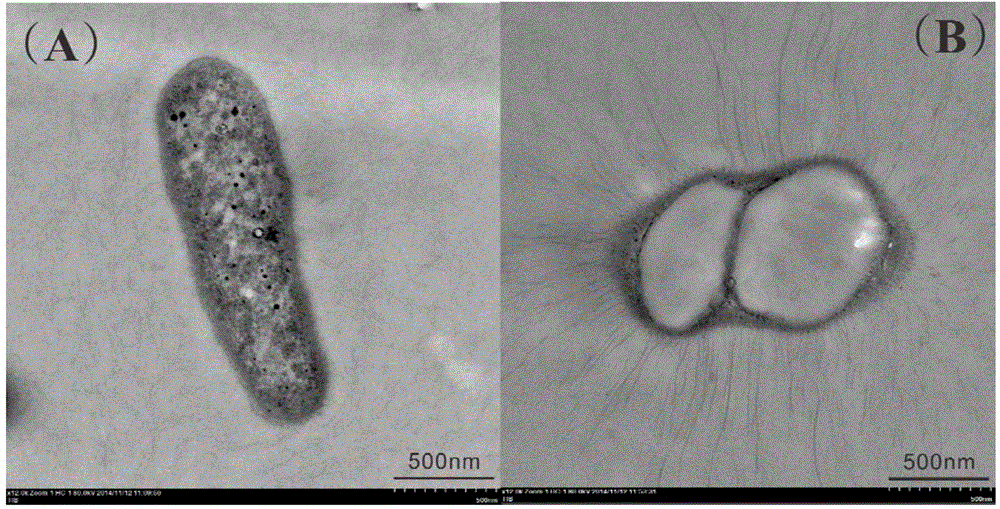

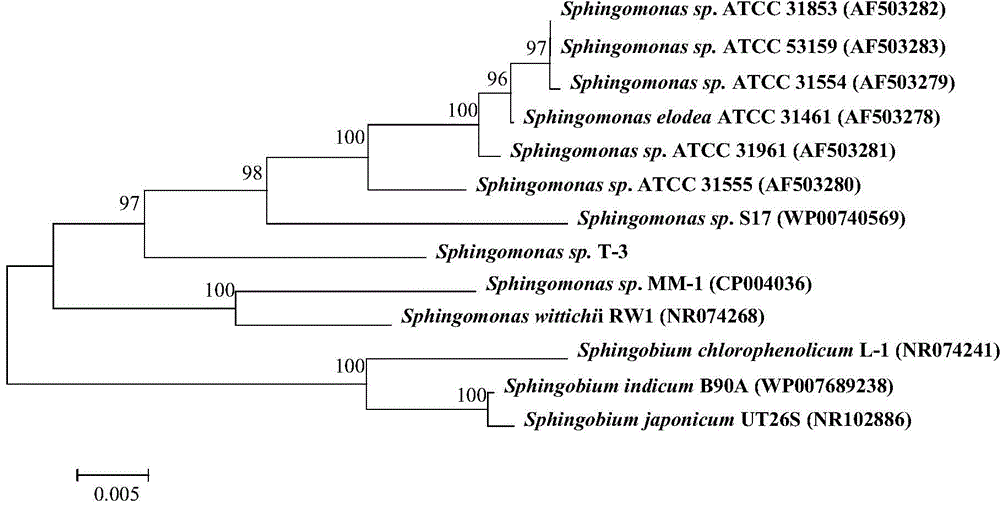

[0033] Example 1. Screening and identification of Sphingomonas sp. T-3

[0034] The strain was isolated from oil-contaminated soil.

[0035] The specific implementation steps are as follows: Take 1g of fresh soil sample and 9ml of sterilized 0.9% normal saline by shaking and mixing, take the supernatant and inoculate it into 100ml of sterilized strain selection liquid medium, culture with shaking at 30℃ for 7 days to enrich the bacteria Kind. Then dilute the coated bacterial solution with 0.9% saline, and add 10 -2 ,10 -3 For the two gradients, 200 μL was applied to the solid plate of the screening medium, and the colony morphology of the growing strain was observed after 3 days of static culture at 30°C. The colony is large and thick, with neat edges, and a single bacteria that seems to have exopolysaccharide production. After Gram staining, 16S rDNA gene sequence (see sequence table) analysis and BIOLOG microbial classification and identification system, the strain is determined...

