Method for preparing crotonic acid through catalytic conversion of poly-3-hydroxybutyrate by using solid catalyst

A technology of hydroxybutyrate and solid catalyst, applied in the preparation of carboxylate/lactone, organic chemistry, etc., can solve the problems of difficult recovery, volatile loss, high vapor pressure, etc., and achieve simple and convenient process operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of method utilizing solid catalyst catalytic conversion poly-3 hydroxybutyrate to prepare crotonic acid, specifically as follows:

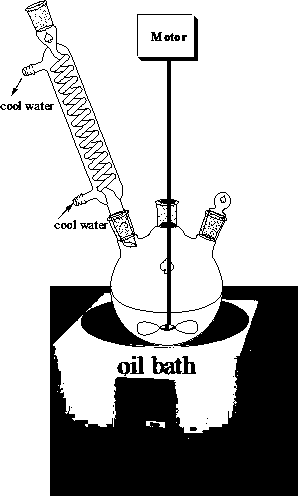

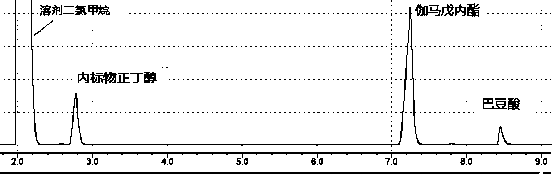

[0035] 6.0g poly-3 hydroxybutyrate, 3g solid acid HND-58 catalyst and 60mL gamma valerolactone were placed in a 250mL three-necked flask reaction system with mechanical stirring and condensation (see figure 1 ), turn on the mechanical stirring (300rpm), the reaction system is heated from room temperature to 170°C at a rate of 8°C / min, and react at 170°C for 12 hours, and the poly-3-hydroxybutyrate is completely converted. Cool to room temperature after completion of the reaction, add 3.0g internal standard n-butanol to the reaction solution, and quantitatively analyze by GC-FID (see figure 2 ) detected that the content of crotonic acid in the product was 5.1 g, thus the productive rate of crotonic acid was 85%. Crotonic acid can be separated from gamma valerolactone by salting out or rectification, and the separated gamma valerolac...

Embodiment 2

[0038] A method for preparing crotonic acid by catalytic conversion of poly-3 hydroxybutyrate with solid catalyst, specifically as follows:

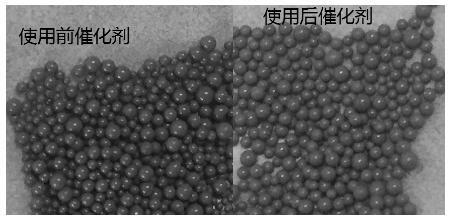

[0039] 6.0g poly-3 hydroxybutyrate, 3g solid superbase HND-63 catalyst and 60mL gamma valerolactone were placed in a 250mL three-necked flask reaction system with mechanical stirring and condensation (see figure 1 ), turn on the mechanical stirring (300rpm), the reaction system was heated from room temperature to 150°C at a rate of 8°C / min, and reacted at 150°C for 4 hours, and the poly-3-hydroxybutyrate was completely converted. Cool to room temperature after completion of the reaction, add 3.0g internal standard n-butanol to the reaction solution, and quantitatively analyze by GC-FID (see Figure 4 ) detects that the content of crotonic acid in the product is 3.9g, thus the productive rate of crotonic acid is 65%. Crotonic acid can be separated from gamma valerolactone by salting out or rectification.

[0040] The solid superbase HND...

Embodiment 3

[0042] A method for preparing crotonic acid by catalytic conversion of poly-3 hydroxybutyrate with solid catalyst, specifically as follows:

[0043] Put 6.0g poly-3 hydroxybutyrate, 3g solid acid NR50 catalyst and 60mL gamma valerolactone were placed in a 250mL three-necked flask reaction system with a mechanical stirring and condensation device (see figure 1), turn on the mechanical stirring (300rpm), the reaction system is heated from room temperature to 160°C at a rate of 8°C / min, and react at 160°C for 12 hours, and the poly-3 hydroxybutyrate is completely converted. After the reaction was completed, it was cooled to room temperature, and 3.0 g of internal standard n-butanol was added to the reaction solution, and the content of crotonic acid in the product was detected to be 3.7 g by GC-FID quantitative analysis, thus the yield of crotonic acid was 62%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com