Method for preparing n-butyric acid from poly 3-hydroxybutyrate

A technology of hydroxybutyrate and n-butyric acid, applied in the preparation of carboxylate/lactone, preparation of carboxylate, chemical instruments and methods, etc., can solve the problems of high separation cost, environmental hazards, low yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing n-butyric acid with poly-3-hydroxybutyrate, said method is as follows:

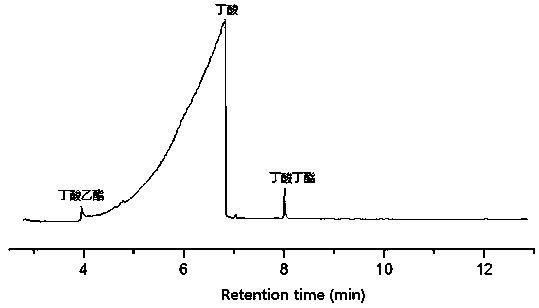

[0023] Put 5 g of poly-3-hydroxybutyrate in a 300 mL high-temperature and high-pressure reactor, pass through hydrogen to remove the air in the reactor, and keep the pressure of hydrogen at 4 MPa, and keep the reactor secret. Turn on the mechanical stirring, control the mechanical stirring speed to 1000 rpm, raise the temperature to 200 °C at 4 °C / min, and react at 200 °C for 24 h. After the reaction, cool down and put it at room temperature, poly 3-hydroxybutyrate is completely converted, and obtain a liquid product based on n-butyric acid (see figure 1 ). The yield of n-butyric acid detected by gas chromatography quantitative analysis is 97%, and the purity of n-butyric acid in the liquid product is 98%.

Embodiment 2

[0025] A method for preparing n-butyric acid with poly-3-hydroxybutyrate, said method is as follows:

[0026] Put 5 g of poly-3-hydroxybutyrate in a 300 mL high-temperature and high-pressure reactor, pass through hydrogen to remove the air in the reactor, and keep the pressure of hydrogen at 5 MPa, and keep the reactor secret. Turn on the mechanical stirring, control the mechanical stirring speed to 800 rpm, raise the temperature to 210 °C at 4 °C / min, and react at a temperature of 210 °C for 18 h. After the reaction, the temperature was lowered and cooled to room temperature, the poly-3-hydroxybutyrate was completely converted, and a liquid product mainly composed of n-butyric acid was obtained. The yield of n-butyric acid detected by gas chromatography quantitative analysis was 95%, and the purity of n-butyric acid in the liquid product was 97%.

Embodiment 3

[0028] A method for preparing n-butyric acid with poly-3-hydroxybutyrate, said method is as follows:

[0029] Put 5 g of poly-3-hydroxybutyrate in a 300 mL high-temperature and high-pressure reactor, pass through hydrogen to remove the air in the reactor, and keep the pressure of hydrogen at 3 MPa, and keep the reactor secret. Turn on the mechanical stirring, control the mechanical stirring speed to 800 rpm, raise the temperature to 220 °C at 4 °C / min, and react at 220 °C for 12 h. After the reaction, the temperature was lowered and cooled to room temperature to obtain a liquid product mainly composed of n-butyric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com