Degradable resin material for operation of oil and gas field and preparation method thereof

A technology for degrading resins, oil and gas fields, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of long contact time, insufficient, dissolution and release, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

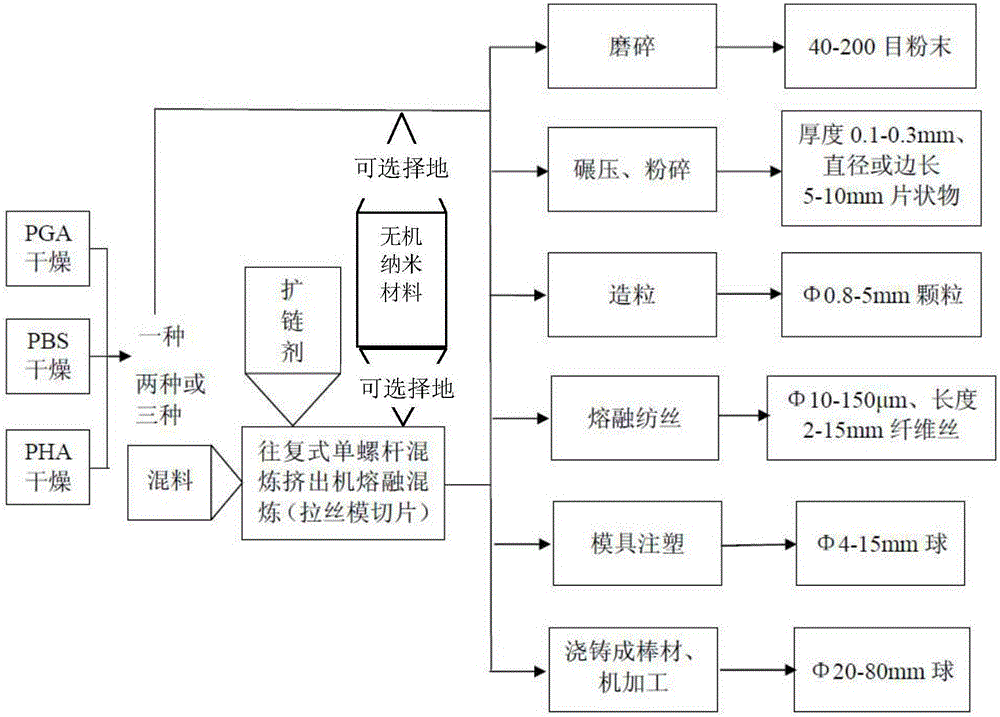

[0040] This embodiment provides a degradable resin material for oil and gas field operations, such as figure 1 As shown, it is prepared by the following steps:

[0041] (1) Stir and dry polyglycolic acid slices with a weight average molecular weight (Mw) of 60,000 at 90-100°C and a vacuum of 90 kPa for 4 hours; Butylene glycol ester slices were stirred and dried for 9 hours at 70-75°C and a vacuum of 90 kPa; poly-3-hydroxybutyrate slices with a weight average molecular weight (Mw) of 50,000 were placed at Under the vacuum degree of 90 kPa, stir and dry for 4 hours, so that the moisture content is lower than 0.1wt%, preferably lower than 0.01wt%;

[0042] (2) Take 100 kilograms of polyglycolic acid slices, 500 kilograms of polybutylene succinate slices and 400 kilograms of poly-3-hydroxybutyrate slices after dewatering and add them to a stainless steel mixer with stirring device , heat up to 50°C, and mix for 10 minutes at a vacuum of 90 kPa;

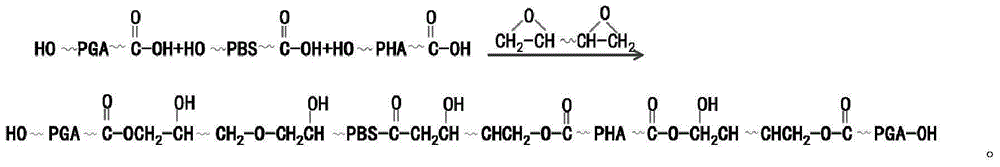

[0043] (3) Add the mixture of ...

Embodiment 2

[0048] The PGA / PBS / PHA resin nano-alloy slices prepared in Example 1 are granulated through a screw granulator at 200°C, the particle diameter is Φ1-1.5 mm, and the temperature is reduced to 10°C / min at a cooling rate of At 20°C, molded Φ1-1.5 mm particles are obtained, and a granular degradable resin material is obtained.

[0049] The Φ1-1.5 mm granular degradable resin material is used in the B2 well (in the well section with a depth of 6417-6563m, the temperature of this well section is 150°C-153°C, and 5 layers are shot, 6417-6428m, 6461-6472m, 6493- 6506m, 6522-6533m and 6549-6563m) wells were temporarily plugged and diverted to fracturing operations, carried by guar jelly fracturing fluid, and temporarily blocked and diverted to fracturing in three times, using 128 kg of Φ1-1.5 mm particle temporary plugging materials for the three times , 150 kg and 280 kg, after 3 diversions, under the same pump injection displacement, the pressure increased by 5.8MPa, 7.2MPa and 13.5M...

Embodiment 3

[0051] This embodiment provides a degradable resin material for oil and gas field operations, such as figure 1 As shown, it is prepared by the following steps:

[0052] (1) Stir and dry polyglycolic acid slices with a weight average molecular weight (Mw) of 25,000 at 100-105°C and a vacuum of 90 kPa for 3.5 hours; Butylene glycol ester chips were stirred and dried for 7.5 hours at 70-75°C and a vacuum of 90 kPa, so that the moisture content was lower than 0.1wt%, preferably lower than 0.01wt%;

[0053] (2) Take 800 kilograms of polyglycolic acid slices and 200 kilograms of polybutylene succinate slices after removing water and add them to a stainless steel mixer with a stirring device, heat up to 50°C, Under kPa, mix for 10 minutes;

[0054] (3) the mixture of polyglycolic acid in the mixer and polybutylene succinate is added in the reciprocating single-screw mixing extruder, adding 6 kilograms of particle diameters is the silicon dioxide of 10-15nm, And add 1.2 kilograms o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com