Embodiment 2

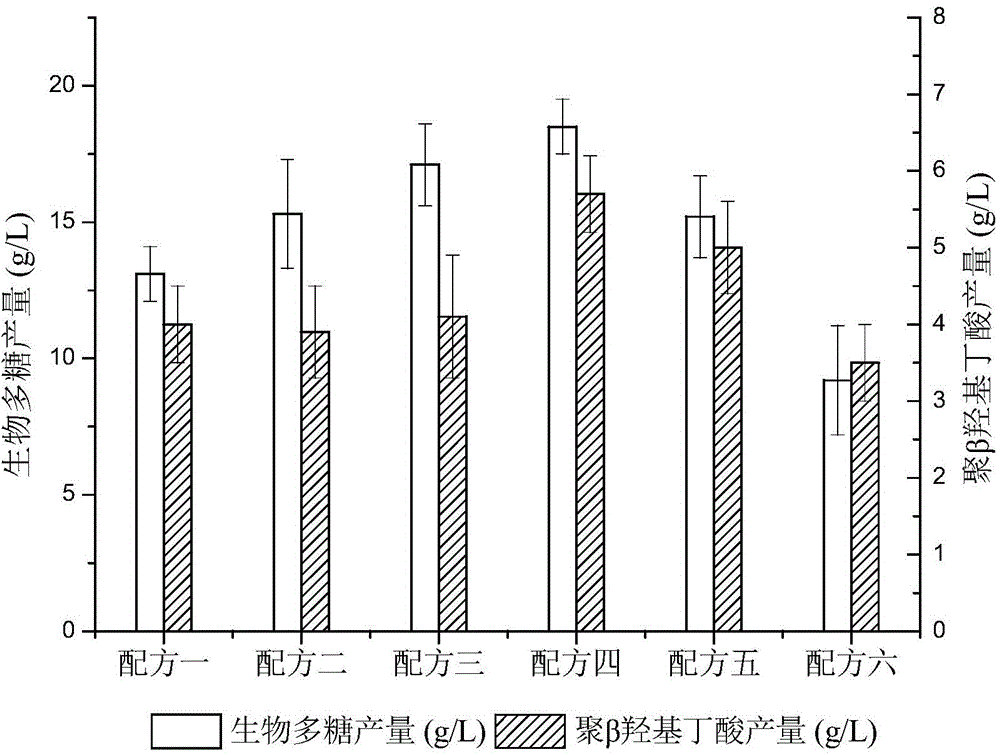

[0039] Example 2: Co-production of biopolysaccharides and poly-β-hydroxybutyric acid in shake flasks

[0040] (1) Inoculate a single colony of Sphingomonas T-3 into 5ml of TPG liquid medium, and culture with shaking at 30°C for 24 hours;

[0041] (2) Inoculate the culture solution prepared in step (1) into 100 ml seed culture medium at an inoculum of 1%, and culture with shaking at 30°C for 24 hours;

[0042] (3) Inoculate the seed liquid prepared in step (2) with a 10% inoculum amount into a glass shaker flask containing 55 ml of fermentation medium, at 30°C, a constant pH of 7.2, and cultivate for 72 hours;

[0043] (4) Dilute the fermentation broth of step (3) with distilled water at least 5 times the volume, heat it at 90-105°C for 15 minutes, and separate the fermentation broth and bacterial cell precipitation by membrane;

[0044] (5) Adjust the pH of the supernatant after membrane separation in step (4) to 3.0 to obtain a jelly-like precipitate, adjust the precipitate to neutral ...

Embodiment 3

[0057] Example 3: Using a 5L fermentor to jointly produce biopolysaccharides and poly-β-hydroxybutyric acid

[0058] (1) Inoculate a single colony of Sphingomonas T-3 into 5ml of TPG liquid medium, and culture with shaking at 30°C for 24 hours;

[0059] (2) Inoculate the culture solution prepared in step (1) into 300 ml seed culture medium at an inoculum amount of 1%, and culture with shaking at 30°C for 24 hours;

[0060] (3) Inoculate the seed liquid prepared in step (2) with an inoculum amount of 10% into a 5L fermentor containing 3.5L of fermentation medium at 30°C and a constant pH of 7.2 for 72 hours;

[0061] (4) Dilute the fermentation broth of step (3) with distilled water at least 5 times the volume, heat it at 90-105°C for 15 minutes, and separate the fermentation broth and bacterial cell precipitation by membrane;

[0062] (5) Adjust the pH of the supernatant after membrane separation in step (4) to 3.0 to obtain a jelly-like precipitate, adjust the precipitate to neutral pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com