Method of using poly-3-hydroxybutyrate to prepare liquid fuel

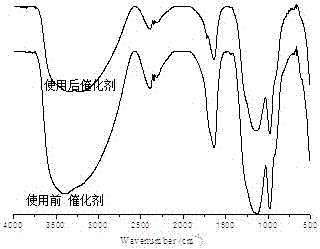

A hydroxybutyrate, liquid fuel technology, which is applied in the preparation of liquid hydrocarbon mixtures, biological raw materials, petroleum industry, etc., can solve problems such as catalyst deactivation, and achieve the effects of convenient operation, excellent reusability and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

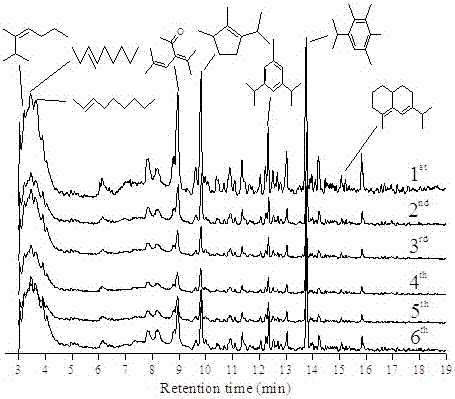

Embodiment 1

[0021] In this embodiment, the specific steps for preparing liquid fuels by using aluminum dihydrogen phosphate to catalyze the conversion of poly-3-hydroxybutyrate are as follows:

[0022] (1) Take 35.0 g of poly-3-hydroxybutyrate and 35.0 g of aluminum dihydrogen phosphate into a 300 mL high-temperature, high-pressure, acid-resistant reaction kettle and mix them evenly. Nitrogen gas is introduced to remove the air in the reaction kettle, and the reaction kettle is sealed. The temperature was programmed to rise for 45 minutes to 240 degrees, and kept at a constant temperature of 240 degrees for 6 hours. After the reaction was completed, it was cooled to room temperature, and the poly 3-hydroxybutyrate was 100% converted, and 74% of the oxygen in the poly 3-hydroxybutyrate was converted to carbon dioxide Formation was removed, and the used catalyst and oil product were obtained by solid-liquid separation. The quality of the oil product was 12.9 g, and the yield was as high as 3...

Embodiment 2

[0032] Take 39 g of poly-3-hydroxybutyrate and 13 g of aluminum dihydrogen phosphate into a 300 mL high-temperature and high-pressure reaction acid-resistant kettle and mix them evenly. Nitrogen gas is introduced to remove the air in the reaction kettle, and the reaction kettle is sealed. The temperature was raised to 270° C., and kept at a constant temperature of 270° C. for 6 hours. After the reaction, it was cooled to room temperature to obtain an oil product.

Embodiment 3

[0034] Take 35 g of poly-3-hydroxybutyrate and 35 g of aluminum dihydrogen phosphate into a 300 mL high-temperature and high-pressure reaction acid-resistant kettle and mix them evenly. Nitrogen gas is introduced to remove the air in the reaction kettle, and the reaction kettle is sealed. The temperature was programmed to rise to 210°C at 5°C / min, and kept at a constant temperature of 210°C for 12 hours. After the reaction was completed, it was cooled to room temperature to obtain an oil product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com