Room temperature curing ultrahigh temperature-resistant adhesive, liquid silicon resin dedicated for the room temperature curing ultrahigh temperature-resistant adhesive and their preparation methods

A liquid silicon and silica gel adhesive technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of temperature resistance limited to 350 ℃, poor bonding performance, etc., to improve the degradation temperature, good Temperature resistance, the effect of excellent temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation method of the liquid silicone resin in this example is as follows: In a three-necked flask equipped with a stirrer, a condenser, and a dropping funnel, add 1091 mL of distilled water and 386 mL of toluene, cool to 0 ° C with ice water, and then place the liquid in the dropping funnel Add 52.9 mL of phenyltrichlorosilane, 83.6 mL of diphenyldichlorosilane, 12.4 mL of methylvinyldichlorosilane, 33.8 mL of dimethyldichlorosilane, and 127 mL of toluene, which were added dropwise into the flask, the temperature was raised to 70°C after dropping, and the stirring was continued for 10 hours to end the reaction. Separate the organic phase, wash with distilled water several times until neutral, dry over anhydrous magnesium sulfate, filter, and remove the solvent under reduced pressure to obtain a transparent liquid silicone resin.

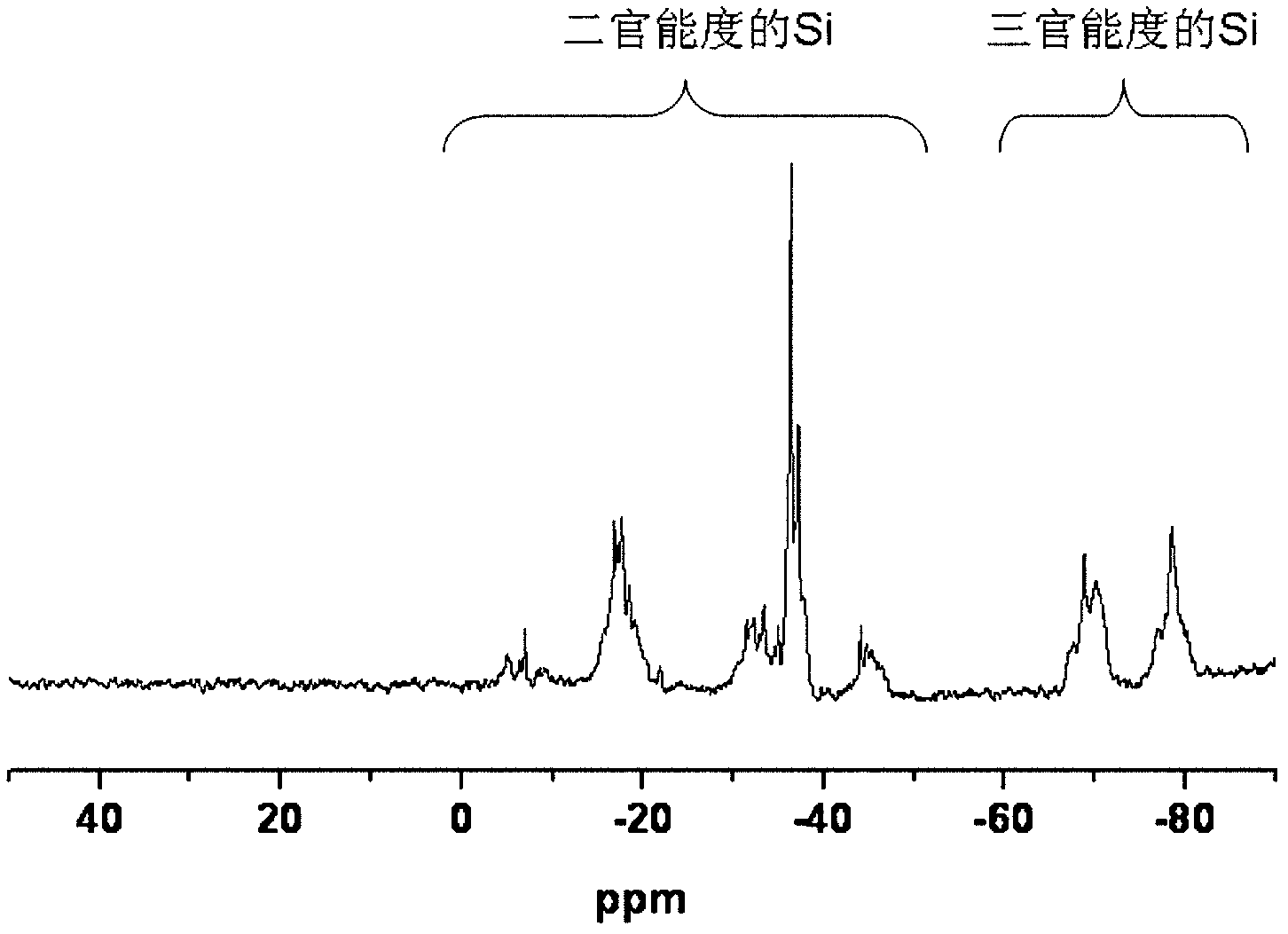

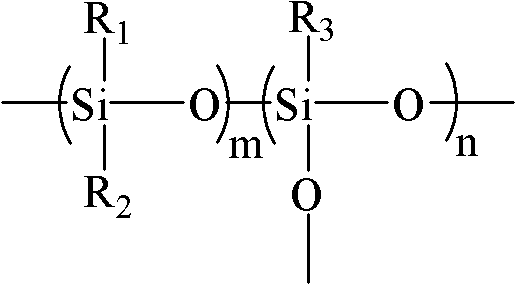

[0045] The liquid silicone resin prepared in this embodiment is R in formula I 1 = methyl or phenyl, R 2 = methyl, vinyl or phenyl...

Embodiment 2

[0047]The preparation method of the liquid silicone resin in this example is as follows: In a three-necked flask equipped with a stirrer, a condenser, and a dropping funnel, add 873 mL of distilled water and 309 mL of toluene, cool to 0 ° C with ice water, and then place the liquid in the dropping funnel Add 16.83 mL of hydrotrichlorosilane, 13.25 mL of diphenyldichlorosilane, 9.9 mL of methylvinyldichlorosilane, 43.74 mL of dimethyldichlorosilane, and 102 mL of toluene, which were added dropwise to In the flask, after dropping, the temperature was raised to 40°C, and stirring was continued for 40 hours to end the reaction. Separate the organic phase, wash with distilled water several times until neutral, dry over anhydrous magnesium sulfate, filter, and remove the solvent from the filtrate under reduced pressure to obtain a transparent liquid silicone resin.

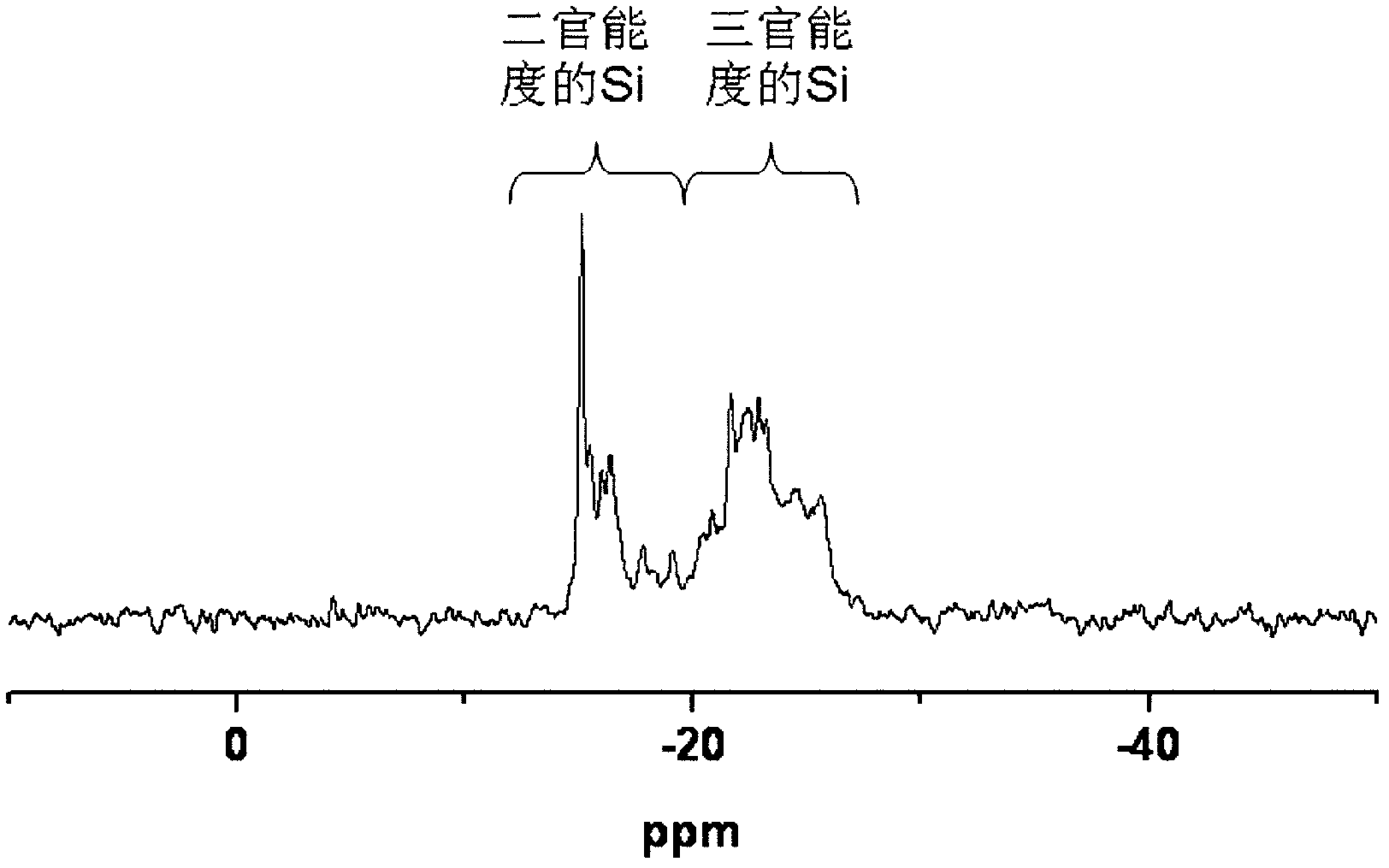

[0048] The liquid silicone resin prepared in this embodiment is R in formula I 1 = methyl or phenyl, R 2 = methyl, ...

Embodiment 3

[0050] The preparation method of the liquid silicone resin in this example is as follows: In a three-neck flask equipped with a stirrer, a condenser, and a dropping funnel, add 873 mL of distilled water and 309 mL of toluene, place it in a water bath at 30°C, and add 30.8 mL of distilled water to the dropping funnel. Add mL of methyltrichlorosilane, 51.61mL of diphenyldichlorosilane, 35.80mL of dimethyldichlorosilane and 102mL of toluene dropwise into the flask, after the dropwise temperature rises to 80°C, continue After stirring for 9 hours, the reaction was terminated. Separate the organic phase, wash with distilled water several times until neutral, dry over anhydrous magnesium sulfate, filter, and remove the solvent under reduced pressure to obtain a transparent liquid silicone resin.

[0051] The liquid silicone resin prepared in this embodiment is R in formula I 1 = methyl or phenyl, R 2 = methyl or phenyl, R 3 =methyl, m=4~6, n=2~4 liquid silicone resin. Its number...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com